Steel no-clean welding flux and preparation method thereof

A welding aid and formulation technology, which is applied in the field of no-clean welding aid for steel and its preparation, can solve the problems of adverse effects on mechanical properties and electrical properties, poor appearance, high corrosion, etc., and achieves no serious odor and can be The effect of good weldability and high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

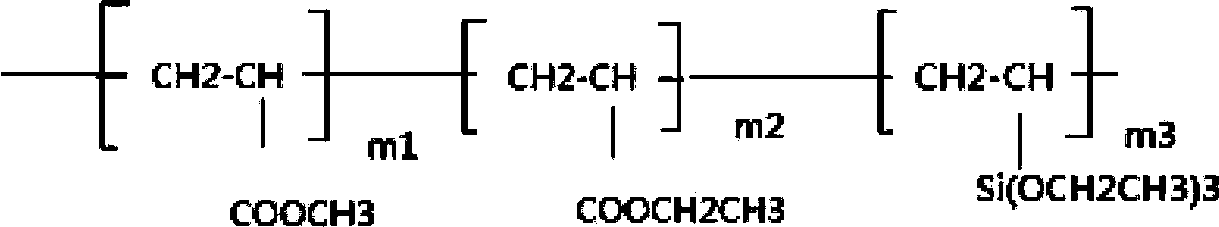

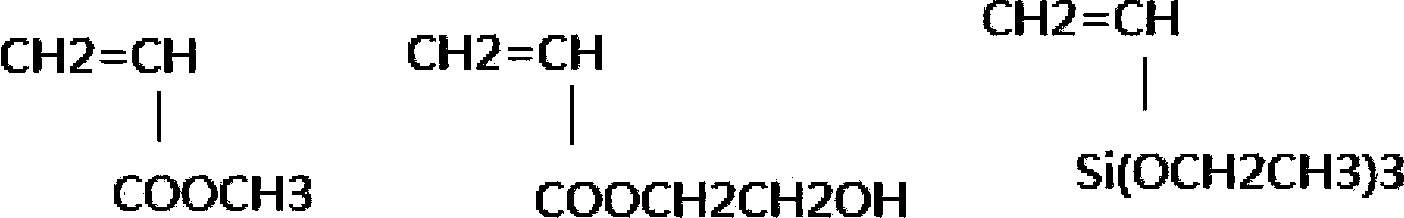

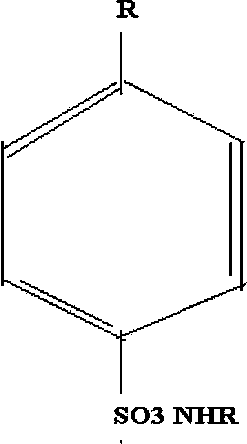

Method used

Image

Examples

Embodiment 1

[0043] A kind of no-clean welding aid for steel, it comprises the following components by weight percentage:

[0044] Silicone modified acrylic resin 30%,

[0045] Mixed alcohol solvent 50%,

[0046] Active blend ingredients 15%,

[0047] Hydroquinone 5%.

[0048] The preparation method is as follows: first mix the liquid components in the formula evenly, then add the solid components and stir evenly to obtain the product.

[0049] The effect of the embodiment: the no-cleaning flux is coated on the steel plate and the solder, and the TIG welding process is adopted, the welding current is 130A, the welding voltage is 15V, and the welding speed is 126mm / min. After welding, there is no residue on the steel plate, and there is a colorless transparent solid, forming a thin film, which shows that it has a protective effect. In addition, it can be seen that the expansion area is larger and the solder joints are more complete. Expansion rate 83.6.

Embodiment 2

[0051] A kind of no-clean welding aid for steel, it comprises the following components by weight percentage:

[0052] Silicone modified acrylic resin 10%,

[0053] Mixed alcohol solvent 80%,

[0054] Active blend ingredients 5%,

[0055] Hydroquinone 5%.

[0056] The preparation method is as follows: first mix the liquid components in the formula evenly, then add the solid components and stir evenly to obtain the product.

[0057] The effect of the embodiment: the no-cleaning flux is coated on the steel plate and the solder, and the TIG welding process is adopted, the welding current is 130A, the welding voltage is 15V, and the welding speed is 126mm / min. After welding, there is no residue on the steel plate, and there is a colorless transparent solid, forming a thin film, which shows that it has a protective effect. Expansion rate 72.6.

Embodiment 3

[0059] A kind of no-clean welding aid for steel, it comprises the following components by weight percentage:

[0060] Silicone modified acrylic resin 35%,

[0061] Mixed alcohol solvent 30%,

[0062] Active blend ingredients 20%,

[0063] Hydroquinone 15%.

[0064] The preparation method is as follows: first mix the liquid components in the formula evenly, then add the solid components and stir evenly to obtain the product.

[0065] The effect of the embodiment: coating the no-cleaning flux on the steel plate and the solder, adopting the TIG welding process, the welding current is 130A, the welding voltage is 15V, and the welding speed is 126mm / min. After welding, there is no residue on the steel plate, and there is a colorless transparent solid, forming a thin film, which shows that it has a protective effect. In addition, it can be seen that the expansion area is larger and the solder joints are more complete. Expansion rate 87.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com