Preparation method for small-size graphene

A graphene, small-scale technology, applied in the field of small-scale graphene preparation, can solve the problems of large graphene defects, high preparation cost, low performance, etc., and achieve the effects of short preparation time, high monolayer ratio, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

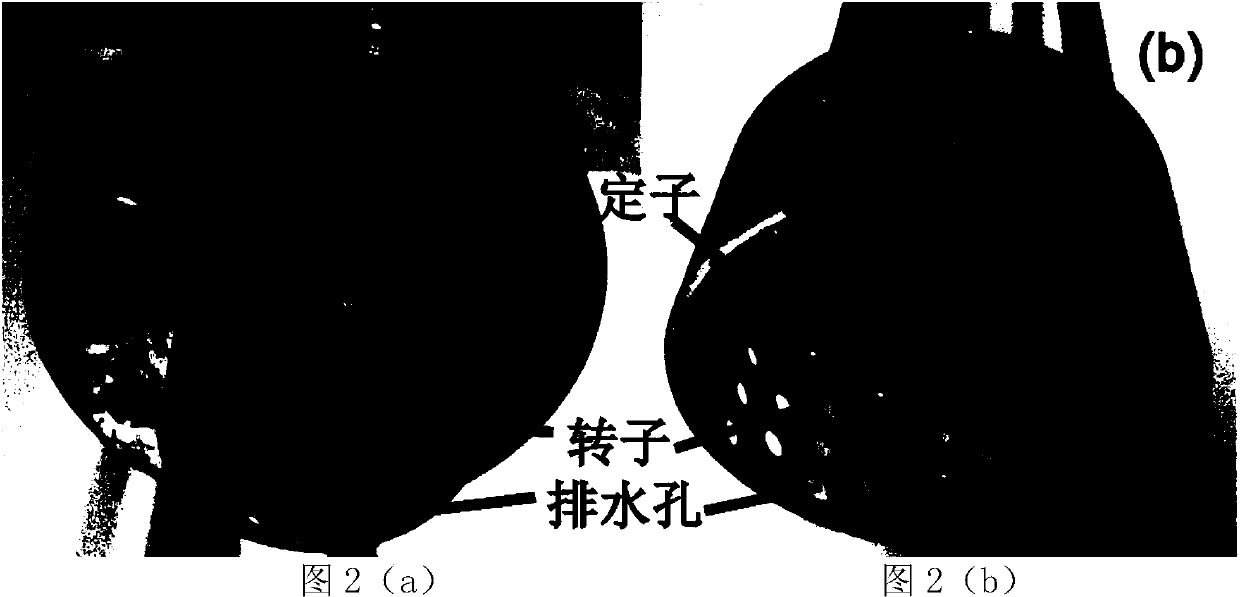

[0041] Example 1, using this method to prepare small-sized graphene in a mixed solvent of 30% by volume isopropanol and water is an example. The small-gap stator-rotor device of the stator-rotor mixer used to generate high-speed rotating fluid is shown in Figure 2(a). The specific process steps are as follows:

[0042] Step 1: take by weighing the flake graphite powder 3.5g that particle diameter is less than 100 microns, be dispersed in the mixed solvent of 30% volume ratio isopropanol and water of 700mL, obtain the graphite dispersion that concentration is 5mg / ml;

[0043]Step 2: Put the prepared graphite dispersion into a cylindrical tank with a diameter of 10 cm, and put the stator-rotor device of the stator-rotor mixer into the center below the liquid surface of the solution;

[0044] Step 3: Turn on the circulating cooling water system to keep the graphite dispersion in the container at a room temperature of about 25°C; use this method to treat the graphite dispersion fo...

Embodiment 2

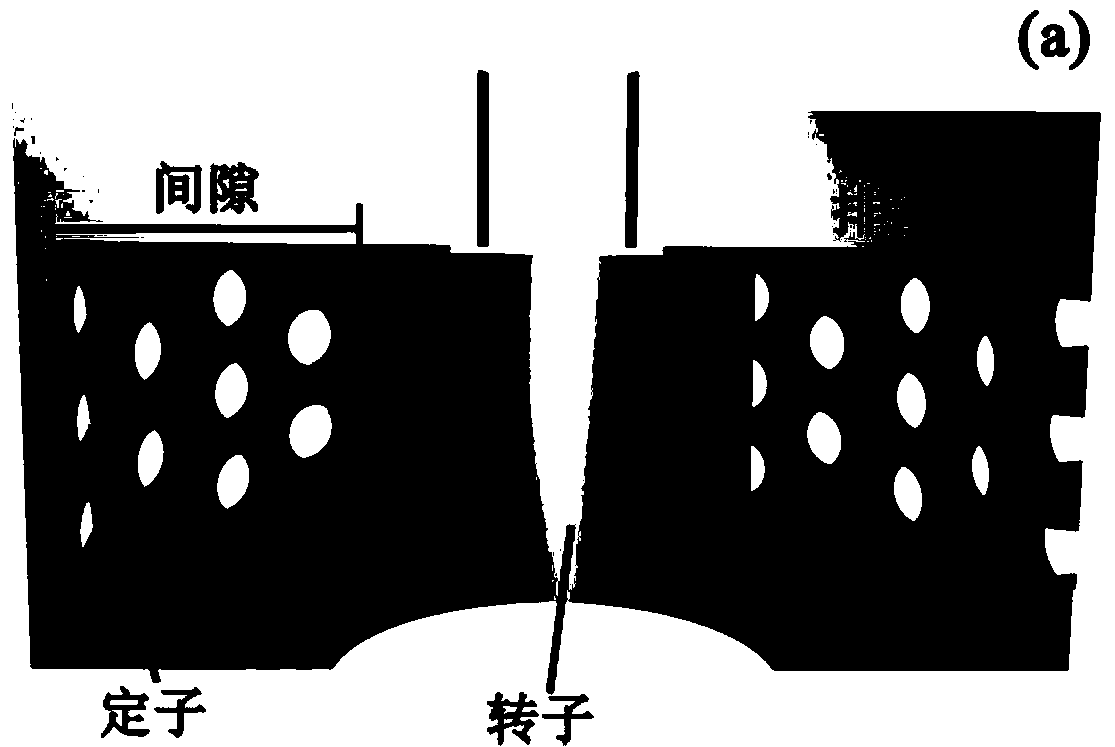

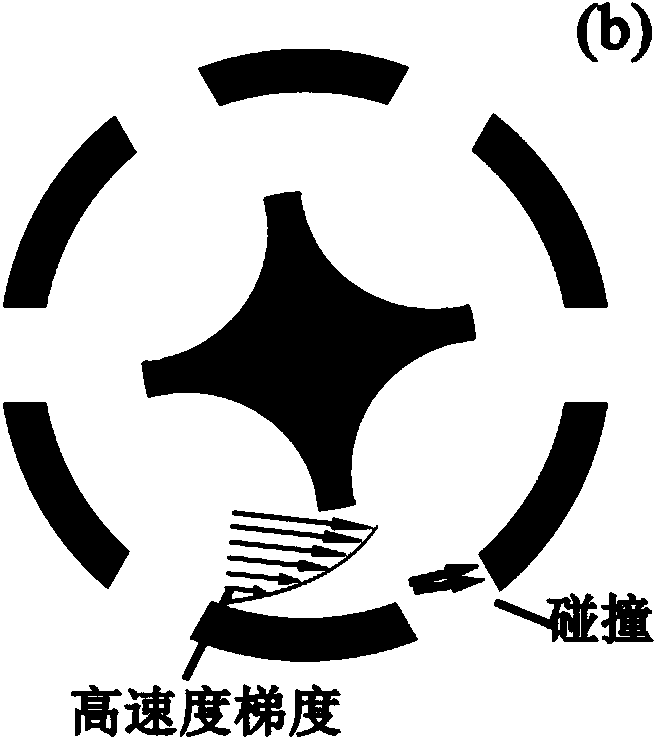

[0047] Embodiment 2, in the mixed solution of water and ethanol, utilize this method to prepare small-sized graphene as embodiment, be used to produce the stator-rotor device real object of the large-gap stator-rotor mixer of high-speed rotating fluid as shown in Figure 2 (b) As shown, Figure 3(a) and (b) are the cross-sectional view of the internal structure and schematic diagram of the force of the stator-rotor mixer used to generate high-rotation fluid in Embodiment 2.

[0048] The specific process steps are as follows:

[0049] Step 1: Configure 700mL of mixed solution of water and ethanol, the mass fraction of ethanol is 40%, and the rest is deionized water, and 7g of flake graphite powder with a particle size of less than 100 microns is dispersed in it to obtain a graphite dispersion with a concentration of 5mg / ml ,

[0050] Step 2: Transfer the prepared graphite dispersion to a cylindrical tank with a diameter of 9.5 cm, and fix the stator and rotor device at the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com