Poly-L-lactic acid (PLLA)/ZIF-8 composite bone scaffold and preparation method thereof

A technology of ZIF-8 and ZIF-80.5, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of low cell activity, slow degradation rate, insufficient mechanical strength, etc., to enhance mechanical properties, promote dispersion, improve The effect of interface binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

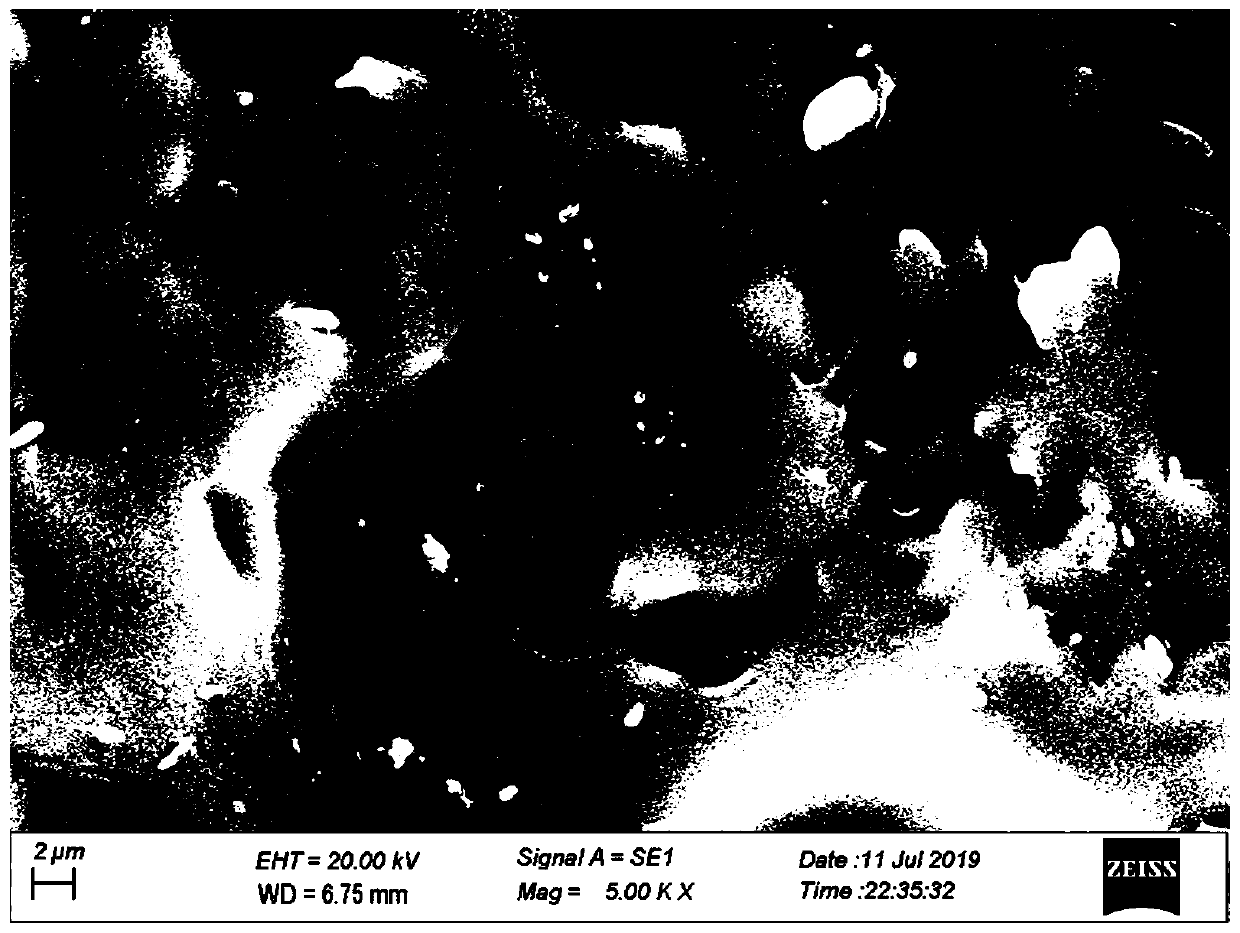

[0045] (1) Use an electronic balance to weigh 0.4g of ZIF-8 powder with a particle size of 0.5-4μm, add it to a beaker filled with 30mL of absolute ethanol solution, and obtain a uniform and stable ZIF-8 suspension after ultrasonic stirring liquid.

[0046] (2) Weigh 19.6 g of PLLA powder with an electronic balance, the particle size is 100-150 μm, add it into a beaker containing 50 mL of absolute ethanol solution, and stir it ultrasonically to obtain a uniform and stable PLLA suspension.

[0047] (3) Add the PLLA suspension dropwise to the mixed suspension of ZIF-8, then mix the mixed solution evenly by magnetic stirring and ultrasonic dispersion, the time of mechanical stirring is 60min, the speed is 900r / min, and the temperature is 50°C , and then filter the uniformly mixed suspension and dry it under vacuum at 50° C. for 12 hours, and finally grind to obtain a uniform PLLA / ZIF-8 composite powder.

[0048] (4) Spread the composite powder obtained above in the selective las...

Embodiment 2

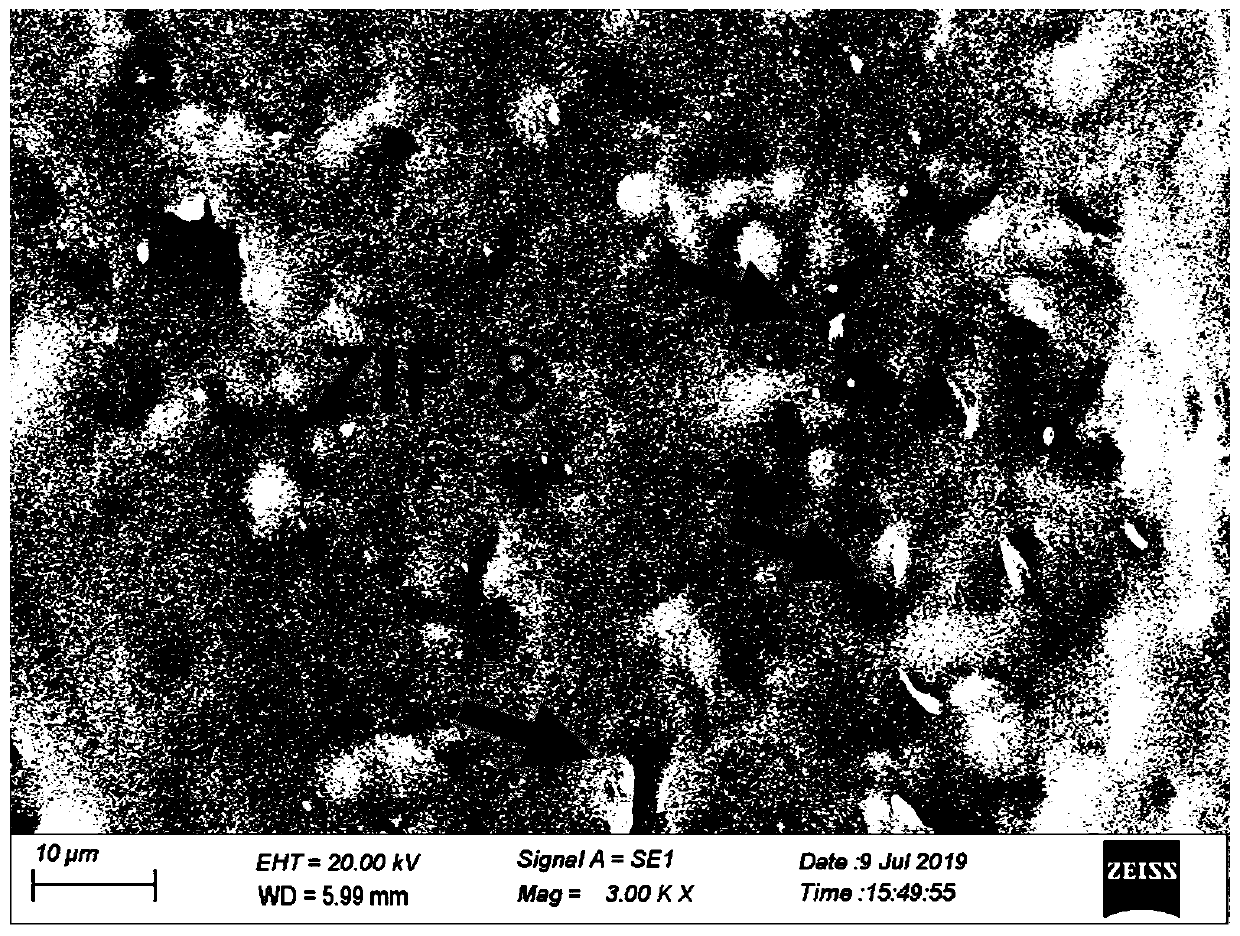

[0052] (1) Use an electronic balance to weigh 0.2g of ZIF-8 powder with a particle size of 0.5-4μm, add it to a beaker filled with 30mL of absolute ethanol solution, and obtain a uniform and stable ZIF-8 suspension after ultrasonic stirring liquid.

[0053] (2) Weigh 19.8 g of PLLA powder with an electronic balance, the particle size is 100-150 μm, add it into a beaker containing 50 mL of absolute ethanol solution, and obtain a uniform and stable PLLA suspension after ultrasonic stirring.

[0054] (3) Add the PLLA suspension dropwise to the mixed suspension of ZIF-8, and then mix the mixed solution evenly through magnetic stirring and ultrasonic dispersion. The time of magnetic stirring is 60min, the speed is 900r / min, and the temperature is 50°C , and then filter the uniformly mixed suspension and dry it under vacuum at 50° C. for 12 hours, and finally grind to obtain a uniform PLLA / ZIF-8 composite powder.

[0055] (4) Spread the composite material powder obtained above in t...

Embodiment 3

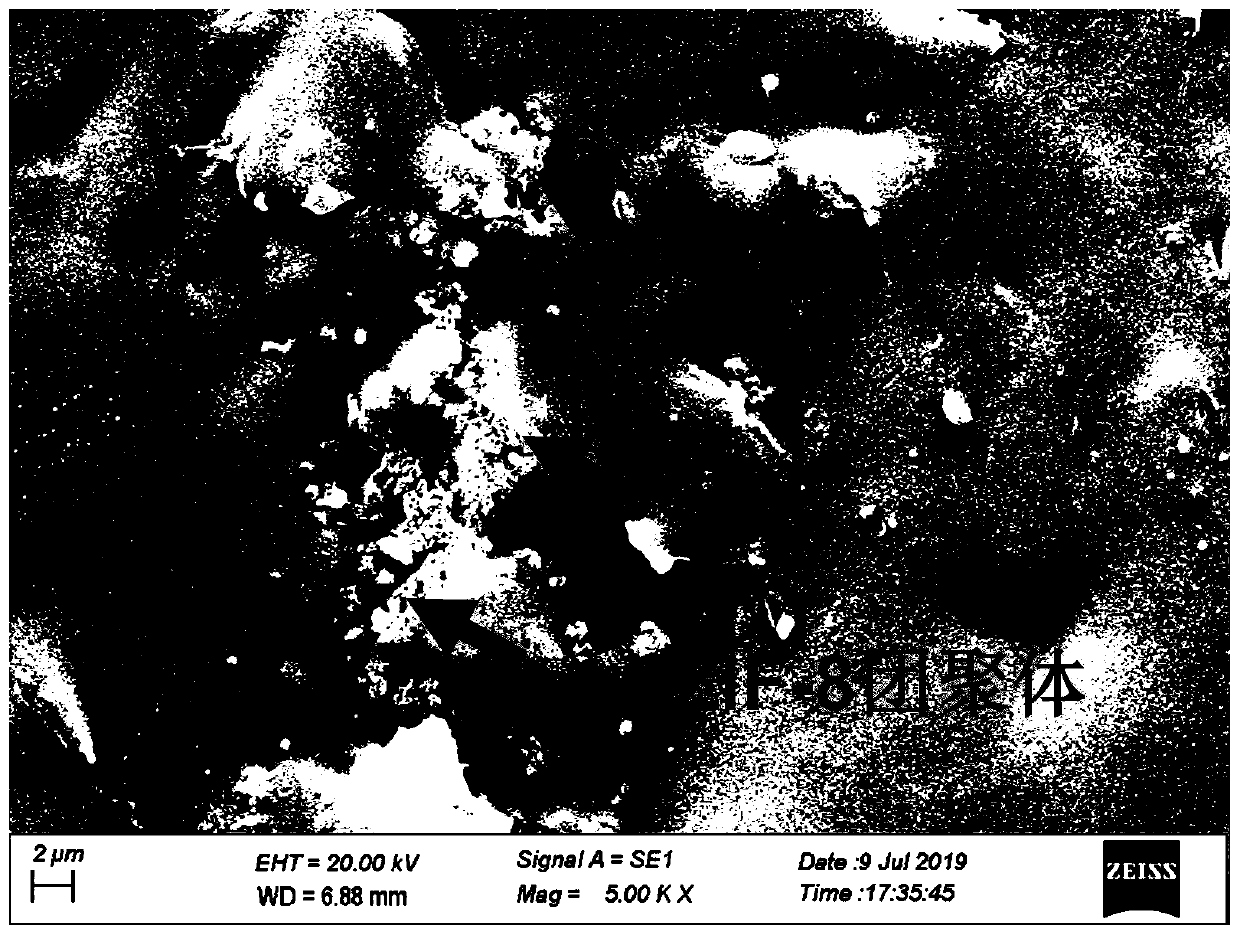

[0059] (1) Use an electronic balance to weigh 0.6g of ZIF-8 powder with a particle size of 0.5-4μm, add it to a beaker filled with 30mL of absolute ethanol solution, and obtain a uniform and stable ZIF-8 suspension after ultrasonic stirring liquid.

[0060] (2) Weigh 19.4 g of PLLA powder with an electronic balance, the particle size is 100-150 μm, add it into a beaker containing 50 mL of absolute ethanol solution, and obtain a uniform and stable PLLA suspension after ultrasonic stirring.

[0061] (3) Add the PLLA suspension dropwise to the mixed suspension of ZIF-8, and then mix the mixed solution evenly through magnetic stirring and ultrasonic dispersion. The time of magnetic stirring is 60min, the speed is 900r / min, and the temperature is 50°C , and then filter the uniformly mixed suspension and dry it under vacuum at 50° C. for 12 hours, and finally grind to obtain a uniform PLLA / ZIF-8 composite powder.

[0062] (4) Spread the composite powder obtained above in the select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com