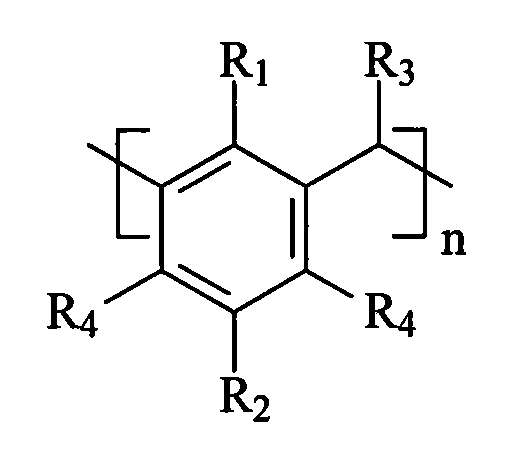

Self-assembled calixarene nucleating agent and application thereof in polylactic resin composition

A technology of polylactic acid resin and self-assembly, applied in the field of polylactic acid nucleating agent, can solve the problems of small molecular weight of nucleating agent, low crystallization rate, loss of ester particles, etc. The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

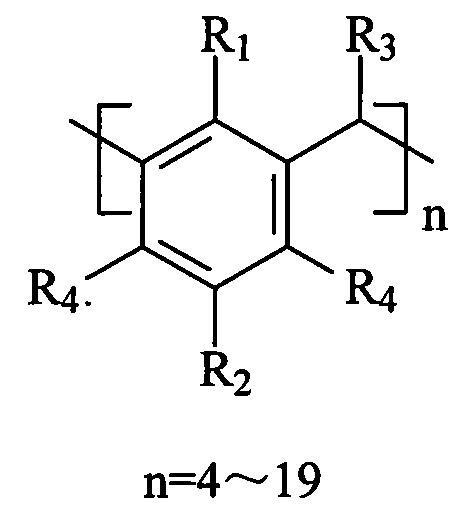

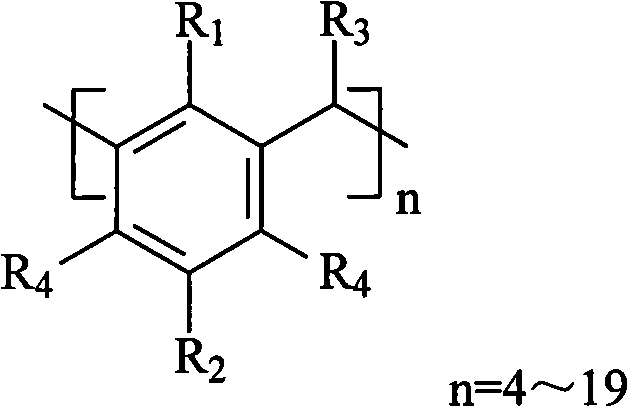

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Self-Assembly Nucleation of Isobutylresorcinol Calixarene and Ethanol

[0031] Add 2g of isobutylresorcinol calixarene to 100mL of ethanol, reflux for 2 hours, distill off 70mL of solvent under reduced pressure, cool and dry to obtain a light yellow powder with a melting point of 290-300°C.

Embodiment 2

[0033] Preparation of Calix-[4]-Resorcinolarene and Ethanol Self-Assembled Nucleating Agent

[0034]Add 2g of calix-[4]-resorcinolarene into 100mL of ethanol and reflux for 2 hours, distill off 70mL of solvent under reduced pressure, cool and dry to obtain a light yellow powder with a melting point of 290-300°C.

Embodiment 3

[0036] Preparation of p-benzoylcalix[6]arene and dichloromethane self-assembled nucleating agent

[0037] 2 g of p-benzoylcalix[6]arene was dissolved in 100 mL of dichloromethane, refluxed for 2 hours, 70 mL of solvent was distilled off under reduced pressure, cooled, and dried to obtain a white powder with a melting point of 370-380 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com