Method for preparing copper-tungsten contact through electron beam infiltration

An electron beam and copper-tungsten technology, which is applied in the field of electron beam infiltration to prepare copper-tungsten contacts, can solve the problem that there is no application in the field of infiltration, and achieve the effects of avoiding element metallurgy, improving infiltration effect and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

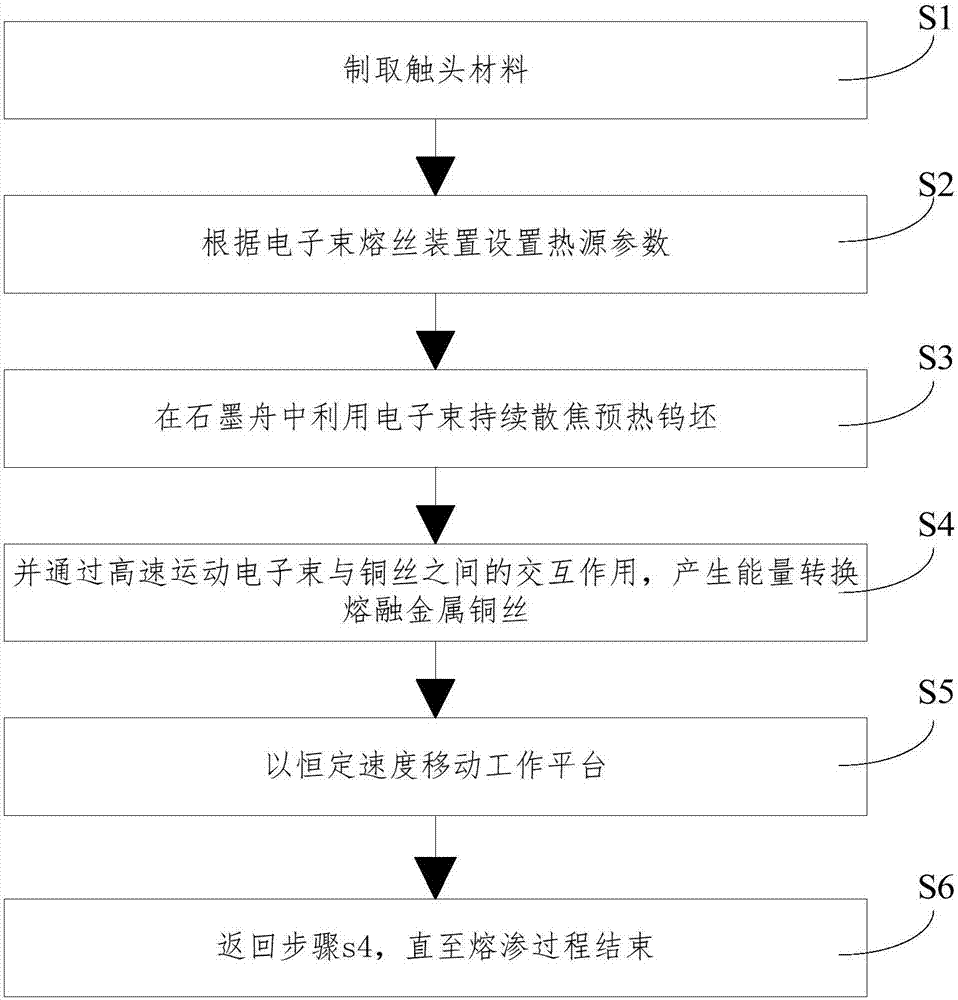

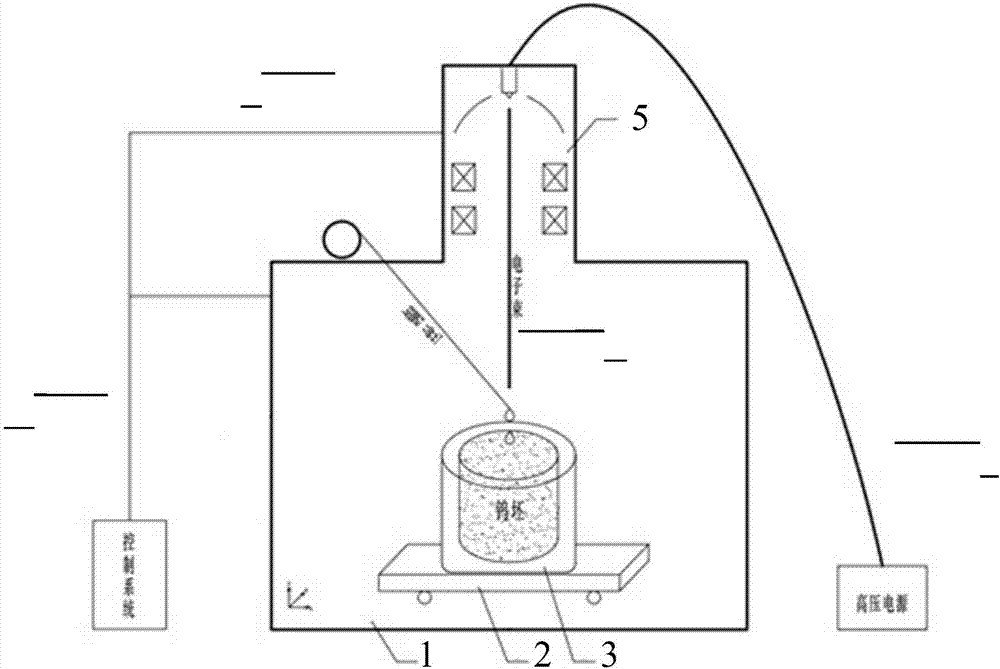

[0026] The following references are attached figure 1 And attached figure 2 , to further elaborate on various embodiments of the present invention.

[0027] in the attached figure 1 Among them, a method for preparing copper-tungsten contacts by electron beam infiltration includes the following sequential steps:

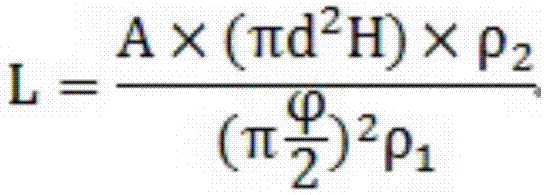

[0028] Step 1, preparing W-A (wt%) Cu contact material. First of all, it is necessary to set the mass fraction of copper, and express the mass fraction of copper as A, and calculate the content of the sample according to the diameter of the copper-tungsten contact, the height of the copper-tungsten contact, the density of the copper-tungsten contact, the density of the copper wire, and the diameter of the welding wire. The copper mass fraction requires the required copper wire length. We denote the diameter of the copper-tungsten contact, the height of the copper-tungsten contact, the density of the copper-tungsten contact, the density of the copper wire, the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com