Microspheric three-dimensional grading micro-nano structure bismuth tungstate photocatalytic material and preparation method thereof

A technology of hierarchical micro-nano structure and photocatalytic materials, applied in the field of catalytic materials research, can solve the problems of limited contact area between pollutants and catalysts, reduce photocatalytic activity, organic waste liquid pollution, etc., and achieve enhanced photocatalytic activity and reaction conditions. Easy to control, prevent agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

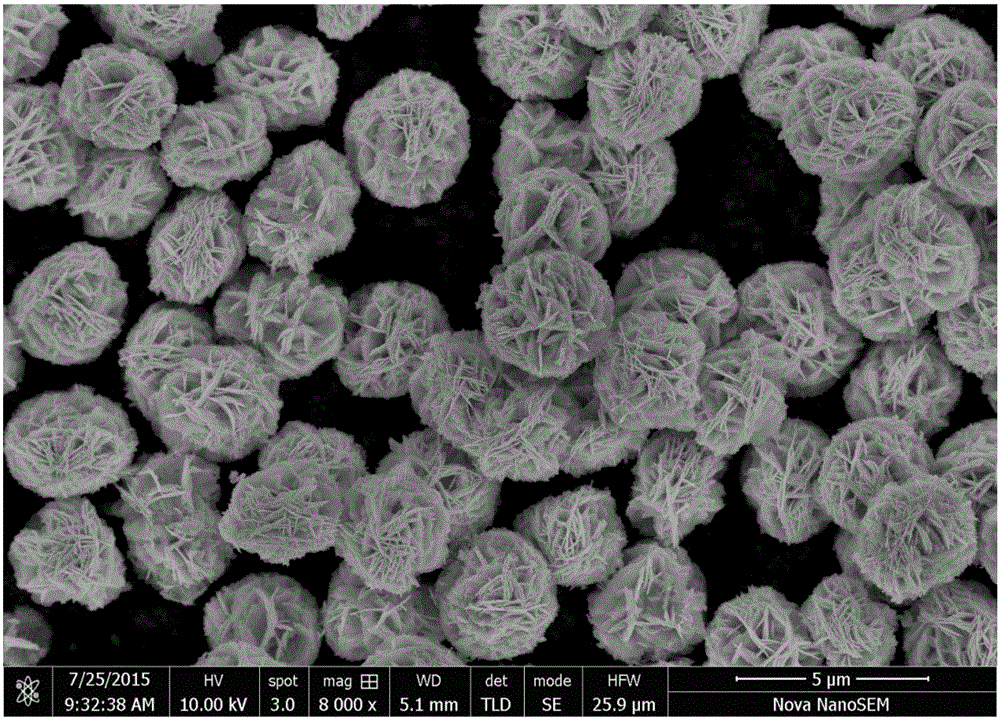

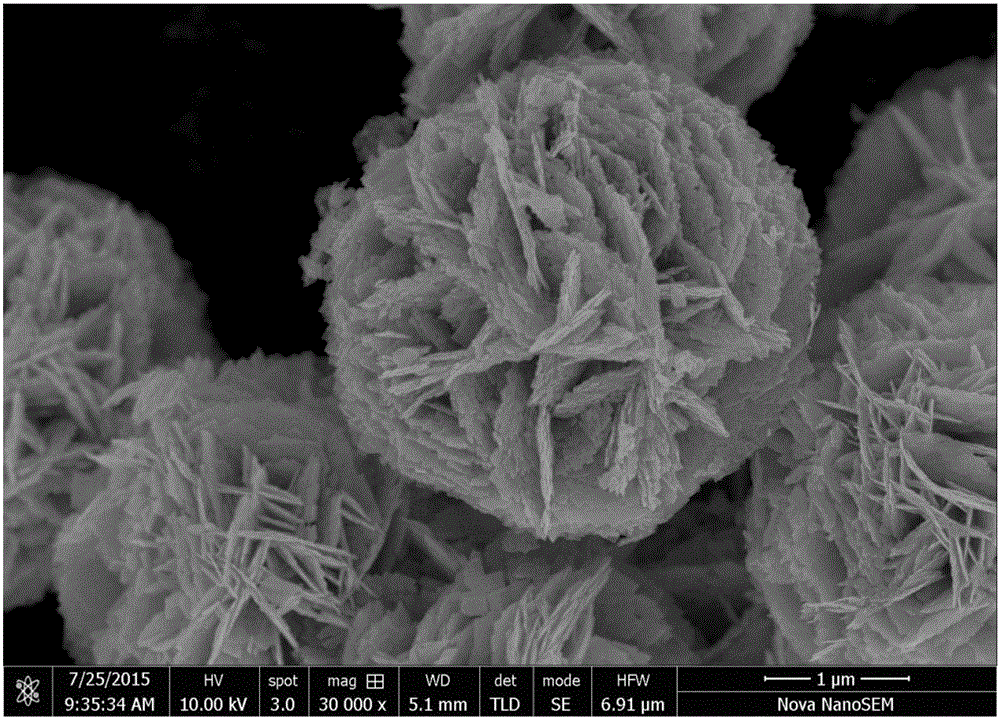

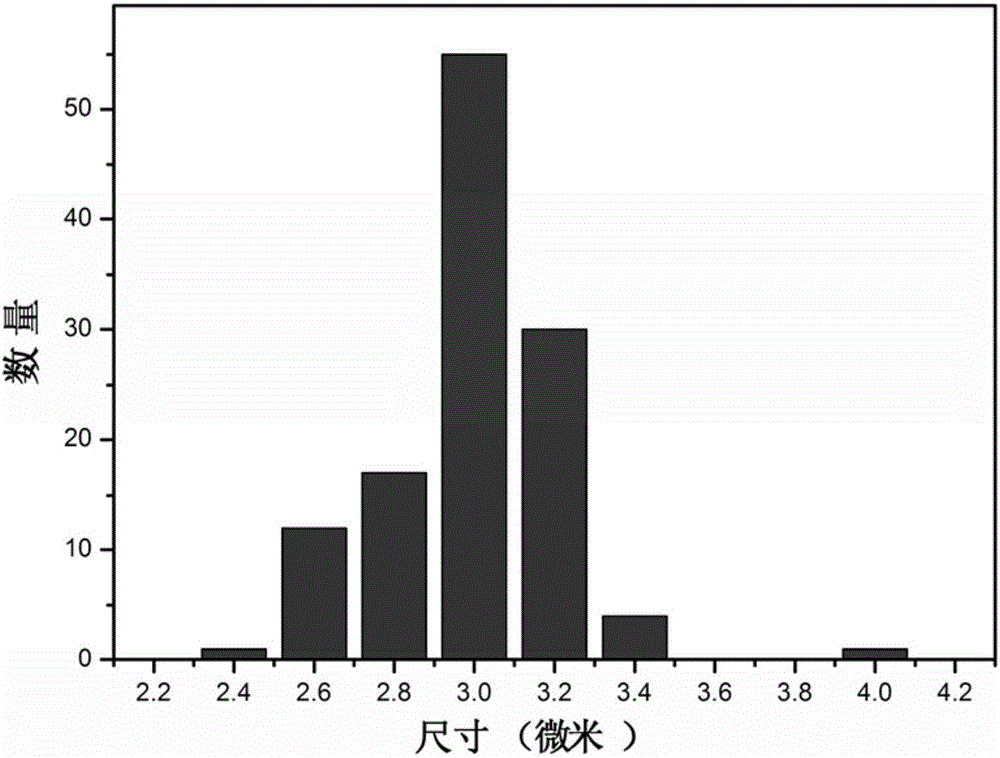

[0033] In this embodiment, the method for preparing a microspherical three-dimensional hierarchical micro-nano structure bismuth tungstate photocatalytic material is realized by the following steps:

[0034] (1) Disperse 0.825g of sodium tungstate dihydrate and 2.425g of bismuth nitrate pentahydrate evenly in 40mL of deionized water, respectively, ultrasonically oscillate for 15min, and stir to obtain sodium tungstate solution and bismuth nitrate solution respectively;

[0035] (2) Add the sodium tungstate solution to the bismuth nitrate solution drop by drop, the molar ratio of sodium tungstate and bismuth nitrate is 1:3, add nitric acid to adjust the pH to 1, react in the reaction kettle at 180°C for 18 hours, wait After the reaction solution was naturally cooled to room temperature, the solid product was isolated;

[0036] (3) The solid product separated in step (2) was washed three times with deionized water and absolute ethanol, and dried at 70° C. to obtain a microspheri...

Embodiment 2

[0040] In this embodiment, the method for preparing a microspherical three-dimensional hierarchical micro-nano structure bismuth tungstate photocatalytic material is realized by the following steps:

[0041] (1) Disperse 0.825g of sodium tungstate dihydrate and 2.425g of bismuth nitrate pentahydrate evenly in 40mL of deionized water, respectively, ultrasonically oscillate for 10min, and stir to obtain sodium tungstate solution and bismuth nitrate solution respectively;

[0042] (2) Add the sodium tungstate solution to the bismuth nitrate solution drop by drop, the molar ratio of sodium tungstate and bismuth nitrate is 1:2, add nitric acid to adjust the pH to 1, and react at 160°C in the reaction kettle for 20 hours, wait After the reaction solution was naturally cooled to room temperature, the solid product was isolated;

[0043] (3) The solid product separated in step (2) was washed three times with deionized water and absolute ethanol respectively, and dried at 80° C. to obt...

Embodiment 3

[0046] In this embodiment, the method for preparing a microspherical three-dimensional hierarchical micro-nano structure bismuth tungstate photocatalytic material is realized by the following steps:

[0047] (1) Disperse 0.825g of sodium tungstate dihydrate and 2.425g of bismuth nitrate pentahydrate evenly in 40mL of deionized water, respectively, ultrasonically oscillate for 12min, and stir to obtain sodium tungstate solution and bismuth nitrate solution respectively;

[0048] (2) Add the sodium tungstate solution to the bismuth nitrate solution drop by drop, the molar ratio of sodium tungstate and bismuth nitrate is 1:4, add nitric acid to adjust the pH to 1, react in the reaction kettle at 150°C for 24 hours, wait After the reaction solution was naturally cooled to room temperature, the solid product was isolated;

[0049] (3) The solid product separated in step (2) was washed three times with deionized water and absolute ethanol, and dried at 75° C. to obtain a microspheri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com