Patents

Literature

162results about How to "Improve crystallization yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

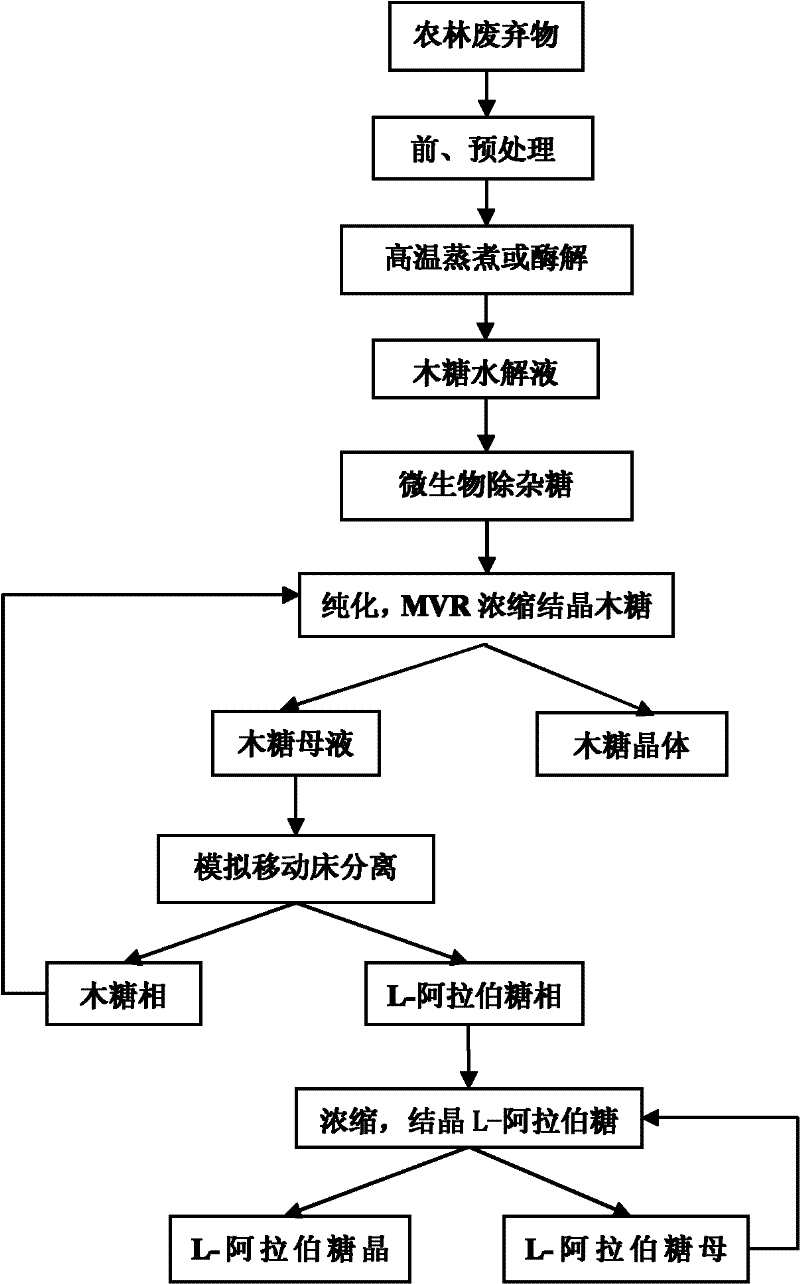

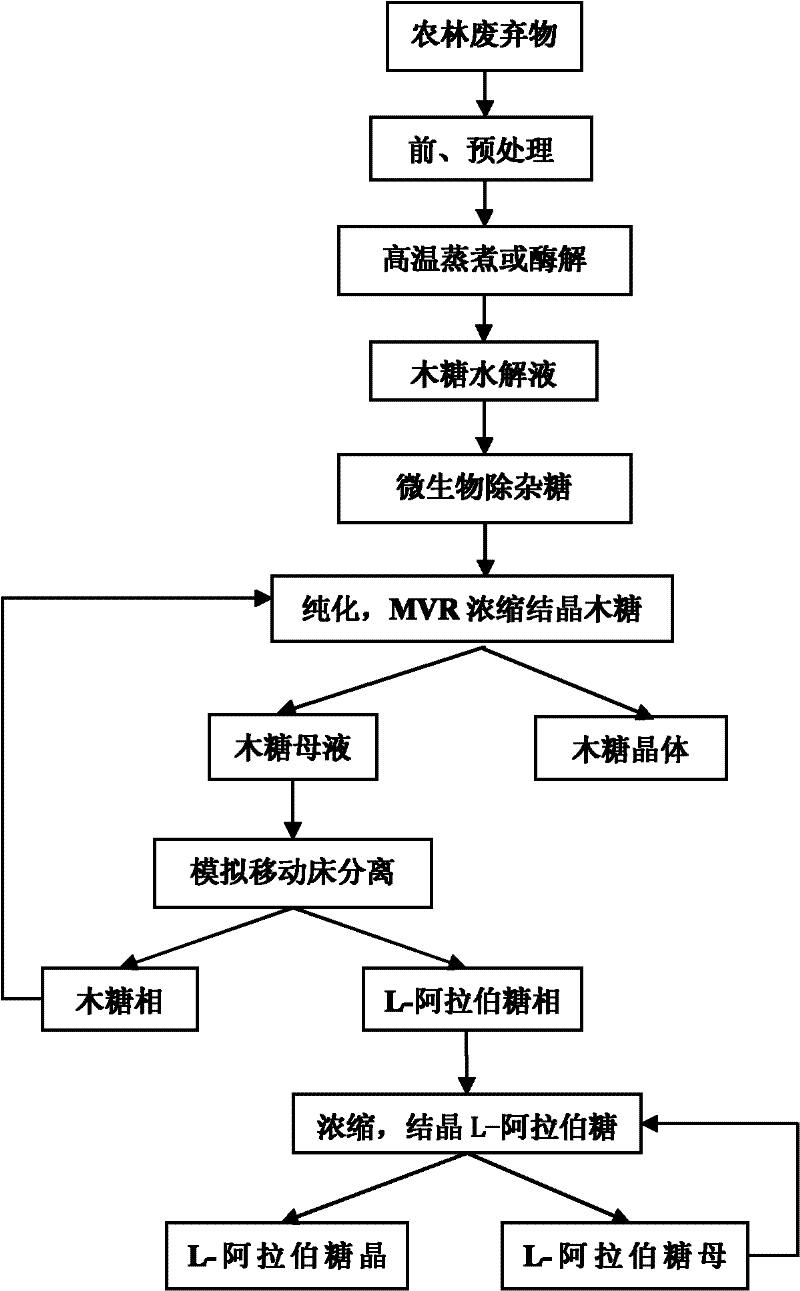

A clean and efficient production process for preparing xylose and l-arabinose

ActiveCN102286571AAddressing the effects of crystallizationHigh yieldSugar derivativesSugar derivatives preparationChromatographic separationYeast

The invention relates to a clean and high-efficiency production process for preparing xylose and L-arabinose and belongs to the field of application of wastes of agriculture and forestry. The production process comprises the following steps of: performing pretreatment on raw materials; hydrolyzing the raw materials in a high-temperature cooking mode; performing neutralizing treatment and performing centrifugal separation on solid slag to obtain xylose or xylooligosaccharide hydrolyzate; adding coarse enzyme solution into xylooligosaccharide solution to hydrolyze to obtain xylose solution; treating the hydrolyzate by Angle yeast; purifying by using active carbon and resin; performing recompression and concentration treatment on the purified hydrolyzate by using a mechanical vapor recompression (MVR) machine; crystallizing the concentrated solution in a gradient program cooling mode to obtain xylose products and xylose mother solution; separating the xylose mother solution by a simulated moving bed or a chromatographic separation technology to obtain a xylose phase and an L-arabinose phase; returning the xylose phase to the xylose solution to concentrate and recrystallize; reusing the xylose mother solution; performing MOVR concentration treatment on the L-arabinose phase and crystallizing in a gradient program cooling mode to obtain L-arabinose products; and reusing the L-arabinose mother solution.

Owner:BEIJING UNIV OF CHEM TECH

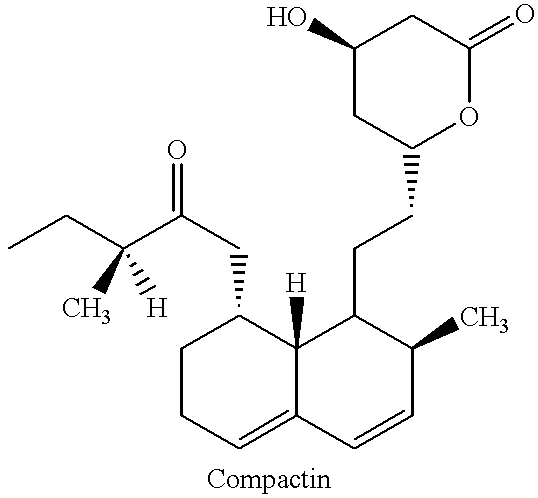

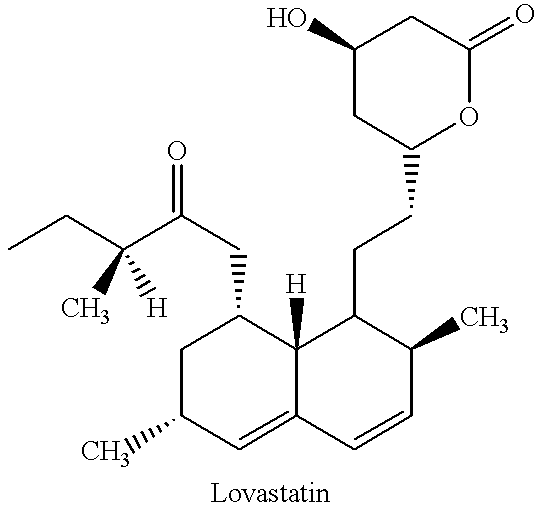

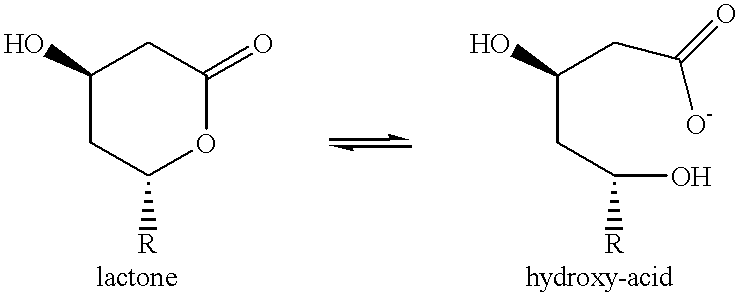

Method of purifying statins from a fermentation broth

InactiveUS6387258B1Good removal effectEfficient extractionIon-exchange process apparatusOrganic active ingredientsPre treatmentSolvent

A process for purifying statin compounds from a fermentation broth by extraction and crystallization is disclosed. A fermentation broth is subjected to a pretreatment procedure which involves an alkaline pretreatment and an alkaline purification. Following the pretreatment procedure, the statin compound is extracted under acidic conditions into a hydrophobic solvent and purified by crystallization. The organic extraction solvent is concentrated and then extracted with a mild base. The statin compound is then purified by crystallization.

Owner:TEVA GYOGYSZERGYAR RESVENYTARSASAG

Refining method of C11-C18 long-chain diacid

InactiveCN102503800AImprove liquidityHigh purityCarboxylic compound separation/purificationOrganic solventAlcohol

The invention provides a refining method of C11-C18 long-chain diacids. granular long-chain diacid crystals are obtained by using methanol and ethanol as organic solvents and adopting a crystallization mode of cooling crystallization with seeding materials combined with flowing addition of dilute solvent aqueous solutions. The method has the advantages of high product purity and high crystallization yield; alcohol solvents are low in price and simple in recovery, which greatly reduces the refining cost of crude products.

Owner:JIANGNAN UNIV

Process for rourifying insuline

InactiveCN1390854AOvercome crystallizationOvercome the disadvantages of pure sodium salt crystallizationPeptide preparation methodsInsulinsPurification methodsSalting out

Owner:JIANGSU WANBANG BIOPHARMLS

Salting-out and solvating-out crystallization method for citicoline

ActiveCN101538300AHigh yieldGood hygroscopicitySugar derivativesCardiovascular disorderFiltrationSalting out

The invention discloses a salting-out and solvating-out crystallization method for citicoline. The method comprises the following steps: adding inorganic sodium salt which accounts for 1 to 20 percent of citicoline and a solvating agent which is 1.0 to 4.0 times the volume of a staring citicoline aqueous solution to a citicoline aqueous solution with a pH value between 5.0 and 8.0 and a concentration between 10 and 400 g / L; stirring the materials at a rotating speed controlled between 20 and 230 rpm at a temperature of between 10 and 40 DEG C; performing pumping filtration after complete crystallization; washing the obtained product with ethanol; drying the obtained product in vacuum; and obtaining the citicoline sodium salt crystals with the purity higher than 99 percent. The method has the advantages that the method obviously improves the quality of final products, raises crystallization yield stability, can control the particle size of the crystals by changing crystallization temperature or the states of a flow field, and is simple to operate, good in repeatability and suitable for the industrial production of the citicoline.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

Crystallization process of 5'-nucleoside-sodium phosphate

InactiveCN1861624AQuality improvementImprove crystallization yieldSugar derivativesSugar derivatives preparationNucleoside monophosphateAlcohol

A crystallizing process for 5'-nucleoside-sodium phosphate includes such steps as proportionally adding the inorganic Na salt and solution educing agent, stirring while crystallizing at 15-40 deg.C, filtering, alcohol washing and vacuum drying. It has high output and controllable size of crystal.

Owner:NANJING UNIV OF TECH

Esterification and crystallizing process for producing glucose halfaldehyde lactone

InactiveCN1817895AImprove crystallization yieldHigh purityEsterified saccharide compoundsSugar derivativesChemistryGlucuronolactone

Esterifying and crystallizing process for preparing glucuronolactone is carried out by oxidizing by starch acid, hydrolyzing, one-stage concentration dewatering for oxidized starch hydrolysate, two-stage dewatering for one-stage concentrate, adding two-stage concentrate into acetic acid to esterify at 65~70 degrees C, distilling to remove weak acid, third-stage dewatering, lowering temperature, crystallizing by dynamic gradient at 25+-5 degrees C, 1~2 degrees C / hr speed ratio and <=40hrs, filtering to obtain crude product. It is cheap, has less consumption, shorter crystallizing time and more output.

Owner:WUHAN CHEM COLLEGE

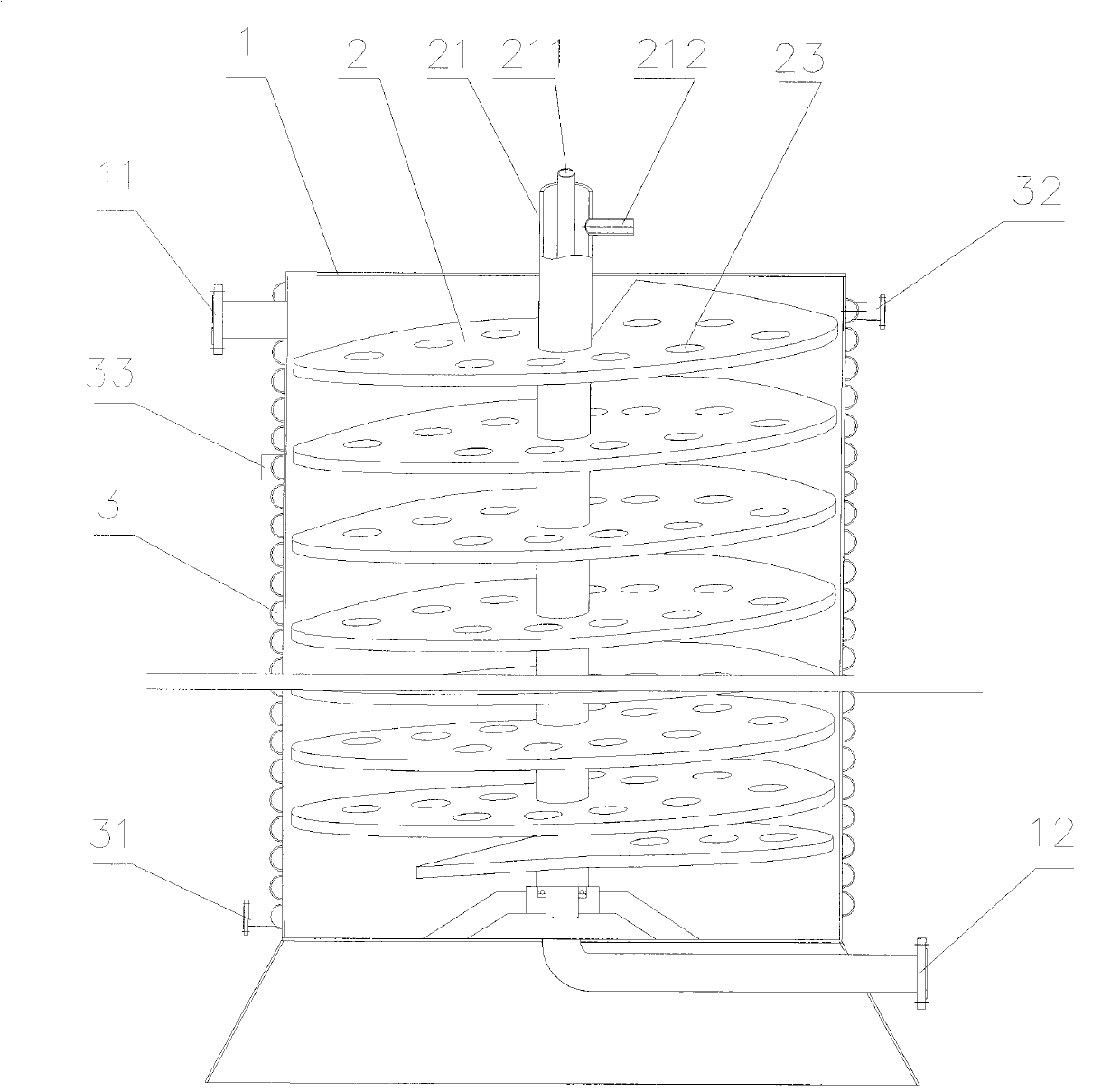

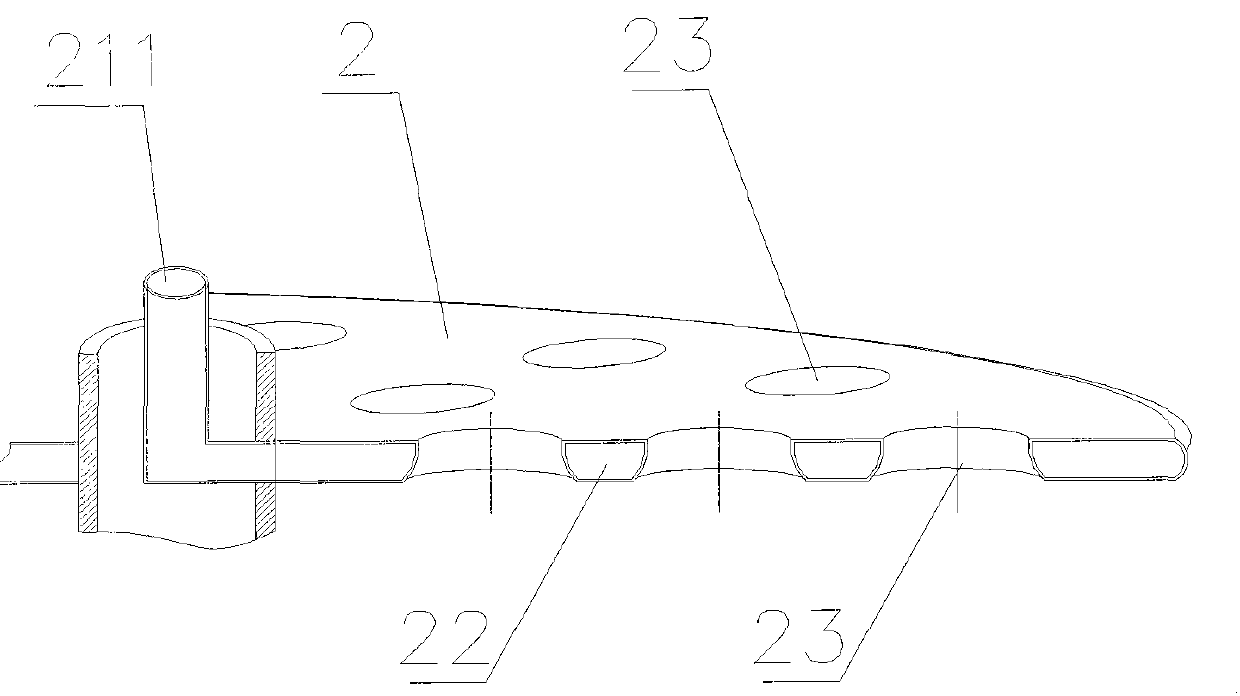

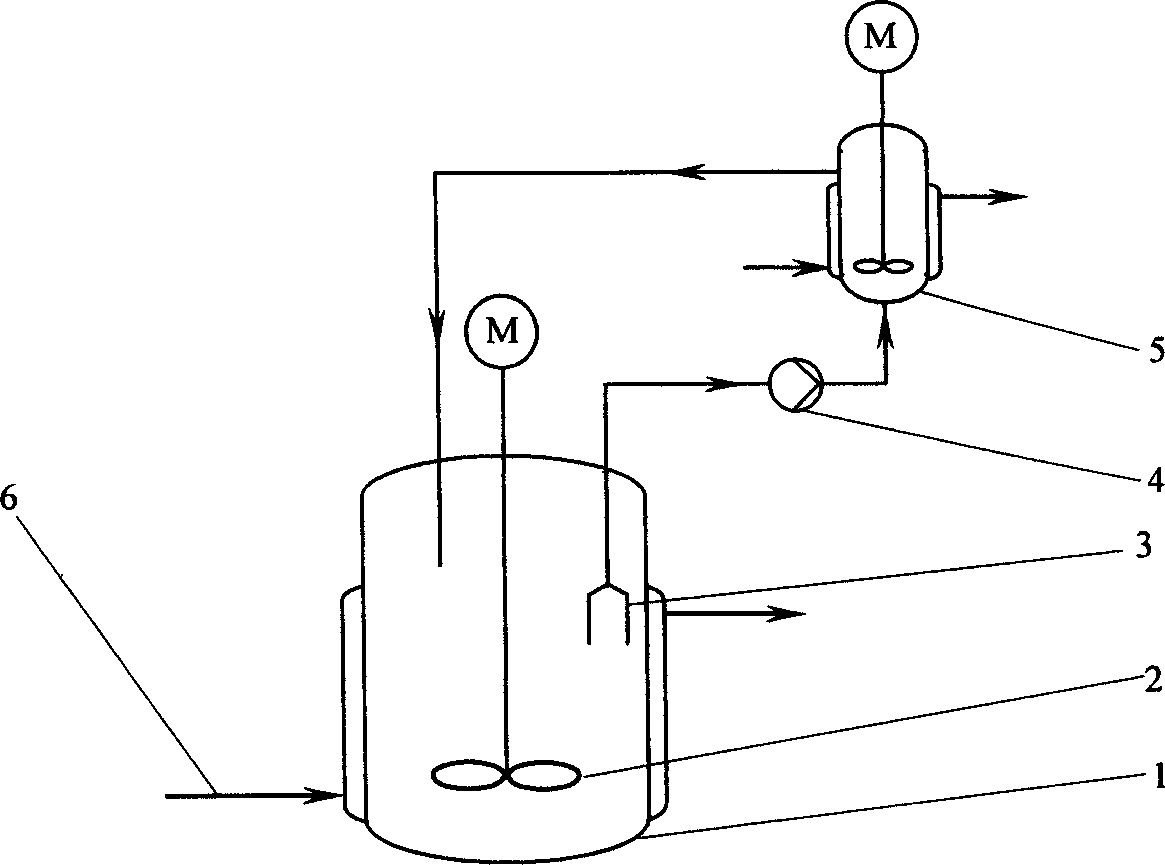

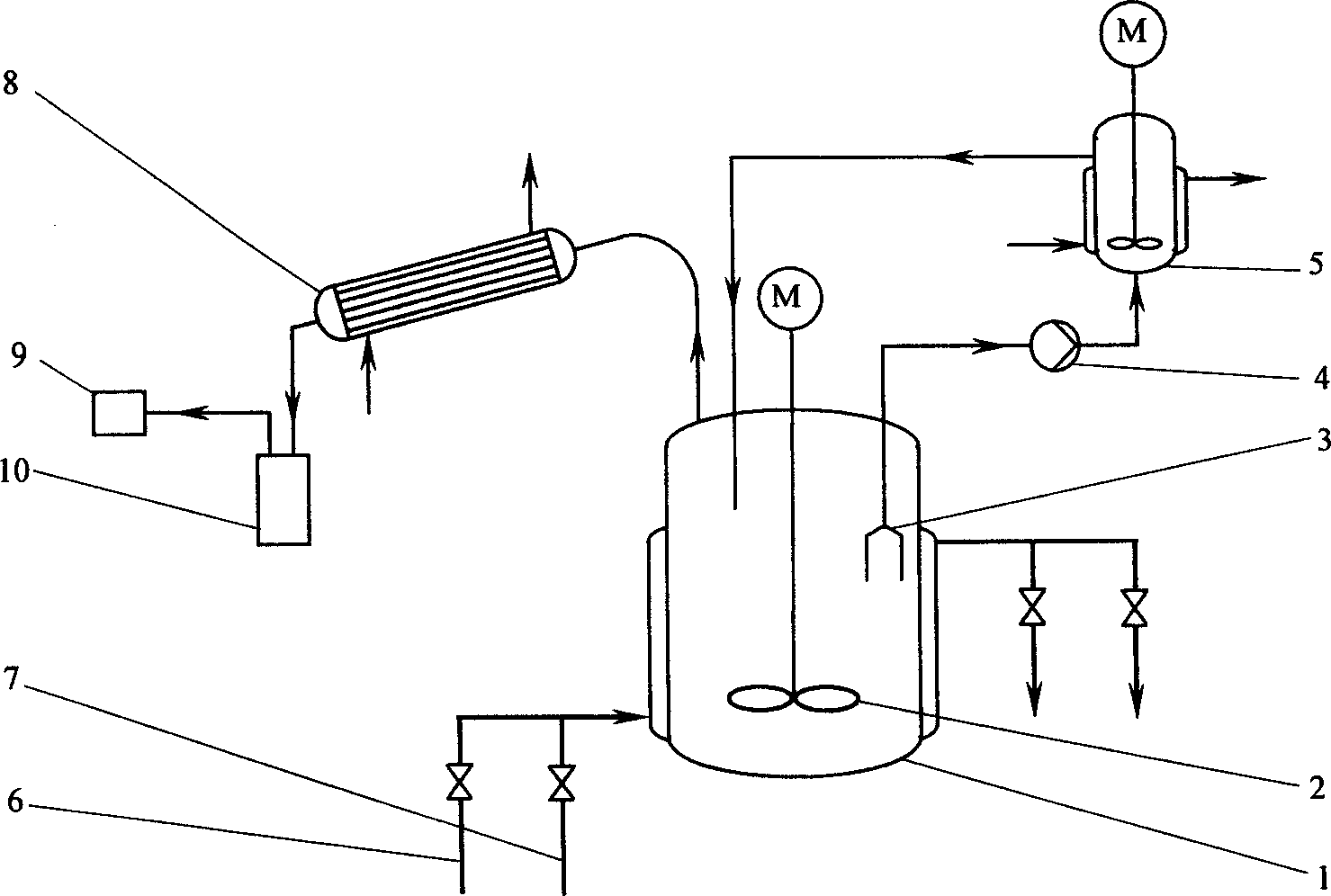

Vertical continuous-cooling crystallization machine

ActiveCN103585781APromote formationMeet the principle requirements of continuous crystallization processSolution crystallizationEngineeringWater jacket

The invention discloses a vertical continuous-cooling crystallization machine. The vertical continuous-cooling crystallization machine comprises an outer cylinder and a spiral stirring paddle. The spiral stirring paddle is erected in the outer cylinder. The outer wall of the outer cylinder is provided with a cooling water jacket. The spiral stirring paddle is arranged in a top suspension way. A shaft of the spiral stirring paddle has a sleeve-type hollow shaft structure. Cavities are formed in blades of the spiral stirring paddle. Upper and low ends of each one of the cavities are communicated with the shaft having the sleeve-type hollow shaft structure. The vertical continuous-cooling crystallization machine has the advantages that 1, a housing jacket and the hollow blades of the spiral stirring paddle are combined and cooling water is fed into the combined structures simultaneously so that a heat exchange area is greatly improved and a crystal yield is greatly improved; 2, the spiral stirring paddle can rotate by 360 degrees so that no-dead corner medium cooling is realized, formation of crystal nucleuses and stable and natural growth of crystals are promoted, a cooling rate is improved and product quality stability is guaranteed; and 3, intelligent configuration improves productivity and reduces a cost.

Owner:姜向前

New process for extracting lactic acid from lactic acid fermentation liquid

ActiveCN102976923ASimple processFully removedOrganic compound preparationCarboxylic compound separation/purificationFiltration membraneIon-exchange resin

The invention discloses a new process for extracting lactic acid from lactic acid fermentation liquid. The process flow comprises the following steps: preparing the fermentation liquid, deproteinizing, removing bacteria, decolorizing with activated carbon, performing plate and frame filtration, filtering with an inorganic ceramic membrane, cooling by a plate type heat exchanger, filtering with an organic nano-filtration membrane, concentrating and performing primary crystallization, performing centrifugal drying, performing resolvation, performing acidolysis, passing through an ion exchange resin column and concentrating to obtain a finished product. The process flow performs membrane filtration twice, namely the filtration with the inorganic ceramic membrane and the filtration with the organic ceramic membrane, wherein the filtration with the inorganic ceramic membrane can remove small insoluble solid impurities, bacteria, colloidal substances, macromolecular sugars and other impurities in filtrate; the filtration with the organic nano-filtration membrane can remove low-molecular weight sugars and multivalent ions in the filtrate; and the purity of the finally prepared finished product lactic acid is as high as 95%-98%, the crystallization yield of the lactic acid is improved from original 70% to above 85%, and the production cost is greatly reduced.

Owner:QINGDAO KEHAI BIOLOGICAL

Method for ultrasonically crystallizing rebaudiosideA

InactiveCN101812096AHigh purityShort crystallization timeSugar derivativesSugar derivatives preparationSolventChemistry

The invention discloses a method for ultrasonically crystallizing rebaudiosideA, which comprises the following steps of: charging stevioside and dissolvent according to the quality volume ratio (kg:L) of 1:4-10; stirring, charging and heating to be the temperature of 40-80 DEG C; constantly keeping the temperature at 30-90 minutes; fast reducing the temperature to be 10-25 DEG C with the velocity of 5-15 DEG C per minute; sequentially statically crystallizing and recrystallizing for 3-12 hours, wherein the ultrasonic wave is adopted to perform auxiliary crystallizing and recrystallizing during statically putting; stirring and performing the ultrasonic wave for 5-15 minutes every 30-90 minutes; and performing solid-liquid separation, dissolution in a washing way, membrane separation, reduced pressure distillation and spray drying to the recrystallized crystalloid to obtain the high-purity rebaudiosideA. The method has the crystallizing time of only 6-24 hours, the rebaudiosideA yield which is more than 75%, even crystallizing grains, and the rebaudiosideA purity which reaches up to be more than 95%, meets the standards of American FDA, can be produced on a large scale, and has obvious effect.

Owner:GANZHOU JULONG HIGH TECH INDAL

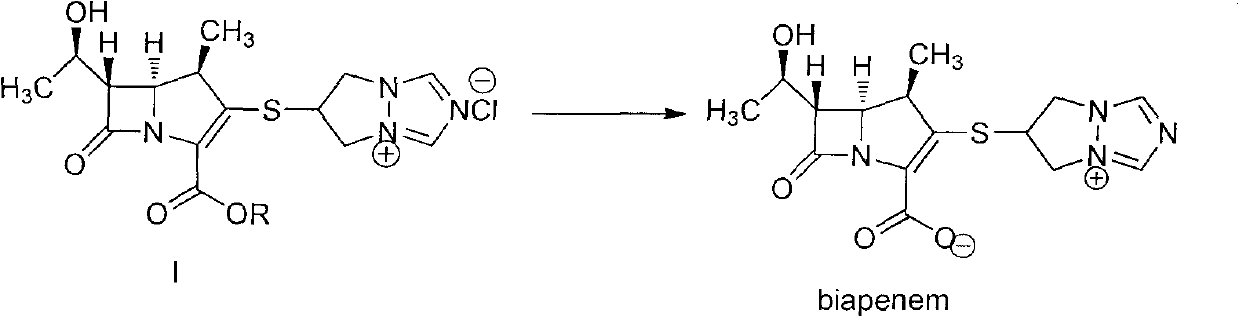

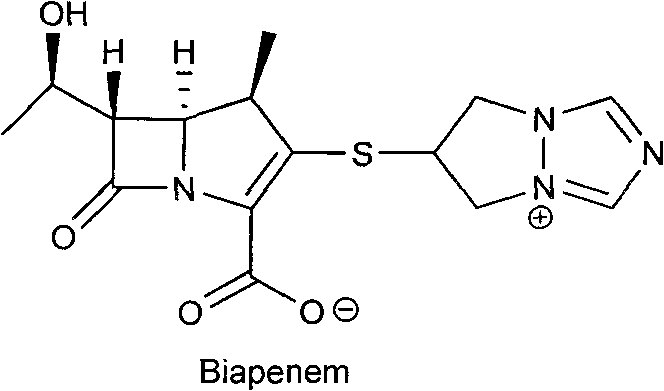

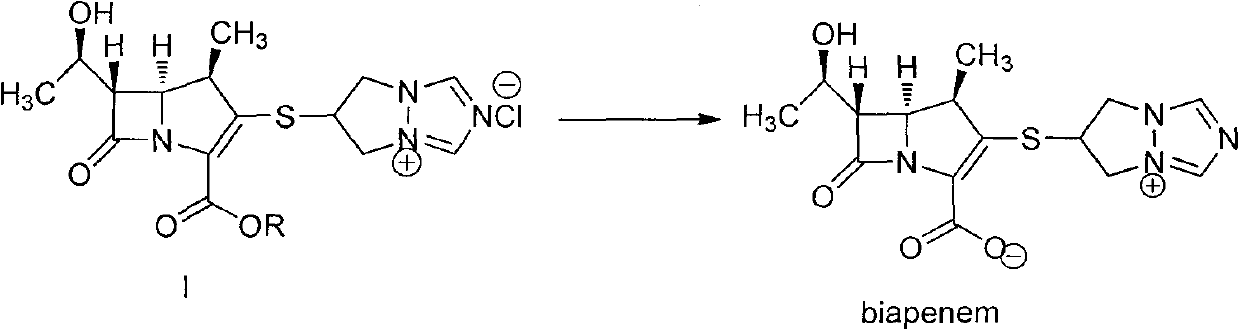

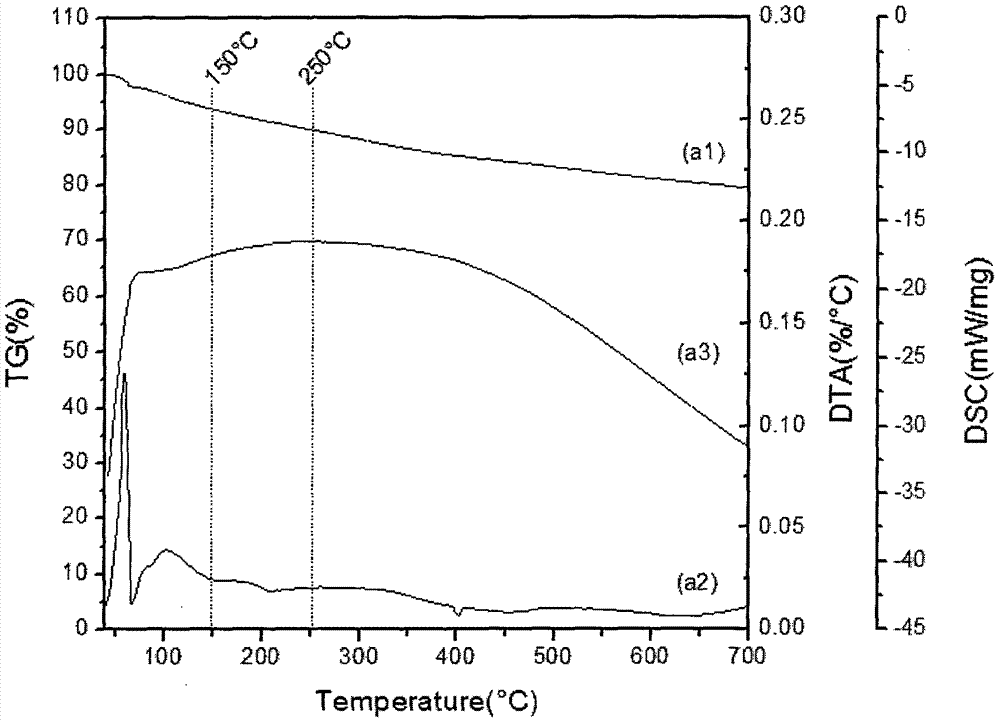

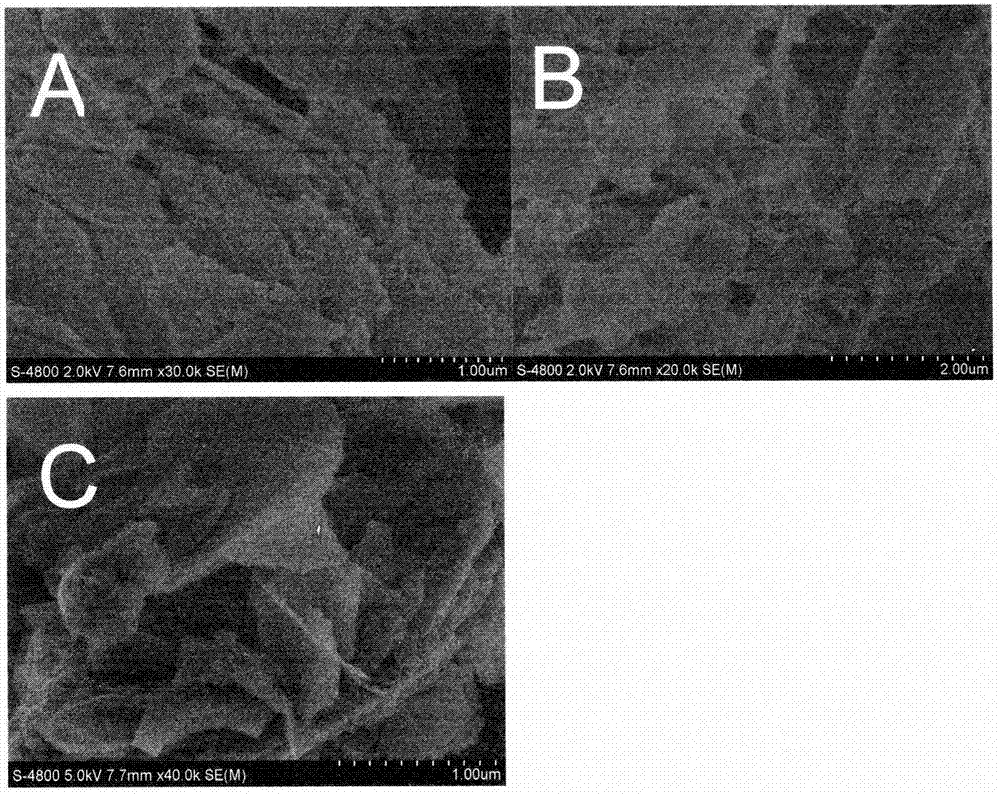

Preparation method of biapenem

ActiveCN102212077AReduce dosageEasy to operateOrganic chemistryBulk chemical productionOrganic acidAlcohol

The invention discloses a preparation method of biapenem. The method comprises the following steps of: undergoing a catalytic hydrogenation reaction on a compound which is shown as a formula I and serves as a raw material and H2 in a mixed solvent of water and an organic solvent; adding an organic base immediately for regulating the pH value after the reaction; adding an organic solvent for precipitating biapenem crystals; and recrystallizing the crystals in water, organic acid and ethanol or ketone to obtain a refined biapenem product. The preparation method has the advantages of easiness for operating, no need of adjusting the pH value with a buffer salt during hydrogenation, no need of resin purification after hydrogenation, no need of special equipment, greatly-lowered water consumption, high yield and high product purity, and is suitable for industrial production.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

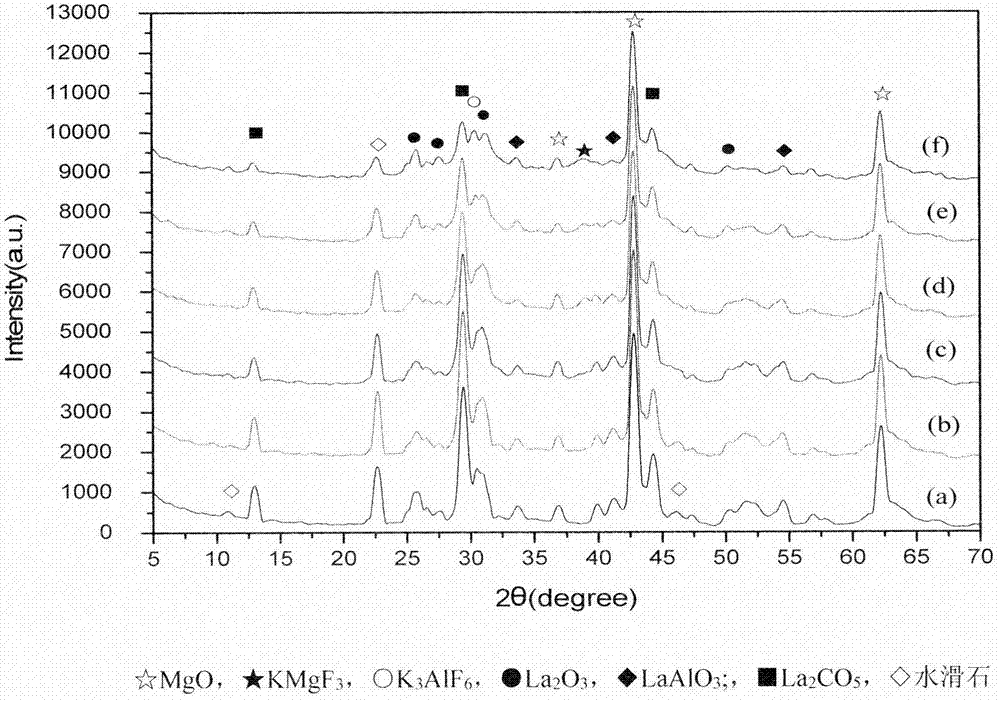

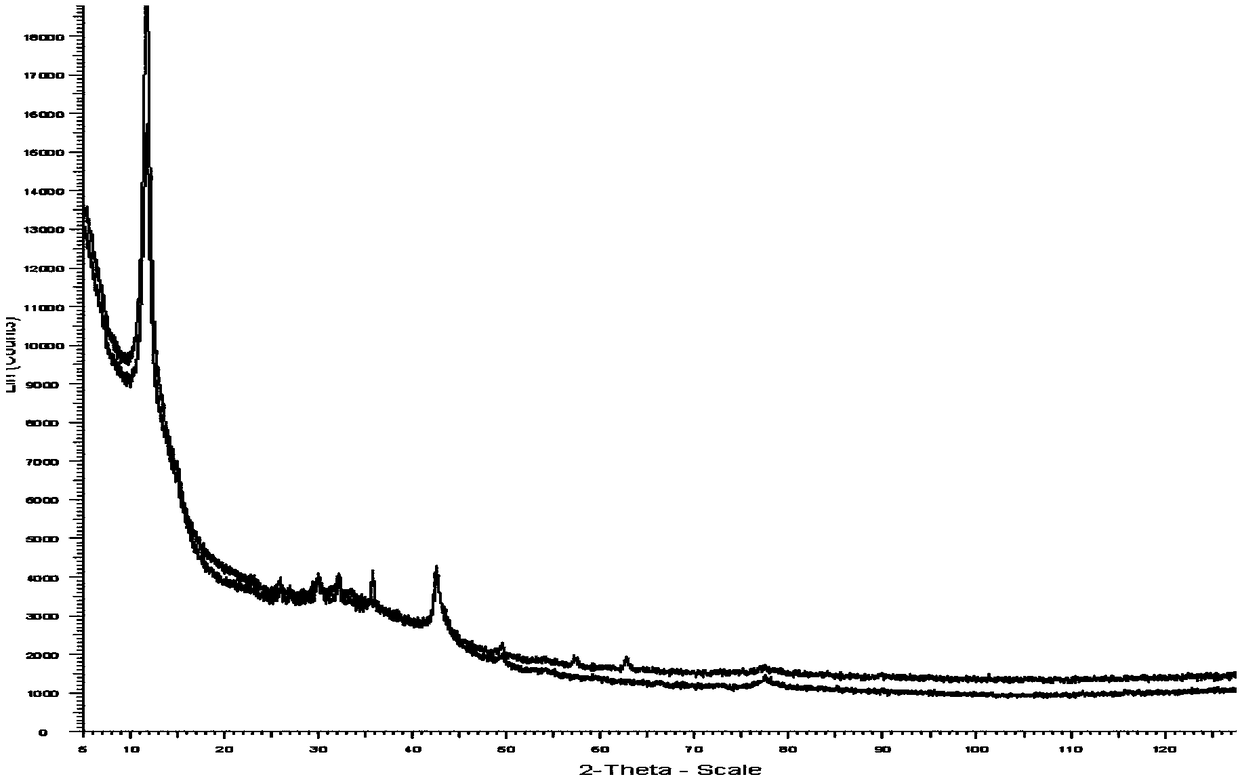

Method for catalytic synthesis of biodiesel by means of hydrotalcite-like immobilized potassium fluoride solid alkalies

ActiveCN107541234AUniform particle sizeHigh crystallinityBiofuelsCatalyst activation/preparationAlkalinityBiodiesel

The invention discloses a method for catalyzing grease and alcoholic substances to synthesize biodiesel by means of hydrotalcite-like immobilized potassium fluoride solid alkalies including KF / MgAlLa,KF / MgAl and KF / MgLa. The solid alkalies are of mesoporous hydrotalcite-like layered structures, the pore diameter is 12-21 nm, the pore volume is 0.04-0.10 cm<3> / g, the specific surface area is 14-30m<2> / g, the alkalinity pKa is 9.3-15.0, the catalytic activity is high, the solid alkalies are easily detached from a reaction system, the repeatability is good, the mass yield of the catalytic synthesis of the biodiesel is 99.1%, and the mass yield of the catalytic synthesis of the biodiesel after the catalyst is reused for 5 times is 80.9%.

Owner:XIANGTAN UNIV

A continuance method for preparing succinic acid

ActiveCN101550079AImprove crystallization yieldImprove product qualityPreparation from carboxylic acid saltsButanedioic acidSuccinic acid

The present invention provides a continuance method for preparing succinic acid includes following steps: adding succinate and inorganic acid into a first level reactor and reacting at a controlled temperature 30 to 95 DEG, and PH 1 to 5, then the reaction product overflowing to a second level reactor, adding succinate and inorganic acid into the second reactor and controlling the temperature at 10 to 80 DEG and PH 0.5 to 4, and then the second reaction product overflowing to a third reactor, adding succinate and inorganic acid into the reactor and controlling the temperature at 0 to 90 DEG and PH 1.5 to 2.5, then the third reactor discharging products into a solid-liquid separation device to obtain the succinate. The method is provided with advantages of high yield, good product quality and low energy consumption.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method for circularly preparing graphene oxide from waste acid resources

ActiveCN108840330AImprove crystallization yieldReduce energy costsCarbon compoundsSulfate/bisulfate preparationDistillationPhosphoric acid

The invention relates to a method for circularly preparing graphene oxide from waste acid resources. The method for circularly preparing graphene oxide from waste acid resources comprises the following steps: (1) preparing graphene oxide slurry; (2) concentrating the slurry through a ceramic filtering membrane to obtain waste acid liquid 1 and graphene concentrated slurry 1, and washing graphene concentrated slurry 1 with water through ceramic filtering equipment to obtain waste acid liquid 2 and graphene concentrated slurry 2; (3) carrying out spray drying on the graphene concentrated slurry2 to obtain graphene oxide powder; (4) distilling, concentrating and crystallizing the waste acid liquid; (5) after detecting the mass ratio of sulfuric acid and phosphoric acid in the mixed concentrated acid, adding new concentrated sulfuric acid and concentrated phosphoric acid to adjust the mass ratio, and mixing the materials uniformly for step (1). According to the method for circularly preparing graphene oxide from waste acid resources provided in the invention, the waste acid generated in the process of preparing graphene oxide is recycled according to a graded decompression distillation concentration and crystallization method to obtain mixed concentrated acid, and graphene oxide is circularly prepared by using the mixed concentrated acid as a raw material.

Owner:新疆烯金石墨烯科技有限公司

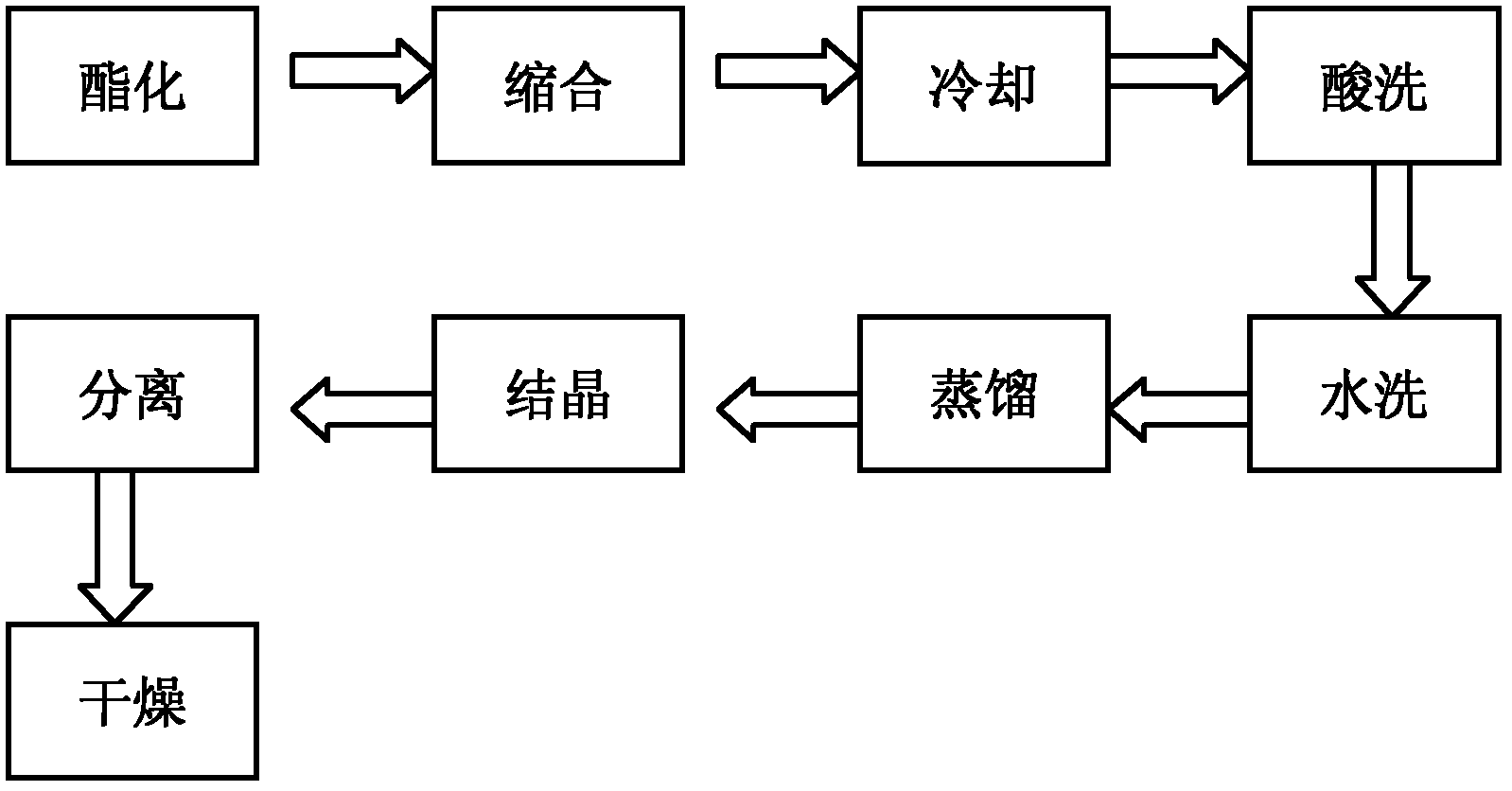

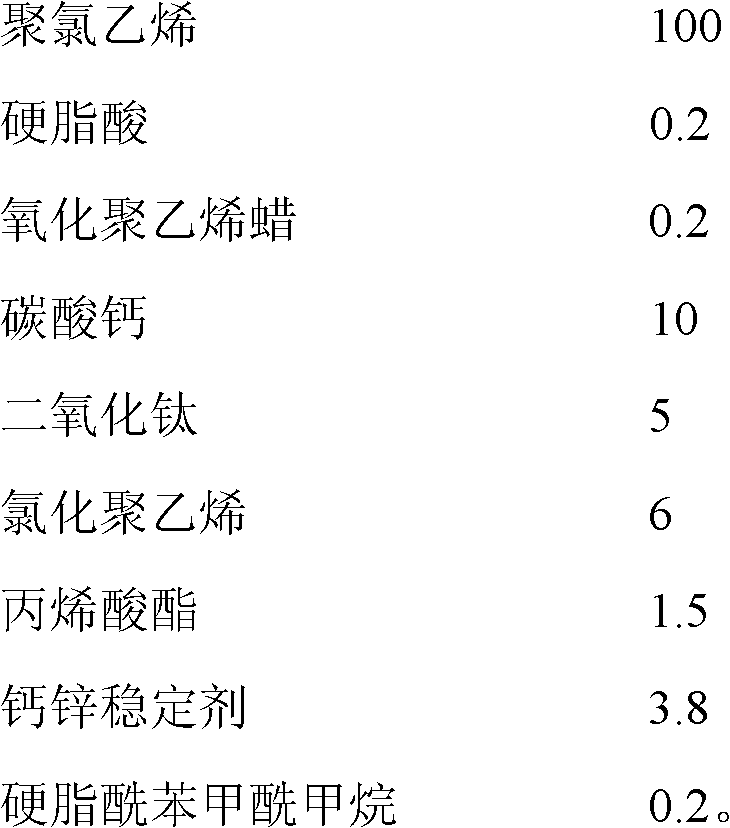

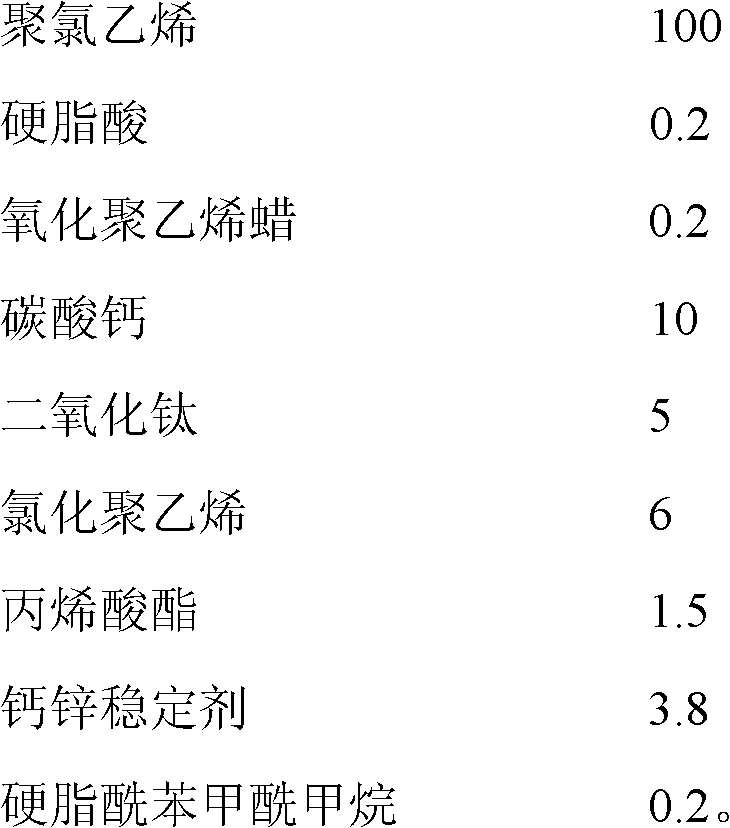

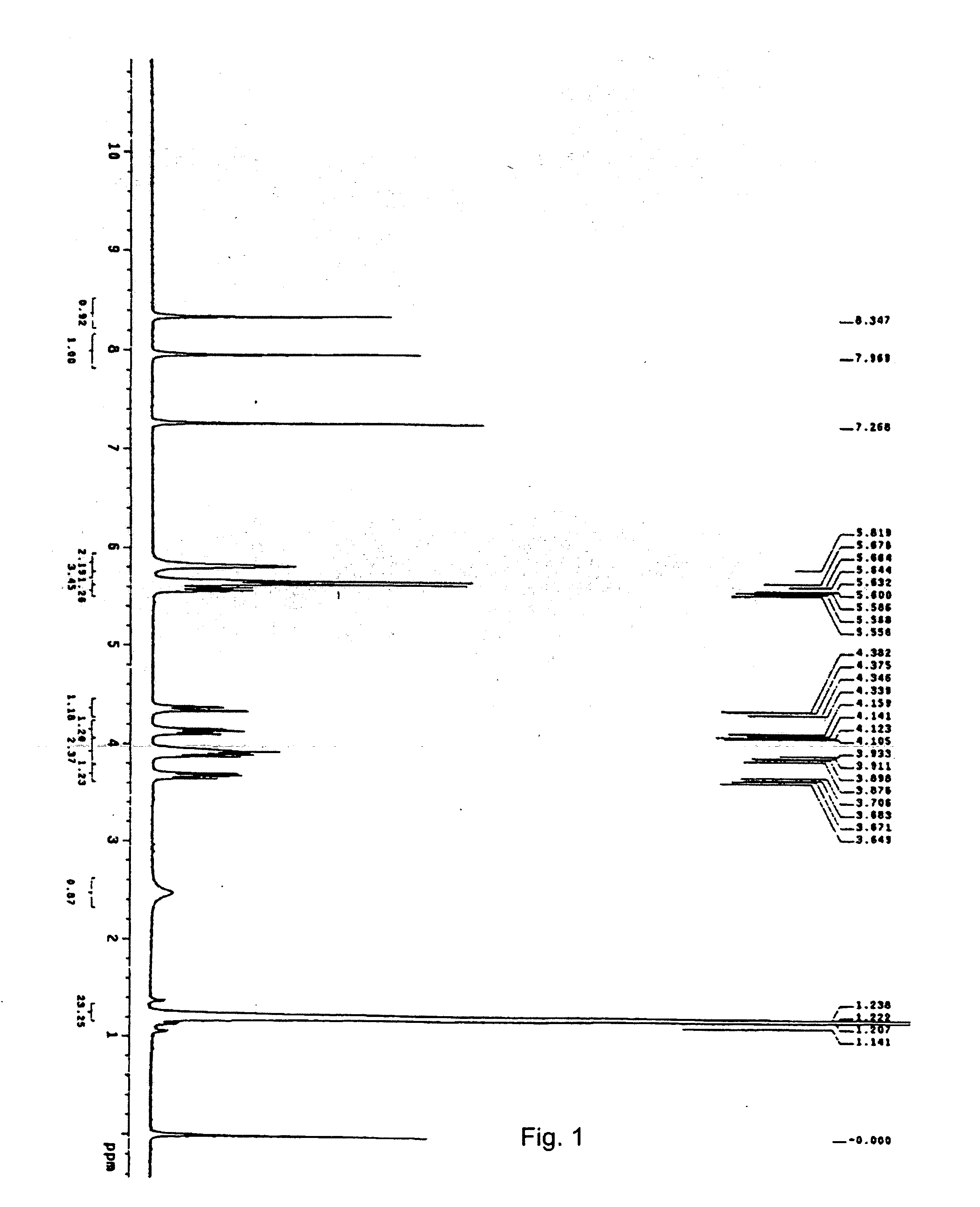

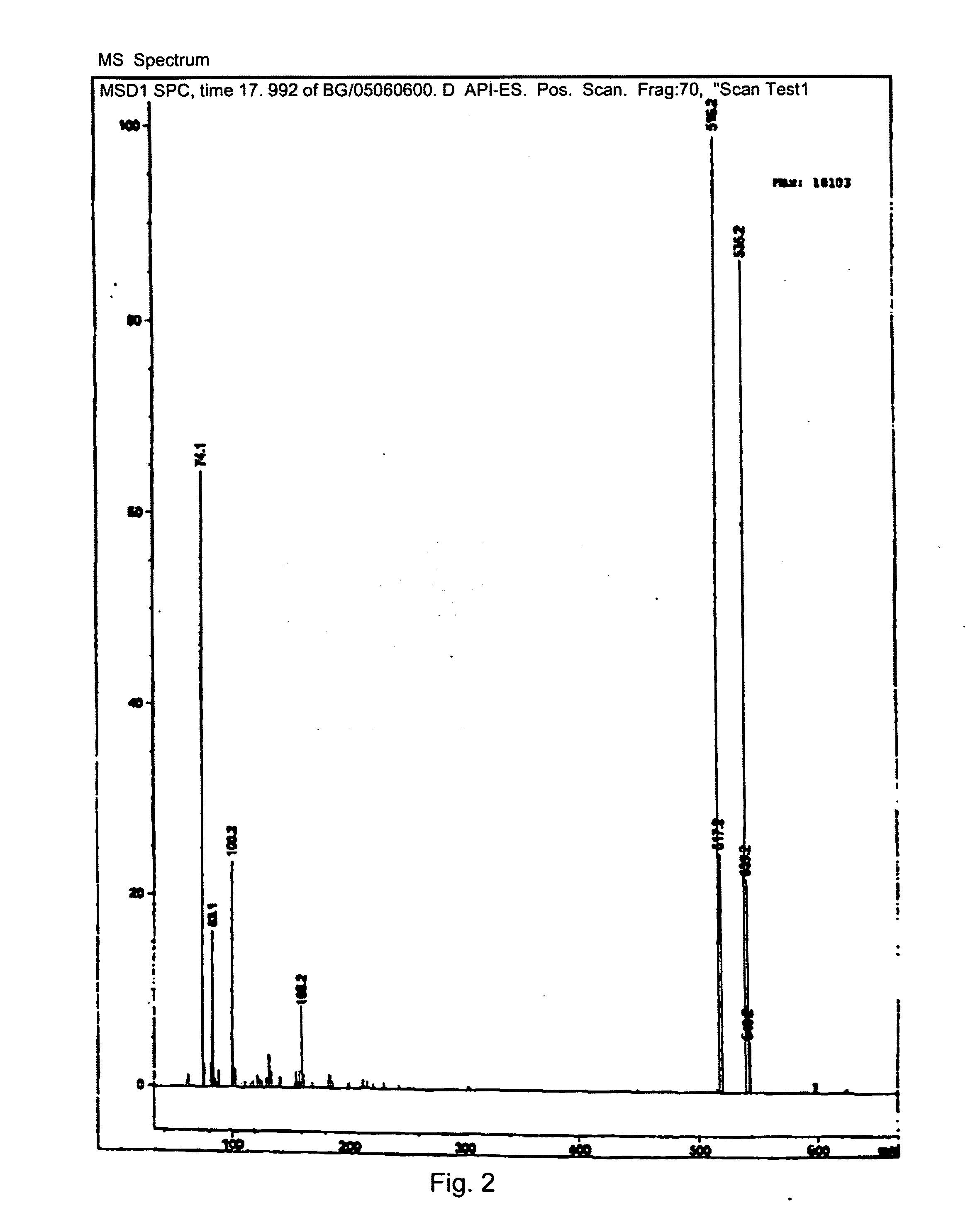

Preparation method of stearoylbenzoylmethane and application thereof to molding processing of thermoplastic resin

ActiveCN102503793AHigh cost of solutionThe condensation reaction cycle is longOrganic compound preparationCarbonyl compound preparationKetoneStearic acid

The invention discloses a preparation method of stearoylbenzoylmethane and an application thereof to molding processing of thermoplastic resin, which belong to preparation of a compound which only contains a CO radical and is only connected with a carbon atom or a hydrogen atom, and particularly relate to preparation of beta-diketone. The stearoylbenzoylmethane is obtained by undergoing a condensation reaction on methyl stearate and acetophenone in an alkaline environment, wherein the methyl stearate is obtained by taking stearic acid and methanol as raw materials, taking sulfuric acid as a catalyst and undergoing an esterification reaction. The invention provides a preparation method of the stearoylbenzoylmethane, which has the advantages of low costs of major raw materials, short condensation reaction period, small quantity of byproducts, high yield of stearoylbenzoylmethane, complete recycling of a solvent, nontoxicity of a crystallization solvent and high crystal yield. The condensation yield is up to 88 percent, the solvent is completely recycled, the crystallization solvent is nontoxic and environmentally-friendly, the crystal yield is up to 95 percent, and the purity of a product, i.e., stearoylbenzoylmethane is up to 98 percent. The invention further provides a method for applying the stearoylbenzoylmethane to molding processing of thermoplastic resin.

Owner:SHANDONG RUIFENG CHEM

Nucleotide Analogue Prodrug and the Preparation Thereof

InactiveUS20100216822A1Better activity profileBetter anti-viral activityBiocideGroup 5/15 element organic compoundsCombinatorial chemistryProdrug

(R)-9-[2-bis[pivaloyloxymeihoxy]phosphinoylmethoxypropyl]adenine (being abbreviated bis-POMPMPA, TD), the derivative and the use thereof. Also including the synthetic process of TD and the procedure for manufacturing solid TD, as well as the composition containing TD and the procedure for manufacturing the composition.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD +1

L-tryptophan refining method

InactiveCN104926709AReduce consumptionIncrease throughputOrganic chemistryActivated carbonAcetic acid

The invention provides an L-tryptophan refining method. The method comprises the steps of dissolving crude products in a water and acetic acid mixed solvent; adding an antioxidant, and regulating the pH value; adding activated carbon for decoloration, and then conducting filtration; conducting cooling crystallization, centrifugal collection of crystals and drying to obtain L-tryptophan. The purity of L-tryptophan refined with the method is not lower than 99.5%. Compared with a vacuum concentration recrystallization refining method, the method has the advantages that steam consumption is reduced greatly, and yield each time is increased by over 50%.

Owner:FUJIAN NORMAL UNIV

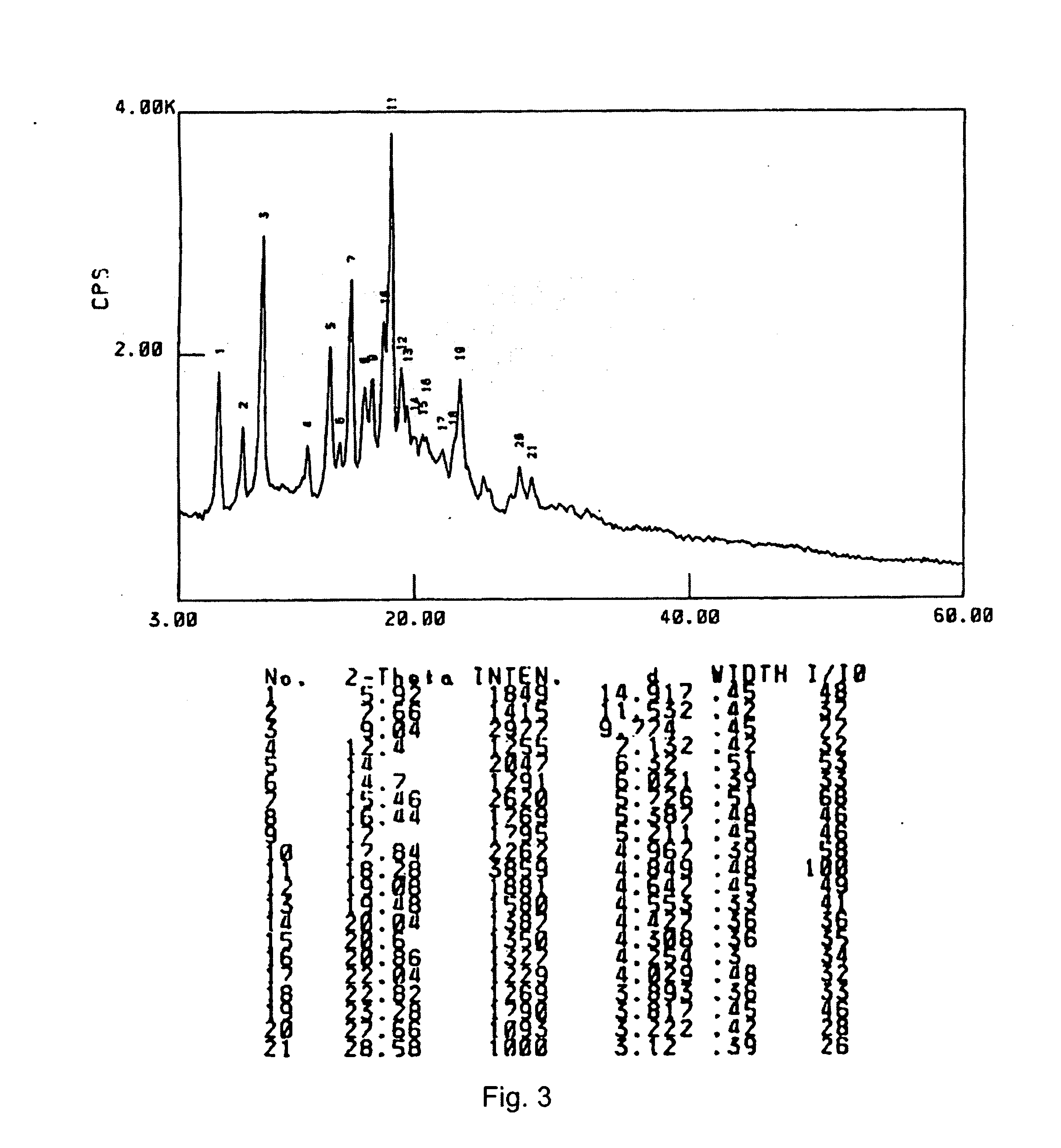

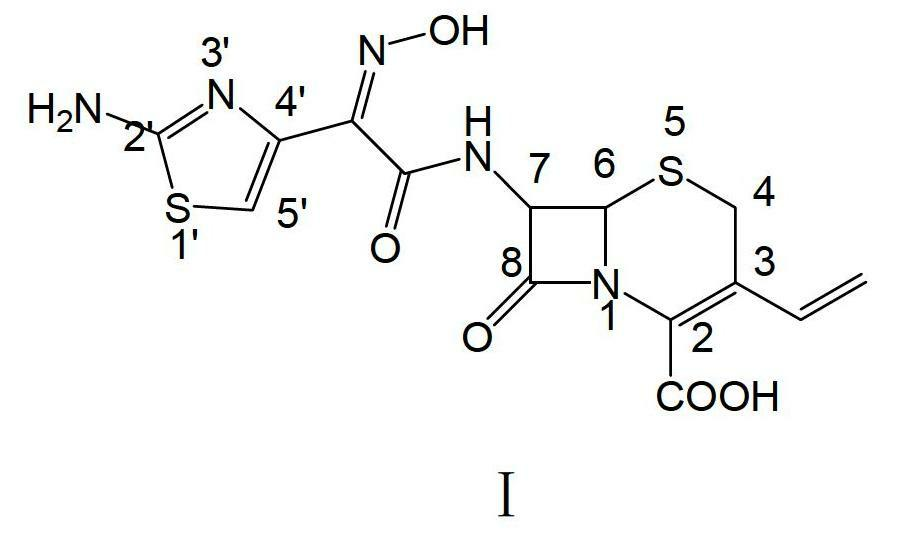

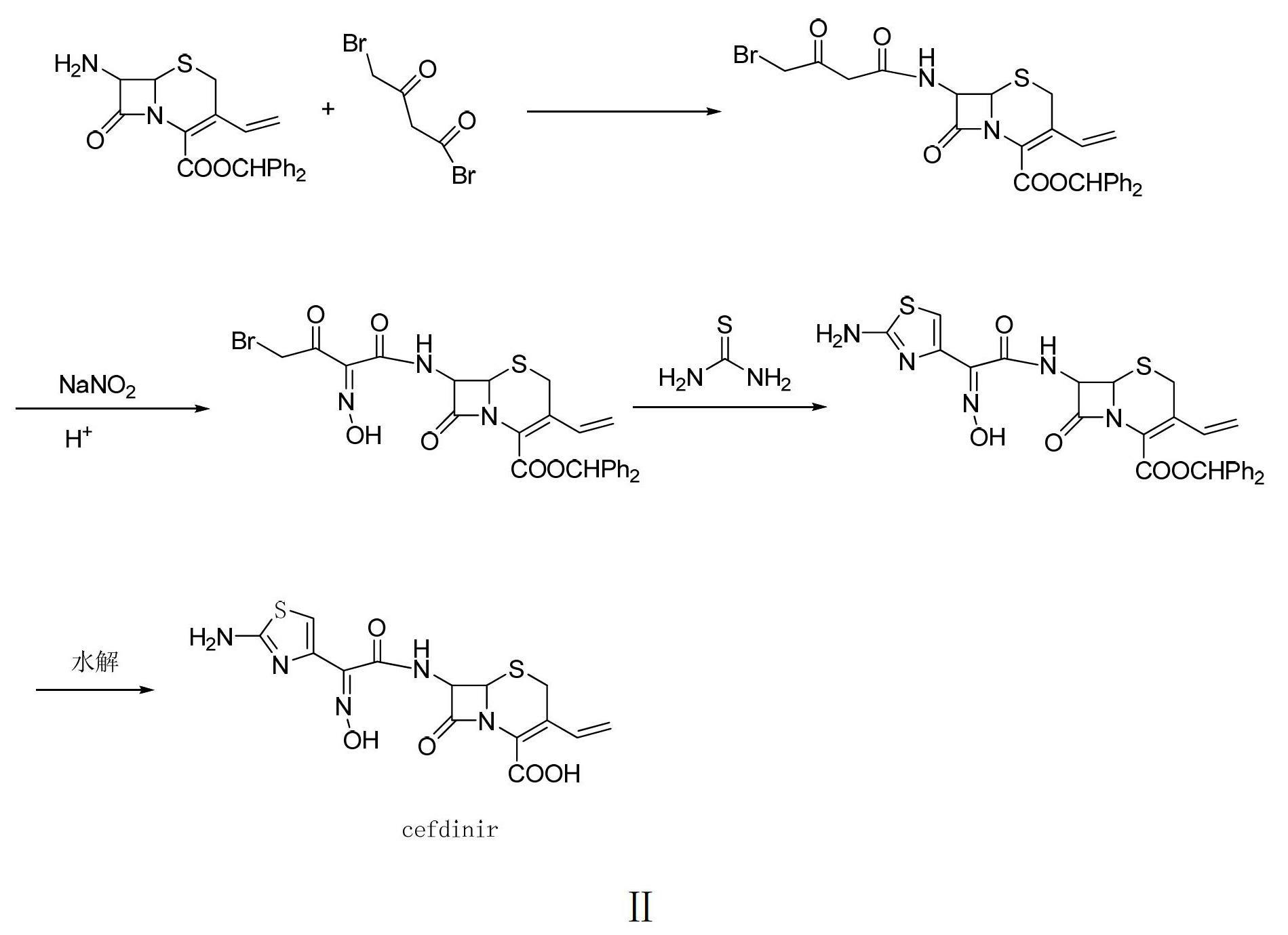

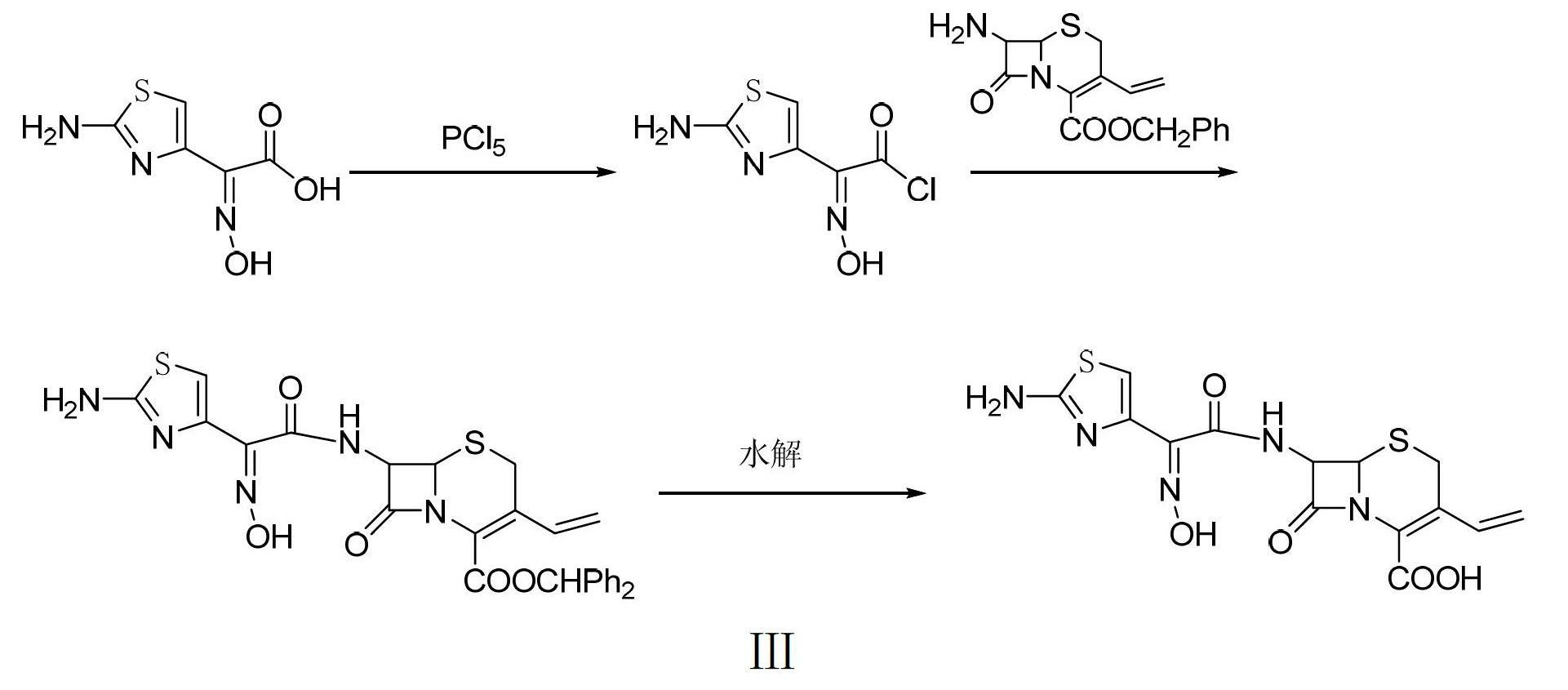

Preparation method of cefdinir

ActiveCN102659817AIncrease the speed of the condensation reactionShort reaction timeOrganic chemistryOrganic solventWater soluble

The invention relates to a preparation method of cefdinir, which comprises the following steps: dissolving T15-AE active ester and 7-AVCA in a water system containing water-soluble organic solvent, carrying out condensation reaction at normal temperature under the action of organic alkali, and directly extracting without regulating the pH value to obtain a cefdinir intermediate; under the combined actions of mixed alkalis, efficiently removing an ester group protective agent from the cefdinir intermediate, and precipitating cefdinir compound salts; and dissolving the obtained cefdinir compound salts in water for decolorization, adding the water-soluble organic solvent, and acidifying to crystallize, thereby obtaining the cefdinir product. The invention is simple to operate, has the advantages of high product purity, low production cost and low environmental pollution, and is suitable for large-scale production.

Owner:ZHEJIANG APELOA TOSPO PHARMA +1

Equipment and method for preparing crystal of vitamin C by fine crystal removing method

The present invention relates to an equipment and its method for preparing vitamin C crystal by adopting fine crystal eliminating method. Said equipment nicludes crystallizer with jacket, fine crystal dissolving device, condensation device, vacuum system and distillate collecting device. Said invention also provides the concrete structure of the above-mentioned every device and their connection mode, also provides the concrete steps of said method.

Owner:天津市北洋方菱工业结晶科技有限公司

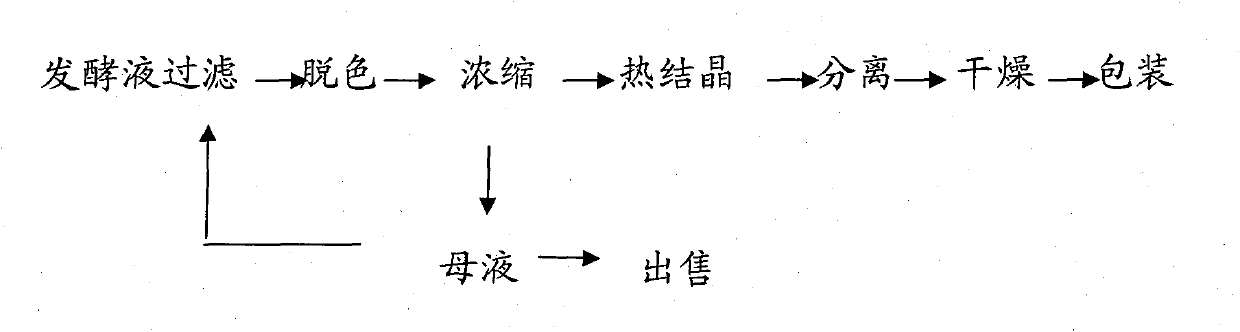

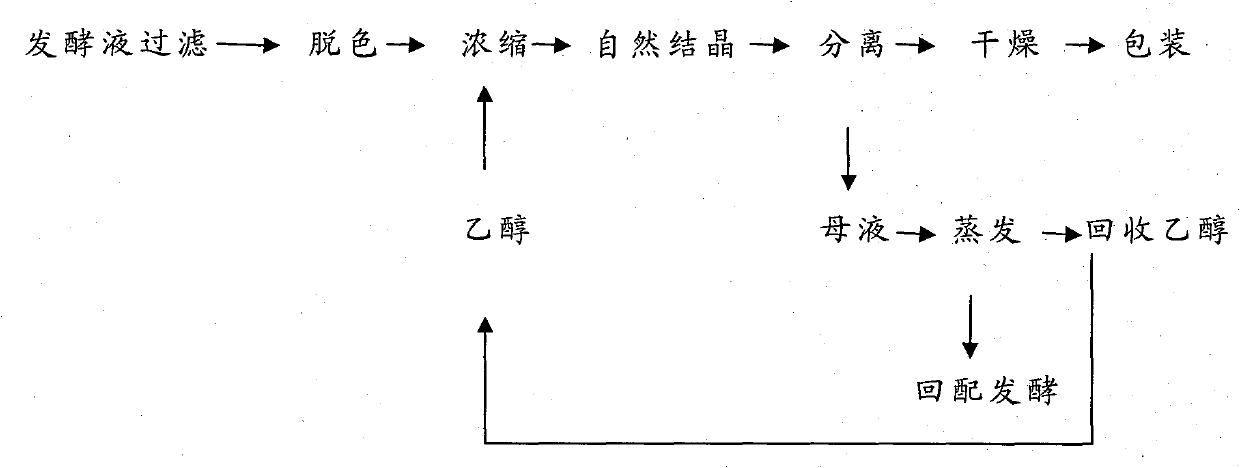

Novel method for extracting sodium gluconate

InactiveCN102086149AImprove crystallization yieldHigh purityFermentationCarboxylic compound separation/purificationAlcohol ethylPhysical chemistry

Owner:XIWANG GROUP

Extracting method of D-xylose and L-arabinose

ActiveCN103193834AAchieve recyclingReduce consumptionSugar derivativesSugar derivatives preparationAgricultural residueL-Arabinose

The invention provides an extracting process of D-xylose and L-arabinose. The extracting process comprises the following steps of: acidizing forestry and agricultural residues, carrying out steam explosion on the acidized forestry and agricultural residues to obtain the forestry and agricultural residues subjected to steam explosion, and finally carrying out aqueous extraction, separation and crystallization to obtain the D-xylose and L-arabinose. According to the technical scheme of the invention, the extracting method has the following advantages that an acid solution is recycled, and therefore the acid consumption is reduced; as the acid in an extracting solution is low in content, the load of a later-peroid purifying treatment is lightened; the peroid is short, continuous steam explosion production can be achieved, and the equipment investment is reduced when the capacity is unchanged; steam is not heated together with the acid solution in the boosting process, so that the steam consumption is greatly reduced, and energy sources are saved; and as the process of separating the D-xylose and the L-arabinose first and then respectively crystallizing is adopted, the purity of massecuite during crystallization of the D-xylose is improved, and the quality and crystallization yield of the D-xylose are improved.

Owner:FUTASTE PHARM CO LTD

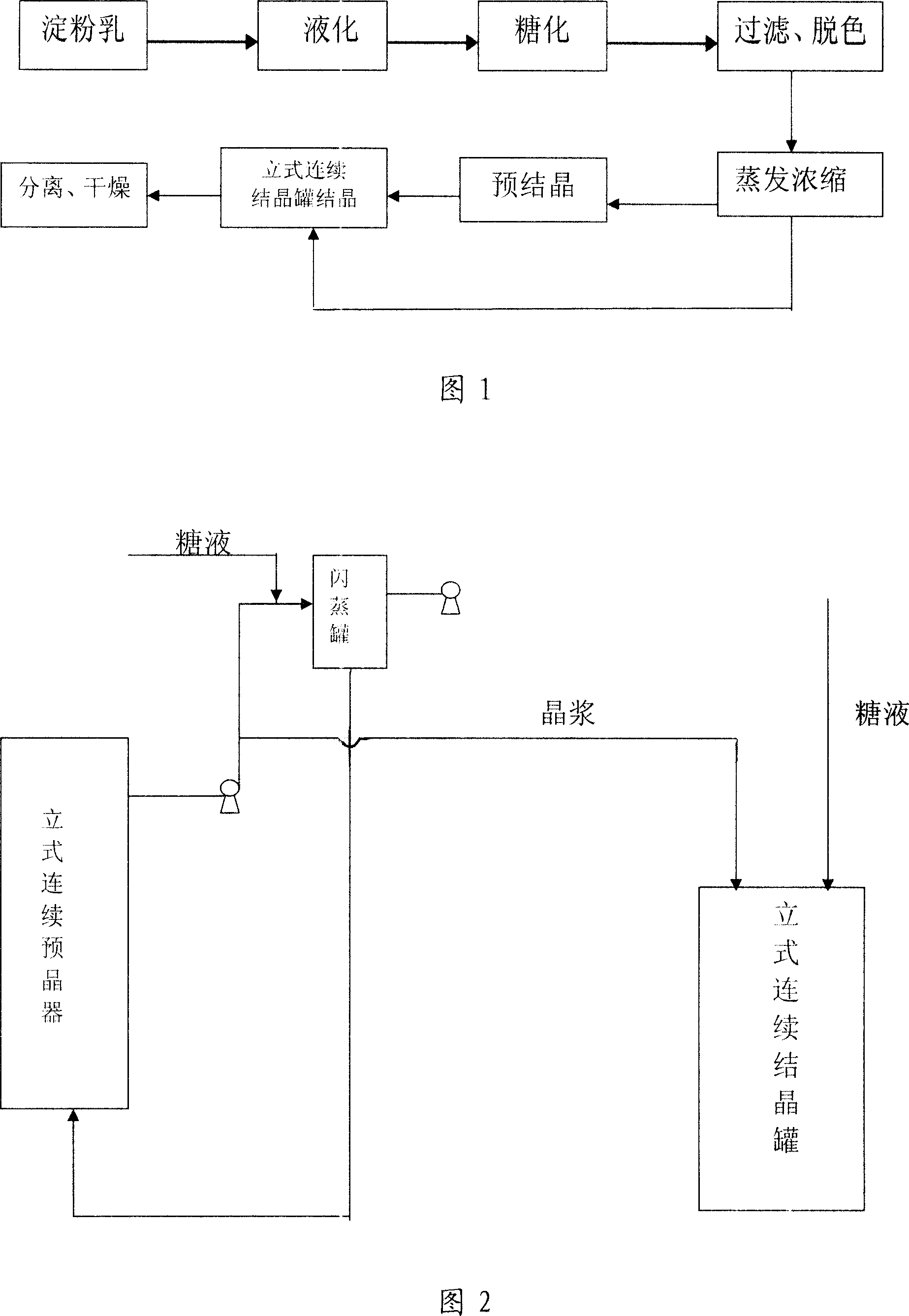

Vertical type continuous crystallization method adopting beforehand crystallization technique

InactiveCN101109020AFast crystallizationRealization of generationGlucose productionGlucose productionChemistry

The invention provides a vertical continuous crystallization process of pre-crystallization, which belongs an improvement of a crystallized glucose production way. Firstly starch milk is liquefied, saccharified, filtered and bleached, evaporated and concentrated to get the sugar solution. Secondly the sugar solution is brought in a flash pot for further evaporation and concentration. Thirdly the sugar solution is continuously sent into the vertical continuous pre-crystallization pot for crystallization for 20 hours to 40 hours. Fourthly part of the pre-crystallized crystal slurry is sent into the vertical continuous pre-crystallization pot as crystal seed, and they're mixed with the filtered and concentrated sugar solution in the vertical continuous pre-crystallization pot for crystallization. Finally the high crystal grain slurry is obtained after 20 to 30 hours crystallization. The invention brings the pre-crystallized slurry into the vertical continuous pre-crystallization pot as the crystal seed, thus increasing the crystal seed, improving the glucose crystallization speed, and reducing the crystallization cycle. The invention also improves the crystallization yield rate and product quality, as well as realizes continuous production.

Owner:SHANDONG XIWANG SUGAR

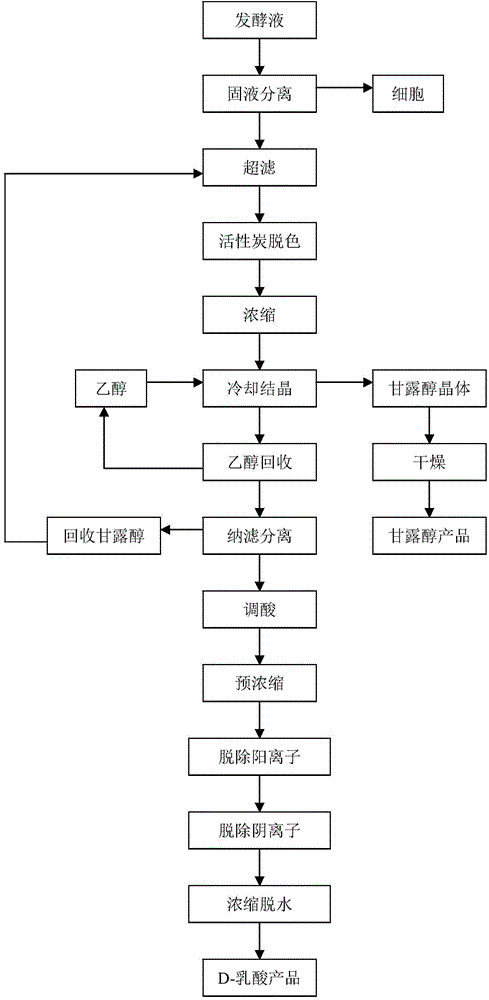

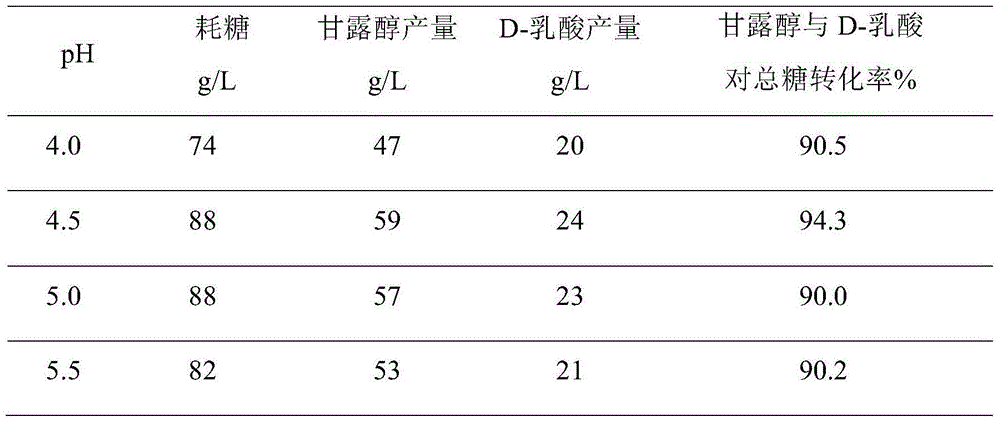

Method for combined production of mannitol and D-lactic acid by virtue of microorganism anaerobic fermentation

InactiveCN104651419AImprove crystallization yieldReduce the difficulty of extractionMicroorganism based processesOxygen compounds purification/separationMicroorganismMANNITOL/SORBITOL

The invention discloses a method for combined production of mannitol and D-lactic acid by virtue of microorganism anaerobic fermentation and belongs to the technical field of biology. The mannitol and D-lactic acid are produced by adopting Leuconostoc pseudomesenteroides G 123 with the preservation number of CCTCC NO:M 2014115 under the condition of anaerobic fermentation. The method comprises the following steps: (a) carrying out fermentation on the strain in a fermentation medium containing fructose syrup to obtain a fermentation broth containing the mannitol and D-lactic acid; and (b) separating the mannitol and D-lactic acid from the fermentation broth, and purifying. According to the method disclosed by the invention, the mannitol and D-lactic acid can be simultaneously produced with high efficiency, the total conversion rates of the mannitol and D-lactic acid to sugar reach 90 percent or more, the extraction yields both reach 83 percent or more, the purity of product is high, and the application prospect is wide.

Owner:NANJING UNIV OF TECH

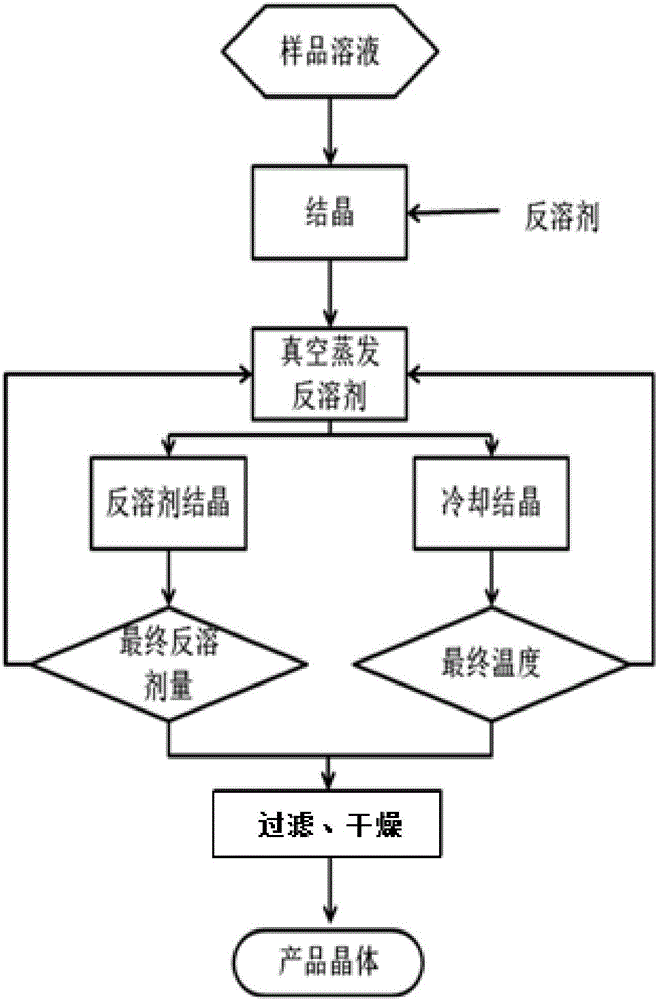

Crystallization method integrating anti-solvent crystallization, vacuum evaporation and cooling or anti-solvent crystallization

ActiveCN105031963AAchieve dissolutionLarge particle sizeSugar derivativesOrganic compound preparationAnti solventVacuum evaporation

The invention provides a crystallization method integrating anti-solvent crystallization, vacuum evaporation and cooling or anti-solvent crystallization. The method comprises the following steps: (1) preliminary anti-solvent crystallization: placing a to-be-crystallized amino acid material into a crystallizer, adding solvent water and allowing the material to be fully dissolved, carrying out heating to 30 to 80 DEG C, adding an anti-solvent into the crystallizer, carrying out full stirring, and allowing a part of the solute in the solution to be crystallized and separated out so as to obtain a to-be-crystallized material; (2) vacuum evaporation and cooling or anti-solvent crystallization: continuing stirring, subjecting an obtained solid-liquid system to evaporation under an absolute pressure of 20 to 60 kPa, cooling the obtained solid-liquid system or adding the same anti-solvent as in the step 1 so as to promote crystals to continue to grow, and repeating the step 2 for 1 to 3 times; and (3), filtering and drying: carrying out filtering, washing and drying so as to prepare a crystallization product. The method provided by the invention has the advantages of convenient and fast operation, high yield and easy realization of industrial scale production, and can obtain the crystallization product with narrow particle-size distribution and a large particle size.

Owner:肇东星湖生物科技有限公司

Method for preparing threonine crystal by threonine fermentation liquid

InactiveCN101759580AQuality improvementHigh yieldOrganic compound preparationAmino-carboxyl compound preparationUltrafiltrationThreonine

The invention relates to a method for preparing threonine crystal by threonine fermentation liquid, comprising the steps of: sterilizing the threonine fermentation liquid, and the carrying out plate-type or tube-type film ultrafiltration, concentration, azeotropic crystallization and other steps to prepare the threonine crystal; and the prepared threonine crystal has the purity of 98.5%, the threonine film ultrafiltration yield of more than 96%, and the azeotropic crystallization yield of more than 95%. The preparation method is an environment-friendly new production technique which has high efficiency, low energy consumption, low cost, simple method and easy popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

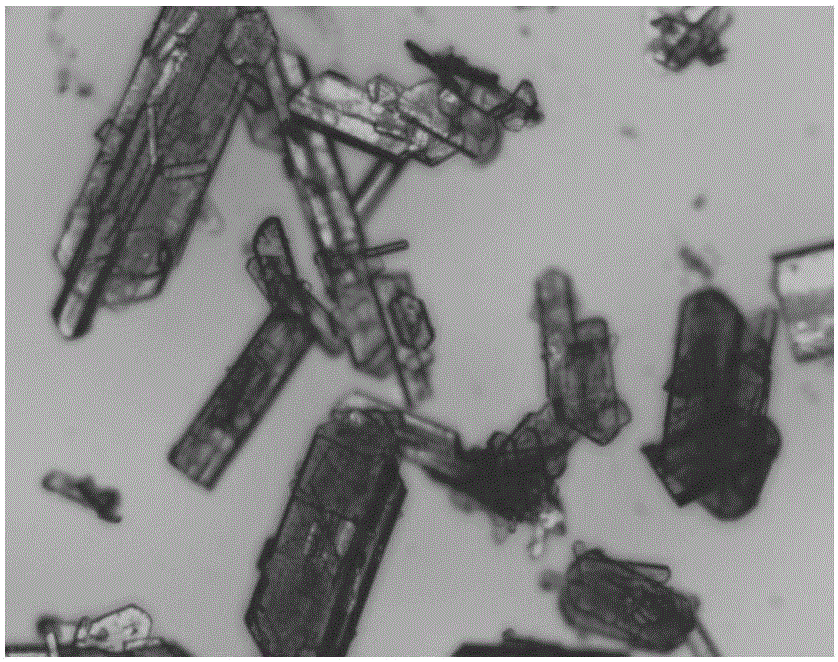

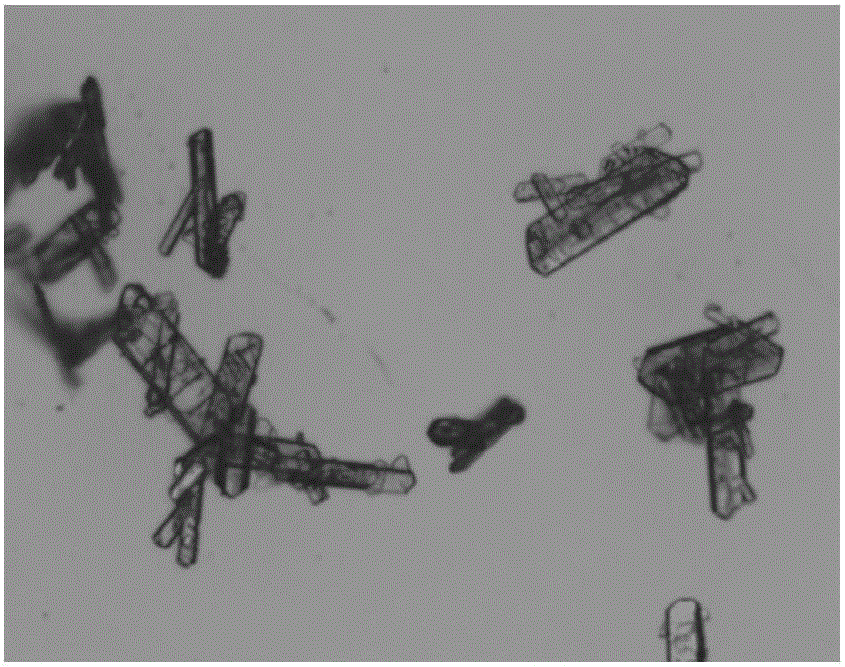

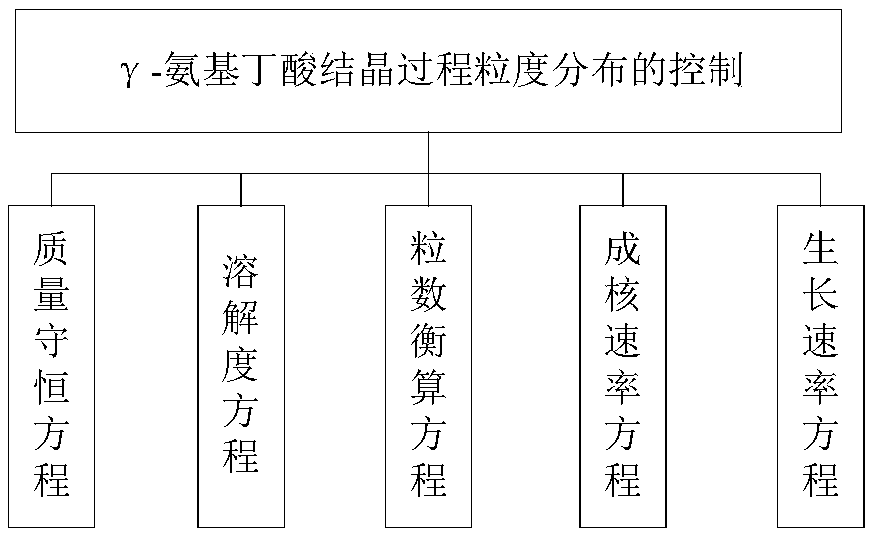

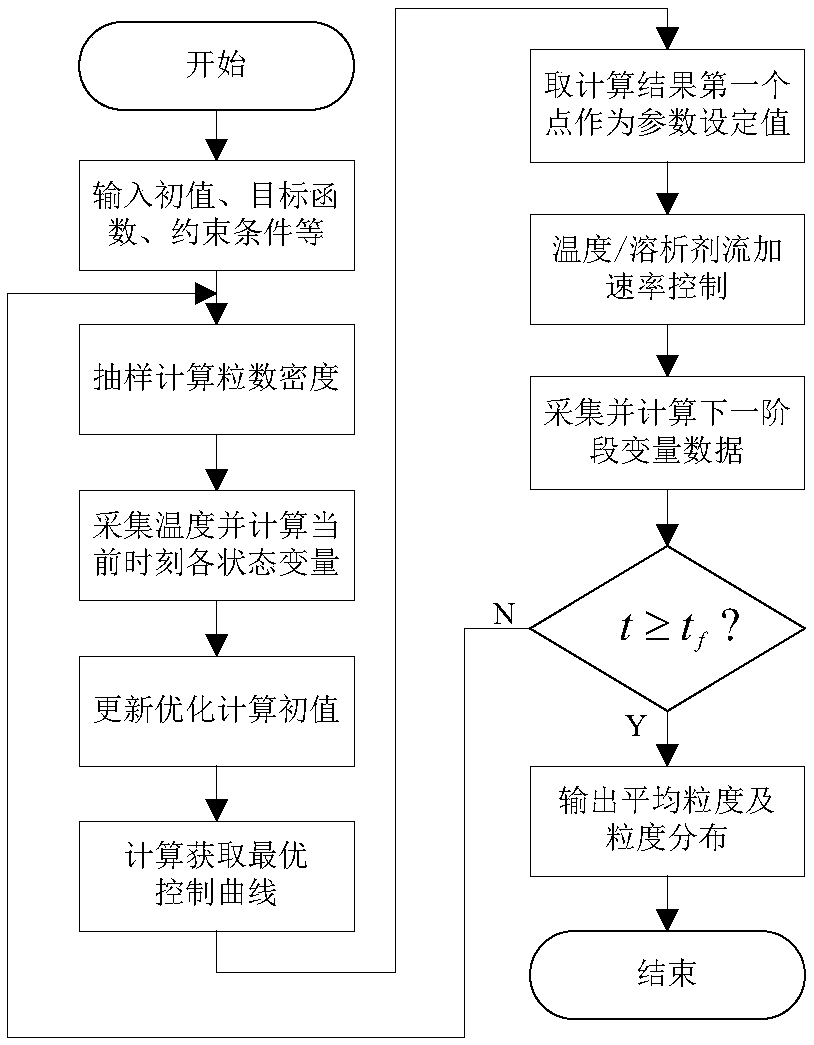

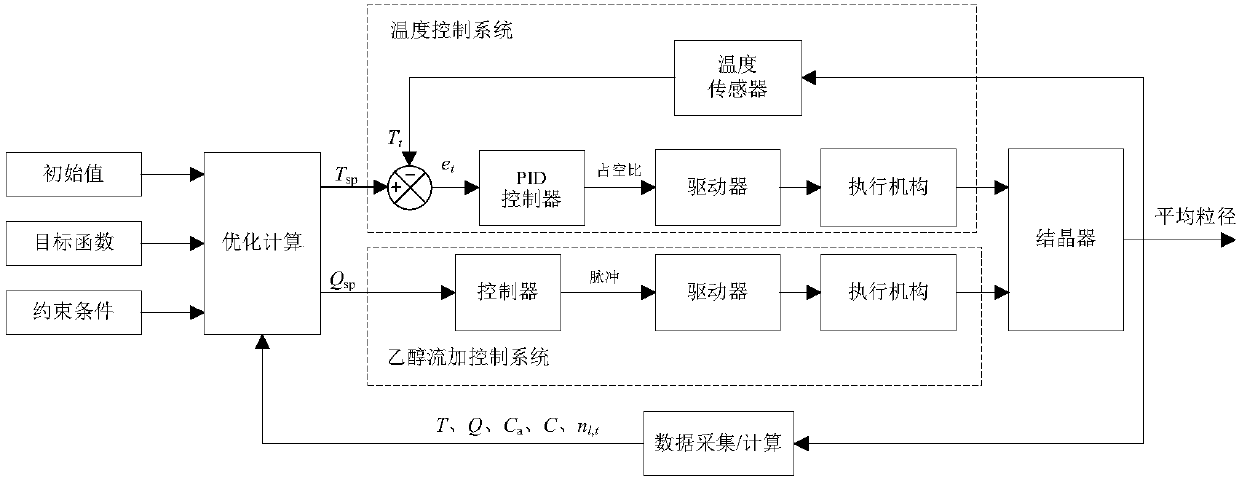

Particle size distribution modeling and control method in crystallization process

ActiveCN108490793AImprove crystallization yieldImprove particle size distributionAdaptive controlControl vectorChemical physics

The invention discloses a particle size distribution modeling and control method in a crystallization process. The particle size control method in the crystallization process comprises the following steps: establishing an optimal control module of particle size distribution in the crystallization process by taking the average crystal particle size as index for measuring the crystal particle size distribution and combining with crystallization process constraint conditions on the basis of a particle size distribution model in the crystallization process; performing discretization and parameterization processing on particle size control vectors in the crystallization process, to solve the optimal control model of the particle size distribution in the crystallization process, so as to obtainan optimal control curve in the crystallization process, and realize maximization of average particle size of crystals. According to the method, an acquiring method of a control curve in the crystallization process can be improved, and the crystallization efficiency and average crystal particle size can be improved.

Owner:SHANDONG UNIV

Secondary crystallization process for xylose

InactiveCN101367842ASimple processEasy to operateSugar derivativesSugar derivatives preparationCentrifugationXylose

The present invention discloses a secondary crystallization technique of xylose, which belongs to the techinical field of functional sugar production. The technique includes the following processes: xylose massecuite is infused into a crystallization pot, and when the infused volume reaches 80 percent to 85 percent of the capacity of the crystallization pot, infusion is stopped; when the temperature is naturally decreased to 80 DEG C, the xylose massecuite is stirred for two hours while the temperature is kept; afterwards, the temperature of the xylose massecuite is reduced at 1 DEG C per hour, and when the temperature reaches 75 DEG C, tiny crystal grains are formed in the xylose massecuite; at the moment, the residual xylose massecuite, which accounts for 20 percent to 15 percent of the capacity of the crystallization pot, is infused into the crystallization pot and uniformly mixed, so that the newly added xylose massecuite is sufficiently mixed with the xylose massecuite with the formed tiny crystal grains; then, when the temperature is naturally reduced to 75 DEG C, the xylose massecuite is stirred for three hours while the temperature is kept; the temperature is decreased again according to the speed rate of 1 DEG C per hour, and when the temperature reaches 30 DEG C to 40 DEG C, crystallization is finished; and centrifugation operation is carried out. Compared with the prior art, the secondary crystallization technique of xylose is characterized by simple operation, high crystallization yield, low production cost, and the like.

Owner:FUTASTE PHARM CO LTD

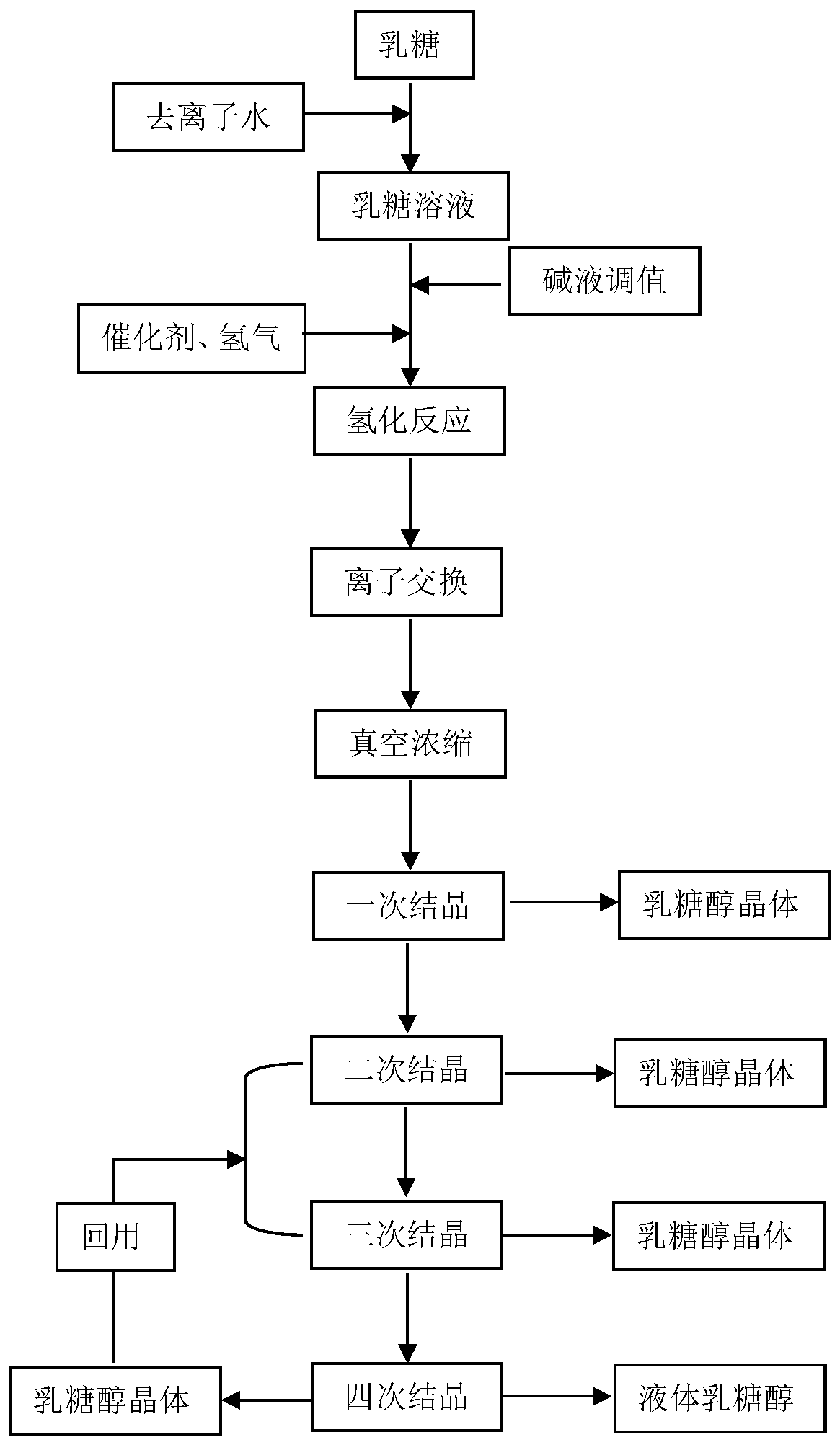

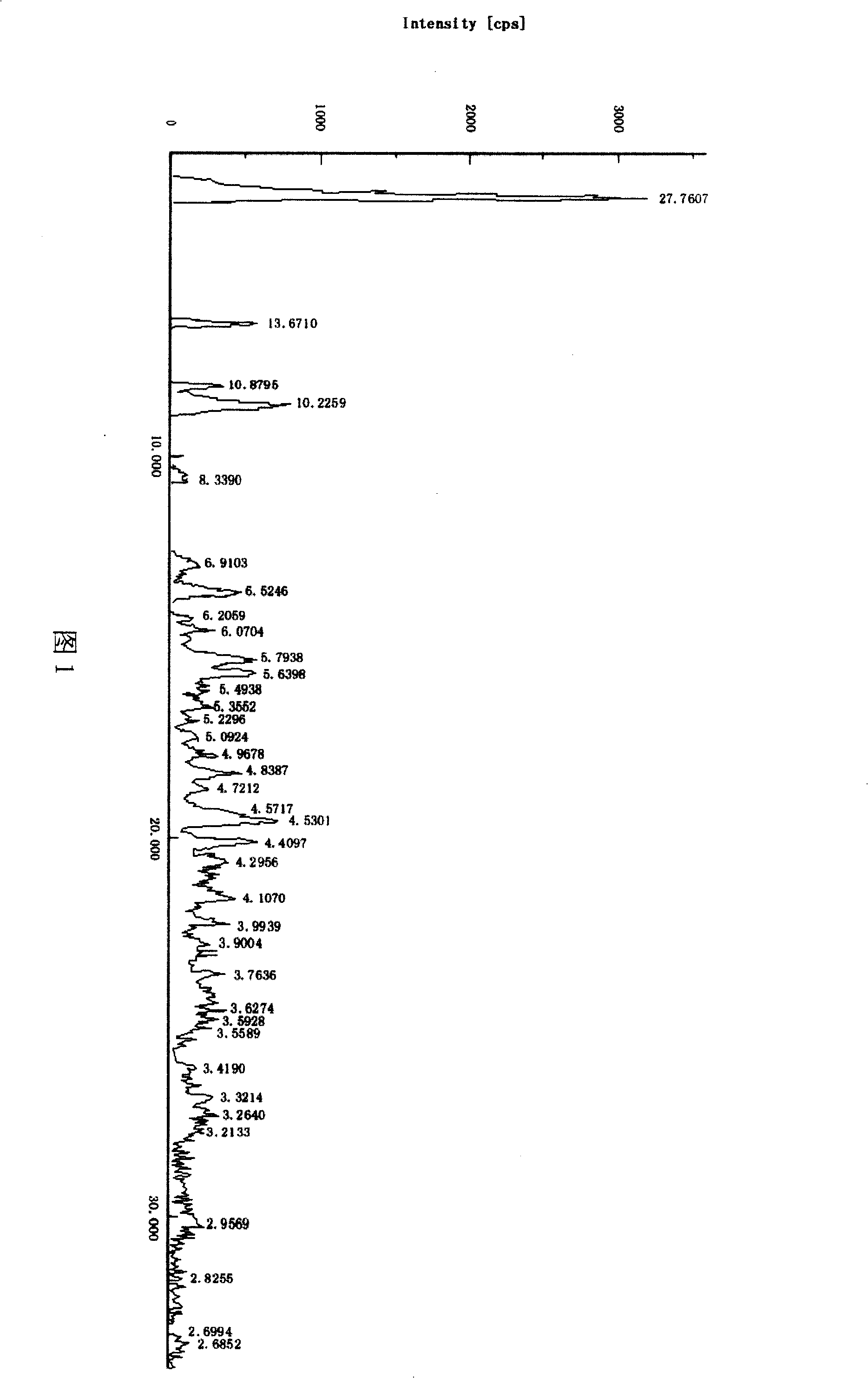

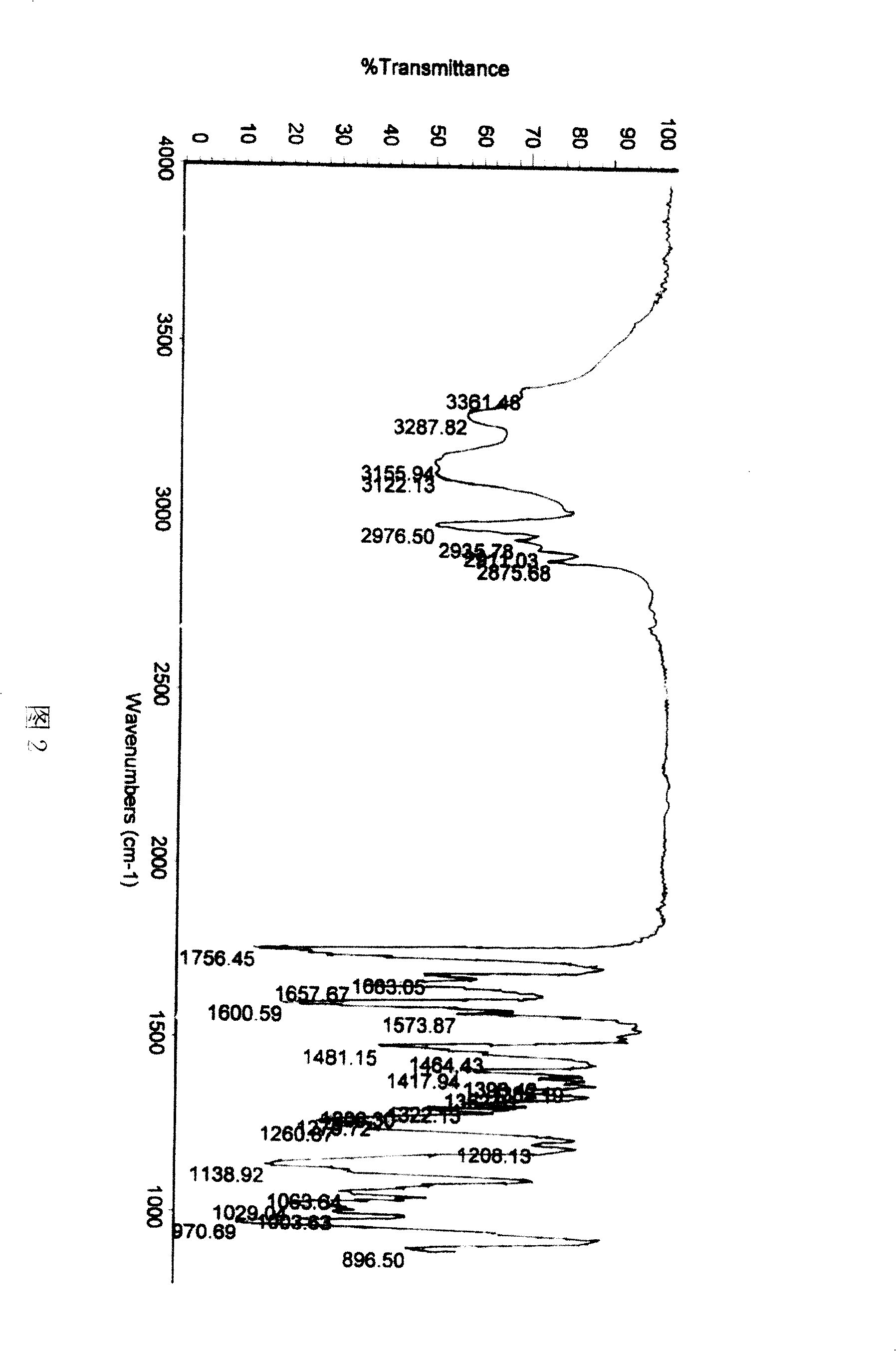

Production technology of lactitol

ActiveCN110818752AConvenient amountHigh activitySugar derivativesSugar derivatives preparationPtru catalystHydrogenation reaction

The present invention discloses a production technology of lactitol. Lactose is added into deionized water to prepare a lactose solution, pH is adjusted, a certain amount of a catalyst is added, a hydrogenation reaction is conducted under high temperature and high pressure to obtain a lactose hydrogenation solution, after the catalyst is removed, a lactitol solution is obtained, the lactitol solution is then purified, and concentration, crystallization and drying are conducted to obtain lactitol crystals. A primary crystallization yield of the lactitol relative to the lactose raw material reaches 55.0%-68.0% and a total yield of the lactitol relative to the lactose raw material reaches 92.2%-96.5%. At the same time, the technology is simplified in processes, liable for production and operation and also relatively low in production cost.

Owner:FUTASTE PHARM CO LTD

Preparation method for adefovir dipivoxil ester waterless crystallization article, prepared adefovir dipivoxil ester waterless crystallization article and uses thereof

ActiveCN101343290AReduce manufacturing costImprove crystallization yieldOrganic active ingredientsGroup 5/15 element organic compoundsPropyl etherHepatitis B virus

Disclosed is a preparation method of an adefovir dipivoxil anhydrous crystal mass, the acquired adefovir dipivoxil anhydrous crystal mass as well as applications thereof, comprising the steps of: A. dissolving a crude product of adefovir dipivoxil with 95 percent ethanol; B. adding ether into a crystallization kettle, agitating the mixture and cooling the temperature to between 2 and 5 DEG C, adding the dissolved solution of adefovir dipivoxil acquired in the step A into the crystallization kettle, and agitating the mixture until reaching crystallization; and filtering the crystal mass, collecting a wet product of the crystal mass and then drying the wet product, wherein, the ether is one or more of iso-propyl ether, n-butyl ether and sec-butyl ether. The obtained crystallization yield reaches over 96 percent, and the crystal mass purity reaches above 99.5 percent. The adefovir dipivoxil anhydrous crystal mass is applied to the preparation of medicines for curing anti-hepatitis B viruses, and has good product activity.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

Method for producing xylose with straw

InactiveCN102212594AHigh xylose crystallization yieldSimple processMicroorganism based processesFermentationXyloseChemistry

The invention discloses a method for degrading the hemicellulose prepared from straw by utilizing the xylanase which is fermented by utilizing actinobacteria. The technical scheme in the invention comprises four main working procedures, namely the preparation of xylanase, the preparation of hemicellulose, the enzymolysis of hemicellulose and the purification and refinement of xylose. The enzymatic method is adopted to produce xylose; and the method has the following advantages: the specificity is high, the conditions are mild, the impurities of the intermediate are fewer, the intermediate is easy to purify and extract, the conversion rate of hemicellulose and the yield of xylose crystals are higher, clean and environmentally-friendly production can be maintained in industry, and the like. The total raw material conversion rate is more than 15% and the xylose content of the finished product is more than 98.5%.

Owner:山西省生物研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com