Heterogeneous nucleating agent toughening-modified phenolic resin foam and preparation method thereof

A technology of phenolic resin foam and heterogeneous nucleating agent, which is applied in the field of preparation of graphene toughened phenolic foam, can solve the problems of poor mechanical properties of phenolic foam, high brittleness and easy slag drop, etc., to achieve easy modification, reduce heat conduction, Enhance the effect of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

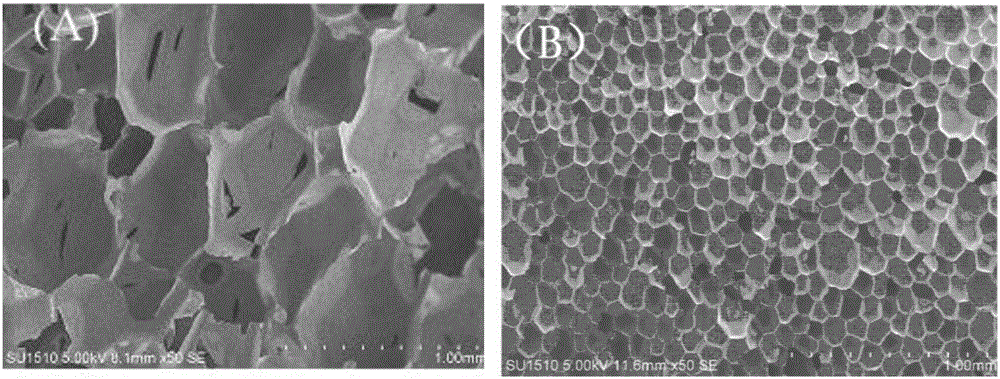

Image

Examples

Embodiment 1

[0028] A heterogeneous nucleating agent toughened modified phenolic resin foam, the preparation method of the foam comprises the steps:

[0029] (1) Preparation of heterogeneous nucleating agent:

[0030] 1. graphene is oxidized into graphene oxide according to the ratio of 1:1 volume ratio of concentrated sulfuric acid (mass concentration is 98%) and concentrated nitric acid (mass concentration is 68%);

[0031] ② Ultrasonic dispersion of 100mg graphene oxide and 100mg calcium oxide in anhydrous tetrahydrofuran for 1 hour, then under the protection of nitrogen, add 2.5mg KH550 dropwise, and stir for 10 hours at 50°C to obtain a black product;

[0032] ③ The black product obtained in step ② is centrifugally washed, dried in a 60°C oven, and fully ground to obtain graphene oxide grafted with a silane coupling agent, which is the heterogeneous nucleating agent;

[0033] (2) Preparation of modified phenolic resin foam:

[0034] ① Weigh 100 parts of expandable phenolic resin, 3 ...

Embodiment 2

[0039] A heterogeneous nucleating agent toughened modified phenolic resin foam, the preparation method of the foam comprises the steps:

[0040] (1) Preparation of heterogeneous nucleating agent:

[0041] 1. graphene is oxidized into graphene oxide according to the ratio of 1:1 volume ratio of concentrated sulfuric acid (mass concentration is 98%) and concentrated nitric acid (mass concentration is 68%);

[0042] ② Ultrasonic dispersion of 100mg graphene oxide and 250mg DCC in anhydrous tetrahydrofuran for 1.5h, then under the protection of nitrogen, add 1mg KH560 dropwise, and stir at 70°C for 30h to obtain a black product;

[0043] ③The black product obtained in step ② is centrifugally washed, dried in an oven at 90°C, and fully ground to obtain graphene oxide grafted with a silane coupling agent, which is the heterogeneous nucleating agent;

[0044] (2) Preparation of modified phenolic resin foam:

[0045] ① Weigh 100 parts of expandable phenolic resin, 5 parts of ethylen...

Embodiment 3

[0049] A heterogeneous nucleating agent toughened modified phenolic resin foam, the preparation method of the foam comprises the steps:

[0050] (1) Preparation of heterogeneous nucleating agent:

[0051] 1. graphene is oxidized into graphene oxide according to the ratio of 1:1 volume ratio of concentrated sulfuric acid (mass concentration is 98%) and concentrated nitric acid (mass concentration is 68%);

[0052] ② Ultrasonic dispersion of 80mg graphene oxide and 160mg calcium chloride in anhydrous tetrahydrofuran for 1 hour, then under the protection of nitrogen, add 5.6mg KH560 dropwise, and stir for 15 hours at 70°C to obtain a black product;

[0053] ③ The black product obtained in step ② is centrifugally washed, dried in an oven at 65°C, and fully ground to obtain graphene oxide grafted with a silane coupling agent, which is the heterogeneous nucleating agent;

[0054] (2) Preparation of modified phenolic resin foam:

[0055] ①Weigh 100 parts of expandable phenolic resin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com