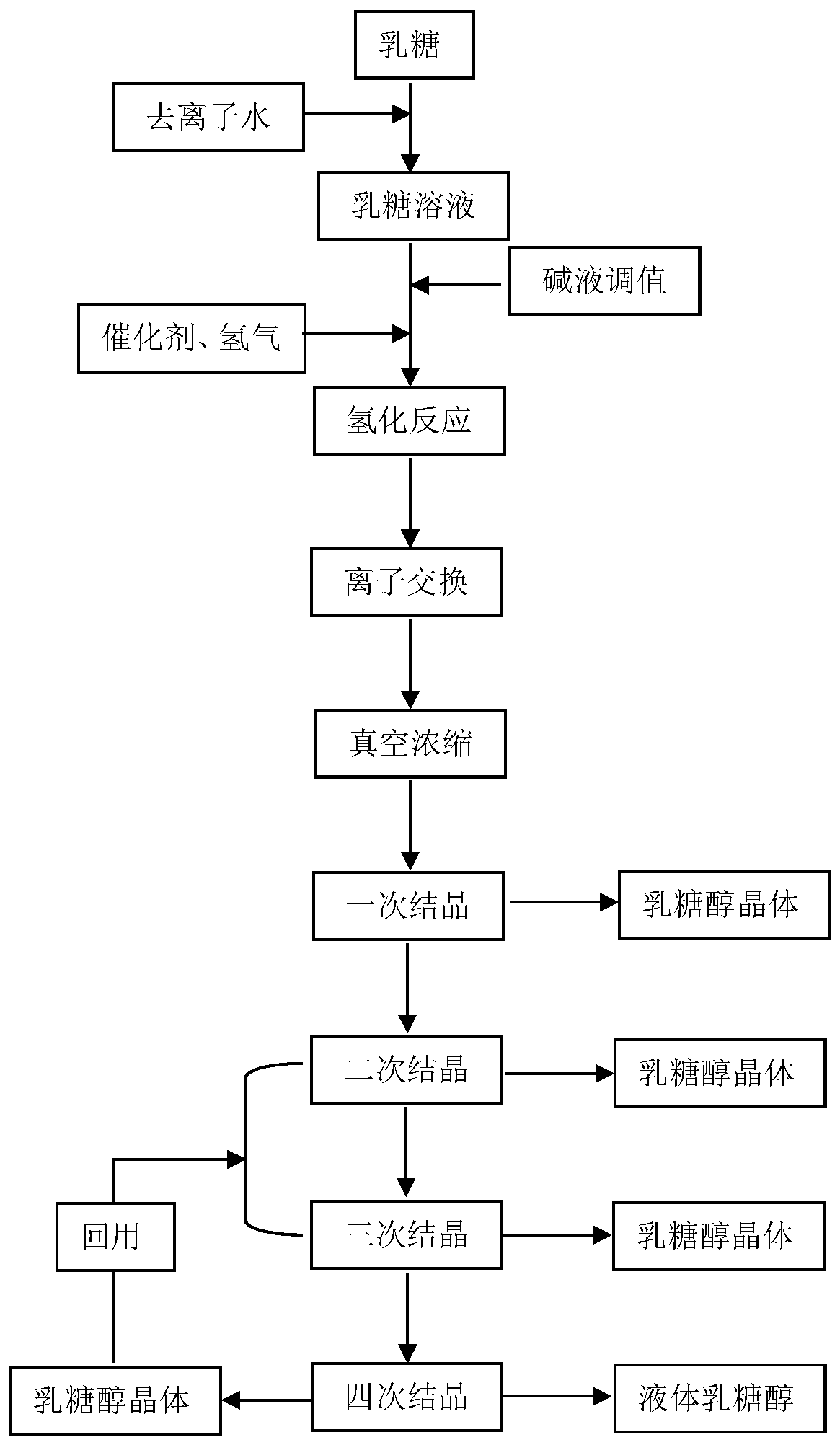

Production technology of lactitol

A production process, the technology of lactitol, applied in the field of production process of functional sugar alcohol, can solve problems such as complex process, achieve the effect of increasing crystallization yield, increasing crystallization efficiency and crystal yield, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 12000.0 grams of lactose into deionized water to form a lactose solution with a concentration of 25.0% by mass, with a purity of 99.0%, adjust the pH to 8.0, add a ruthenium carbon catalyst with 2% lactose mass, set the hydrogenation temperature to 110°C, and the hydrogen pressure to 8.0 MPa, reacted for 3.0 hours to obtain a lactose hydrogenation solution, filtered to remove the catalyst to obtain a lactitol solution, collected the catalyst and reused it, the index of the lactitol solution was: mass percentage concentration 26.5%, lactitol purity 92.9%, lactose residual 4.8% , Conductivity 186.0μs / cm, transmittance 95.0%.

[0036] Ion-exchange the lactitol solution through a mixed bed at a speed of 2BV to obtain a lactitol purification solution, the indicators are: mass percentage concentration 23.0%, lactitol purity 93.5%, electrical conductivity 10.5μs / cm, and light transmission 99.9%.

[0037] Primary crystallization: the lactitol solution is concentrated to a m...

Embodiment 2

[0043] Add 12000.0 grams of lactose into deionized water to make a lactose solution with a mass percentage concentration of 45.0%, adjust the pH to 8.5, add a ruthenium carbon catalyst with 8% lactose mass, set the hydrogenation temperature to 120°C, hydrogen pressure to 10.0MPa, and react at 2.0 h, to obtain a lactose hydrogenation solution, filter and remove the catalyst to obtain a lactitol solution, collect the catalyst and reuse it, the index of the lactitol solution is: mass percentage concentration 48.0%, lactitol purity 98.7%, lactose residual 0.1%, electrical conductivity 123.0 μs / cm, transmittance 99.0%.

[0044] The lactitol solution was ion-exchanged through the mixed bed at a speed of 4BV to obtain a lactitol purification solution. The indicators were: mass percentage concentration 41.0%, lactitol purity 99.1%, electrical conductivity 4.68 μs / cm, and light transmission 100%.

[0045] Primary crystallization: the lactitol solution is concentrated to a mass percenta...

Embodiment 3

[0050] Add 12000.0 grams of lactose into deionized water to form a lactose solution with a concentration of 40.0% by mass, adjust the pH to 9.5, add a Raney nickel catalyst with 6% lactose mass, set the hydrogenation temperature to 115°C, and the hydrogen pressure to 9.0MPa. After 1.5 hours, the lactose hydrogenation solution was obtained, and the catalyst was removed by filtration after sedimentation to obtain a lactitol solution. The catalyst was collected and reused. The indicators of the lactitol solution were: mass percentage concentration 43.0%, lactitol purity 98.5%, electrical conductivity 126.0μs / cm, light transmittance 98.9%.

[0051] The lactitol solution was ion-exchanged through the mixed bed at a speed of 3BV to obtain a lactitol purification solution. The indicators were: mass percentage concentration of 38.0%, lactitol purity of 99.1%, electrical conductivity of 5.3μs / cm, and light transmission of 100%.

[0052] Primary crystallization: the lactitol solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com