Device system and preparation technology for preparing submicron material through continuous hydrothermal method

A technology for submicron preparation and preparation process, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of immature process technology, easy agglomeration, and low crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

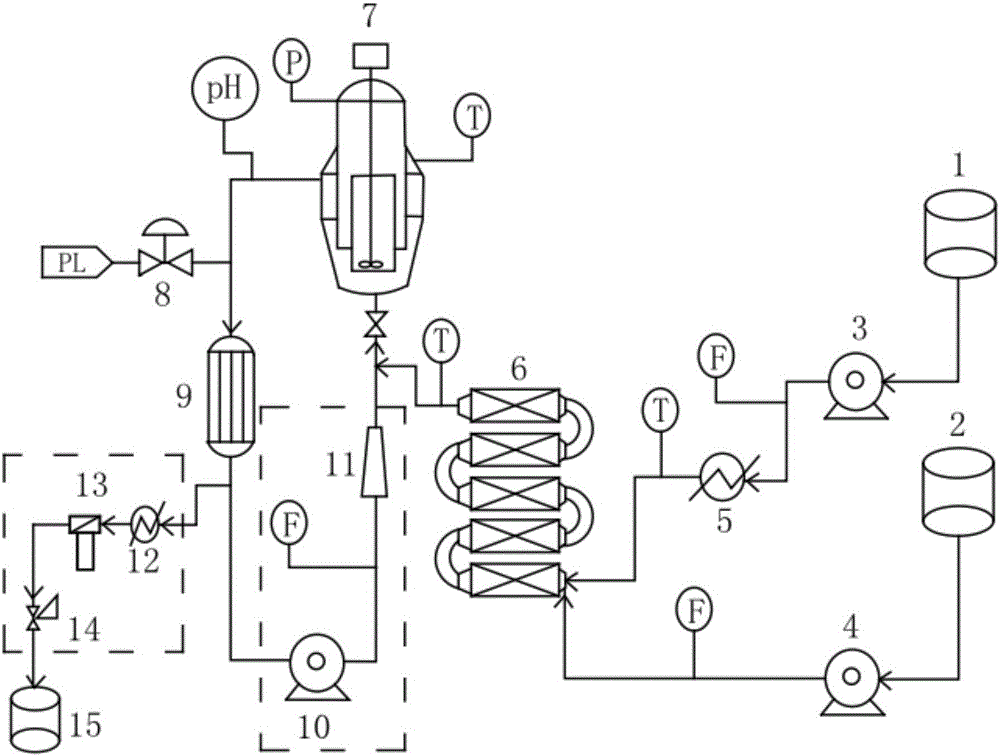

[0034] A preparation process for preparing submicron materials by continuous hydrothermal method, the process comprises the following steps:

[0035] The first raw material liquid contained in the first batching kettle 1 is transported by the first feed pump 3 and then enters the preheater 5 to preheat to a certain temperature, and the second raw material liquid contained in the second batching kettle 2 passes through the second feeding pump 4 Transport and enter the first crystallizer 6 according to a certain volume ratio with the preheated first raw material liquid to obtain a slurry, which flows in the first crystallizer 6 at a certain flow rate for a period of time before entering the second crystallization device 6;

[0036] The slurry enters the second crystallizer 6 for crystallization, and part of the slurry flows out from the discharge port of the second crystallizer 6, exchanges heat through the heat exchanger 9, and is driven by the circulation pump 10 and is connec...

Embodiment 1

[0046] Taking the preparation of submicron titanium dioxide by sulfuric acid method as an example, the preparation process of submicron titanium dioxide by continuous hydrothermal method is as follows:

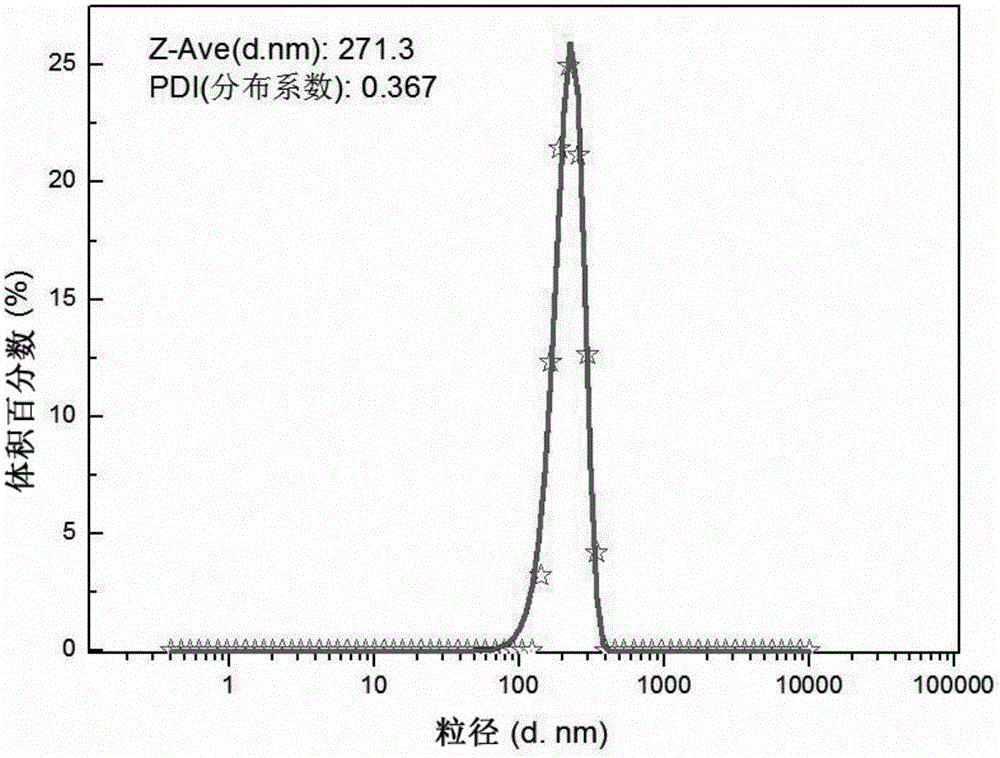

[0047] The first raw material liquid is a titanium sulfate liquid precursor solution, and the second raw material liquid is an aqueous solution. TiO in titanium sulfate liquid precursor solution 2 Concentration 260g / L, acidity coefficient F value (effective acid and total TiO 2 The concentration ratio) is 2.0, the iron-to-titanium ratio (the ratio of the concentration of iron ions in the titanium solution to the total titanium concentration) is 0.21, the stability of the titanium solution is >500, the clarity is good, and the temperature is 40°C. The outlet temperature of the preheated water through the preheater 5 is 125°C, the volume ratio of the titanium sulfate liquid precursor solution entering the first crystallizer 6 and the preheated water is 1:4, and the pipe diamete...

Embodiment 2

[0050] The preparation process of submicron titanium dioxide prepared by continuous hydrothermal method is as follows:

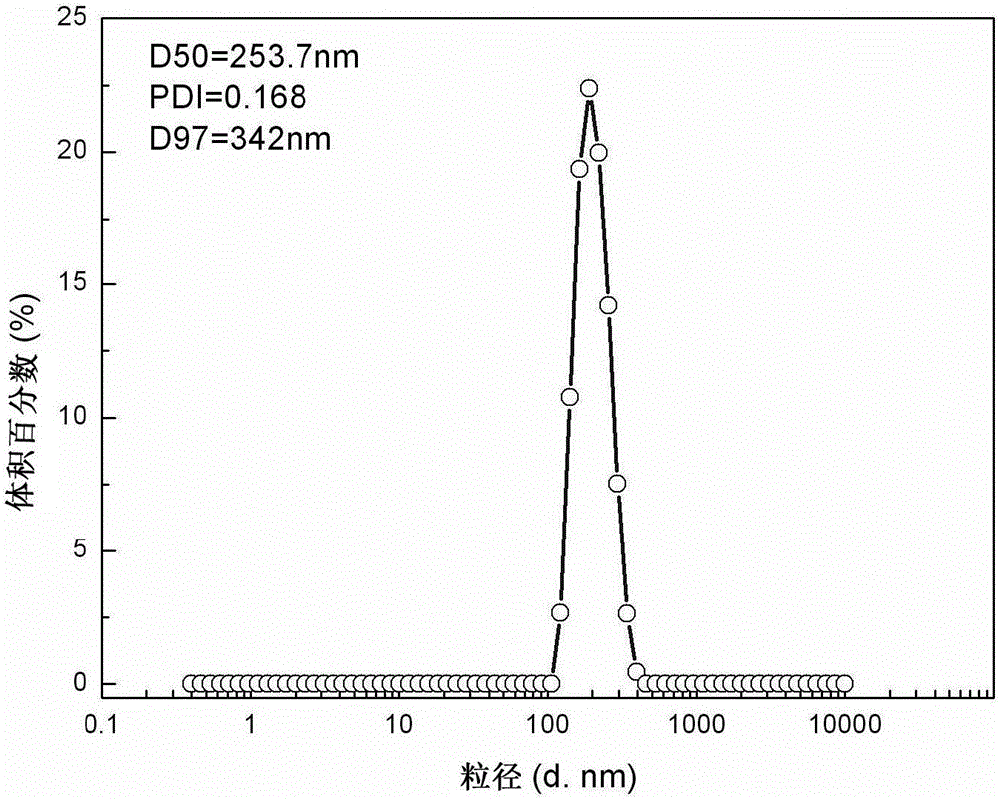

[0051] The first raw material liquid is a titanium sulfate liquid precursor solution, and the second raw material liquid is an aqueous solution. TiO in titanium sulfate liquid precursor solution 2 Concentration 300g / L, acidity coefficient F value (effective acid and total TiO 2 The concentration ratio) is 1.8, the iron-to-titanium ratio (the ratio of the concentration of iron ions in the titanium solution to the total titanium concentration) is 0.21, the stability of the titanium solution is >500, the clarity is good, and the temperature is 30°C. The outlet temperature of the preheated water through the preheater 5 is 180°C, the volume ratio of the titanium sulfate liquid precursor solution entering the first crystallizer 6 and the preheated water is 1:1, and the pipe diameter of the first crystallizer 6 It is DN125. The flow rate of the precursor solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com