Metal corrosion inhibitor and preparation method thereof

A metal corrosion inhibitor and corrosion inhibitor technology, applied in the direction of organic chemistry, can solve the problem of not seeing CO2 gas-liquid two-phase corrosion inhibitor, so as to reduce the wetting angle, improve the utilization rate, strength and compactness Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

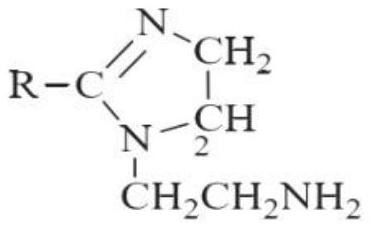

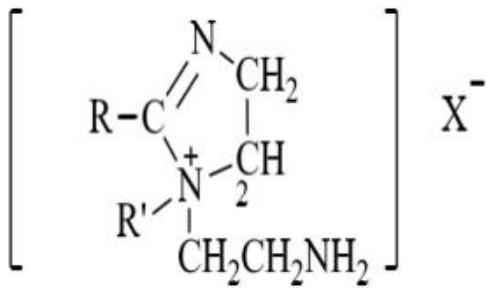

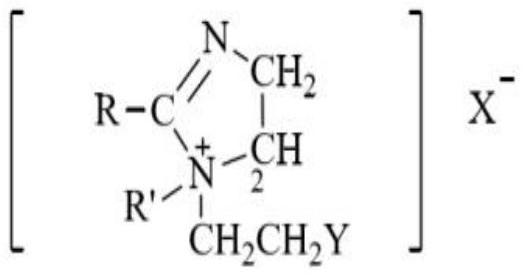

[0038] Preparation of 2-ethylthiazamide ethylbenzyl-1-heptadecenyl imidazoline quaternary ammonium salt

[0039] Cis-octadec-9-enoic acid and triethylenetetramine were amidated at 130°C for 1 hour at a molar ratio of 1:0.55, and then cyclized at 250°C for 7 hours, and then 2 times the mole of benzyl chloride was added, quaternization reaction at 100°C for 3 hours, and finally add equimolar ethyl disulfide nitrogen at 100°C for 1 hour to obtain natural gas storage CO 2 The liquid phase corrosion inhibitor in the gas-liquid two-phase corrosion inhibitor is 2-ethylthiazamide ethylbenzyl-1-heptadecenyl imidazoline quaternary ammonium salt.

Embodiment 2

[0041] Preparation of quaternary ammonium salt of 2-ethylxanthogenoamine ethylbenzyl-1-methylimidazoline

[0042] Acetic acid and triethylenetetramine were amidated at 120°C for 1 hour at a molar ratio of 1:0.5, then cyclized at 220°C for 6 hours, and then 2 times the mole of benzyl chloride was added, and the quaternization reaction was carried out at 100°C for 2.5 hours. Finally, equimolar ethylsulfonate was added to react at 100°C for 1 hour to obtain the gas phase corrosion inhibitor 2-ethylsulfonate amine ethylbenzyl-1-methyl in the CO2 gas-liquid two-phase corrosion inhibitor of natural gas storage imidazoline quaternary ammonium salt.

Embodiment 3

[0044] Determination of corrosion inhibition rate by static weight loss method (liquid phase)

[0045] The experimental temperature is 50°C, the CO2 partial pressure is 0.50MPa, the liquid phase salinity is 30000mg / L, and the CO2 2 Liquid-phase corrosion inhibitor 2-Ethylthiazoamine ethylbenzyl-1-heptadecenyl imidazoline quaternary ammonium salt (YX), CO 2 Gas-phase corrosion inhibitor 2-ethylsulfonated aminoethylbenzyl-1-methylimidazoline quaternary ammonium salt (QX), sodium butylsulfonate (DH) combined liquid phase corrosion inhibition experiment, the experimental results are shown in Table 3 .

[0046] Concentration / (mg / L) CR / (mm / a) IE / % 0 0.9214 —— 150 / (QX) 0.2567 72.1 150 (YX) 0.1516 83.5 150 (DH) 0.4918 46.6 60(QX)+100(YX)+30(DH) 0.0456 95.1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com