Patents

Literature

34results about How to "Excellent soldering performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rosin halogen-free scaling powder for lead-free soldering paste

InactiveCN1709638ASolve the serious problem of high temperature oxidationImprove liquidityWelding/cutting media/materialsSoldering mediaAcyl groupAlloy

The invention relates to a scaling powder, especially applying to the alloy's department such as SnAgCu, SnAgCuRE and SnAg and so on. The quality percent of the present invention is the activation dosage of the organic acid which consists of the duality acid, the three-member acid, the hydroxyl acid, the balminess acid in the fattiness race 4-30wt%,the changed capable colophony which is one or more mixed of the converged colophony, the hydrogen sulfide colophony and the divergent colophony 29-67wt%, the becoming electuary which is one or more mixed of the assembled glycol2000,the assembled glycol4000 and the assembled glycol6000 1-20wt%,the olefin as the tranquilization dosage 0.5-8wt%,the touched and altered dosage which one or more mixed of the hydrogen sulfide castor oil and the compound of the acyl and amine 1-8wt% and the remain is the impregnant of the high boiling point which is one or more mixed of the butyl dissolved fine dosage, the calorie certain alcohol of the cymene and the calorie certain alcohol of the second radicle. The invention doesn't contain the halogen and penetrate the copper mirror after welding. It has high insulated resistances, the excellent function of the assisting burning. Also it solves the problem of oxidation in the high temperature and the appropriate viscosity of the welding cream.

Owner:BEIJING UNIV OF TECH

Lead-free and halogen-free solder paste for electronic industry

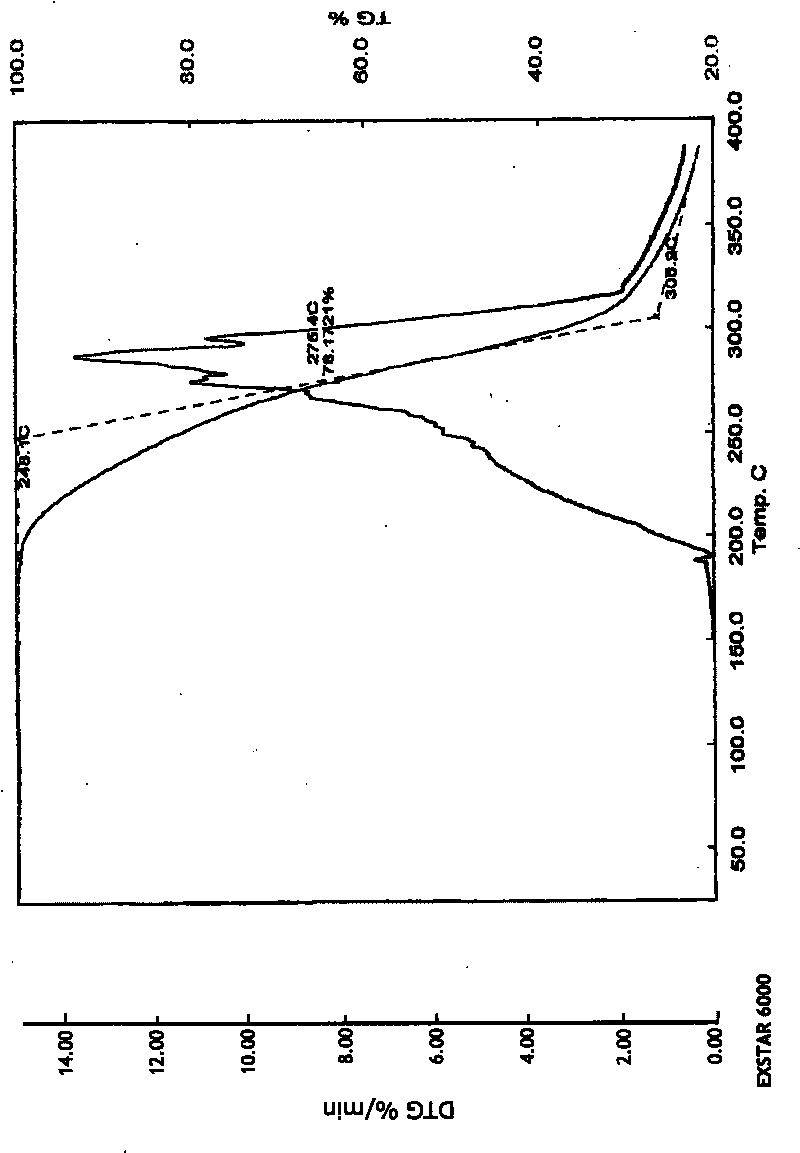

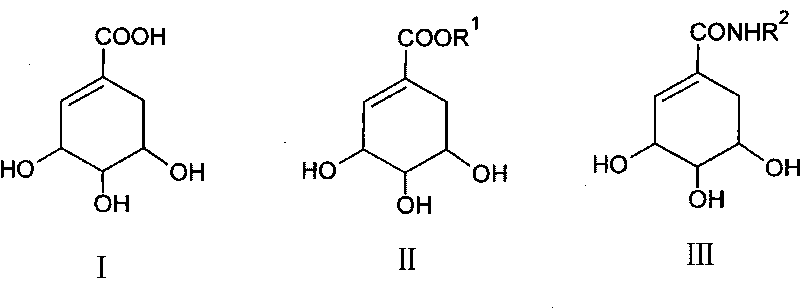

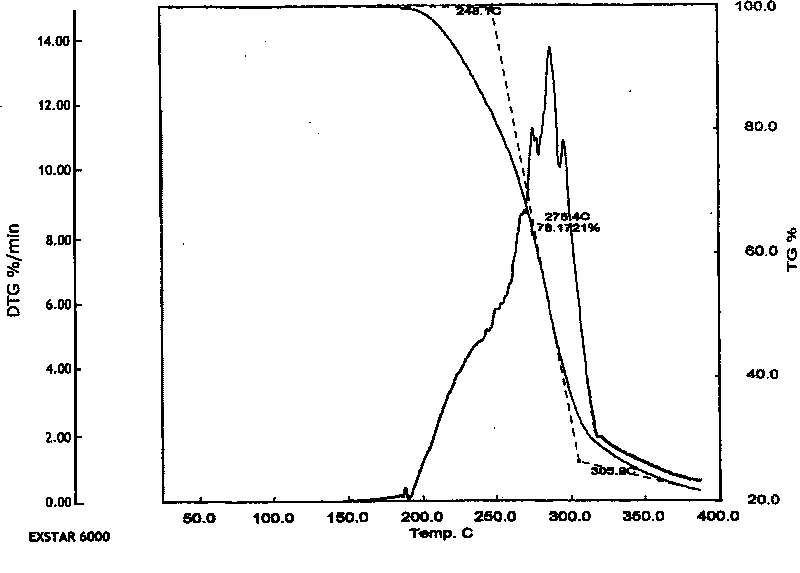

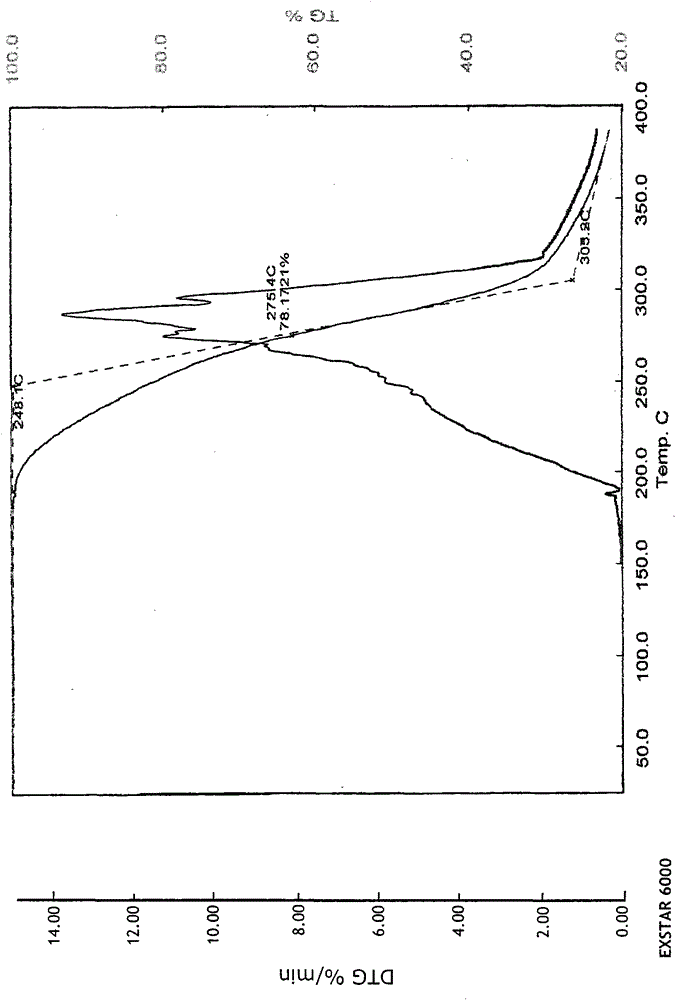

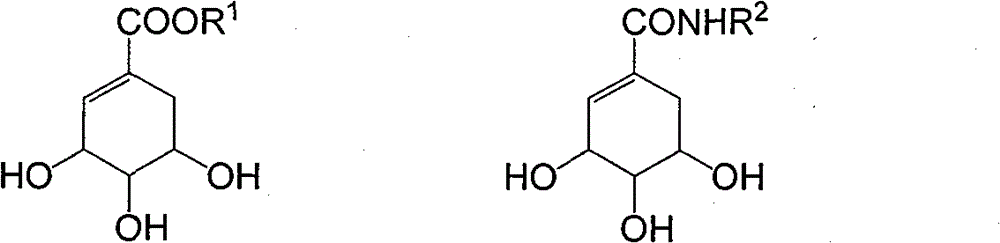

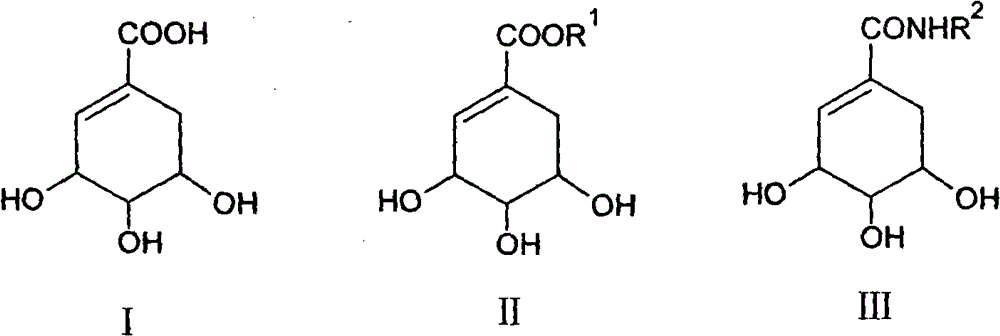

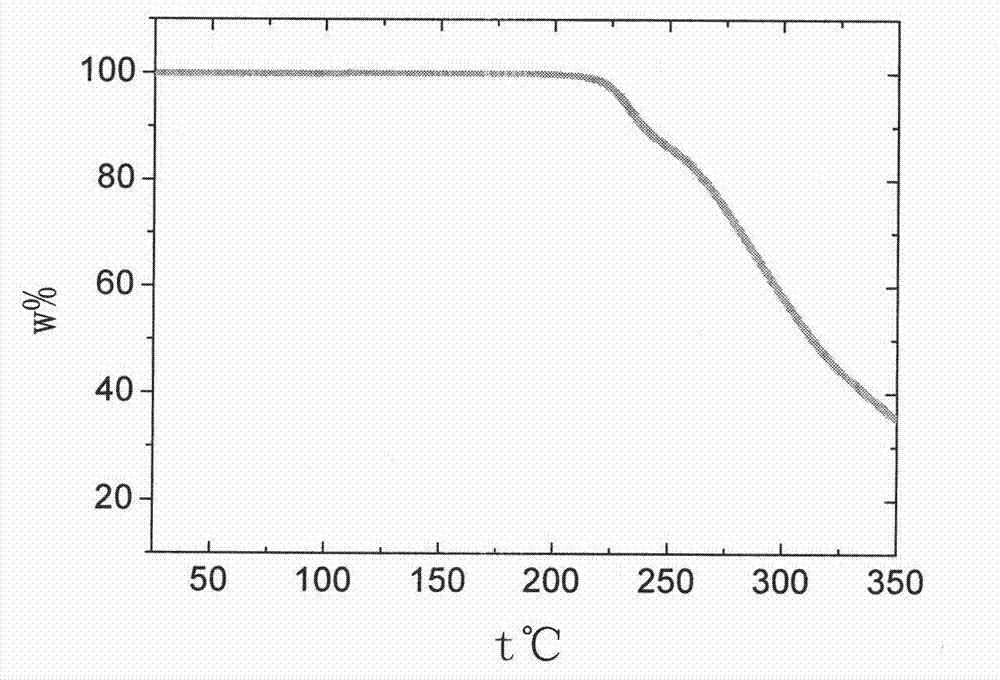

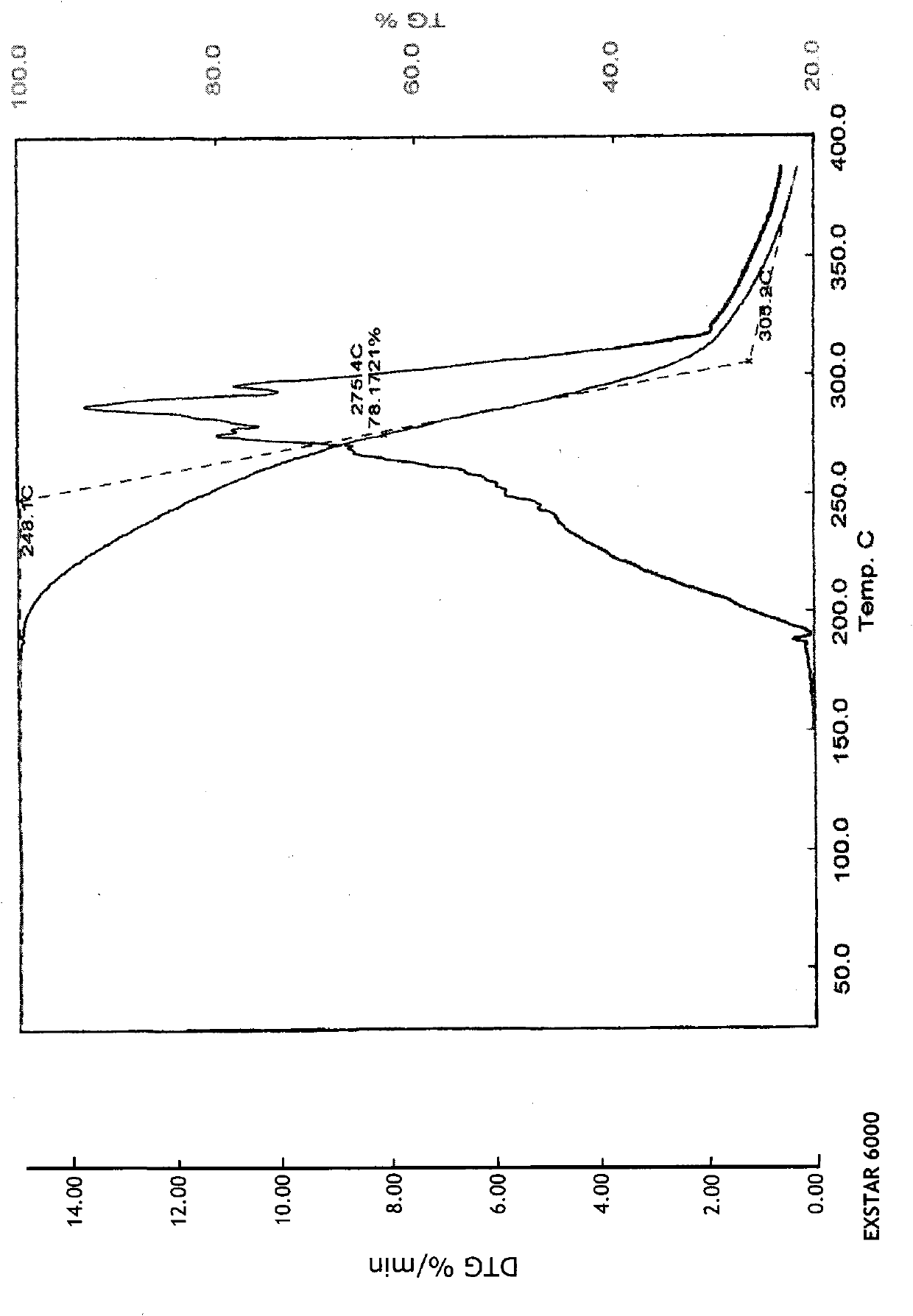

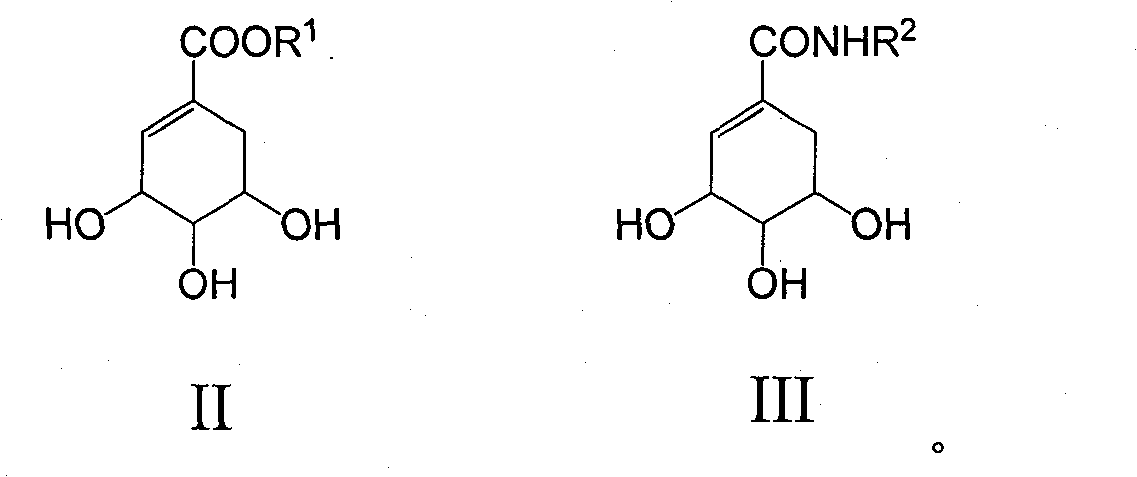

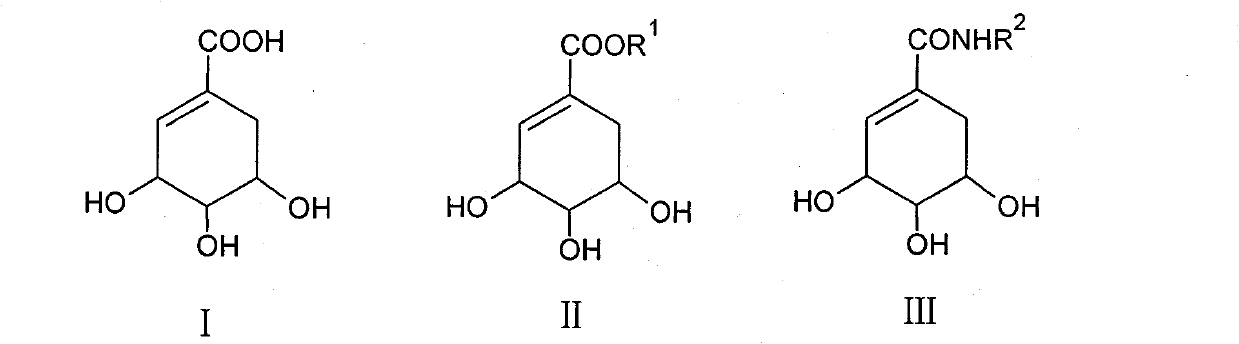

InactiveCN101733588AImprove wettabilityReduce foulingWelding/cutting media/materialsSoldering mediaSolderabilityShikimic acid

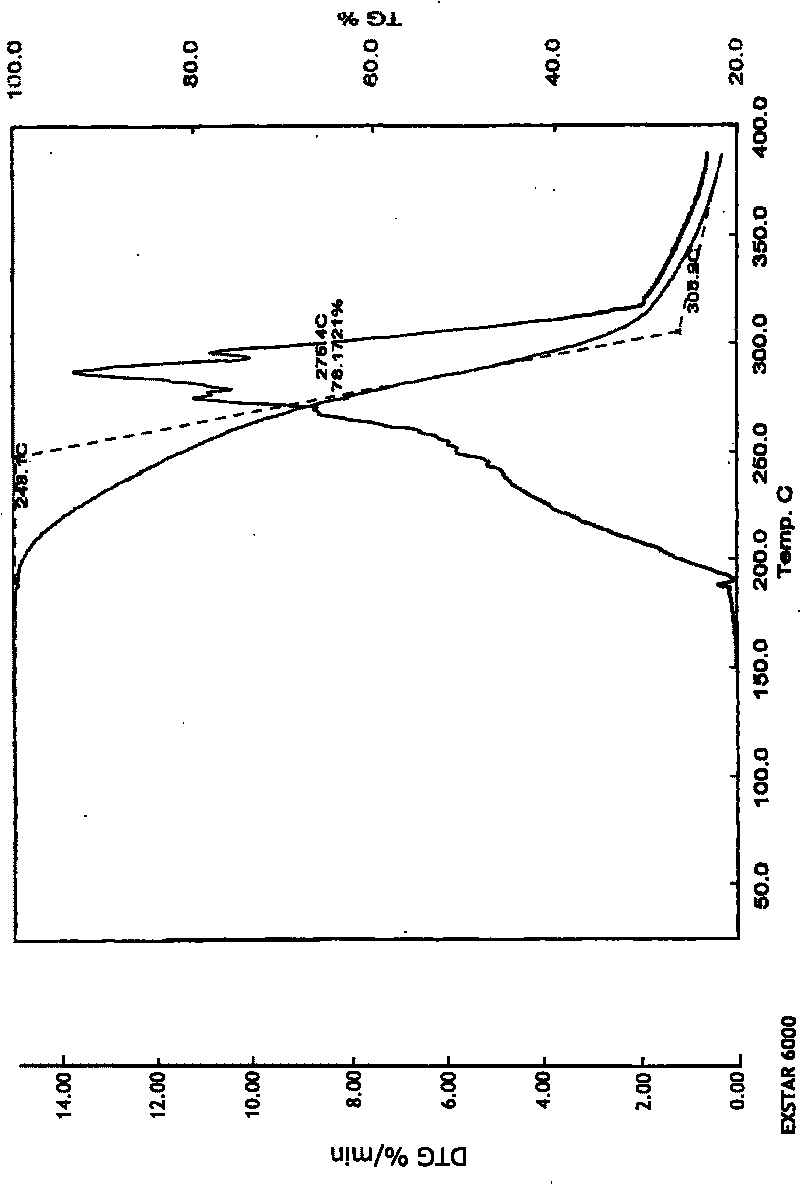

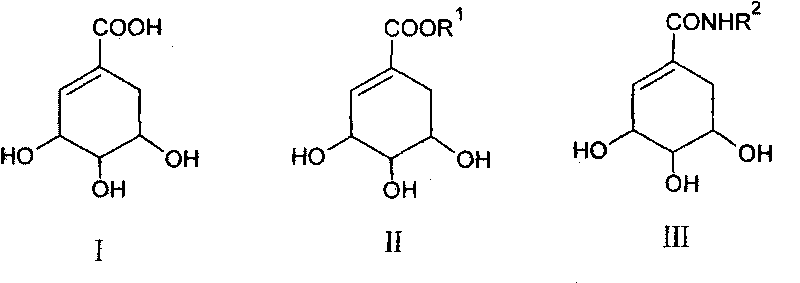

The invention relates to a chemical soldering flux in the electronic industry, in particular to a solder paste used for arranging electronic elements and the alloy welding powder is lead-free alloy. The technical scheme of the invention is as follows: the lead-free and halogen-free solder paste for electronic industry comprises 85-94wt% of alloy welding powder and 6-15wt% of flux, wherein the flux comprises 20-60wt% of resin, 10-60wt% of solvent, 1-10wt% of rheology control agent, 0.1-40wt% of activator and the balance stabilizer; and the alloy welding powder is lead-free welding powder and is characterized in that the activator contains one or more of shikimic acid with the constitutional formula shown in formula I, shikimate with the constitutional formula shown in formula II and amide of shikimic acid with the constitutional formula shown in formula III. The beneficial effect of the invention is as follows: shikimic acid or a derivative thereof is used as the activator so as to increase the wettability of the halogen-free product so as to reduce bad effects caused by the solderability in production.

Owner:SICHUAN UNIV +1

Non-cleaning flux for low temperature paste and preparing method of flux

InactiveCN107442970ASimple preparation processEasy to operateWelding/cutting media/materialsSoldering mediaActive agentAntioxidant

The invention discloses non-cleaning flux for low temperature paste, and a preparing method of the flux and belongs to the technical field of welding flux. The flux comprises, by mass percent, 79 to 82% of a compound solvent, 7 to 14% of an active agent, 2 to 5% of a thixotropic agent, 0.1 to 0.5% of a corrosion inhibitor, 1 to 8% of a pH conditioning agent, 0.5% of an antioxidant and 0.25% of a film-forming agent. The compound solvent is composed of a high-boiling-point organic solvent with the boiling point exceeding 200 DEG C and a low-boiling-point organic solvent with the boiling point lower than 200 DEG C, the high-boiling-point organic solvent is a mixture of ethylene glycol and ethylene glycol butyl ether, the low-boiling-point organic solvent is a mixture of one or two of ethyl alcohol and isopropyl alcohol, the active agent is lactic acid, the thixotropic agent is castor oil, the corrosion inhibitor is benzotriazole, the pH conditioning agent is organic amine, the antioxidant is toluic acid butyrate, and the film-forming agent is polyethylene glycol 2000. The method is simple in technology, operation is easy, the flux can be used in cooperation with flux powder with the melting point lower than 100 DEG C, activity is high, wettability is good, post-welding residue is little, corrosion resistance is high, and no tin sweat phenomenon happens.

Owner:NORTHEASTERN UNIV

Low-temperature, halogen-free, low-solid-content modified rosin-type welding flux and preparation method thereof

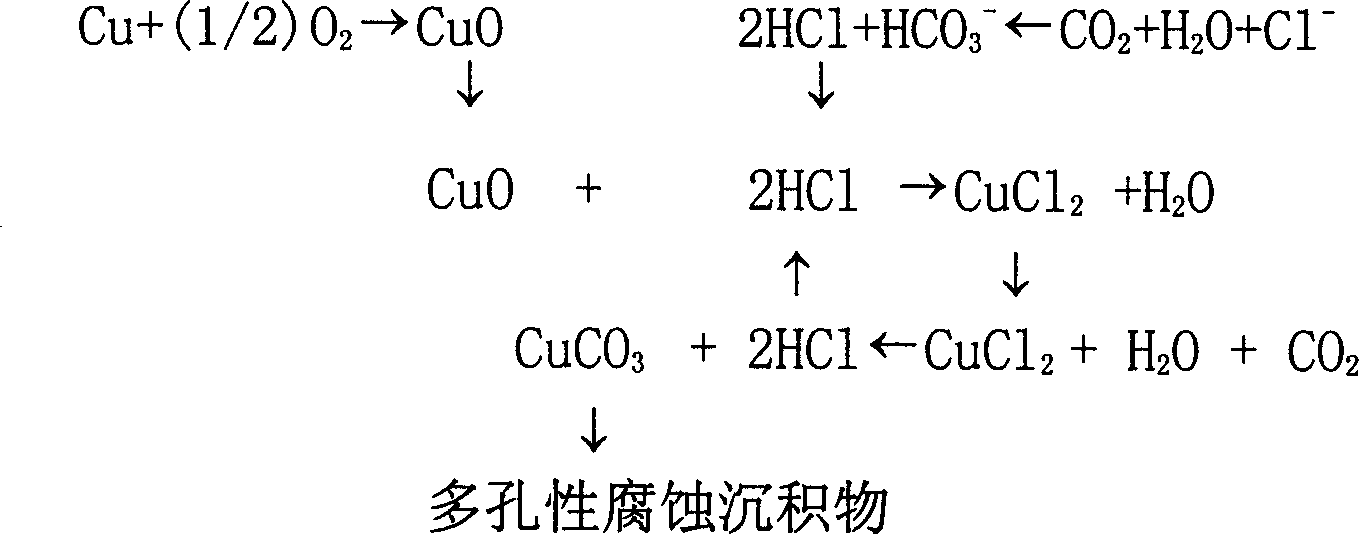

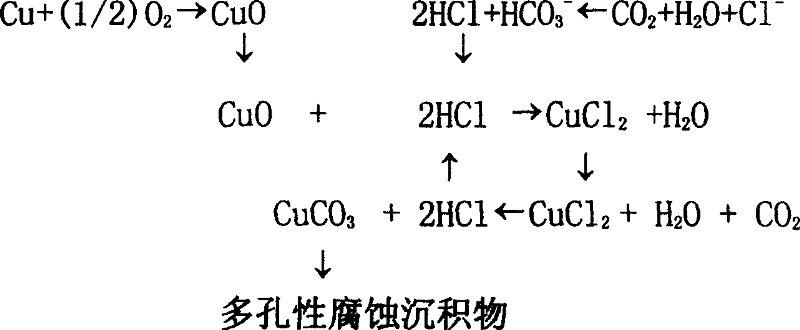

InactiveCN108817731AGood solid contentSolid content modified rosin type flux has good fluidityWelding/cutting media/materialsSoldering mediaPrecipitationCorrosion

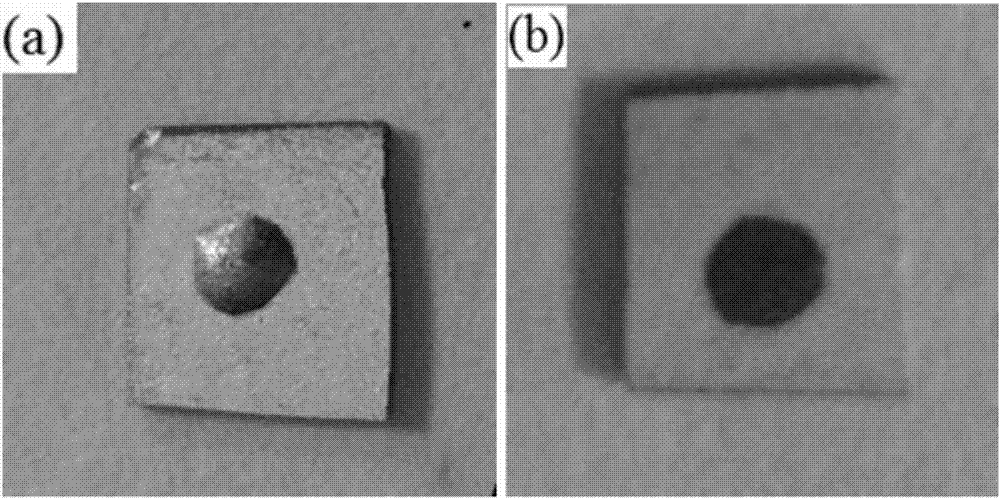

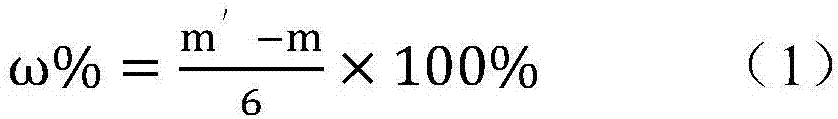

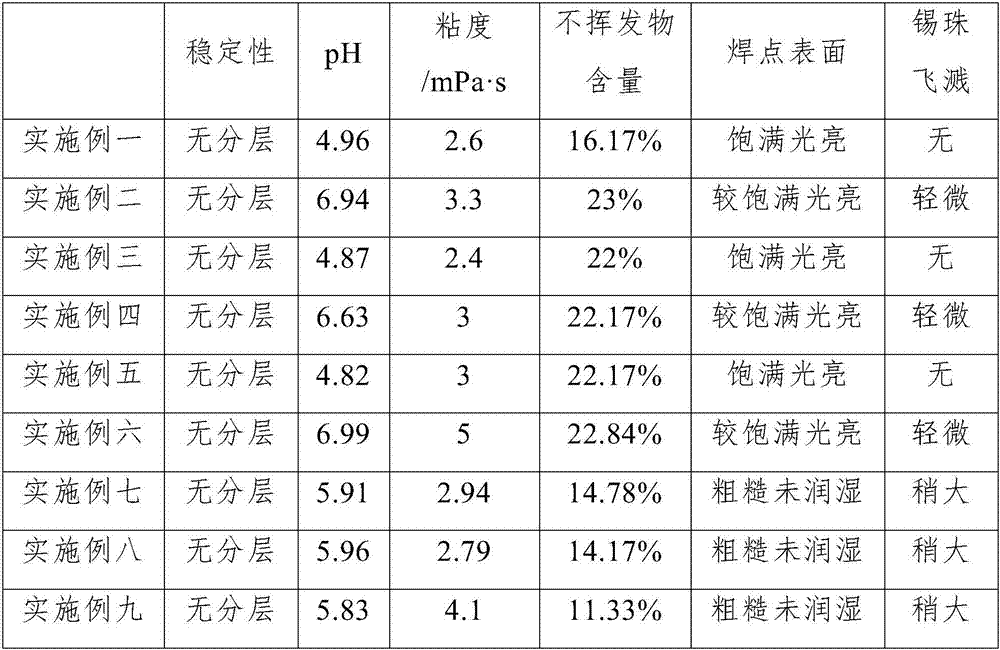

The invention relates to a low-temperature, halogen-free, low-solid-content modified rosin-type welding flux. The welding flux is prepared form, by mass, 10-15% of modified rosin, 1-5% of organic acidactivator, 0.35-1% of glycerin, 0.009-1% of benzotriazole, 0.3-1 % of triethanolamine, a surfactant and the balance organic solvent, wherein the surfactant is 0.5-3% of the mass of the organic acid activator. The prepared low-temperature, halogen-free and low-solid-content modified rosin-type welding flux prepared has good fluidity, no precipitation and delamination phenomena, no halogen elements, a small amount of modified rosin, a good spreading rate, good weldability, bright and full welding spots and less residues after welding, little corrosion is caused, and cleaning is not needed; therequirements for environmental protection are met; an operation method is sample, the temperature is moderate, there are less experimental steps, the cost is low, less by-products are generated in a synthesis process and are easy to remove, and the synthesis time is short.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Lead-free no-clean soldering flux and preparation method thereof

ActiveCN102689114AExcellent soldering performanceImprove insulation performanceWelding/cutting media/materialsSoldering mediaSolderingCopper plating

The invention relates to the technical field of soldering flux, in particular to lead-free no-clean soldering flux and a preparation method thereof. The soldering flux has the advantages of no halogen, strong soldering ability and no corrosion; and solids are not remained on the surface of a soldered object without cleaning, and the phenomena of no joint soldering and no short circuit can be avoided after soldering; and therefore, the lead-free no-clean soldering flux is particularly suitable for single-side circuit boards which are difficult to solder or copper-plating and nickel-plating circuit boards.

Owner:广东剑鑫科技股份有限公司

Rosin halogen-free scaling powder for lead-free soldering paste

InactiveCN100336626CSolve the serious problem of high temperature oxidationImprove liquidityWelding/cutting media/materialsSoldering mediaAcyl groupAlloy

The invention relates to a scaling powder, especially applying to the alloy's department such as SnAgCu, SnAgCuRE and SnAg and so on. The quality percent of the present invention is the activation dosage of the organic acid which consists of the duality acid, the three-member acid, the hydroxyl acid, the balminess acid in the fattiness race 4-30wt%,the changed capable colophony which is one or more mixed of the converged colophony, the hydrogen sulfide colophony and the divergent colophony 29-67wt%, the becoming electuary which is one or more mixed of the assembled glycol2000,the assembled glycol4000 and the assembled glycol6000 1-20wt%,the olefin as the tranquilization dosage 0.5-8wt%,the touched and altered dosage which one or more mixed of the hydrogen sulfide castor oil and the compound of the acyl and amine 1-8wt% and the remain is the impregnant of the high boiling point which is one or more mixed of the butyl dissolved fine dosage, the calorie certain alcohol of the cymene and the calorie certain alcohol of the second radicle. The invention doesn't contain the halogen and penetrate the copper mirror after welding. It has high insulated resistances, the excellent function of the assisting burning. Also it solves the problem of oxidation in the high temperature and the appropriate viscosity of the welding cream.

Owner:BEIJING UNIV OF TECH

No-clean flux high in welding passing rate

InactiveCN106392380AExcellent soldering performanceNo residueWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

The invention discloses no-clean flux high in welding passing rate, and belongs to the technical field of flux. The no-clean flux is specifically prepared from a solvent, an active agent, a film-forming agent, a surface active agent, a stabilizer and a corrosion inhibitor. The flux is high in welding aid capacity; the bad phenomena of hard skin films, caking, viscosity changing and the like are avoided; the viscosity is stable; corrosiveness is avoided; no residual solid exists on the surface of a welded object; cleaning is not needed; the phenomena of joint welding and short circuits are avoided after welding; the welding passing rate of a precision device can be guaranteed; and the no-clean flux is suitable for single-face circuit boards or copper plated and nickel plated circuit boards hard to weld.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

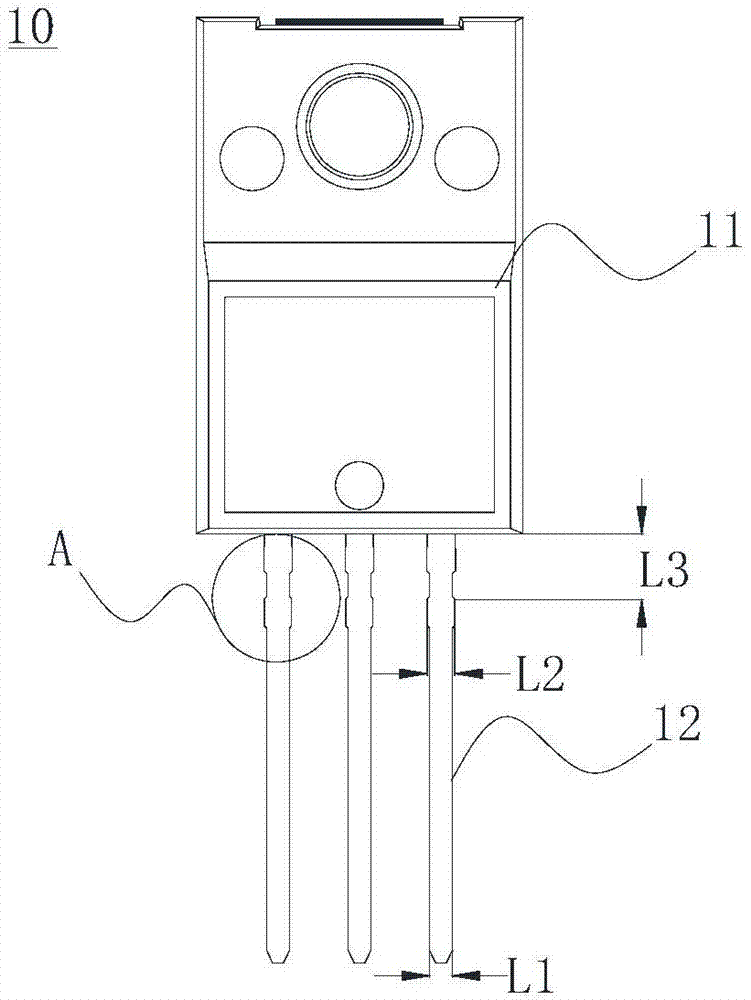

Semiconductor packaging device, semiconductor lead frame and rib-cutting method thereof

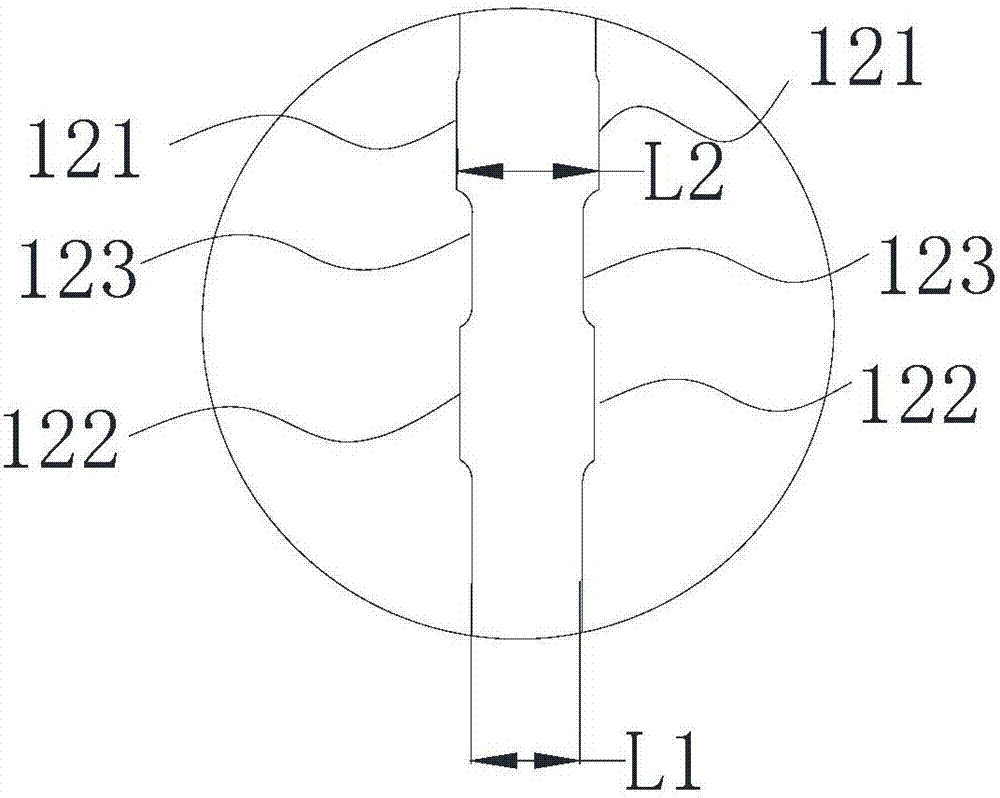

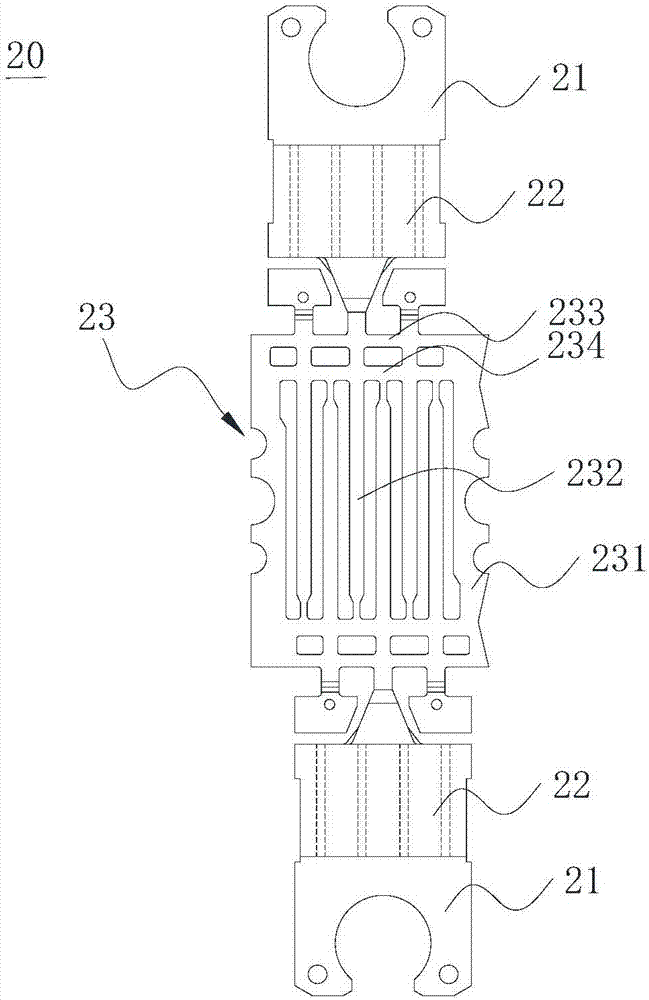

PendingCN107275308AImprove welding strengthImprove welding effectSemiconductor/solid-state device detailsSolid-state devicesWave structureDevice material

The invention discloses a semiconductor packaging device, a semiconductor lead frame and a rib-cutting method thereof. The semiconductor packaging device comprises a packaging housing; a semiconductor device encapsulated in the packaging housing; and pins to be electrically connected with the semiconductor device and exposed out of the packaging housing. The two side, adjacent to the packaging housing, of each pin have square-wave structures each formed by two protrusions and a groove. The protrusions and the grooves are arranged successively and alternately along the length direction of the pin. When the pins and a PCB are soldered, soldering tin gathers in the grooves. The semiconductor lead frame and the rib-cutting method thereof are used for manufacturing the semiconductor packaging device. The semiconductor packaging device, the lead frame and the rib-cutting method thereof can improve the soldering performance and reliability of the pin and the PCB.

Owner:SHENZHEN STS MICROELECTRONICS CO LTD

Inorganic flux

InactiveCN103846574AExcellent soldering performanceEasy to cleanWelding/cutting media/materialsSoldering mediaHydrofluoric acidChloride

The invention discloses an inorganic flux. The flux comprises the following components in percentage by mass: 35% to 55% of hydrochloric acid, 20% to 30% of hydrofluoric acid, 15% to 20% of zinc chloride, and 5% to 15% of stannic chloride. By adopting the method, the inorganic flux has the advantages that the welding assisting capability is good, the water dissolving effect is realized, the cleaning is easy, the corrosiveness is high, the oxide films on the ferrous and non-ferrous metal surfaces can be effectively removed, the efficiency is high, and the like; the broad market prospect is obtained in the popularizing of the inorganic flux.

Owner:SUZHOU LOTTE CHEM TECH

Halogen-free soldering flux for electronic industry

InactiveCN101733586AImprove wettabilityReduce badWelding/cutting media/materialsSoldering mediaSolventChemistry

The invention relates to a chemical soldering flux in the electronic industry, in particular to a soldering flux for arranging electronic elements. The technical scheme of the invention is as follows: the soldering flux for electronic industry comprises solvent, resin, activator and surfactant and is characterized in that the activator contains one or more of shikimic acid with the constitutionalformula shown in formula I, shikimate with the constitutional formula shown in formula II and amide of shikimic acid with the constitutional formula shown in formula III. The soldering flux can increase the wettability of the halogen-free product so as to reduce bad effects caused by the solderability of the traditional halogen-free soldering flux in production.

Owner:SICHUAN UNIV +1

Steel no-clean welding flux and preparation method thereof

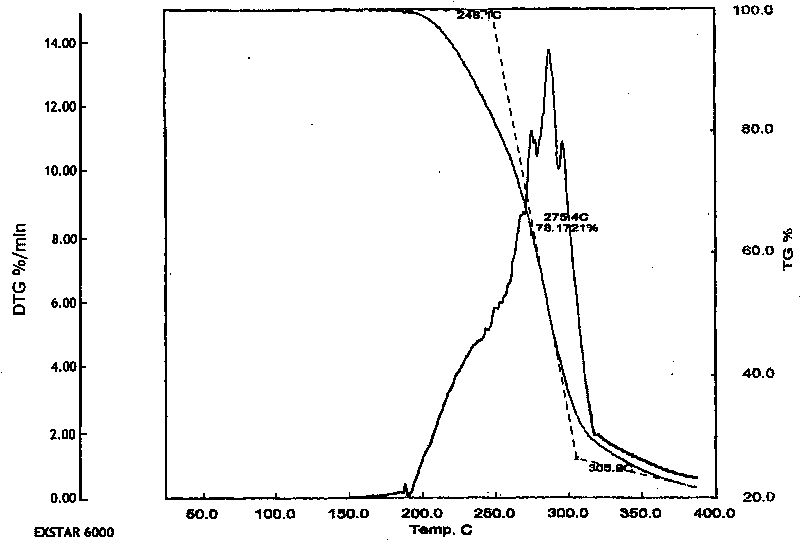

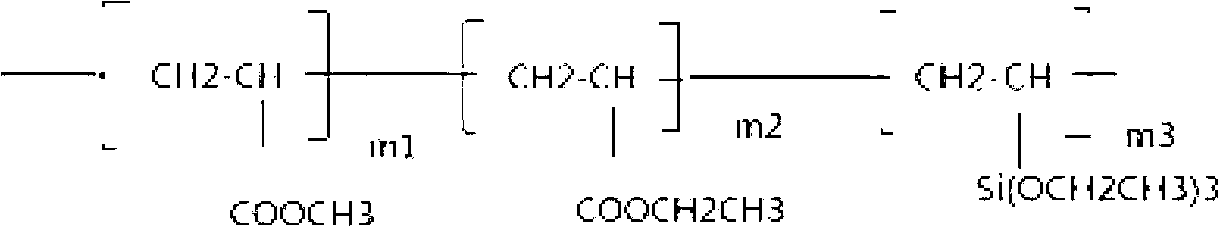

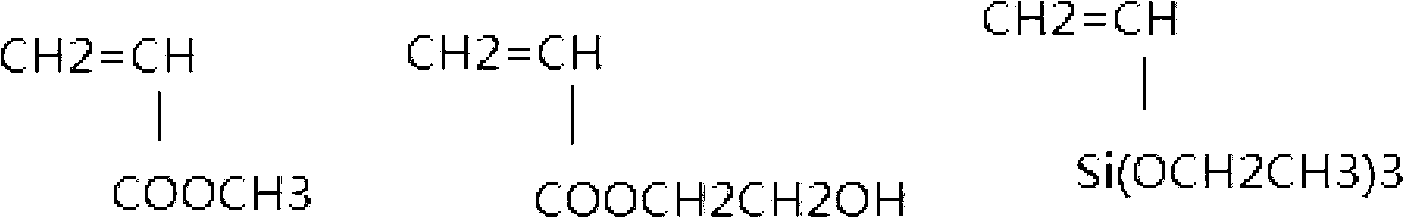

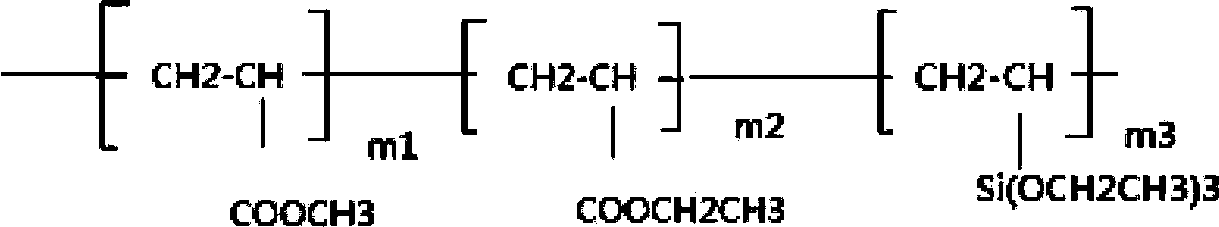

InactiveCN102794581ANo pollution in the processExcellent soldering performanceWelding/cutting media/materialsSoldering mediaAlcoholAcrylic resin

The invention discloses a steel no-clean welding flux. The steel no-clean welding flux is characterized by comprising the following components in weight percent: 10-35% of organic silicon modified acrylic resin, 15-80% of mixed alcohol solvent, 5-30% of active mixed component and 1-20% of benzenediol. The invention further discloses a preparation method for the steel no-clean welding flux. The steel no-clean welding flux is an environment-friendly novel welding flux which is no-clean, good in weld assistant property, large in expansion rate, non-corrosive and residue-free.

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method for electronic substrate welding assistant

InactiveCN106514056AAvoid disadvantagesExcellent soldering performanceWelding/cutting media/materialsSoldering mediaMaleopimaric acidAcrylic resin

The invention discloses a preparation method for an electronic substrate welding assistant and belongs to the technical field of welding assistants. Aiming at the defects that a large number of halide ions are contained in residues of current electronic substrate welding flux, the electric insulation performance is lowered, and pollution is liable to occur, the preparation method adopts succinic acid and oxalic acid triethanolamine are adopted as core materials, acrylic resin serves as a shell material, and microencapsulation compound active substances are obtained; then rosin of masson pine rosin serves as raw materials to prepare maleopimaric acid polyethylene glycol ester; and finally, the maleopimaric acid polyethylene glycol ester is mixed with the microencapsulation compound active substances, benzotriazole and the like to prepare the electronic substrate welding assistant. According to the preparation method, the microencapsulation compound active substances are prepared, thus the surface activity of the welding assistant is increased, the compatibility between the welding assistant and a welding assistant is enhanced, maleic anhydride and other volatile assistants overcome the defects that the electric insulation performance is lowered due to the fact that too many halide ions are left in residues of traditional welding flux, so that the environment pollution degree is lowered, and wide economic prospects are achieved.

Owner:常州市鼎升环保科技有限公司

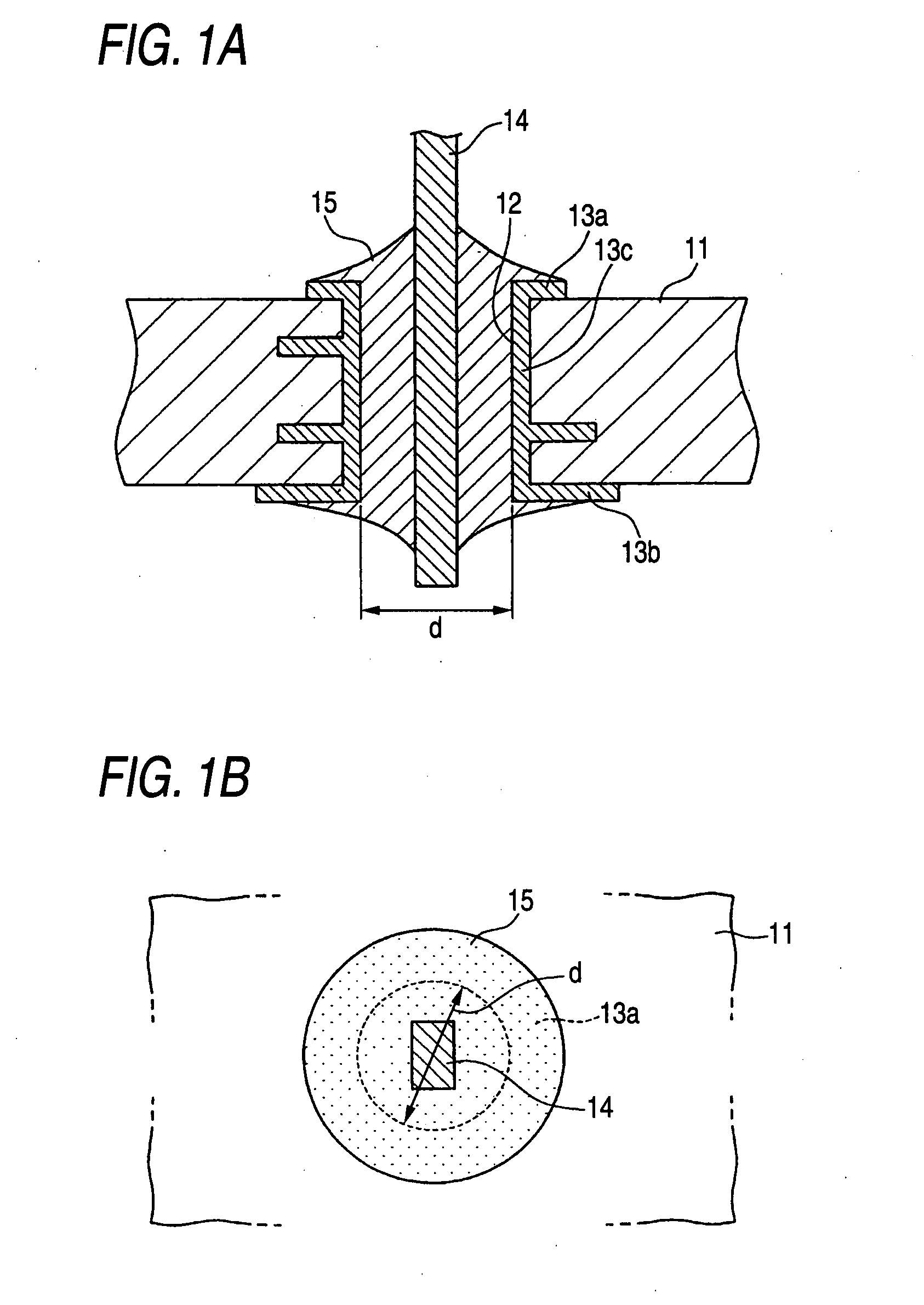

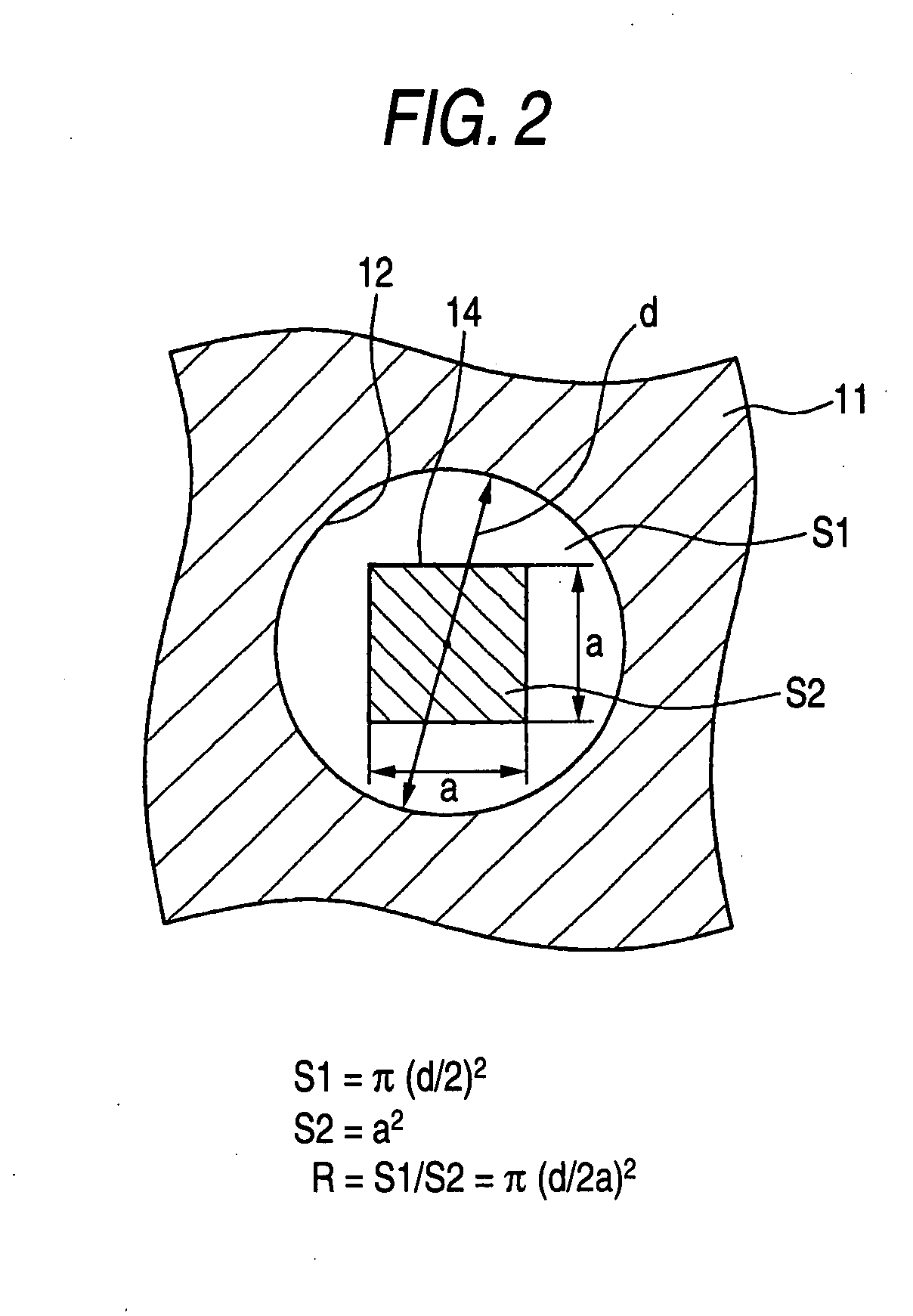

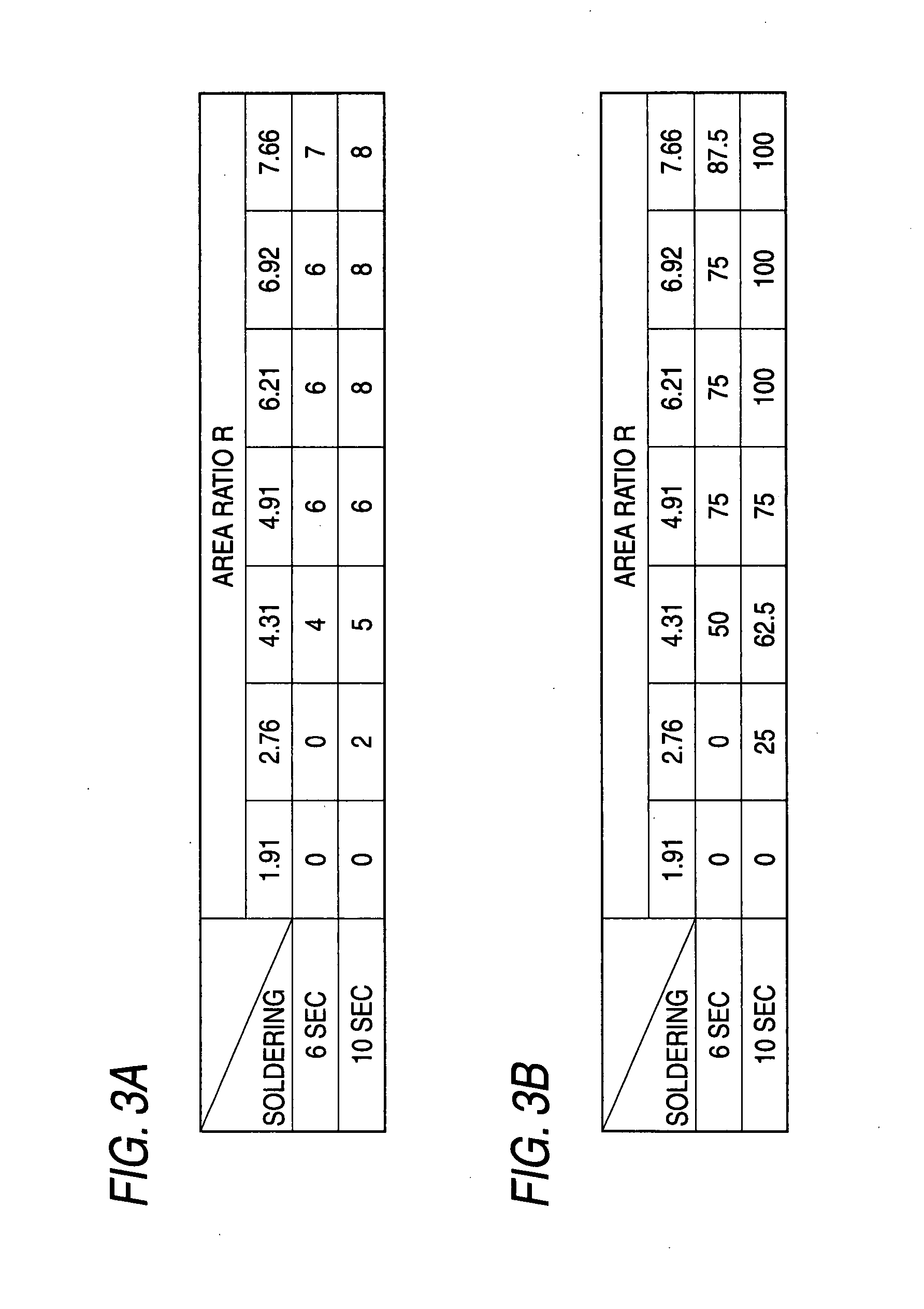

Soldering structure of through hole

InactiveUS20070205251A1Excellent soldering performanceFast heat conductionCooking-vessel materialsPrinted circuit aspectsElectrical conductorEngineering

A through hole is formed in a printed board. Conductor patterns are formed on an upper face and a lower face of the printed board in such a manner that the conductor patterns are electrically connected to each other, by means of a through hole solder. A lead terminal of an electronic component is inserted into the through hole and soldered with a lead free solder. According to this invention, an area of an opening of the through hole is set to be four times or more as large as a cross sectional area of the lead terminal. In this manner, heat conduction on occasion of soldering can be enhanced, and the soldering can be favorably performed, even when the lead free solder having a high melting point is used.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Soldering flux composition containing cyclohexane citrate

InactiveCN102303199AHigh purityLess impurity ionsWelding/cutting media/materialsSoldering mediaCITRATE ESTERSoldering

The invention discloses a soldering flux composition containing cyclohexane citrate, and also discloses a method for preparing the cyclohexane citrate and an application of the cyclohexane citrate as an additive of the soldering flux. The cyclohexane citrate has the purity of above 99 percent and is prepared by the method comprising the following steps of: 1, taking citric acid, adding pure water, heating and dissolving completely, and then filtering and clarifying; 2, slowly adding the filtered citric acid solution in the corresponding quantity of cyclohexane under the condition of stirring, reacting at a temperature of 60-90 DEG C, and finally adding the cyclohexane or citric acid to regulate pH to be 7.5-9; 3, heating and concentrating until a crystal coating occurs, pouring a heat solution in a tray while heating for cooling to be in a block shape; and 4, cutting the blocky cyclohexane citrate in the tray into small blocks, and drying at a temperature of 80-95 DEG C to obtain the soldering flux composition. The soldering flux composition containing the cyclohexane citrate has low cost, less environment pollution and enhanced soldering capacity.

Owner:广州化学试剂厂

Soldering flux and preparation method thereof

InactiveCN105945455ASimple ingredientsThe production process is simpleWelding/cutting media/materialsSoldering mediaIonChemistry

The invention relates to a flux, in particular to a soldering flux and a preparation method thereof. In the soldering production process of electronic products, a flux containing halide is generally used; and after soldering, more residues are generated, and the residues contain halide ions to gradually cause such problems as reduction of electric insulation performance and short circuit. In order to realize the purpose of the invention, the invention provides the soldering flux; and the soldering flux comprises the following components in percentage by weight: 25-35% of rosin, 55-70% of ethanol, 2-6% of triethanolamine, and 1-3% of aniline. In addition, the invention further provides the preparation method of the soldering flux; and the flux prepared according to the formula and the method contains no halide ions, cannot gradually cause such problems as reduction of electric insulation performance and short circuit, has no need to clean the flux residues on an electronic printed board, is simple in components and preparation process, and is excellent in fluxing effect.

Owner:沈根来

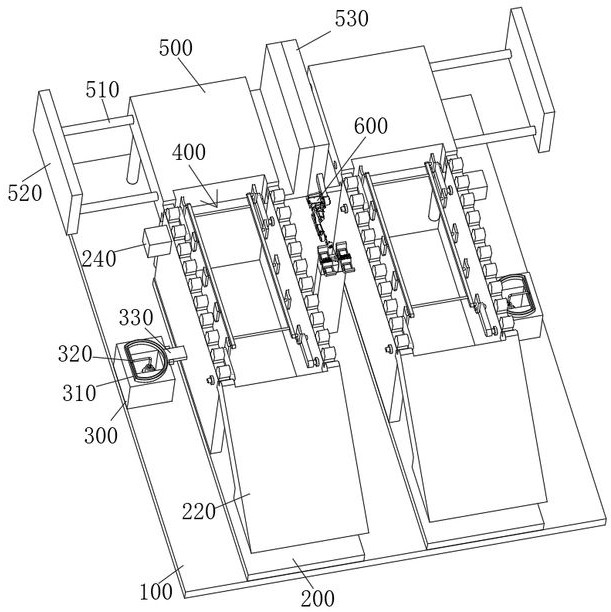

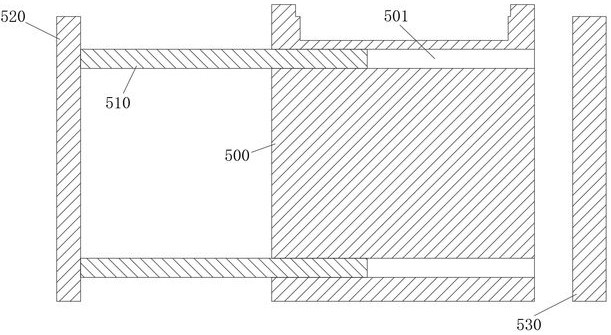

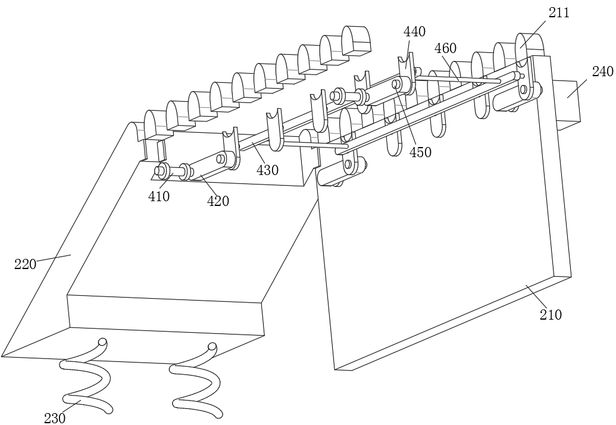

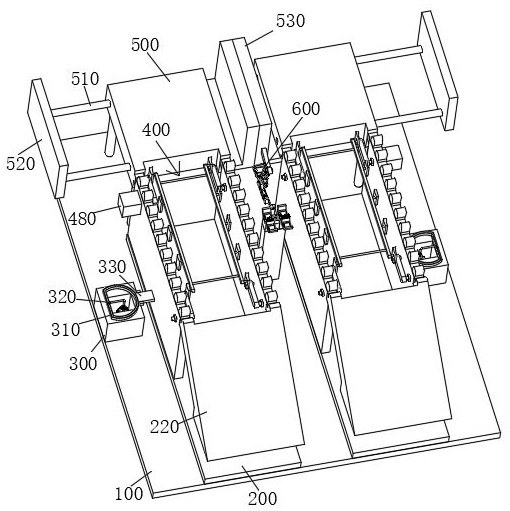

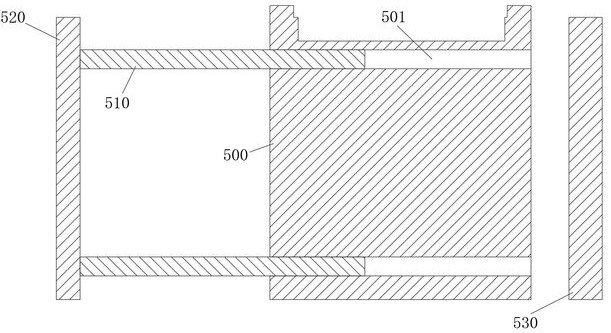

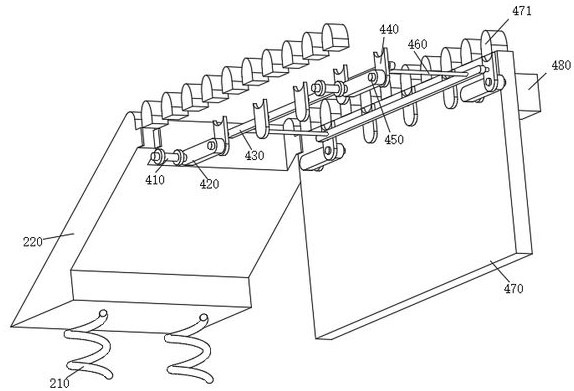

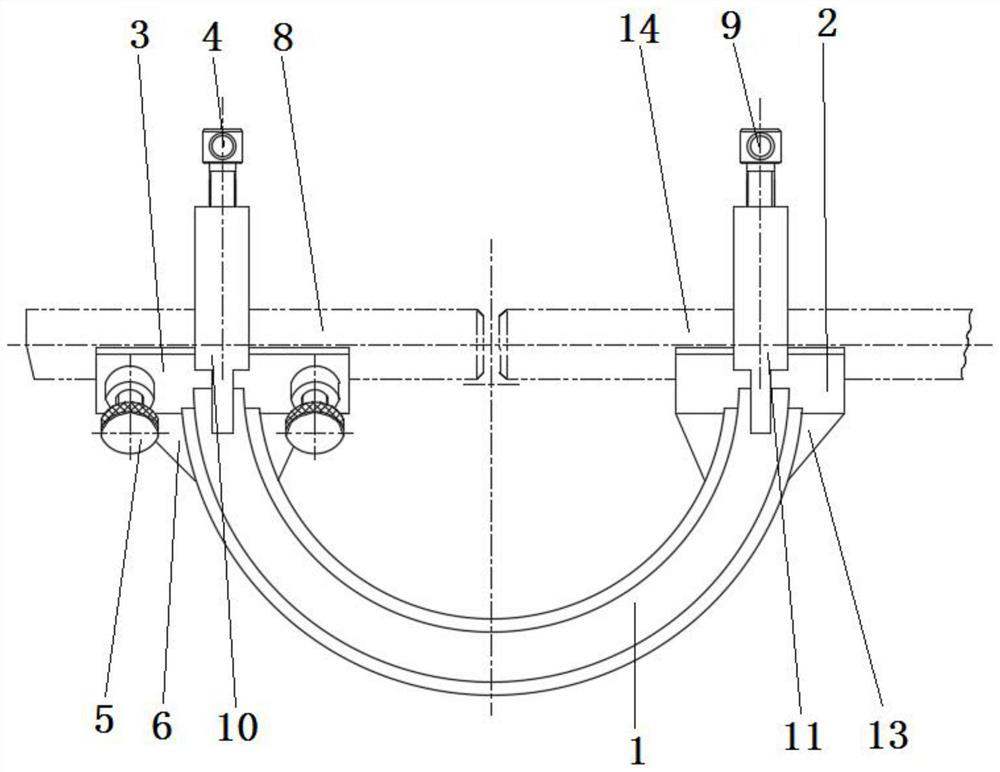

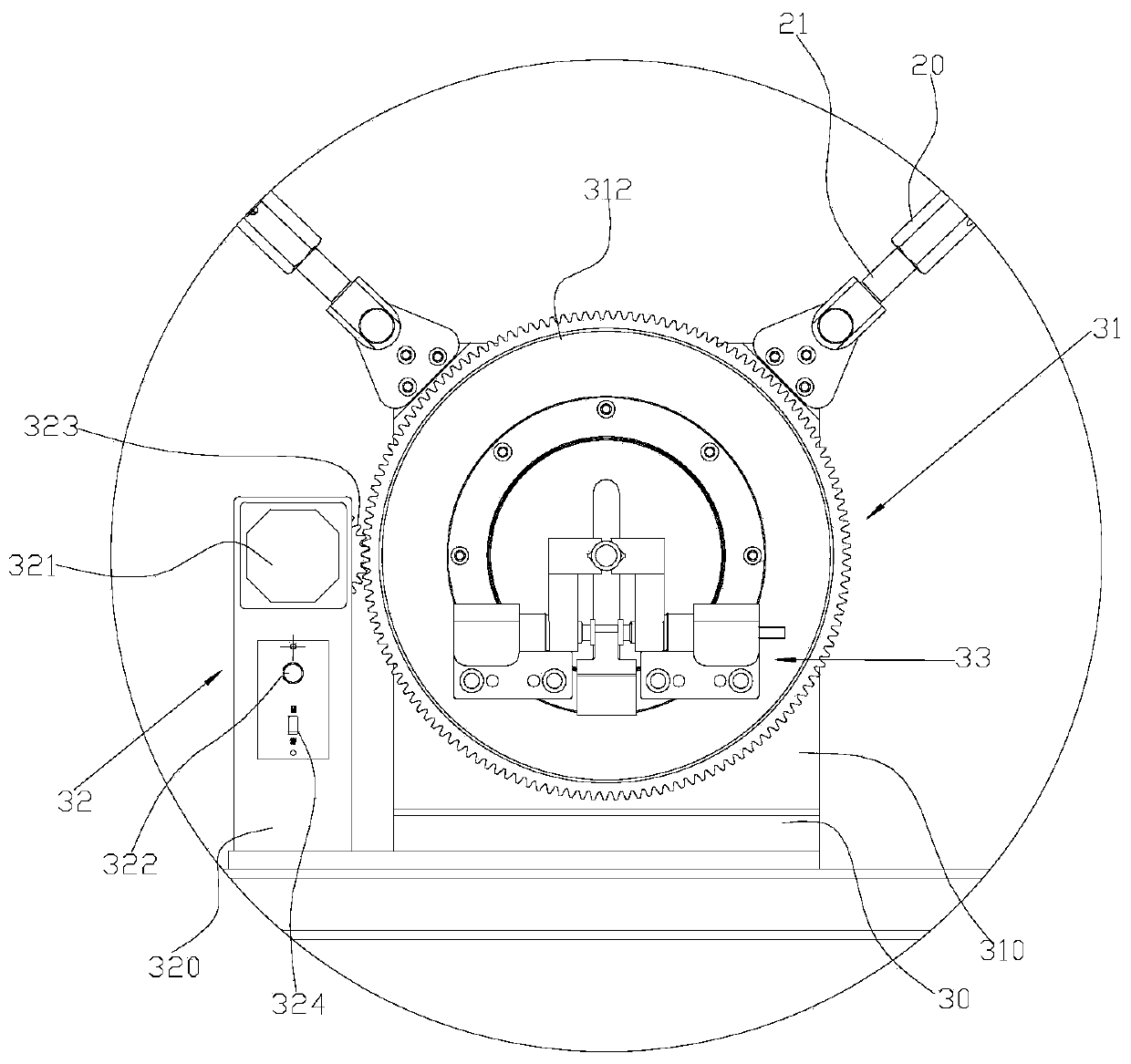

Auxiliary positioning device for mechanical automatic welding

ActiveCN112171173AEasy to flushExcellent soldering performanceWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelElectric machinery

The invention relates to the technical field of welding positioning, in particular to an auxiliary positioning device for mechanical automatic welding. The auxiliary positioning device comprises a fixing plate, two first base plates are connected to the top surface of the fixing plate in a sliding mode, a U-shaped table is fixedly connected to the position, corresponding to the position between the two first base plates, of the top surface of the fixing plate, second base plates are arranged on the top surface of the fixing plate, and multiple supporting columns are arranged on the bottom surfaces of the second bottom plates. According to the auxiliary positioning device, the first base plates on the two sides are pushed inwards, pipe orifices of two pipelines are tightly attached to the interior of a first clamping ring and is located in the first clamping ring, a second clamping ring is closed, the pipelines on the two sides are tightly buckled by the first clamping ring and the second clamping ring, at the moment, the two pipelines are welded by a mechanical arm welding gun, in addition, a double-shaft motor drives second driving wheels at the two ends to rotate synchronously, the second driving wheels drive first driving wheels attached to the second driving wheels to rotate, the first driving wheels drive the pipelines clamped inside to rotate, the rotating pipelines are completely welded under the action of the mechanical arm welding gun, and the welding efficiency is improved by means of rotating welding of the pipelines.

Owner:北京六九零一科技有限公司

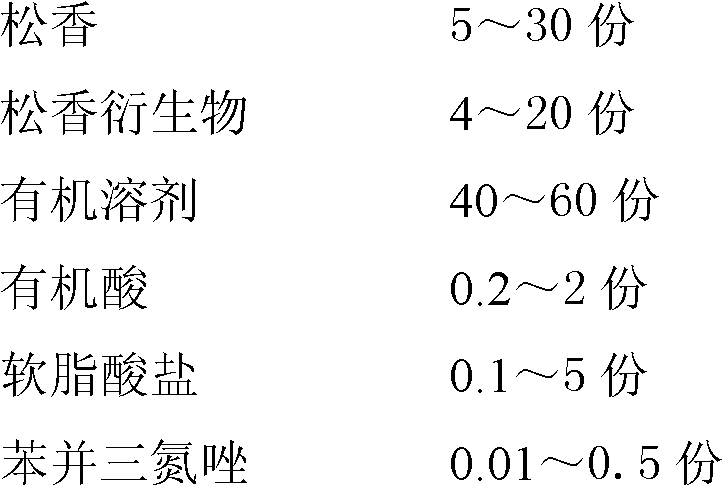

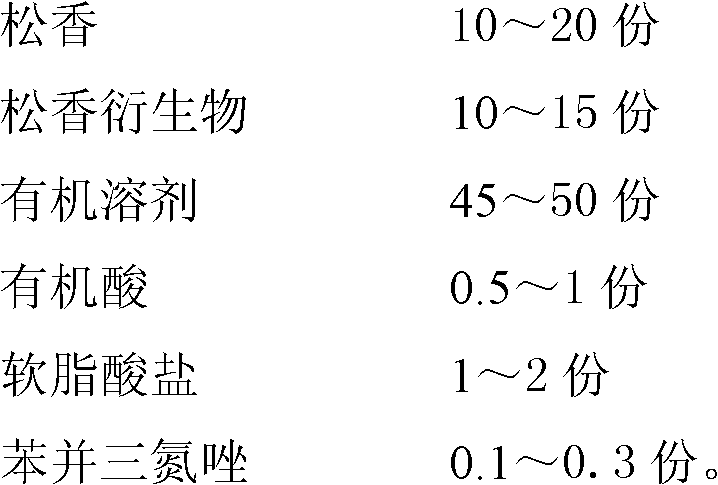

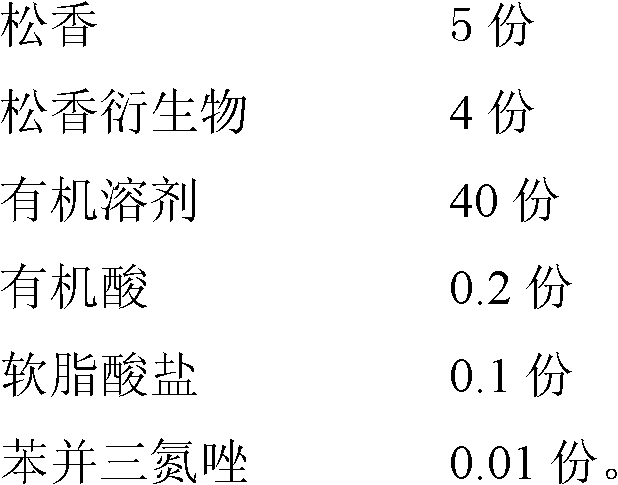

Resin type scaling powder

InactiveCN102794580AExcellent soldering performanceHigh electrical insulationWelding/cutting media/materialsPrinted circuitsOrganic acidDip soldering

The invention discloses resin type scaling powder which comprises the following ingredients: 5-30 parts of rosin, 4-20 parts of rosin derivative, 40-60 parts of organic solvent, 0.2-2 parts of organic acid, 0.1-5 parts of palmitate and 0.01-0.5 part of benzotriazole. The scaling powder has an excellent solder-aiding effect, is capable of improving the electrical insulating property and expandability of an electric welding product without washing and drying and is convenient in use; and the scaling powder is applicable to automatic wave-soldering, dip soldering and manual soldering of a printed circuit board, and also can be used for carrying out anti-oxidation pre-coating on the leads of whole electronic components of the printed circuit board.

Owner:太仓市联林活性炭厂

Lead-free no-clean soldering flux and preparation method thereof

ActiveCN102689114BExcellent soldering performanceImprove insulation performanceWelding/cutting media/materialsSoldering mediaCopper platingSoldering

Owner:广东剑鑫科技股份有限公司

Halogen-free low-carbon environment-friendly flux

InactiveCN103846576AHigh insulation resistanceGood solderabilityWelding/cutting media/materialsSoldering mediaInsulation resistanceSolvent

The invention discloses a halogen-free low-carbon environment-friendly flux. The flux comprises the following components in percentage by mass: 50% to 80% of polyethylene glycol, 1% to 3.5% of oxidized polyethlene wax, 2.5% to 4.5% of fatty acid ester surface active agent, 1.3% to 3.5% of high-quality abieten, 0.8% to 2.6% of active reinforcing agent, 1.5% to 4.3% of stabilizing agent, and the balance of high-boiling point deionized water as a solvent. By adopting the method, the halogen-free low-carbon environment-friendly flux has the advantages that the halogen is not contained, the insulation resistance is high, and the welding assisting performance is good; compared with the traditional alcohol-based flux, the flux uses water as the solvent, the carbon content is lower, and the emission of carbon dioxide is reduced.

Owner:SUZHOU LOTTE CHEM TECH

Ultrasonic welding device and ultrasonic welding method

PendingCN114535773AAvoid breakingAvoid breakageWelding/soldering/cutting articlesMetal working apparatusMetallurgyUltrasonic welding

The invention discloses an ultrasonic welding device and an ultrasonic welding method, the ultrasonic welding device comprises a welding head and a welding seat, two symmetrical sides of the welding head are provided with welding parts, the welding parts are connected through a connecting part, the welding parts are internally provided with a plurality of welding teeth arranged at intervals, and the welding teeth are neatly arranged to form a straight strip with a notch. According to the invention, the damage of the welding teeth at the edge of the welding part to the tab foil is reduced, the problem of tab foil breakage is avoided, and the product percent of pass is improved.

Owner:WANXIANG 123 CO LTD

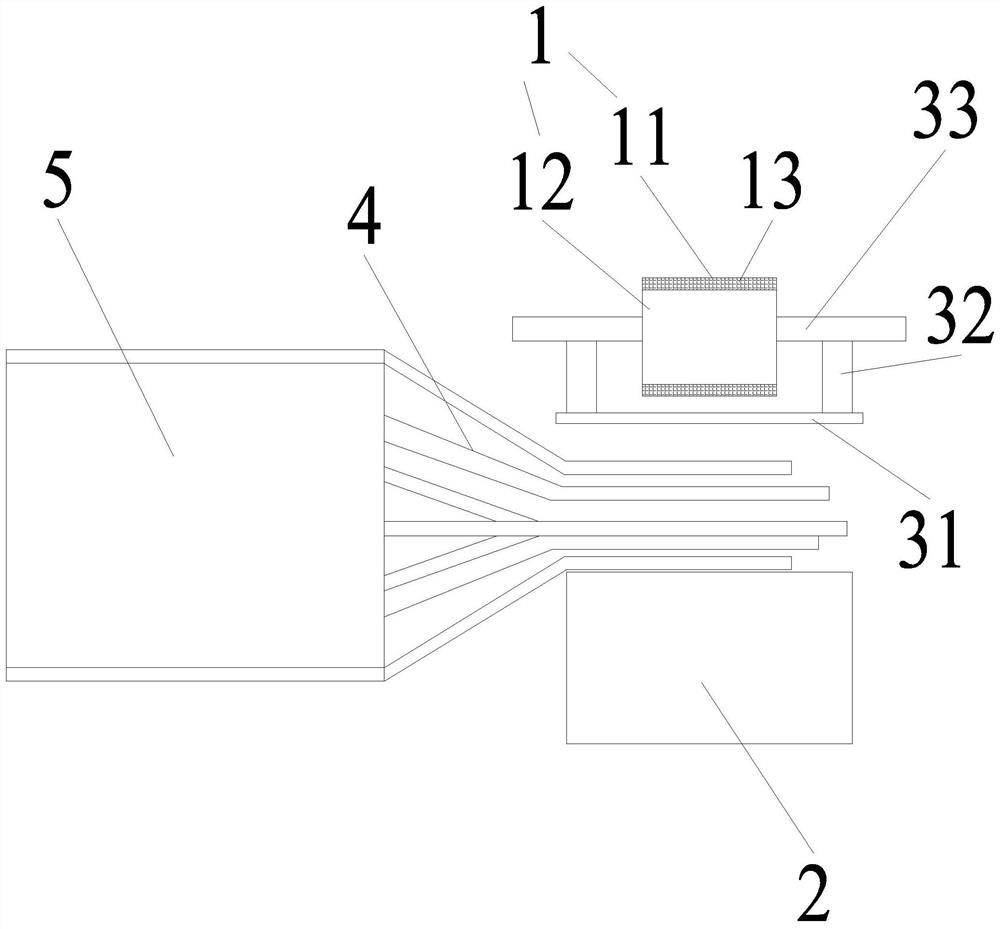

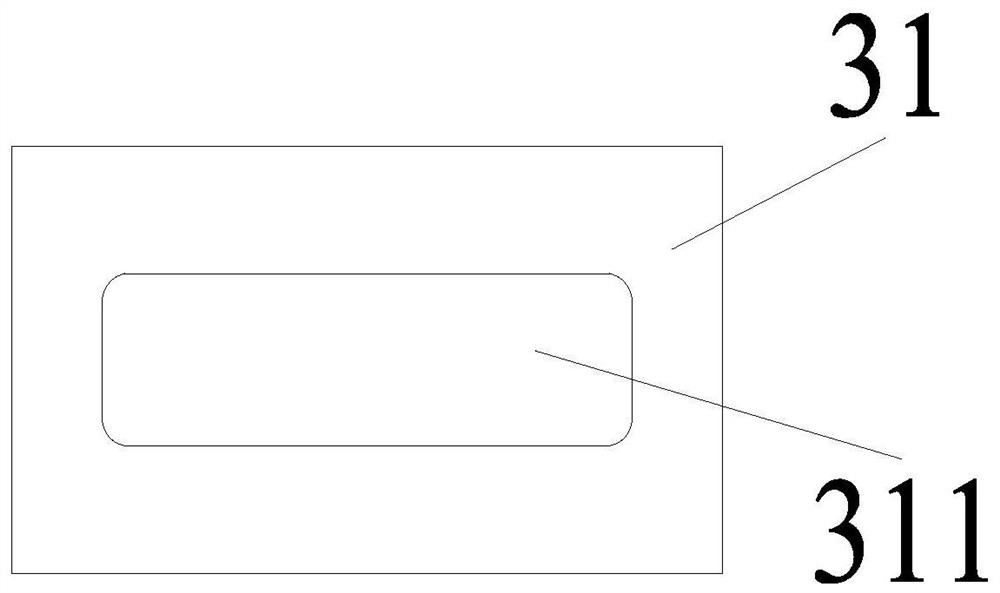

An auxiliary positioning device for mechanical automation welding

ActiveCN112171173BEasy to flushExcellent soldering performanceWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelElectric machinery

The invention relates to the field of welding positioning technology, in particular to an auxiliary positioning device for mechanical automation welding, including a fixed plate, the top surface of the fixed plate is slidingly connected with two first bottom plates, and the top surface of the fixed plate corresponds to the two second bottom plates. A U-shaped platform is fixedly connected between one base plate, and a second base plate is provided on the top surface of the fixed plate, and a plurality of support columns are provided on the bottom surface of the second base plate. In the present invention, by pushing the first bottom plates on both sides inward, the nozzles of the two pipes are close to and located inside the first clamp ring, and the second clamp ring is closed, so that the first clamp ring and the second clamp ring will The pipes on both sides are tightly fastened. At this time, the welding torch of the mechanical arm welds the two pipes, and the double-axis motor drives the second driving wheel at both ends to rotate synchronously. The second driving wheel drives the first driving wheel that is attached to it to rotate. The wheel drives the internally clamped pipe to rotate, and the rotating pipe is completely welded under the action of the welding torch of the mechanical arm. The rotating welding of the pipe improves the welding efficiency.

Owner:北京六九零一科技有限公司

Halogen-free soldering flux for electronic industry

InactiveCN101733586BInhibit aggregationInhibition formationWelding/cutting media/materialsSoldering mediaSolderabilityShikimic acid

Owner:SICHUAN UNIV +1

A low-temperature, halogen-free, low-solid-content modified rosin-type flux and preparation method thereof

InactiveCN108817731BGood solid contentSolid content modified rosin type flux has good fluidityWelding/cutting media/materialsSoldering mediaOrganic acidOrganic solvent

The invention relates to a low-temperature, halogen-free, low-solid-content modified rosin-type welding flux. The welding flux is prepared form, by mass, 10-15% of modified rosin, 1-5% of organic acidactivator, 0.35-1% of glycerin, 0.009-1% of benzotriazole, 0.3-1 % of triethanolamine, a surfactant and the balance organic solvent, wherein the surfactant is 0.5-3% of the mass of the organic acid activator. The prepared low-temperature, halogen-free and low-solid-content modified rosin-type welding flux prepared has good fluidity, no precipitation and delamination phenomena, no halogen elements, a small amount of modified rosin, a good spreading rate, good weldability, bright and full welding spots and less residues after welding, little corrosion is caused, and cleaning is not needed; therequirements for environmental protection are met; an operation method is sample, the temperature is moderate, there are less experimental steps, the cost is low, less by-products are generated in a synthesis process and are easy to remove, and the synthesis time is short.

Owner:ZHONGYUAN ENGINEERING COLLEGE

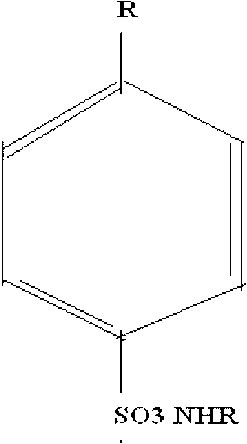

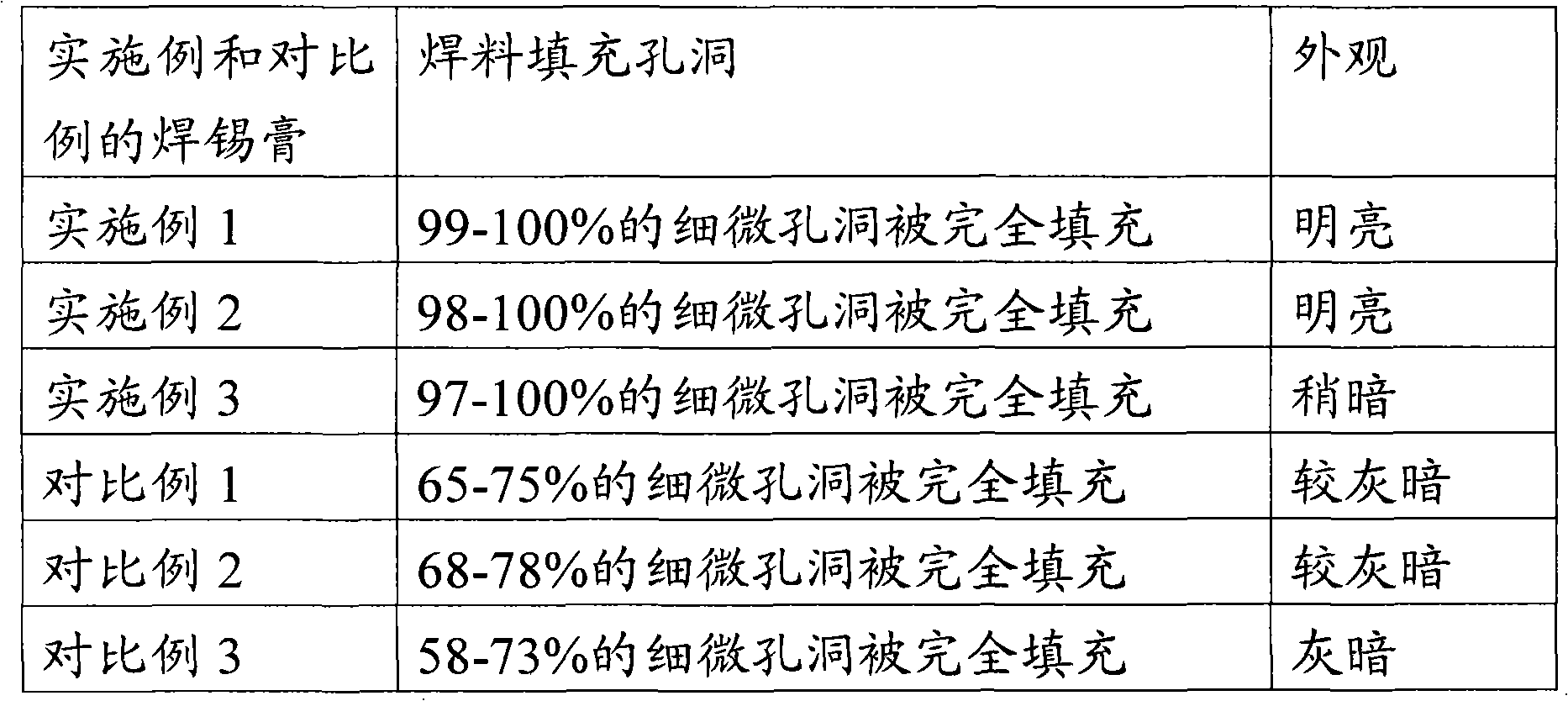

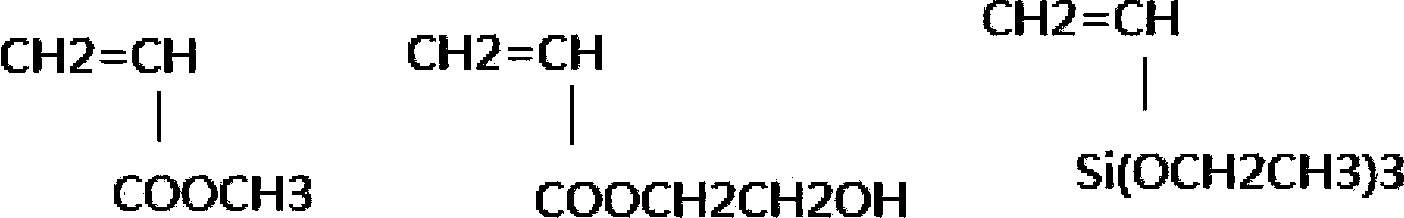

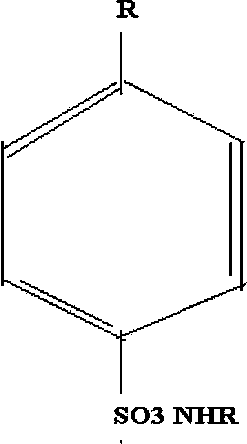

Unleaded halogen-free soldering paste with high wettability

InactiveCN102069315BImprove wettabilityGood storage stabilityWelding/cutting media/materialsSoldering mediaActive agentSolvent

The invention relates to a soldering assistant chemical used for electronic assembly, in particular to an unleaded halogen-free soldering paste in the field of brazing material used for electronic surface assembly, which consists of 80-93 percent by weight of solder alloy powder and 7-20 percent by weight of flux, wherein the solder alloy powder is unleaded alloy, and the flux comprises 30-55 percent by weight of resin, 20-50 percent by weight of solvent, 1-8 percent by weight of thixotropic agent and 0.01-20 percent by weight of active agent, and the active agent comprises amino acid p-toluenesulfonic acid salt and / or amino-acid ester p-toluenesulfonic acid salt. The soldering paste has higher wettability, reduces corrosivity, has good storage stability, is unleaded and halogen-free, meets the requirement of environmental protection, and can be applied to the electronic industry.

Owner:SICHUAN UNIV +1

Lead-free and halogen-free solder paste for electronic industry

InactiveCN101733588BInhibit aggregationInhibition formationWelding/cutting media/materialsSoldering mediaSolderabilityShikimic acid

Owner:SICHUAN UNIV +1

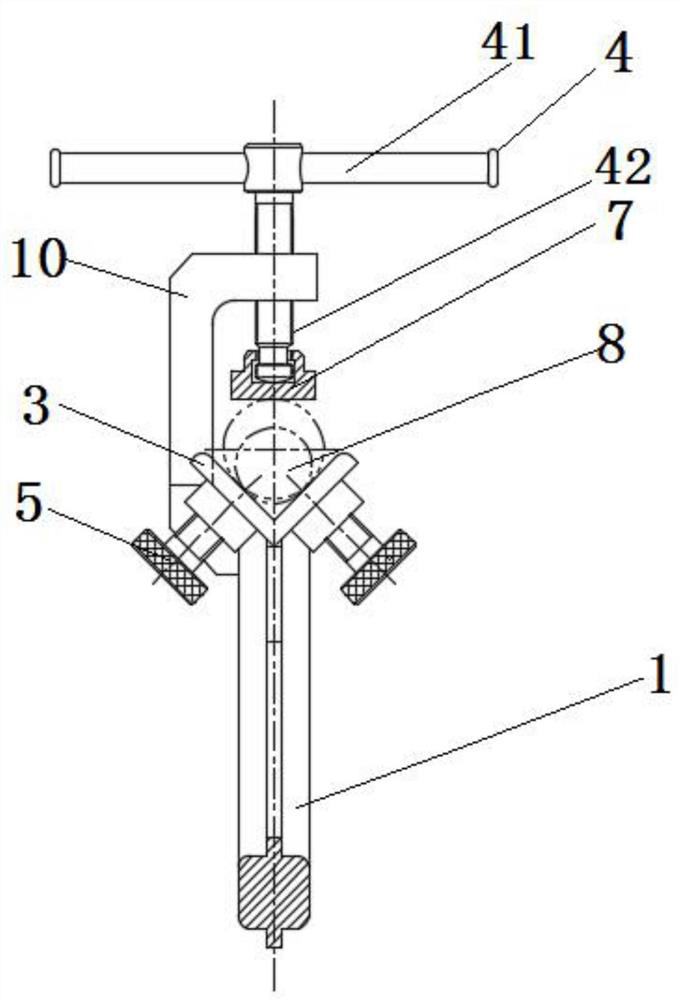

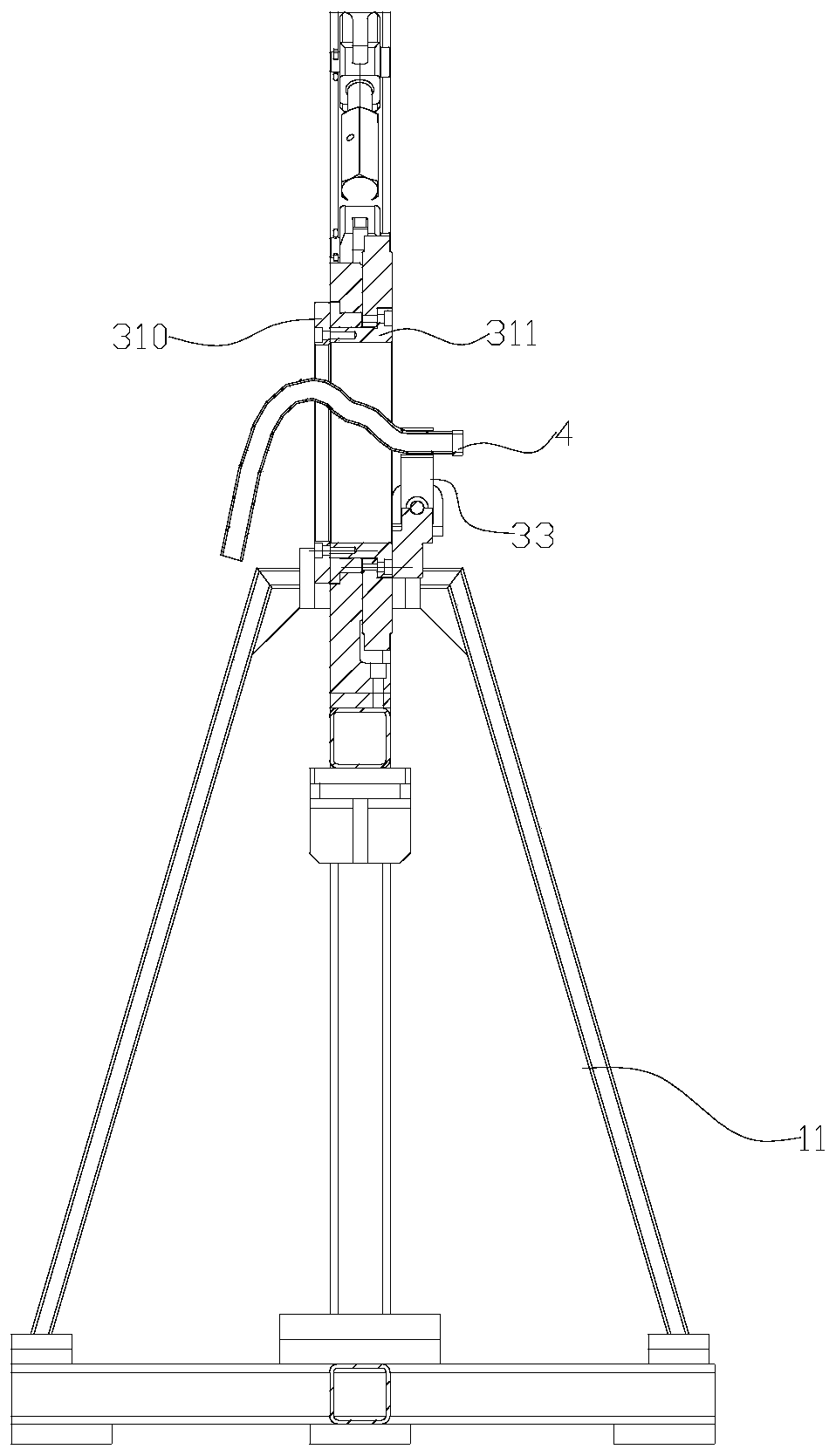

Adjustable reducing pipe butt joint positioning device and using method thereof

InactiveCN111730281AGood immobilizationSimple structureWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeManufacturing engineering

The invention discloses an adjustable reducing pipe butt joint positioning device and a using method thereof, and belongs to the field of boiler manufacturing. The problems that the machining precision is low and the production efficiency is low when a steel pipe is welded at present are solved. The device comprises an adjusting bent plate, short fixing angle steel, long fixing angle steel, a first pressing mechanism, a second pressing mechanism, a first supporting arm and a second supporting arm; one end of the adjusting bent plate is connected with the long fixing angle steel, the other endof the adjusting bent plate is connected with the short fixing angle steel, the first pressing mechanism is inserted into a first threaded hole of the first supporting arm, a first mounting arm is fixedly mounted at one end of the adjusting bent plate, the second pressing mechanism is inserted into a second threaded hole of the second supporting arm, and the second supporting arm is fixedly mounted at the other end of the adjusting bent plate. The reducing pipe butt joint positioning device is simple in structure and convenient to disassemble and assemble, the using method is concise in step,a large amount of manpower is saved, and the machining efficiency and the machining precision are improved.

Owner:HARBIN BOILER

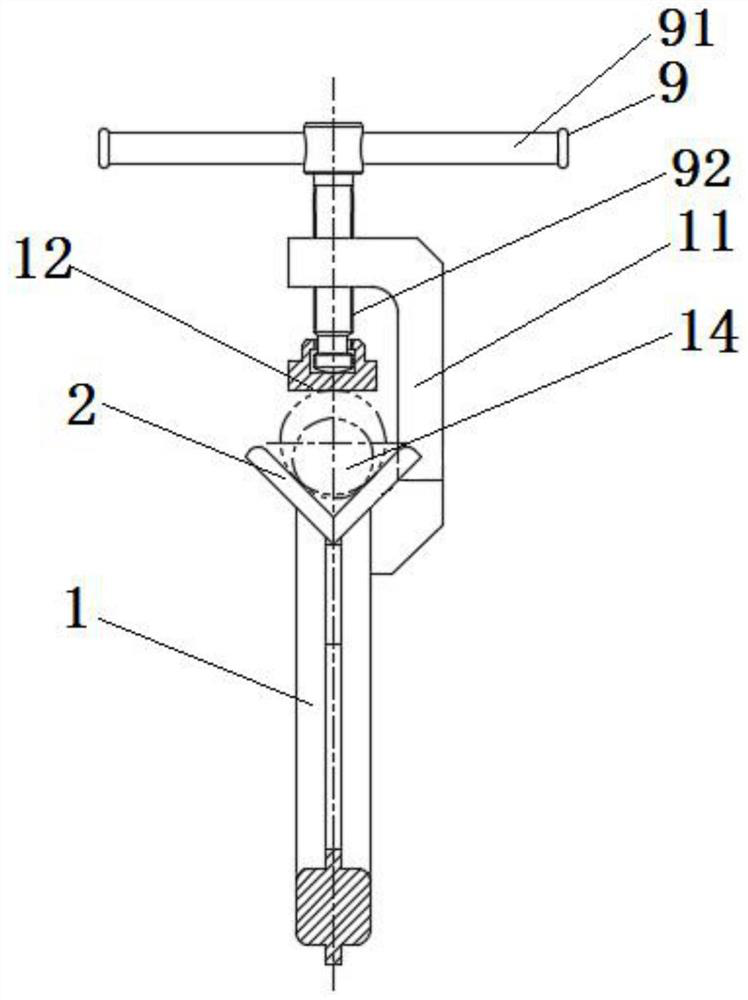

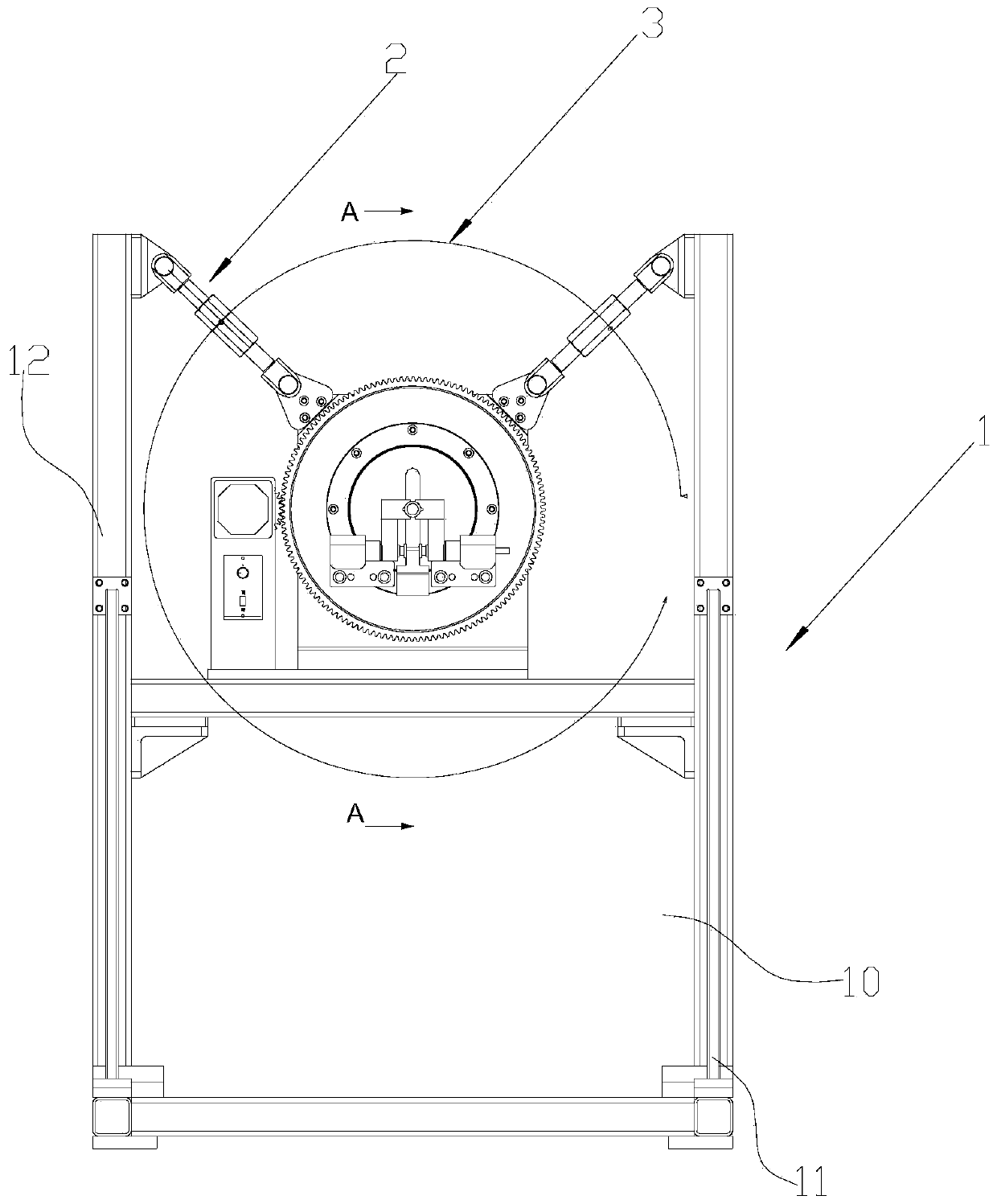

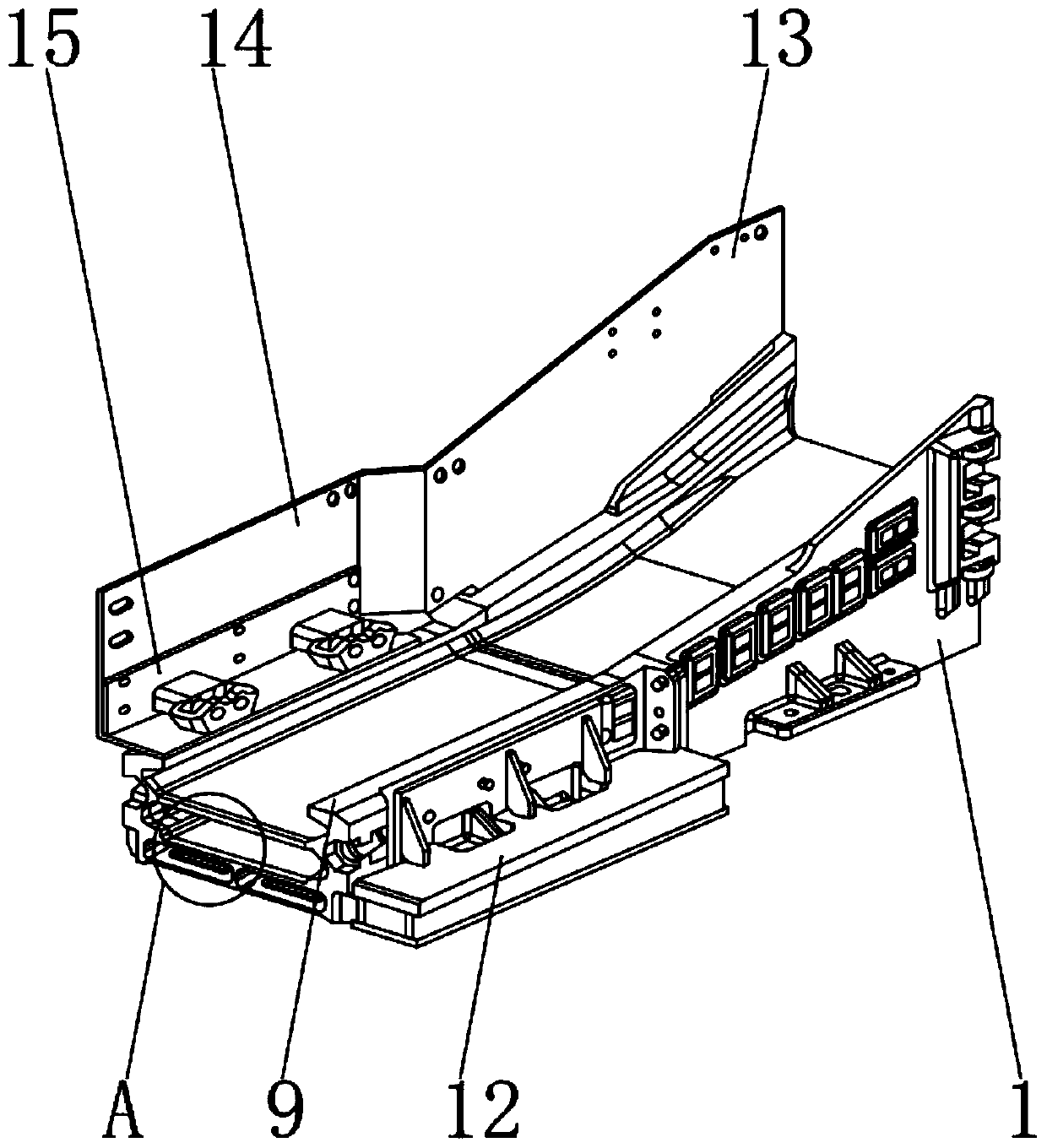

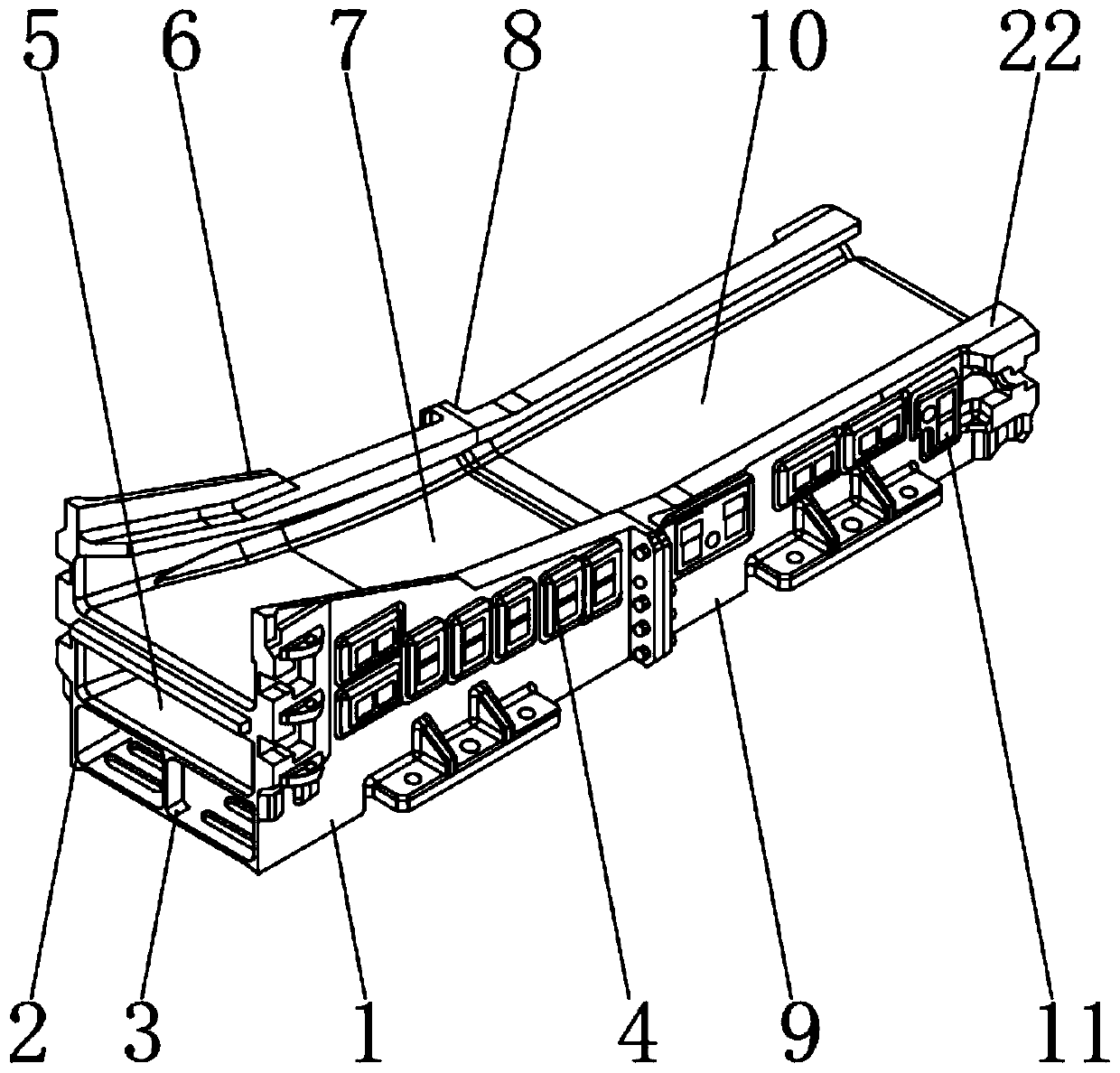

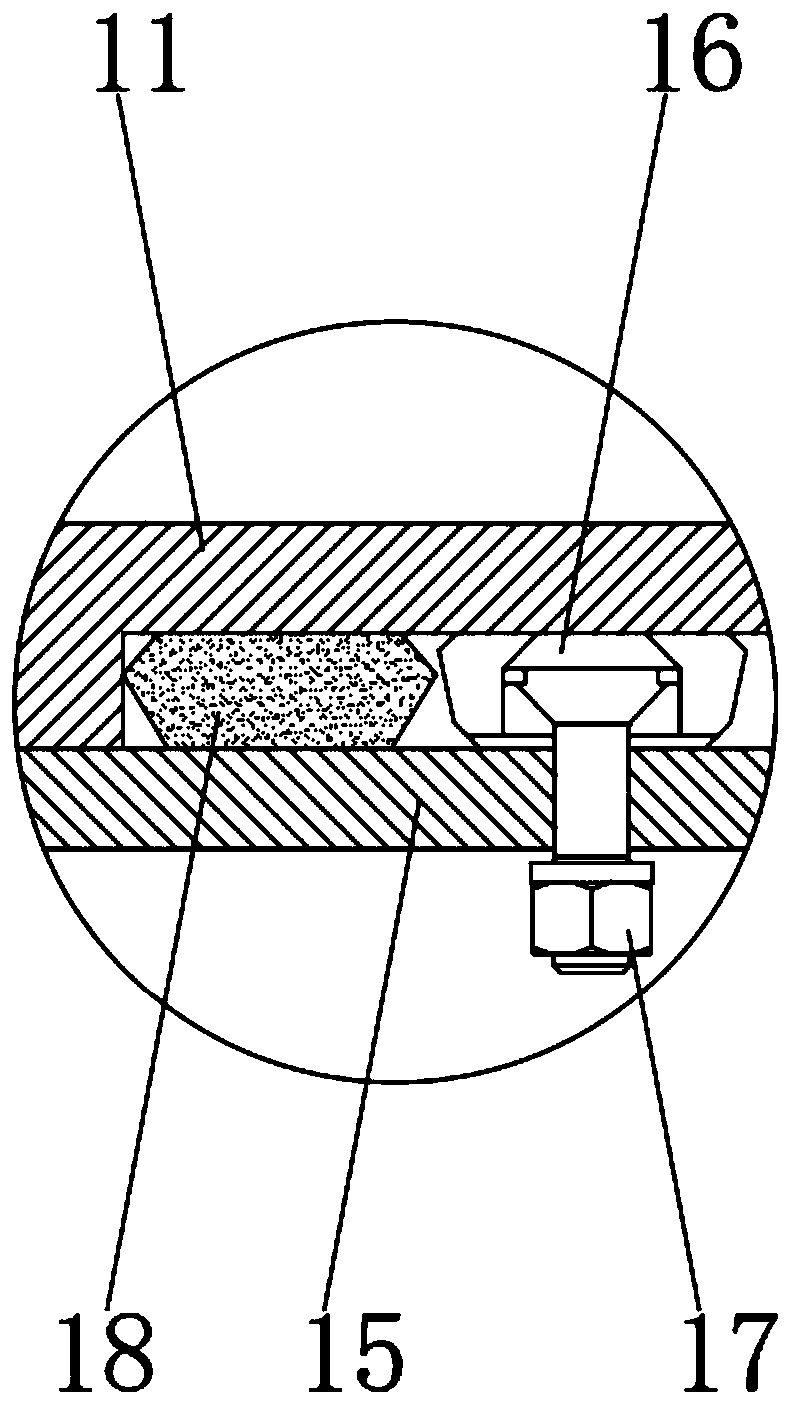

Automatic rotary welding device for bent pipe fitting

The invention discloses an automatic rotary welding device for a bent pipe fitting. The automatic rotary welding device comprises a supporting mechanism, pull rod assemblies and a rotary positioning mechanism, wherein the pull rod assemblies are arranged on the supporting mechanism, and the rotary positioning mechanism is arranged between the pull rod assemblies and the supporting mechanism. The rotary positioning mechanism comprises a support, a rotary assembly, a driving assembly and a pipe fitting centering assembly, wherein the support is arranged on the supporting mechanism, the rotary assembly is rotationally connected with the support, the driving assembly is arranged on the supporting mechanism and used for driving the rotary assembly to rotate, the pipe fitting centering assemblyis arranged on the rotary assembly, and the positioning center of the pipe fitting centering assembly and the center of the rotary assembly are located on the same central axis. The device is reliableto use and convenient to operate, the specific rotary positioning mechanism is designed according to the characteristics of complex space bending of an aero-engine, the pipeline can automatically rotate when the complex space bending of the aero-engine and pipelines with different diameters are welded, manual argon arc welding is located at a flat welding position, the number of times of arc starting and stopping is one, and the welding effect is effectively improved.

Owner:AECC AERO SCI & TECH CO LTD

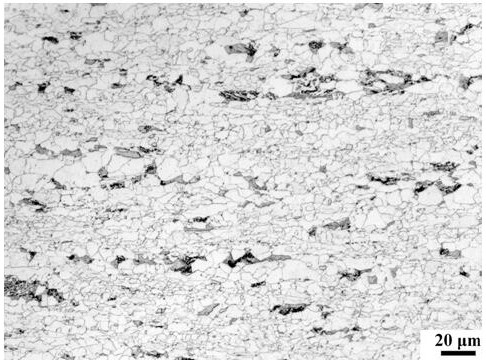

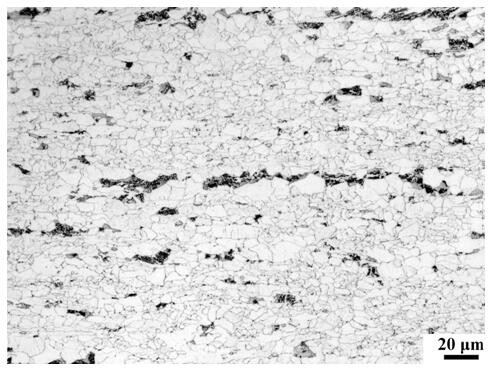

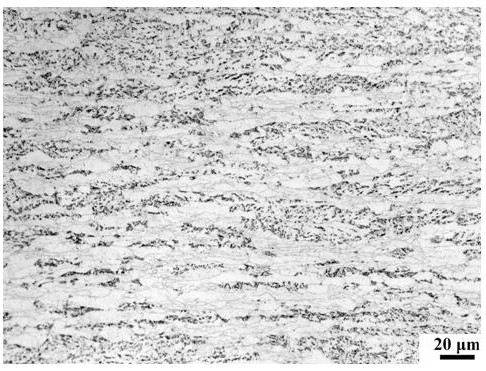

Structural steel plate for wind power and production method thereof

The invention discloses a structural steel plate for wind power and a production method thereof. Chemical composition of steel plate: C:0.075%~0.115%, Si:0.11%~0.19%, Mn:1.39%~1.49%, Cr:0.08%~0.16%, Ni:0.08%~0.16%, Nb:0.012%~ 0.018%, Ti: 0.008%~0.016%, Alt: 0.025%~0.045%, the rest is iron, carbon equivalent 0.355%~0.370%. The steel plate is prepared by sequentially heating the continuous casting slab, rolling in the recrystallization zone, rolling in the non-recrystallization zone, rolling in the two-phase zone and air cooling in the cooling bed. The steel plate is a multi-phase structure composed of polygonal ferrite, deformation-induced ferrite and bainite, which not only has low cost and high production rhythm, but also has excellent welding performance, strength and toughness, and plate shape.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Steel no-clean welding flux and preparation method thereof

InactiveCN102794581BNo pollution in the processExcellent soldering performanceWelding/cutting media/materialsSoldering mediaAlcoholAcrylic resin

Owner:JIANGSU UNIV OF SCI & TECH

Integrally-cast transition groove for scraping machine

The invention discloses an integrally-cast transition groove for a scraping machine, and relates to the field of scraping machine accessories. The integrally-cast transition groove for the scraping machine comprises a first transition groove body and a second transition groove body, a first lingual plate is arranged at the upper end of the first transition groove body, upper wing plates are arranged on the two sides of the upper end of the first lingual plate correspondingly, reserved threaded holes are formed in the upper wing plates, a first sealing bottom plate is arranged at the lower endof the first transition groove body, a first chain way bottom plate is arranged in the middle of the first transition groove body, a first supporting frame is arranged between the first chain way bottom plate and the first sealing bottom plate, and first bolt connecting bases are fixedly installed on the outer surfaces of the two sides of the first transition groove body. According to the integrally-cast transition groove for the scraping machine, the easy-to-wear parts of the first transition groove body and the second transition groove body are all integrally cast and formed, so that a chainway is integrally cast without welding, the poor welding performance and generation of welding defects are avoided, and the overall strength is improved.

Owner:河北冀凯铸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com