Resin type scaling powder

A flux, resin-based technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of low production efficiency, troublesome operation, and unsatisfactory flux effect, and improve electrical insulation. performance, ease of use, and excellent soldering effect

Inactive Publication Date: 2012-11-28

太仓市联林活性炭厂

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the production process of printed circuit boards, it needs to be soldered. In order to improve the quality of electric welding, flux is generally used, but the effect of flux in the prior art is not ideal, and after electric welding, it needs to be washed and dried. The operation is troublesome and the production efficiency is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

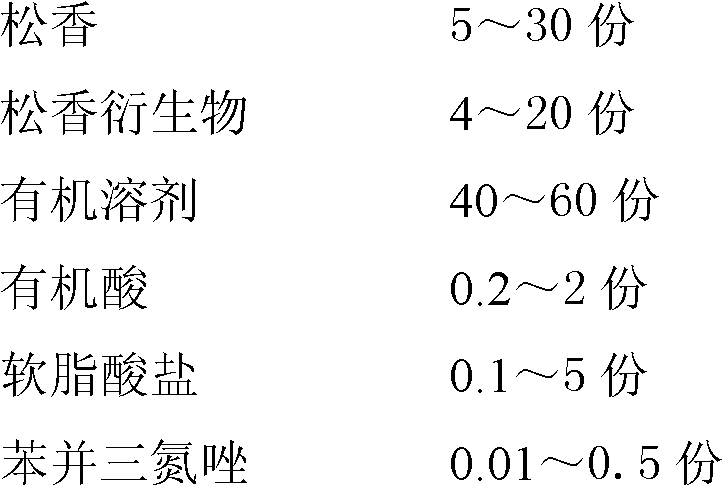

[0013] A kind of resin type soldering flux, it comprises the component of following parts by weight:

[0014]

Embodiment 2

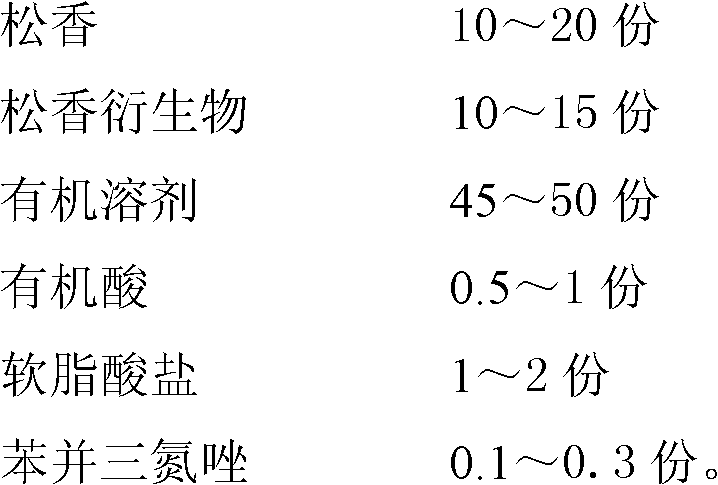

[0016] A kind of resin type soldering flux, it comprises the component of following parts by weight:

[0017]

Embodiment 3

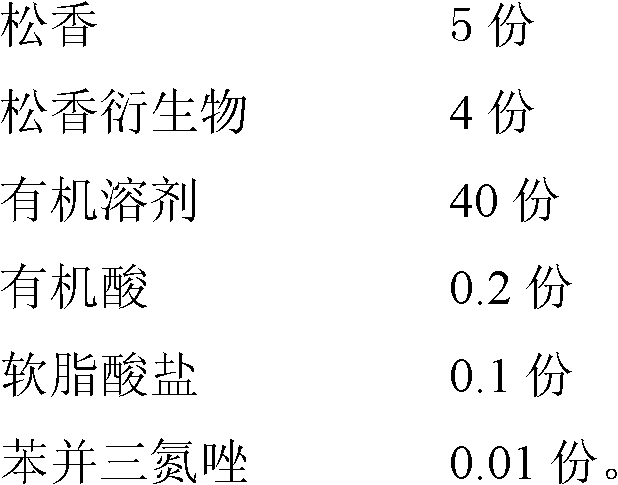

[0019] A kind of resin type soldering flux, it comprises the component of following parts by weight:

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses resin type scaling powder which comprises the following ingredients: 5-30 parts of rosin, 4-20 parts of rosin derivative, 40-60 parts of organic solvent, 0.2-2 parts of organic acid, 0.1-5 parts of palmitate and 0.01-0.5 part of benzotriazole. The scaling powder has an excellent solder-aiding effect, is capable of improving the electrical insulating property and expandability of an electric welding product without washing and drying and is convenient in use; and the scaling powder is applicable to automatic wave-soldering, dip soldering and manual soldering of a printed circuit board, and also can be used for carrying out anti-oxidation pre-coating on the leads of whole electronic components of the printed circuit board.

Description

technical field [0001] The invention relates to a flux, in particular to a resin type flux. Background technique [0002] In the production process of printed circuit boards, it needs to be soldered. In order to improve the quality of electric welding, flux is generally used, but the effect of flux in the prior art is not ideal, and after electric welding, it needs to be washed and dried. The operation is cumbersome and the production efficiency is low. Contents of the invention [0003] The present invention is just to overcome the above-mentioned shortcomings, and the technical problem to be solved is to provide a resin-type flux with good fluxing effect. [0004] In order to solve the problems of the technologies described above, the technical scheme adopted in the present invention is as follows: [0005] A kind of resin type soldering flux, it comprises the component of following parts by weight: [0006] [0007] Wherein, as a preferred proportion, a resin type...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/362B23K101/42

Inventor 薛剑平

Owner 太仓市联林活性炭厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com