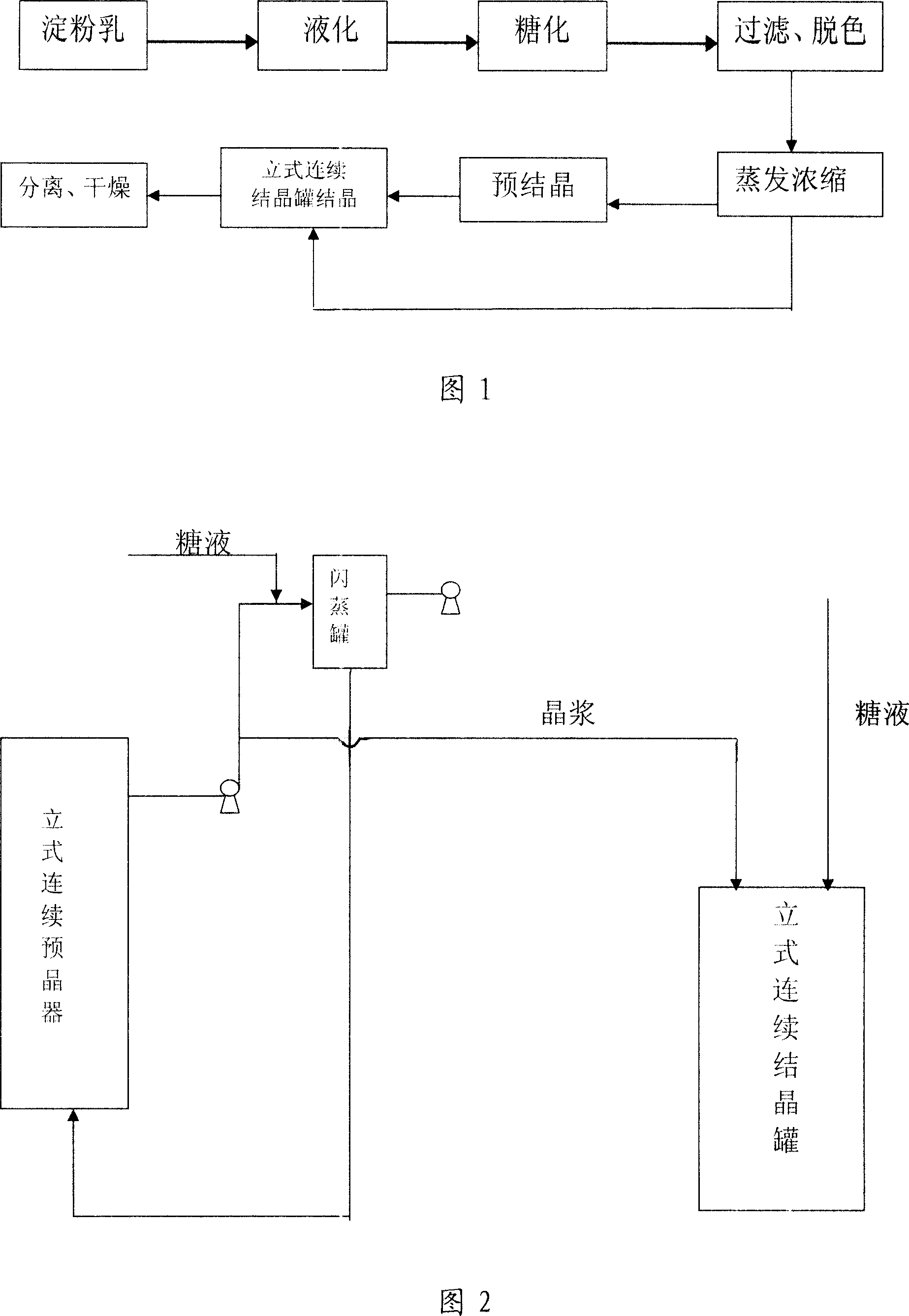

Vertical type continuous crystallization method adopting beforehand crystallization technique

A vertical, crystallization technology, applied in the application, sugar production, sugar production and other directions, can solve the problems of unsatisfactory crystallization speed and crystallization yield, many parameters, complex process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below.

[0010] The feed temperature of the sugar liquid entering the vertical continuous crystallization tank is 44°C-50°C. This is the optimum feed temperature.

[0011] Same as the prior art, in the vertical continuous crystallization tank in the present invention, there must be a stirring device made of stirring paddle, stirring shaft, etc., as well as a cooling device, a feeding device, and a supporting crystal continuous extraction device (crystal Separator). The structure of the vertical continuous precrystallization tank is similar to that of the vertical continuous crystallization tank, and will not be described in detail.

[0012] The sugar liquid formed after liquefaction, saccharification, filtration and decolorization of starch milk, evaporation and concentration must be pumped into the flash tank at a certain flow rate, the flow rate is 6m 3 / h to 8m 3 / h. The sugar liquid is pre-crystallized in the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com