Semi-solid state machining and integrating system

An integrated system, semi-solid technology, applied in the field of metal processing, can solve the problems such as the lack of great breakthroughs in large-scale parts, the difficulty of precise control of core process parameters, and the low degree of automation of the production process, achieving rapid prototyping and processing. The effect of cost reduction and reduced contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

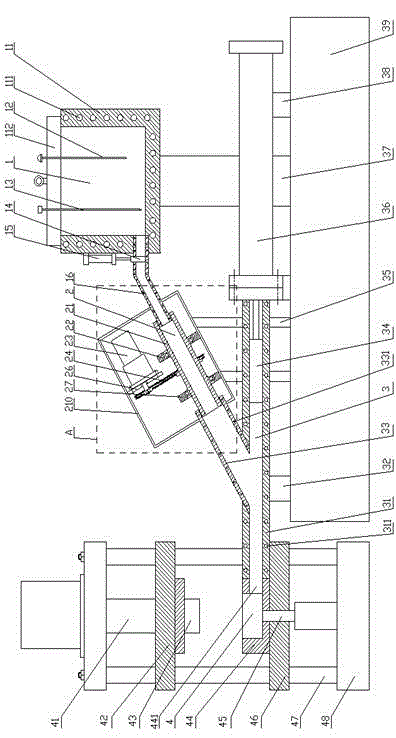

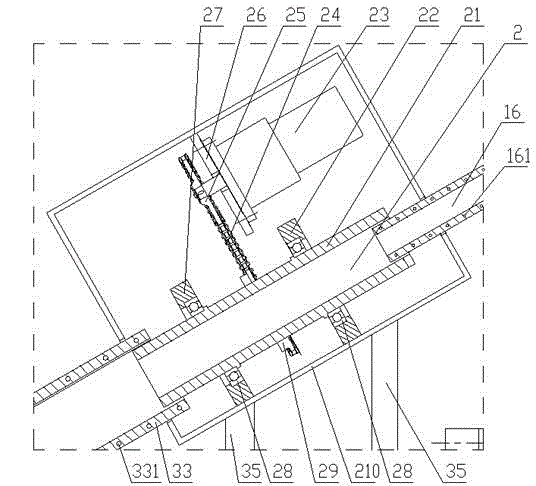

[0021] as attached figure 1 , attached figure 2 As shown, the semi-solid processing integrated system of the present invention is composed of four major parts: a melting furnace assembly 1 , a slurry preparation assembly 2 , a mold injection assembly 3 , and an extrusion molding machine assembly 4 .

[0022] The melting furnace assembly 1 includes a melting furnace support 37, a melting furnace 11, an upper draft pipe 16 and a discharge door 17; the melting furnace support 37 is fixed on the base 39, and the melting furnace 11 is fixed on the melting furnace support 37 top, melting furnace 11 furnace wall is equipped with melting furnace heating resistor 111, used for smelting metal alloy after electrification, melting furnace cover 112 is equipped with liquid level gauge 13 and thermoelectric corner 12, liquid level gauge 13 and thermoelectric corner The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com