Patents

Literature

45results about How to "High surface insulation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free and cleaning-free soldering flux for lead-free solder

InactiveCN101733589ALow solid contentLess rosin contentWelding/cutting media/materialsSoldering mediaAntioxidantHigh surface

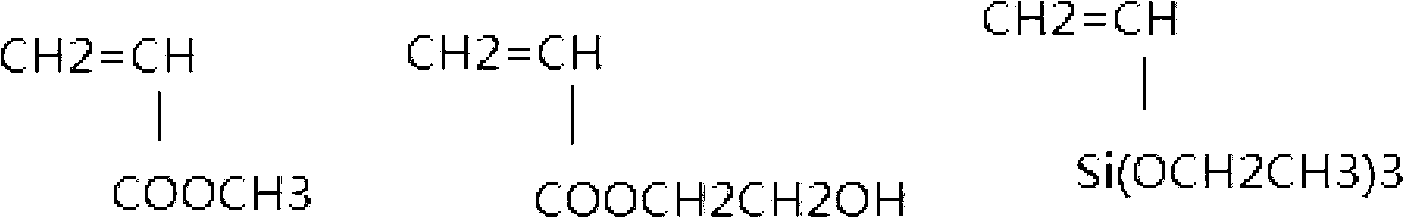

The invention relates to a halogen-free and cleaning-free soldering flux for a lead-free solder, belongs to the technical field of PCB soldering of the electronic industry, and solves the problem that dielectric residues are maintained on a printed board soldered by using the prior soldering flux. The halogen-free and cleaning-free soldering flux for the lead-free solder comprises the following components according to part by weight: 1-5 parts of rosin, 75-90 parts of organic solvent, 1-10 parts of organic acid activating agent, 0.01-1 part of halogen-free surfactant and 0.01-1 part of antioxidant. The halogen-free and cleaning-free soldering flux for the lead-free solder in the invention has low solid content, small rosin content, high surface insulation resistance, and replete and smooth solder joint, is free from corrosion and halogen, has no toxicity and strong penetrating odor, and does not pollute environment basically. Residues are hardly remained on the surface of a PCB soldered by the soldering flux.

Owner:上海一远电子科技有限公司

Halogen-free scaling powder used for lead-free solder paste and preparation method thereof

ActiveCN103008921AHigh surface insulation resistanceNo penetrating corrosionWelding/cutting media/materialsSoldering mediaAntioxidantActive agent

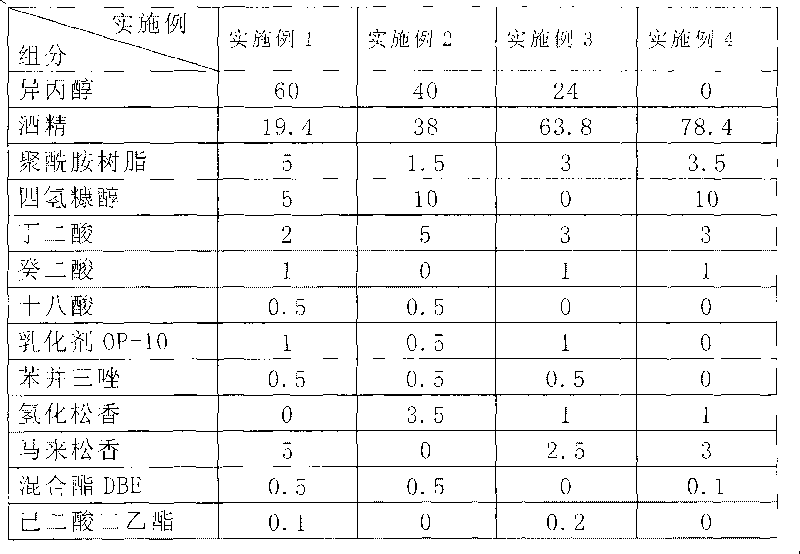

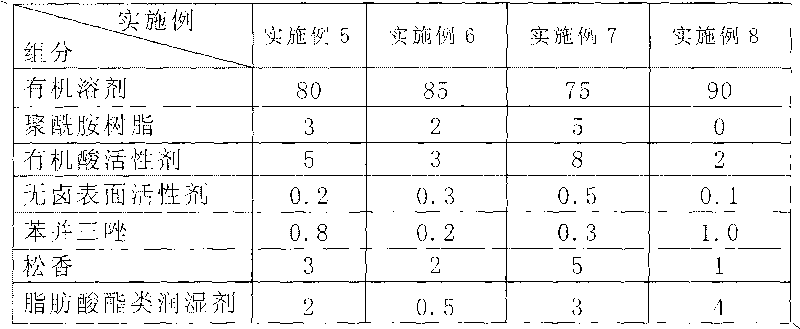

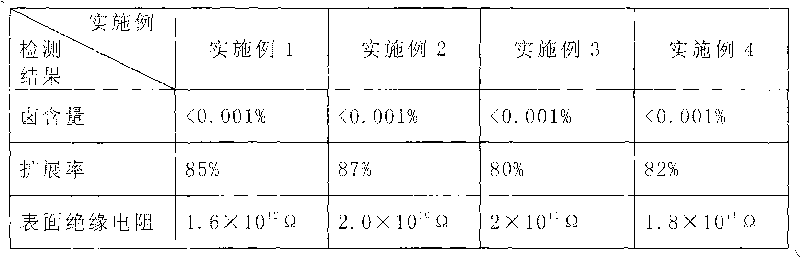

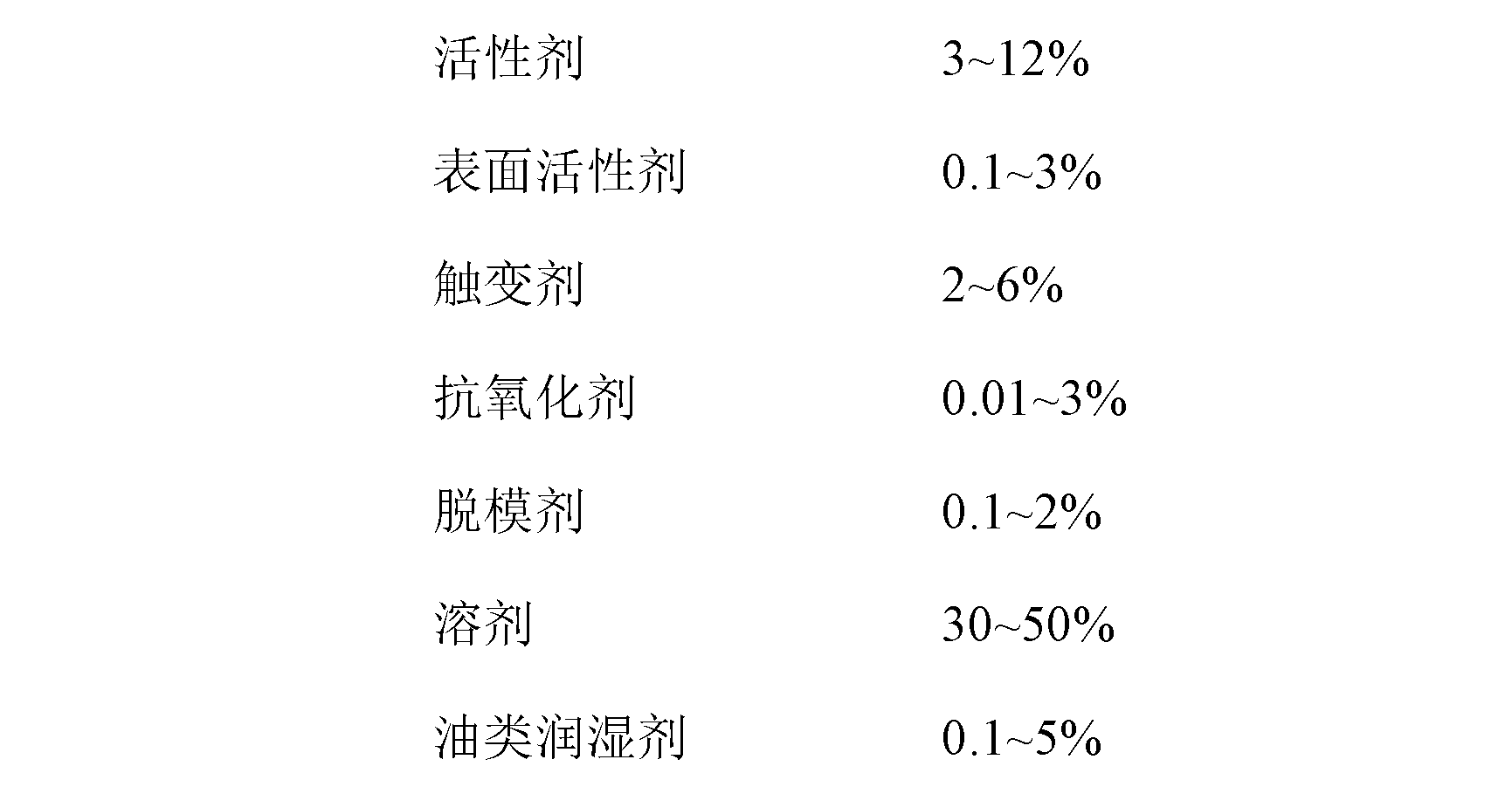

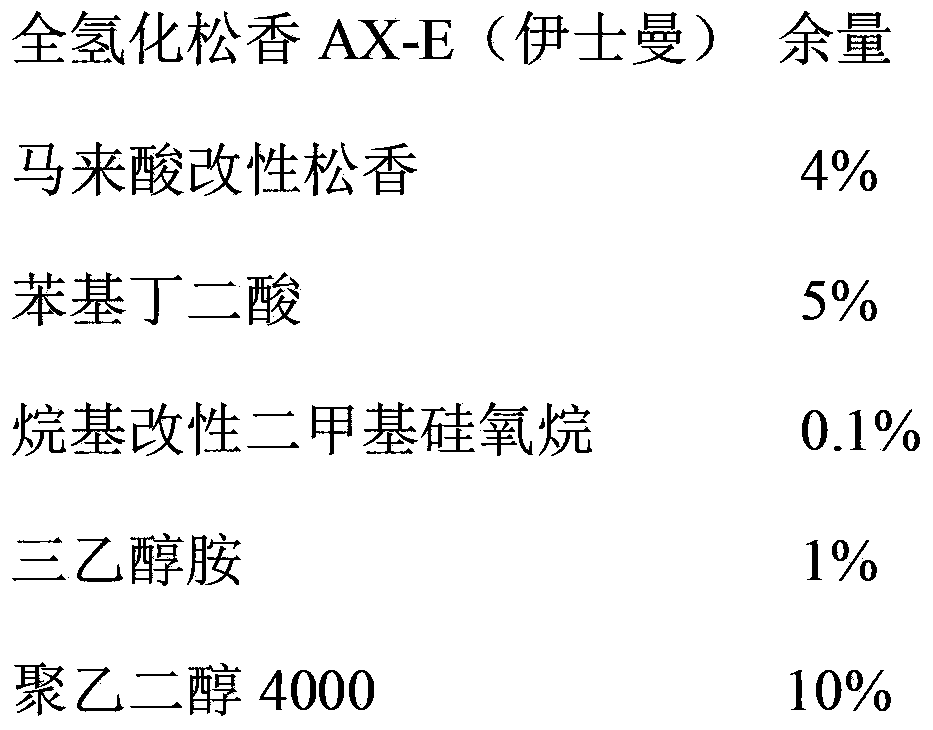

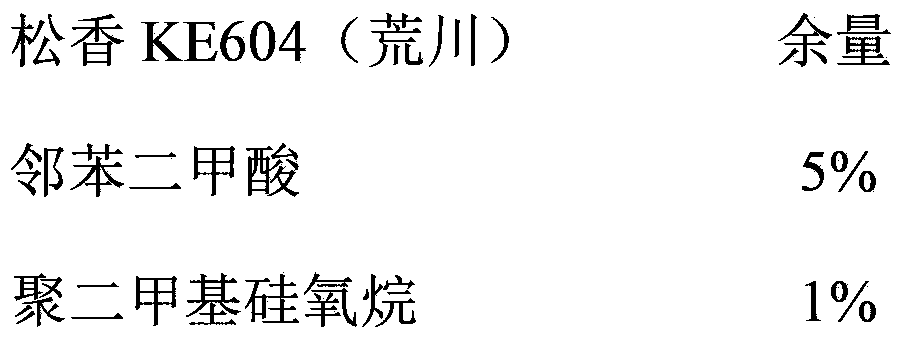

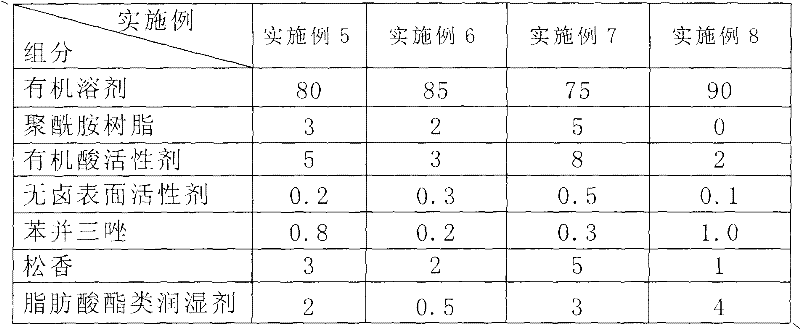

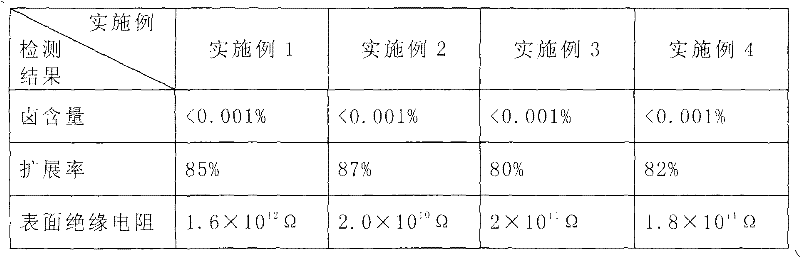

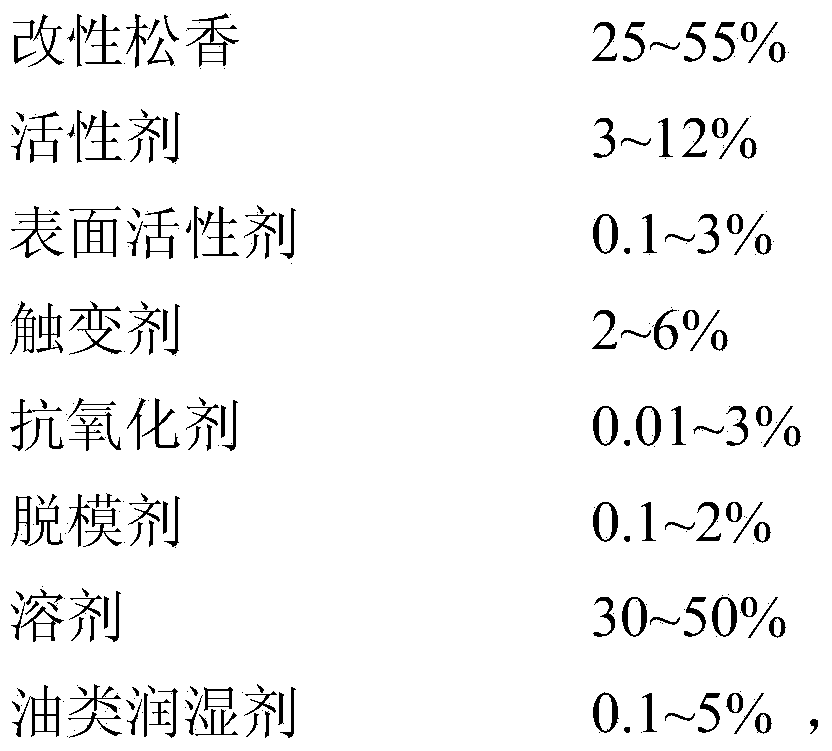

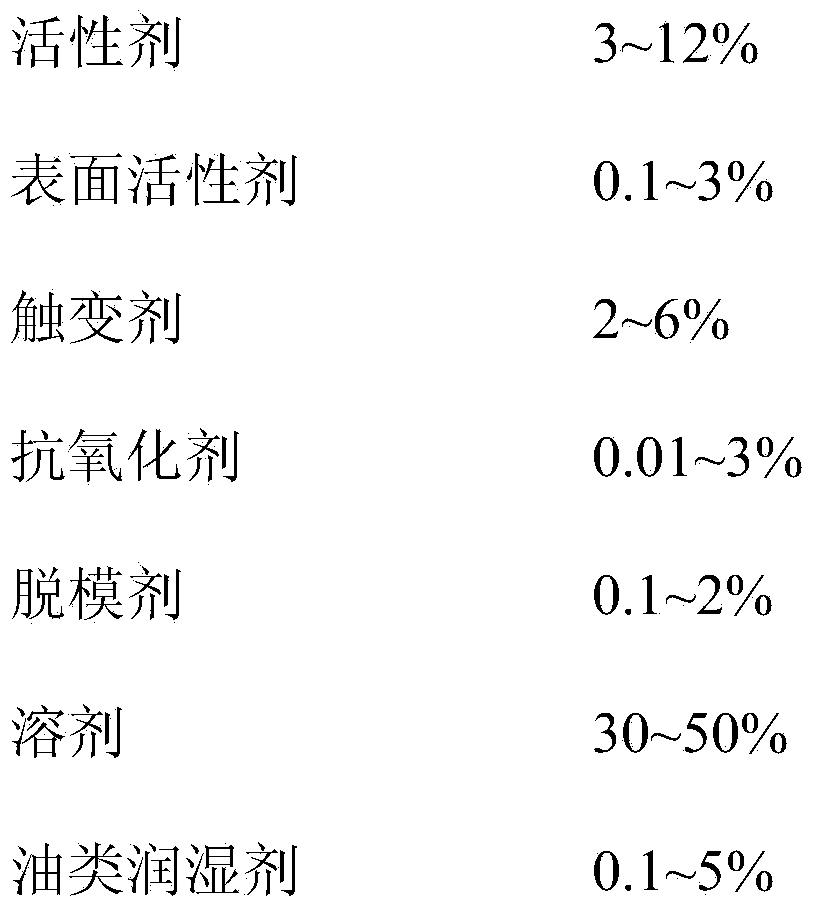

The invention relates to a halogen-free scaling powder used for a lead-free solder paste and a preparation method thereof. The halogen-free scaling powder used for the lead-free solder paste is characterized by being composed of the following components by weight percent: 25-55% of modified rosin, 3-12% of active agent, 0.1-3% of surface active agent, 2-6% of thixotropic agent, 0.01-3% of antioxidant, 0.1-2% of release agent, 30-50% of solvent and 0.1-5% of oil wetting agent, wherein the scaling powder does not contain halogen; the activity of the scaling powder can be obviously improved through adding organic carboxylic acid and hydroxy carboxylic acid as the active agent, and combining the active agent with the surface active agent; and in addition, the oil wetting agent is used, so that a layer of thin continuous oil membrane is enabled to cover the surface of a welding spot in a whole reflow soldering technological process of the solder paste, thereby playing an oxygen insulating function, and greatly improving the expansibility and the wetting property. The solder paste prepared by the scaling powder provided by the invention and a tin-silver-copper lead-free solder has the advantages of being good in printing performance, clean in demoulding, good in solderability and strong in wettability, having no penetrability corrosion in a bronze mirror after soldering, being high in soldering spot reliability and excellent in mechanical property, and capability of satisfying the high reliability requirements of high-end electronic products.

Owner:广东中实金属有限公司 +1

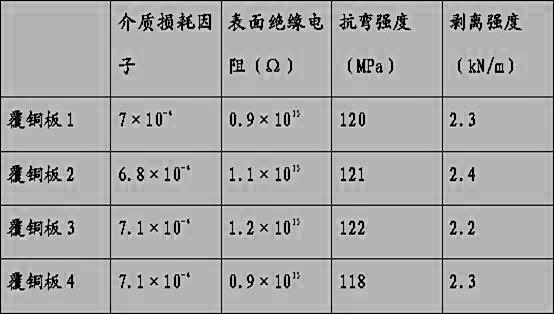

Soldering paste and soldering flux thereof, and preparation methods thereof

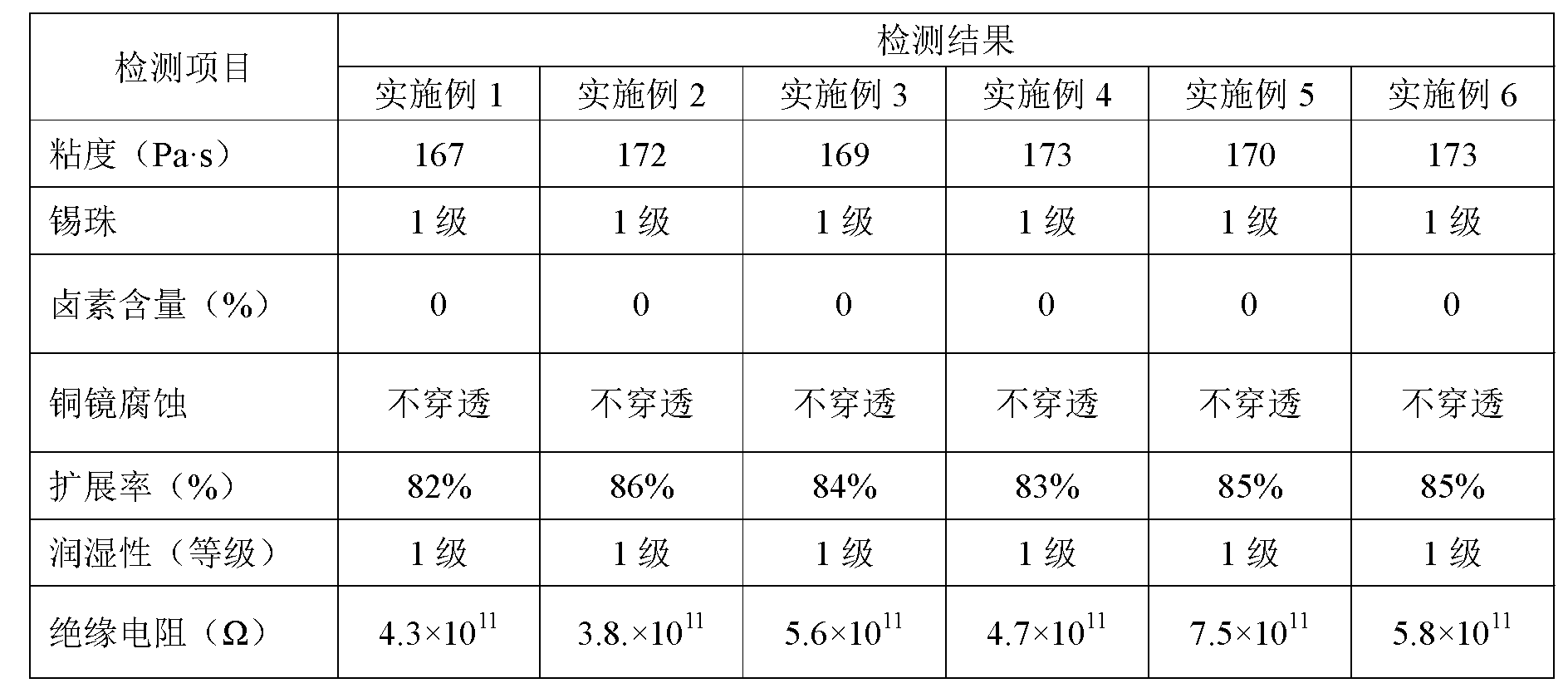

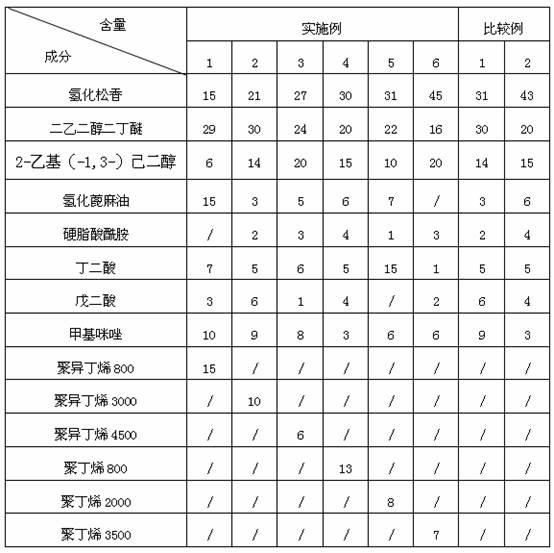

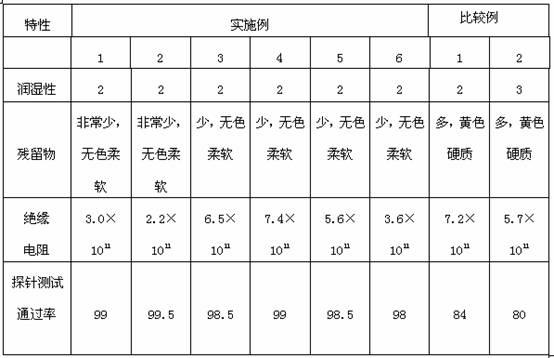

ActiveCN102179644AGood welding performanceHigh surface insulation resistanceWelding/cutting media/materialsSoldering mediaViscous liquidPolybutylene

The invention discloses soldering paste and a soldering flux thereof, and preparation methods thereof. The soldering paste comprises lead-free soldering powder and the soldering flux, wherein the soldering flux comprises the following raw materials in percentage by weight: 6-15 percent of polyisobutene or polybutylene, 3-10 percent of imidazoles compound, 15-45 percent of rosin, 3-15 percent of thixotropic agent, 3-15 percent of active agent and the balance of solvent; therefore, through adding at least one of polyisobutene or polybutylene and replacing partial rosin with the polyisobutene orpolybutylene, on the one hand, the consumption of the rosin can be reduced so that yellow rosin residuals are reduced, on the other hand, the polyisobutene or polybutylene residuals are both colorless and transparent viscous fluid and can soften the harder rosin residuals so that soldering paste residuals are soft, colorless and transparent substances, therefore, the probe test passing rate is greatly improved, and an effective guarantee is provided for the welding quality of electronic products.

Owner:DONGGUAN YONGAN TECH

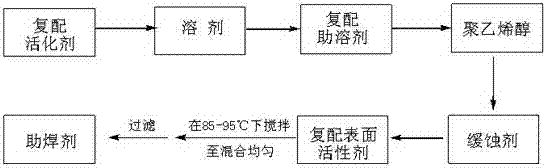

Low-VOC (volatile organic compound) non-cleaning flux comprising complex surfactant and method for preparing same

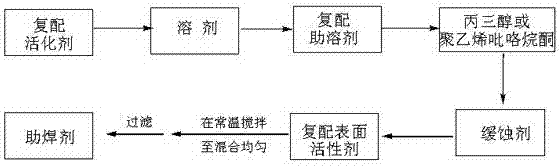

InactiveCN102699576AReduce dosageLow solidsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceActive agent

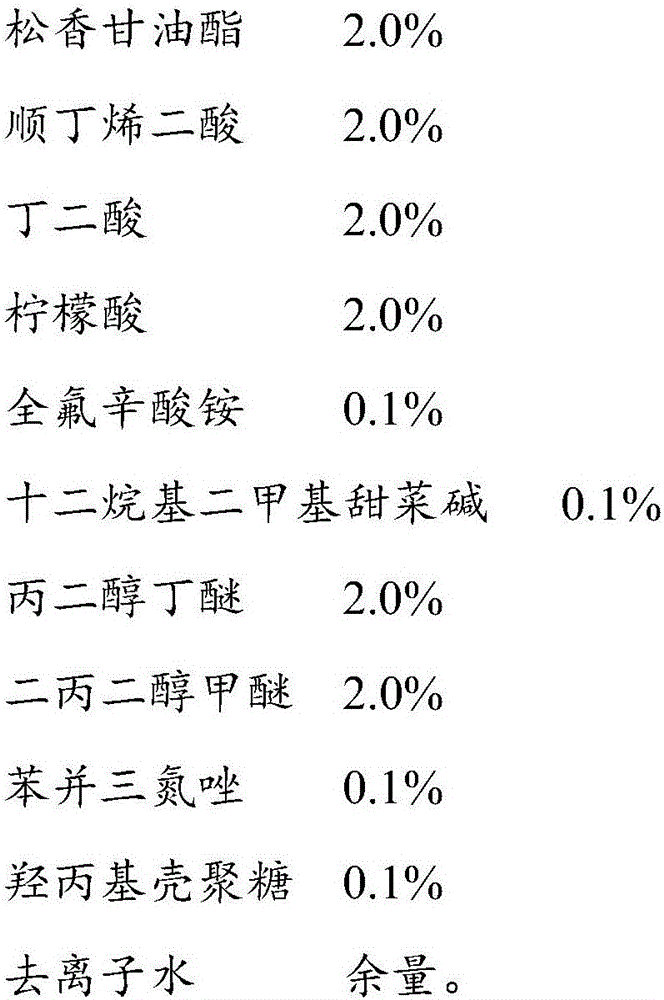

The invention discloses a low-VOC (volatile organic compound) non-cleaning flux comprising a complex surfactant and a method for preparing the flux. The flux can be coated on the welding surface of printed circuit boards in a spraying and dip way, is applicable to the lead-free welding process and mainly comprises deionized water, a complex activating agent, a complex surfactant, a complex co-solvent, a film-forming agent and a corrosion inhibitor. The flux contains less than 4.5% of VOC and less than 2.5% of solid, is environmentally friendly, free from cleaning, nonflammable and not easy to burn, has high insulation resistance and is convenient to store and transport. The process for preparing the flux is simple and suitable for the preparation of a large amount of flux and the industrial production, and the raw materials for preparing the flux are easy to obtain and low in cost.

Owner:GUANGDONG UNIV OF TECH

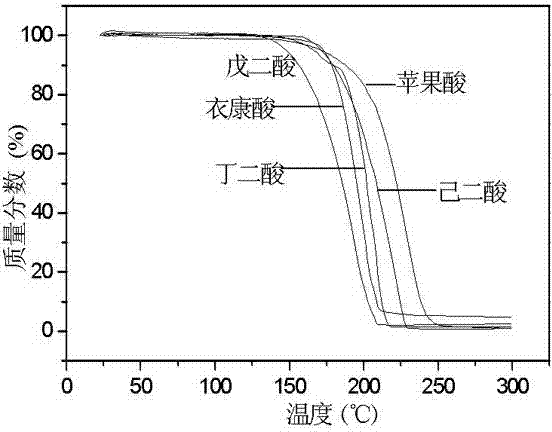

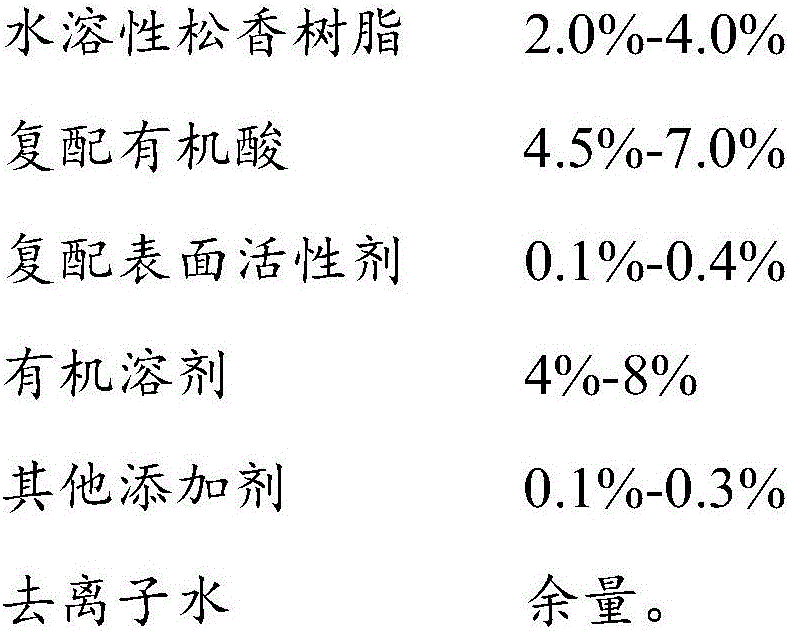

Water-base scaling powder and preparation method and application thereof

ActiveCN106493487AGood weldabilityExcellent tin penetration performanceWelding/cutting media/materialsSoldering mediaWater basedTin

The invention discloses water-base scaling powder and a preparation method and application thereof. The water-base scaling powder is prepared from, by mass, 2.0-4.% of water-soluble rosin resin, 4.5-7.0% of formulated organic acid, 0.1-0.4% of formulated surfactant, 4-8% of organic solvent, 0.1-0.3% of other additives and the balance deionized water. On one hand, the water-base scaling powder is completely suitable for a wave-soldering welding technology, and has the advantages that the weldability is high, the tin penetration property is excellent, postwelding residues are few on the plate surface, the surface insulation resistance is extremely high and the water-base scaling powder is easy to clean; on the other hand, the water-base scaling powder is mild in smell, and in the welding process, the scaling powder is low in smog, high in wettability, free of flashing point and safe to use, and the affinity of the scaling powder is good for water. The preparation method is environmentally friendly and safe, harmless to human body and free of flashing point, the technological conditions are easy to control, and the properties of the prepared water-base scaling powder are stable.

Owner:SHENZHEN UNIBRIGHT TECH

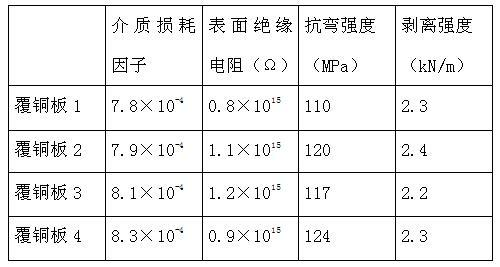

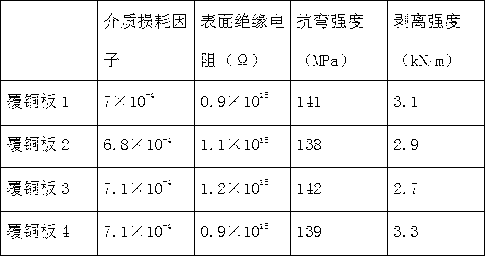

Method for preparing polytetrafluoroethylene copper-clad plate

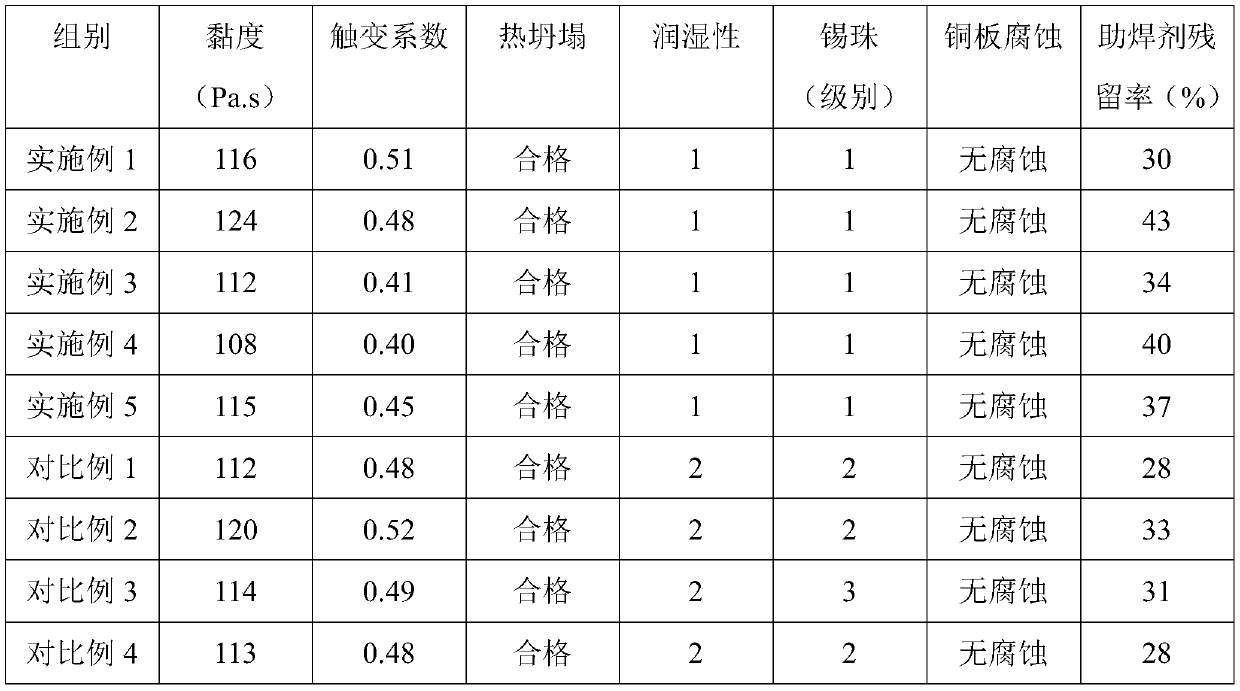

InactiveCN102173172AHigh surface insulation resistanceImprove flexural strengthLamination ancillary operationsLaminationDielectricGlass fiber

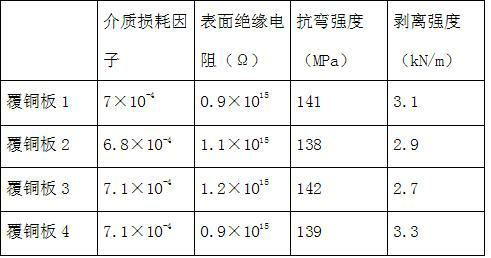

The invention discloses a method for preparing a polytetrafluoroethylene copper-clad plate, which comprises the following steps of: pretreating glass fiber cloth, preparing impregnation liquid, preparing dielectric cloth by impregnating the glass fiber cloth, and cladding copper and aluminum on the dielectric cloth, wherein the step of cladding copper and aluminum on the dielectric cloth comprises the following sub-steps of: a, cutting the dielectric cloth, copper foils and aluminum foils according to required sizes; and b, staking on a template in a sequence of an aluminum foil, a copper foil, the dielectric cloth, a copper foil and an aluminum foil, putting into a hot press, raising the temperature in a mode of wave bands, applying pressure of 6-9MPa when the temperature is between 360 and 380DEG C, cooling, and quenching when the temperature is reduced to be 200DEG C to obtain the modified polytetrafluoroethylene copper-clad plate. The dielectric cloth copper-clad plate has the dielectric loss factor reduced from 1*10<-3> to 7*10<-4>, the surface insulation resistance improved from 1*10<10> to the average 10<15>, the bending strength improved from 80MPa to average 140MPa, and the peel strength from 1.5kN / m to average 3kN / m.

Owner:禹胜林

Preparation method of dielectric cloth for preparing copper-clad plate

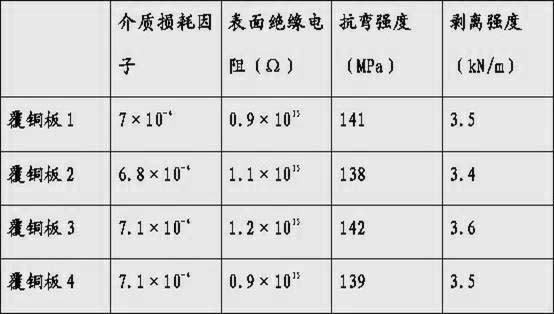

ActiveCN102114453AHigh surface insulation resistanceImprove flexural strengthLiquid surface applicatorsCoatingsGlass fiberPolymer science

The invention discloses a preparation method of dielectric cloth for preparing copper-clad plate. The method comprises the following steps of: a, performing heat treatment and drying on a glass fiber fabric; b, preparing two kinds of impregnation liquid, namely impregnation liquid I and impregnation liquid II; c, impregnating the glass fiber fabric treated in the step a in the impregnation liquid I, and drying in a drying tunnel with the temperature of between 60 and 250 DEG C; d, impregnating the glass fiber fabric treated in the step c in the impregnation liquid II and drying in the drying tunnel with the temperature of between 60 and 250 DEG C; and e, solidifying the glass fiber fabric obtained in the step d in a three-section temperature rise drying channel with the temperature of between 350 and 400 DEG C to obtain the dielectric cloth. The dielectric loss factor of the copper-clad plate prepared from the dielectric cloth is reduced from 1*10<-3> to 7*10<-4>, the surface insulation resistance is improved from 1*10<10> to mean 10<15>, the bending strength is improved from 80MPa to mean 140MPa, and the peeling strength is improved from 1.5kN / m to mean 3.5kN / m.

Owner:广德东风电子有限公司

Low-splash and halogen-free welding agent for tin wires and preparation method thereof

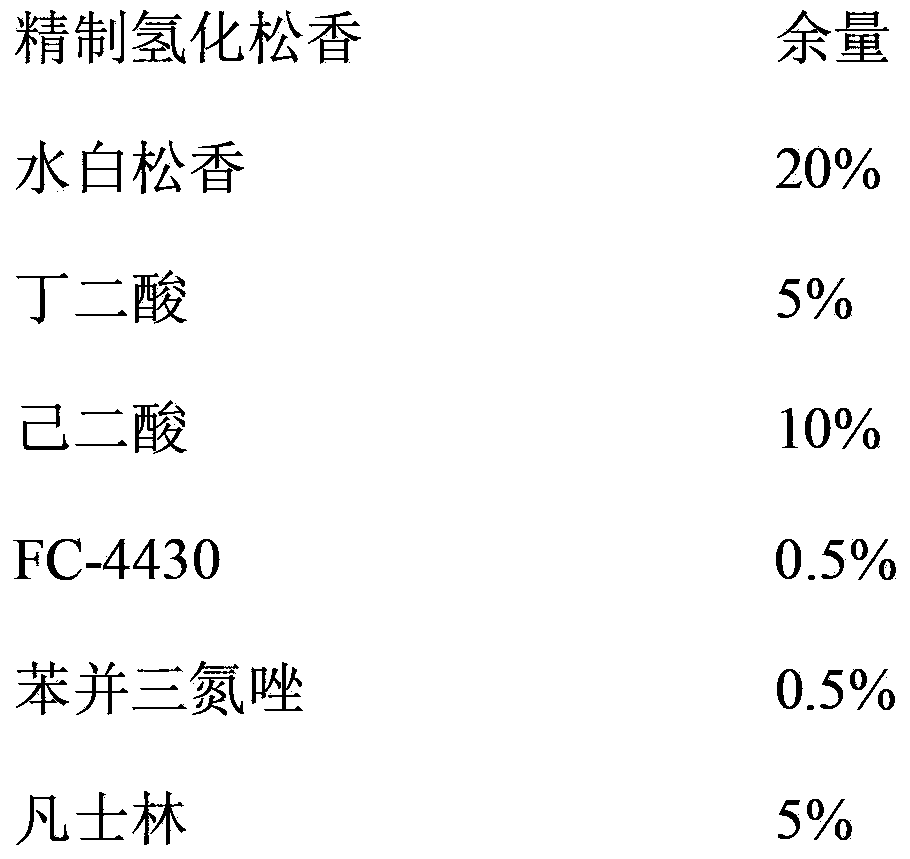

InactiveCN103394824AHigh surface insulation resistanceImprove wettabilityWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention discloses a low-splash and halogen-free welding agent for tin wires and a preparation method thereof. The welding agent is mainly used for agent cores of tin-based alloy tin wires. The welding agent is composed of, by weight, 80-90% of rosin and rosin derivatives, 5-15% of active agents, 0.1-2% of efficient surface active agents, 0.5-2% of corrosion inhibitors and 3-10% of viscosity modifiers. The prepared halogen-free welding agent for the tin wires is needless of any halogen element, is little in splash and smoke when welding is conducted, has high activity, is high in surface insulation resistance, and can be used for preparing tin-lead series tin wires, tin-copper series tin wires and tin-silver-copper series tin wires. The prepared tin wires are good in wetting performance, high in reliability after being welded, and light and full in welding point.

Owner:BEIJING COMPO ADVANCED TECH

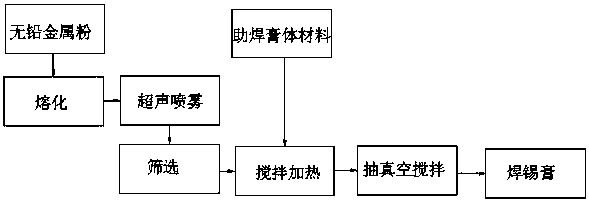

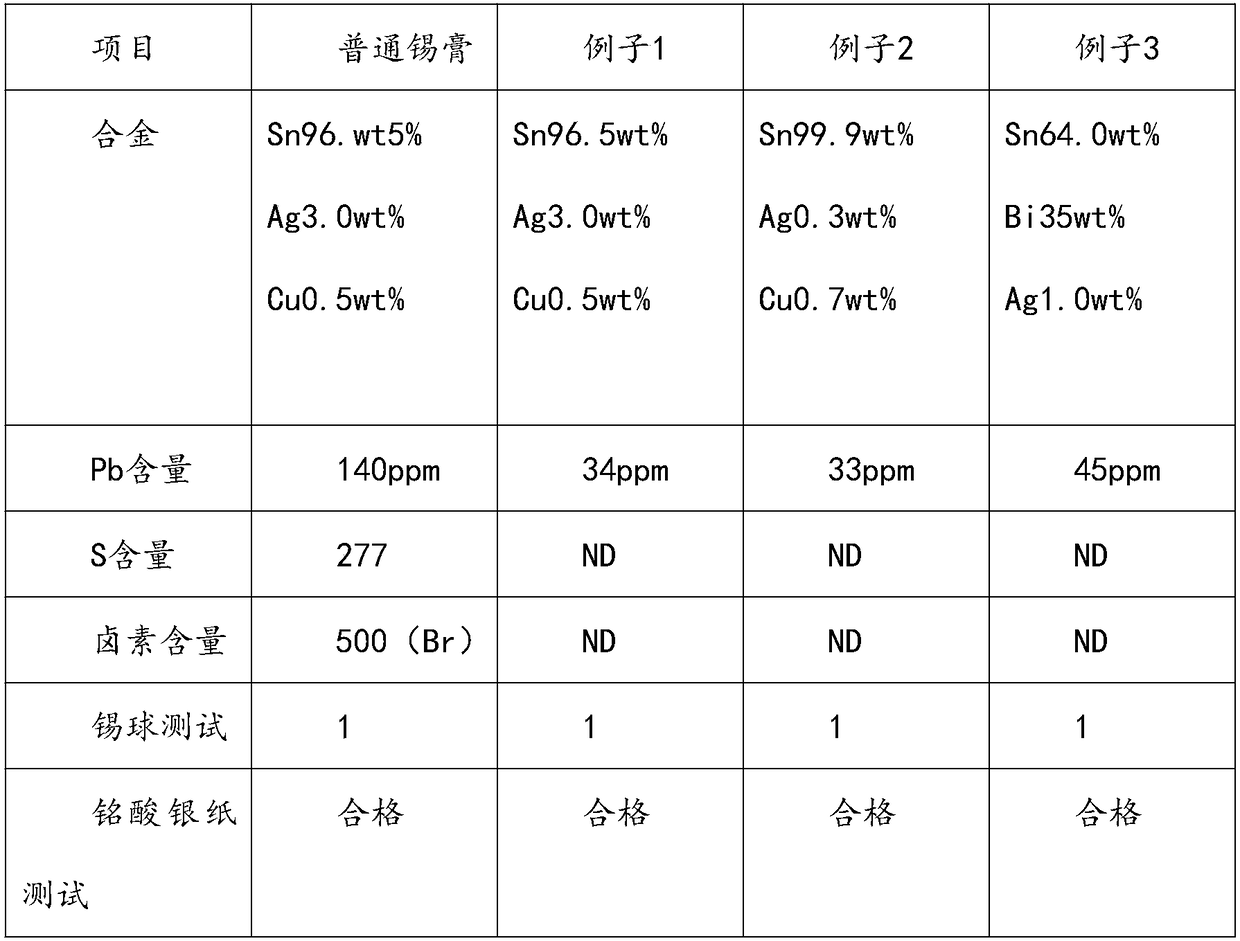

Halogen-free sulfur-free and lead-free solder paste

InactiveCN108161269AGood printabilityImprove solderabilityWelding/cutting media/materialsSoldering mediaActive agentAntioxidant

The invention discloses halogen-free sulfur-free and lead-free solder paste. The halogen-free sulfur-free and lead-free solder paste is solder past formed by mixing 87.5-90.5 wt.% of lead-free metal powder and 9.5-12.5 wt.% of weld-aid paste materials. The halogen-free sulfur-free and lead-free solder paste is characterized in that the lead-free metal powder comprises, by weight, 96.5% of Sn, 3.0%of Ag, and 0.5% of Cu, and the weld-aid paste materials comprise, by weight, 25-55% of modified rosin, 3-12% of an active agent, 0.1-3% of a surface active agent, 2-6% of a thixotropic agent, 0.013%of an antioxidant, 0.1-2% of a release agent, and 30-50% of a solvent. The halogen-free sulfur-free and lead-free solder paste uses organic acid and hydroxy carboxylic acid as the active agent, and oil substances are wetting gent. The solder paste is not only without halogen, high in extension rate, and strong in wettability, but also a bronze mirror has no penetrating corrosion after welded, andthe surface has high insulation resistance. The weld-aid paste and the solder paste made from the lead-free and tin-free alloyed powder have the advantages of high weldability, high welding spot reliability, and good mechanical performance and the like, and the strict requirement of high reliability in modern electronic industry can be met.

Owner:SHENZHEN BANGDA TECH CO LTD

Novel environmental-protection flux

ActiveCN105583550AHigh soldering activityNon-polluting propertiesWelding/cutting media/materialsSoldering mediaTripropylene glycolCarboxylic acid

The invention discloses novel environmental-protection flux which comprises solvent, surfactants and an addition agent. Main ingredients of the flux comprise deionized water, polypropylene glycol 1200, hydroxybenzotriazole, secondary alcohol ethoxylate, tripropylene glycol n-butyl ether, tetraethylene glycol dimethyl ether, succinic acid and an aliphatic dicarboxylic acid mixture. The solvent of the flux is formed by mixing the deionized water of different types, alcohols and ethers. The mixed solvent has a suitable boiling point, more polar groups and moderate viscosity, and endows the flux with high activity. Few residues are generated. The effect of protecting the welding surface is achieved. Different types of the surfactants with different components are used in cooperation, and the surfactants have a good synergistic effect and can improve wettability of welding flux and prevent oxidation. The surface of the flux is clean, and the flux is free from halogen, low in carbon, environmentally friendly and capable of meeting the use requirement of welding.

Owner:苏州柯仕达电子材料有限公司

Steel no-clean welding flux and preparation method thereof

InactiveCN102794581ANo pollution in the processExcellent soldering performanceWelding/cutting media/materialsSoldering mediaAlcoholAcrylic resin

The invention discloses a steel no-clean welding flux. The steel no-clean welding flux is characterized by comprising the following components in weight percent: 10-35% of organic silicon modified acrylic resin, 15-80% of mixed alcohol solvent, 5-30% of active mixed component and 1-20% of benzenediol. The invention further discloses a preparation method for the steel no-clean welding flux. The steel no-clean welding flux is an environment-friendly novel welding flux which is no-clean, good in weld assistant property, large in expansion rate, non-corrosive and residue-free.

Owner:JIANGSU UNIV OF SCI & TECH

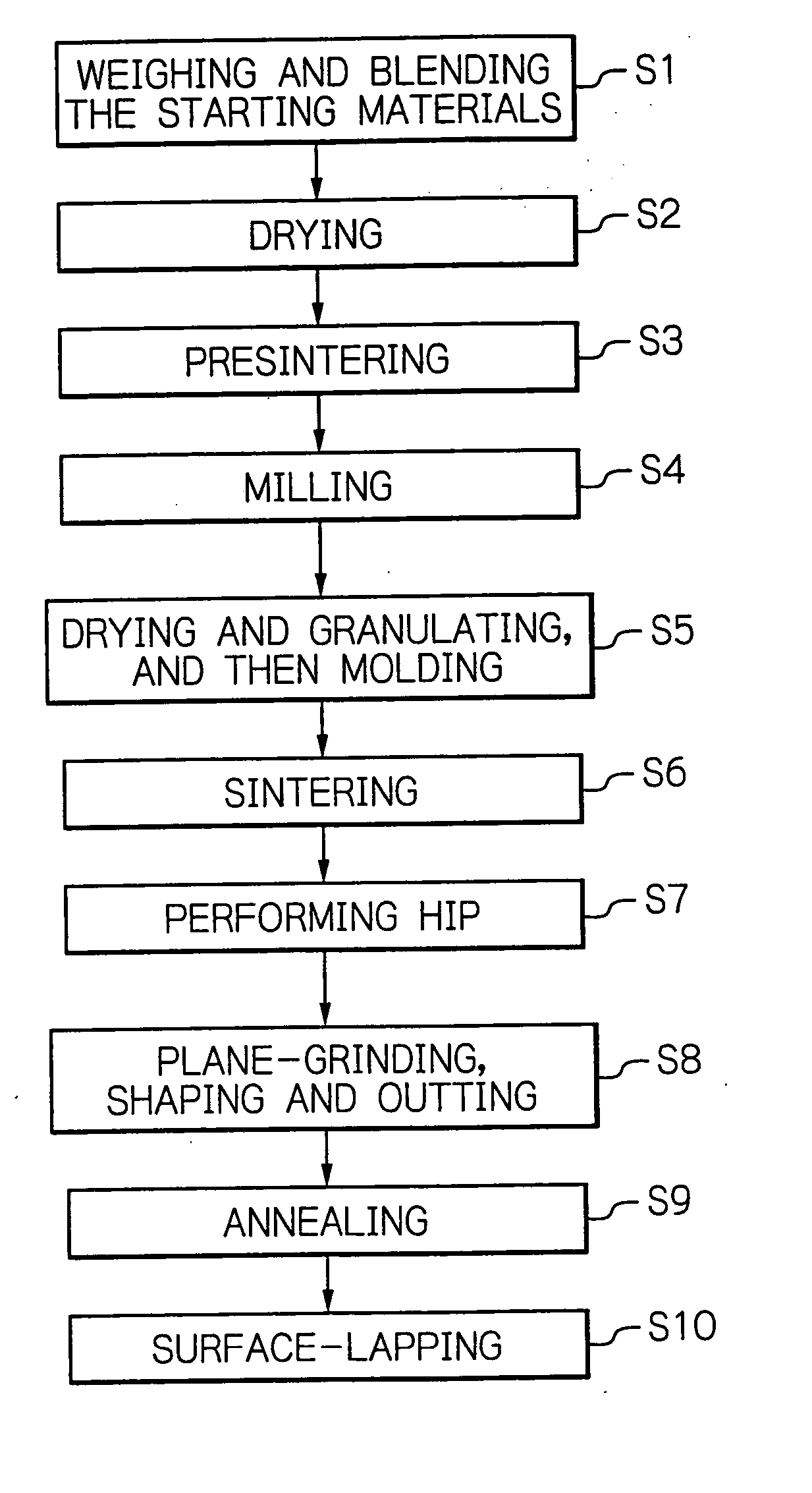

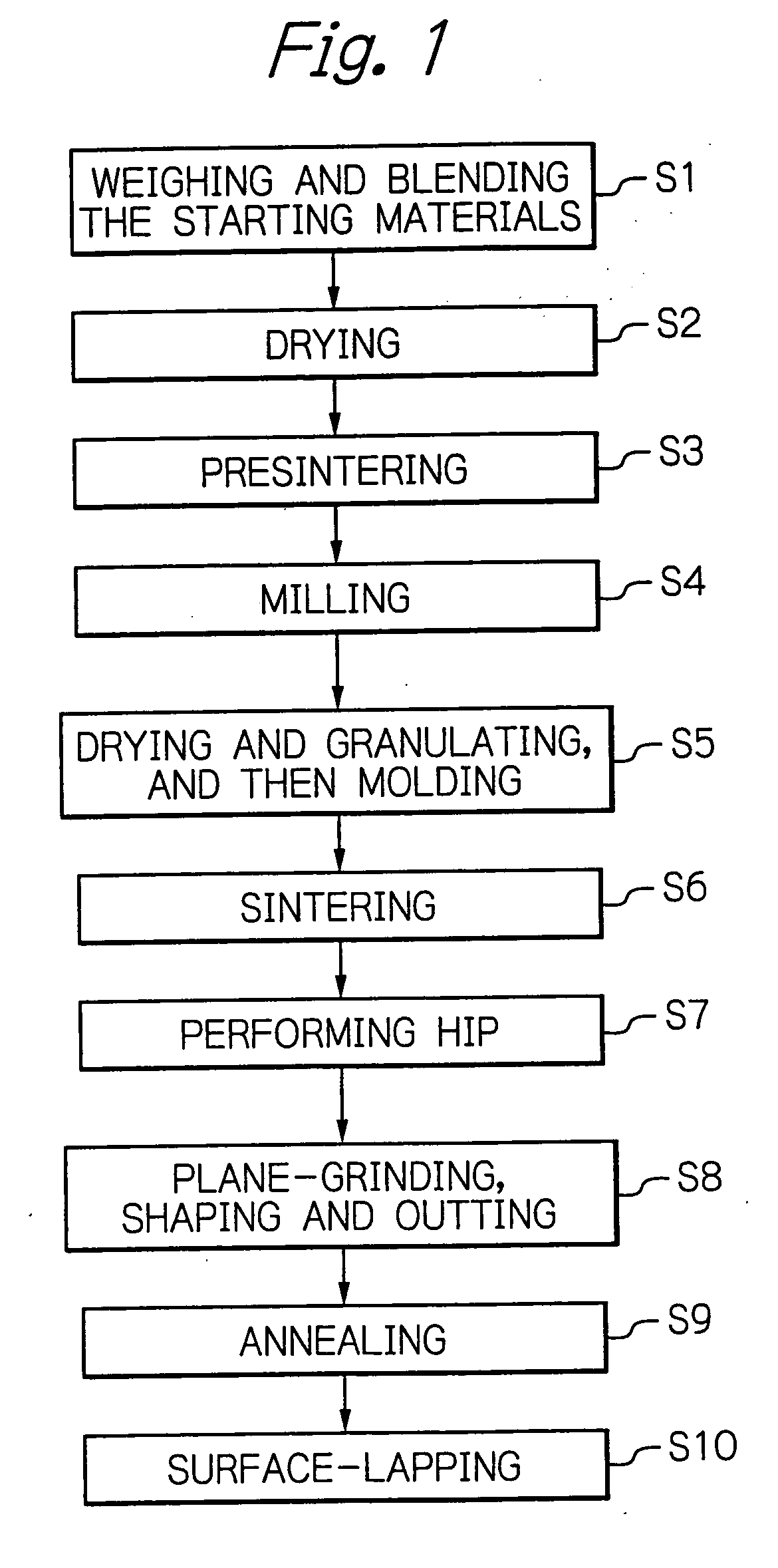

Ferrite substrate for thin-film inductors, thin-film common mode filter using the substrate, thin-film common mode filter array using the substrate and manufacturing method of the substrate

InactiveUS20070077458A1High surface insulation resistanceLess surface-degradationInorganic material magnetismFerroso-ferric oxidesInductorHot isostatic pressing

A ferrite substrate for thin-film inductors is provided by means of blending raw materials to meet a composition of di-iron trioxide (Fe2O3): 40 to 55 molt %, nickel oxide (NiO): 5 to 35 molt, zinc oxide (ZnO): 10 to 40 molt %, and bismuth trioxide (Bi2O3): 150 to 750 ppm, or of Fe2O3: 40 to 55 molt %, NiO: 5 to 35 mol %, ZnO: 10 to 40 mol %, cupric oxide (CuO): 5 to 10 molt, and manganese dioxide (MnO2): 0.5 to 2 molt %, and then molding and sintering the blended material, and applying hot isostatic pressing to the sintered article. A thin-film common mode filter and a thin-film common mode filter array using the ferrite substrate and the manufacturing method of the substrate are also provided.

Owner:TDK CORPARATION

Preparation method of modified polytetrafluoroethylene copper clad plate

InactiveCN102173175AImprove permeabilitySmall discreteLamination ancillary operationsFibre treatmentGlass fiberDielectric loss factor

The invention discloses a preparation method of a modified polytetrafluoroethylene copper clad plate, which comprises the following steps: pretreating glass fiber cloth, impregnating the glass fiber cloth, cladding copper and aluminum on the medium cloth, wherein the impregnation liquid for impregnating the glass fiber cloth is a perfluoro-alkoxy concentrated dispersion liquid modified polytetrafluoroethylene dispersion liquid. The copper clad plate using the medium cloth impregnated in the impregnation liquid has lower dielectric loss factor, higher surface insulation resistance, higher bending strength and higher peel strength.

Owner:禹胜林

Wash-free soldering flux

ActiveCN108581275AAvoid corrosionHigh surface insulation resistanceWelding/cutting media/materialsSoldering mediaSolventInsulation resistance

The invention relates to the technical field of welding material and discloses a wash-free soldering flux. The flux contains the following components in terms of mass percentage: 7.0 to 8.5% of film former, 3.5 to 4.0% of active agent, 0.3 to 0.4% of surfactant, 0.20 to 0.25% of corrosion inhibitor, 0.45 to 0.50% of additive and the remaining is solvent. The above components are uniformly mixed, heated to 70 to 80 DEG C, and undergo reflux stirring reaction for 2 to 2.5 hours, cooled to 20 to 25 DEG C, and filtered to obtain the product. The wash-free soldering flux does not contain a halide active agent, has strong ability to remove metal oxides, has low spatter value and is basically non-corrosive to the device, and has good soldering quality. It has a very high surface insulation resistance, is wash-free after welding, saves equipment and solvents, and is environmentally friendly.

Owner:五河县俊宝钢结构有限公司

Preparation method of platinized copper powder lead-free soldering paste

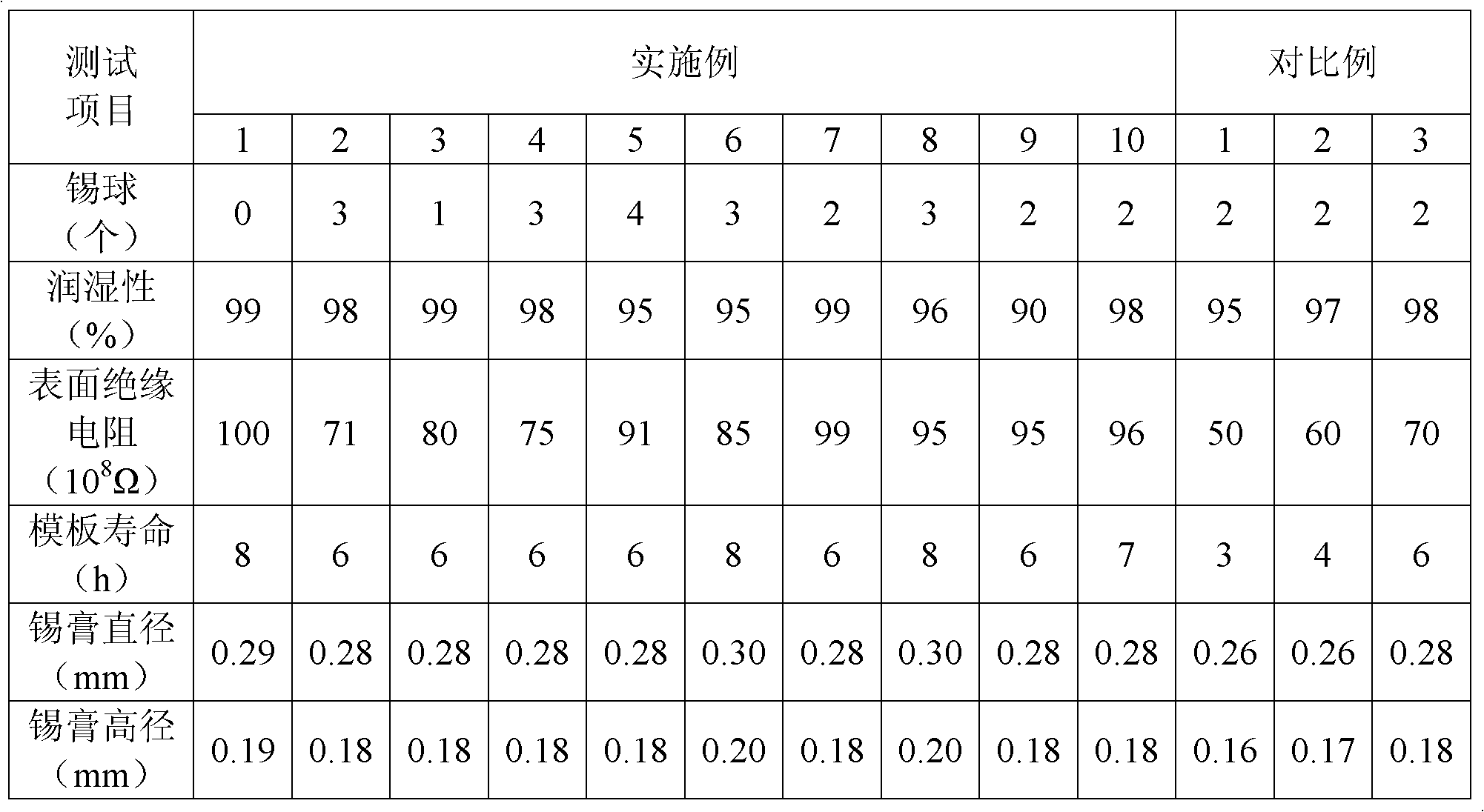

InactiveCN105750763AHigh surface insulation resistanceExtended service lifeWelding/cutting media/materialsSoldering mediaInsulation resistanceRosin

The invention relates to a preparation method of a platinized copper powder lead-free soldering paste, and belongs to the technical field of material preparation.The method comprises the steps that copper powder with no oxide layer and a stannic chloride solution are mixed and stirred, the mixture is centrifuged, lower-layer precipitation is washed and dried to obtain activated copper powder, the activated copper powder and matter such as absolute ethyl alcohol are mixed and stirred, a platinum nitrate solution is dropwise added into the mixture, centrifugation is carried out, lower-layer precipitation is washed and dried to obtain platinized copper powder for use, rosin and matter such as ammonium cholate are mixed and heated to prepare scaling powder for use, the platinized copper powder and tin powder are mixed, the mixture is pressed into a blank, the blank is heated, cooled, subjected to ball milling and screened and then is mixed with the platinized copper powder and calcined, and therefore the lead-free soldering paste can be prepared.The surface insulation resistance of the prepared lead-free soldering paste is high and reaches 95*108-105*108 Ohm; by using the platinized copper powder lead-free soldering paste, the service life of a template is prolonged and can reach up to 9h.

Owner:袁春华

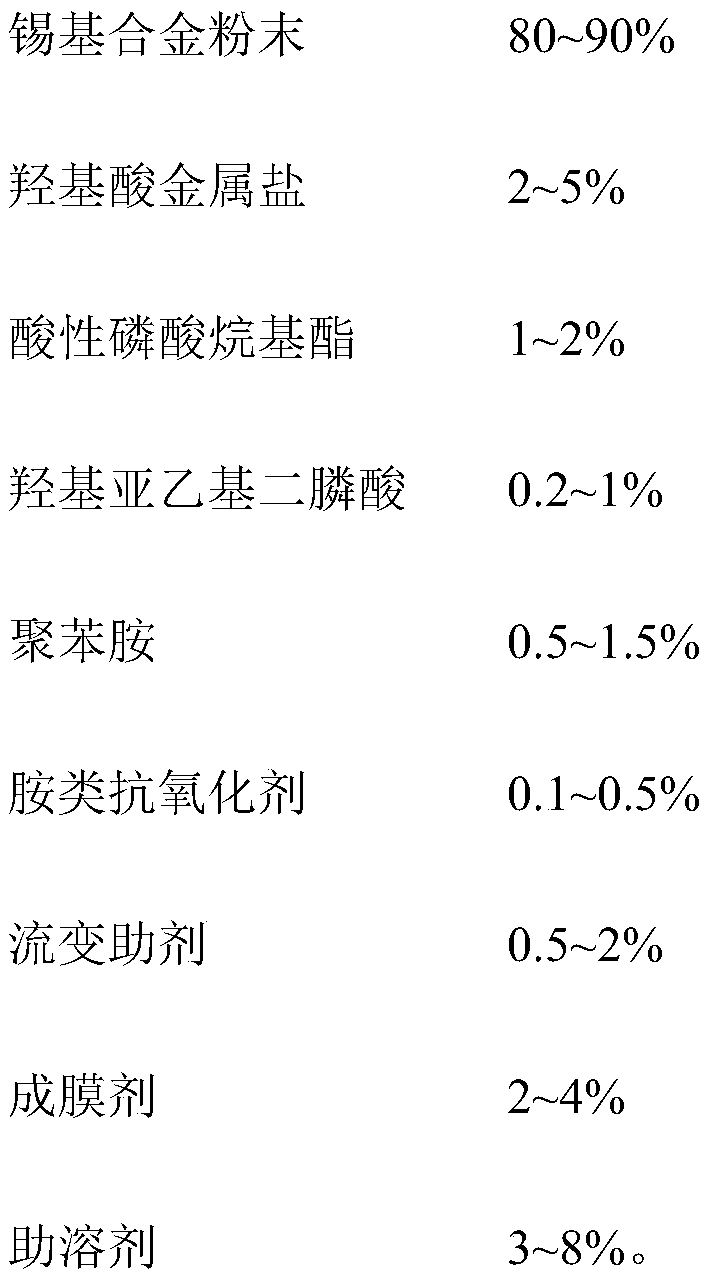

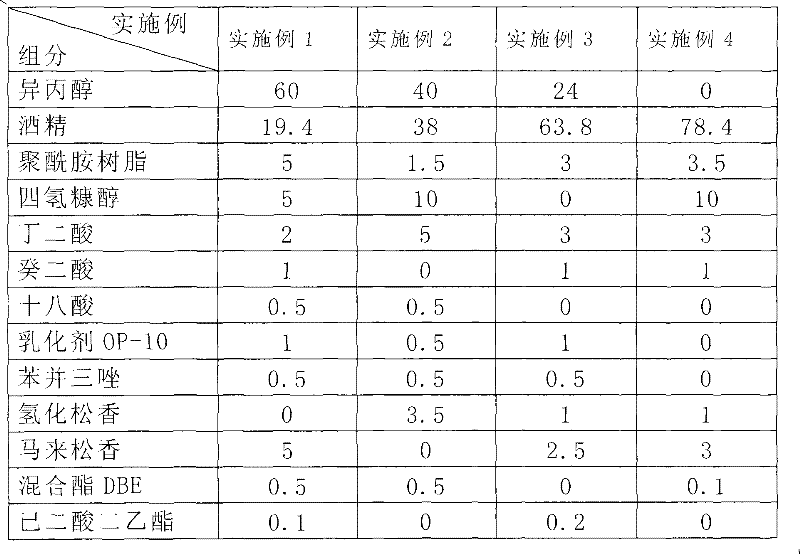

High-performance halogen-free and lead-free soldering paste and preparation method thereof

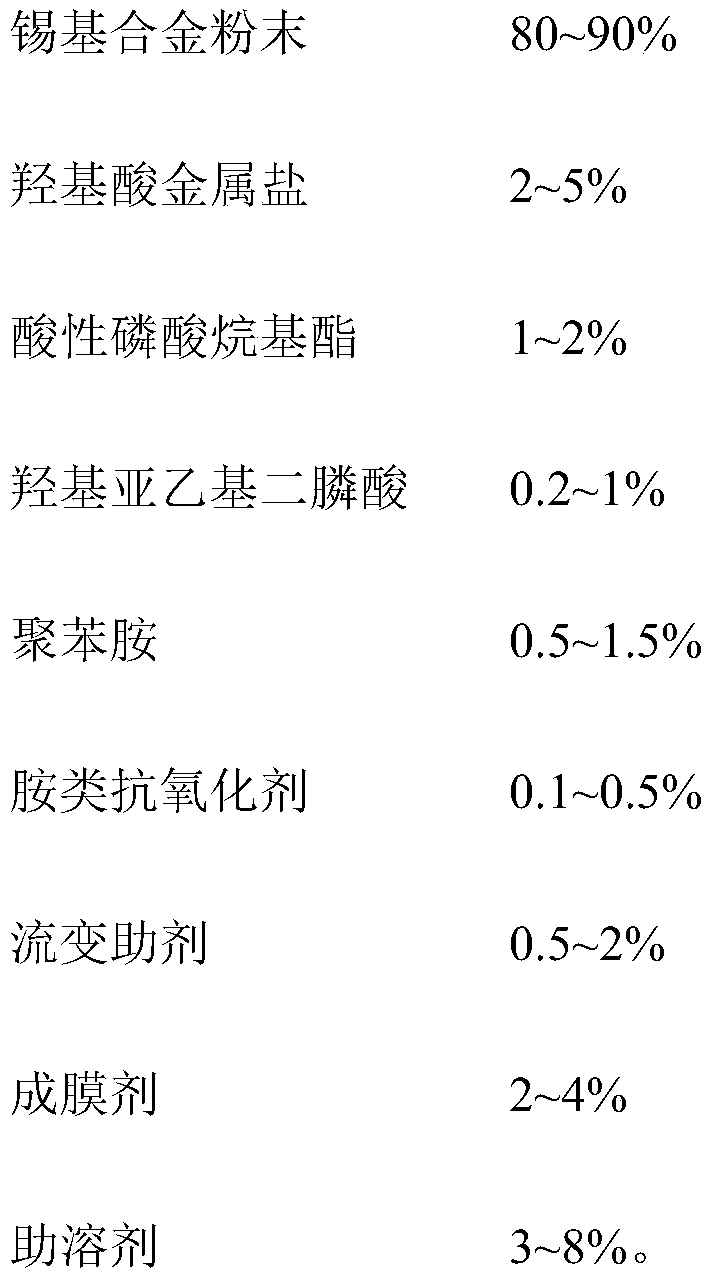

ActiveCN110202293AAvoid blackeningPromote wettingWelding/cutting media/materialsSoldering mediaAlkyl phosphateSoldering

The invention discloses high-performance halogen-free and lead-free soldering paste and a preparation method thereof. The halogen-free and lead-free soldering paste comprises, by mass percent, 80-90%of tin base alloy powder, 2-5% of hydroxy acid metal salt, 1-2% of acid alkyl phosphates, 0.2-1% of (1-hydroxyethylene) diphosphonic acid, 0.5-1.5% of polyaniline, 0.1-0.5% of amine antioxidants, 0.5-2% of rheological additives, 2-4% of film formers and 3-8% of hydrotropic agents. The soldering paste has high activity, low corrosivity and a few residues, the common problems such as periphery blackening after welding, too many tin beads and too many residues of current low temperature lead-free soldering paste can be well solved, the defective rate of printing is greatly reduced, and the reliability of welding is improved.

Owner:深圳市可为锡业有限公司

Impregnation liquid used in copper clad plate preparation process

InactiveCN102167873AHigh surface insulation resistanceImprove flexural strengthGlass/slag layered productsMetal layered productsGlass fiberDielectric loss factor

The invention discloses an impregnation liquid used in a copper clad plate preparation process, which comprises a first impregnation liquid and a second impregnation liquid, wherein the first impregnation liquid is formed by stirring and mixing a perfluoro-alkoxy concentrated dispersion and distilled water in a volume ratio of 1:1.4; and the second impregnation liquid is formed by evenly mixing a perfluoro-alkoxy concentrated dispersion, a polytetrafluoroethylene concentrated dispersion and distilled water in a volume ratio of 1:12:6. The dielectric loss factor of the copper clad plate with glass fiber cloth impregnated by the impregnation liquid disclosed by the invention is reduced from 1*<-3> to 7*10<-4>, the surface insulation resistance is raised from 1*10<10> to 10<15> on average, the bending strength is raised from 80 MPa to 120 MPa on average, and the peel strength is raised from 1.5kN / m to 2.3kN / m on average.

Owner:吴江市东风电子有限公司

Halogen-free and cleaning-free soldering flux for lead-free solder

InactiveCN101733589BLow solid contentLess rosin contentWelding/cutting media/materialsSoldering mediaAntioxidantHigh surface

The invention relates to a halogen-free and cleaning-free soldering flux for a lead-free solder, belongs to the technical field of PCB soldering of the electronic industry, and solves the problem that dielectric residues are maintained on a printed board soldered by using the prior soldering flux. The halogen-free and cleaning-free soldering flux for the lead-free solder comprises the following components according to part by weight: 1-5 parts of rosin, 75-90 parts of organic solvent, 1-10 parts of organic acid activating agent, 0.01-1 part of halogen-free surfactant and 0.01-1 part of antioxidant. The halogen-free and cleaning-free soldering flux for the lead-free solder in the invention has low solid content, small rosin content, high surface insulation resistance, and replete and smooth solder joint, is free from corrosion and halogen, has no toxicity and strong penetrating odor, and does not pollute environment basically. Residues are hardly remained on the surface of a PCB soldered by the soldering flux.

Owner:上海一远电子科技有限公司

Halogen-free scaling powder used for lead-free solder paste and preparation method thereof

ActiveCN103008921BHigh surface insulation resistanceNo penetrating corrosionWelding/cutting media/materialsSoldering mediaActive agentAntioxidant

The invention relates to a halogen-free scaling powder used for a lead-free solder paste and a preparation method thereof. The halogen-free scaling powder used for the lead-free solder paste is characterized by being composed of the following components by weight percent: 25-55% of modified rosin, 3-12% of active agent, 0.1-3% of surface active agent, 2-6% of thixotropic agent, 0.01-3% of antioxidant, 0.1-2% of release agent, 30-50% of solvent and 0.1-5% of oil wetting agent, wherein the scaling powder does not contain halogen; the activity of the scaling powder can be obviously improved through adding organic carboxylic acid and hydroxy carboxylic acid as the active agent, and combining the active agent with the surface active agent; and in addition, the oil wetting agent is used, so that a layer of thin continuous oil membrane is enabled to cover the surface of a welding spot in a whole reflow soldering technological process of the solder paste, thereby playing an oxygen insulating function, and greatly improving the expansibility and the wetting property. The solder paste prepared by the scaling powder provided by the invention and a tin-silver-copper lead-free solder has the advantages of being good in printing performance, clean in demoulding, good in solderability and strong in wettability, having no penetrability corrosion in a bronze mirror after soldering, being high in soldering spot reliability and excellent in mechanical property, and capability of satisfying the high reliability requirements of high-end electronic products.

Owner:广东中实金属有限公司 +1

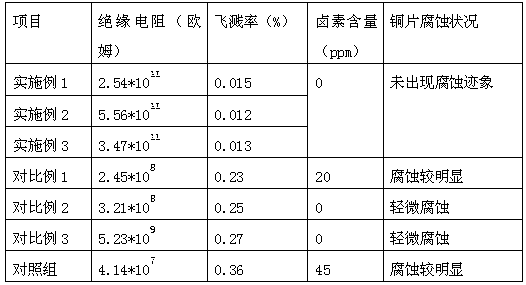

Welding-aiding agent for circuit board welding and preparation method thereof

ActiveCN107262972AHigh activityLess corrosiveWelding/cutting media/materialsSoldering mediaOXALIC ACID DIHYDRATEPotassium carbonate

The invention discloses a welding-aiding agent for circuit board welding. The welding-aiding agent comprises the following components of, by weight, 20-30 parts of cerium oxide, 2-10 parts of oxalic acid, 3-8 parts of butyl acetate, 1-3 parts of alundum powder, 1-5 parts of a fluorocarbon surfactant, 2-15 parts of potassium carbonate, 2-12 parts of sodium carbonate, 5-18 parts of hydroxy organic acid, 3-9 parts of formic-acid-rich ester, 2-10 parts of alkylol amine, 3-9 parts of glycerin monostearate, 0.5-2.5 parts of pib succinimide and 3-10 parts of antioxygen. The manner that the hydroxy organic acid which is high in activity, less in residue and low in corrosion and the alkylol amine are compounded into an active substance compound assisted by and matched with a fluorocarbon surfactant, the antioxygen and glycerin monostearate and the like is adopted, the environmentally-friendly welding-aiding agent for circuit board welding is prepared, the welding-aiding agent is low in residue, small in corrosion, liable to be washed and free of lead and halogen, and the welding-aiding agent has good suitability, inoxidizability, rheological property and stability with lead-free tin welding micro powder.

Owner:盐城市贝加尔电子材料有限公司

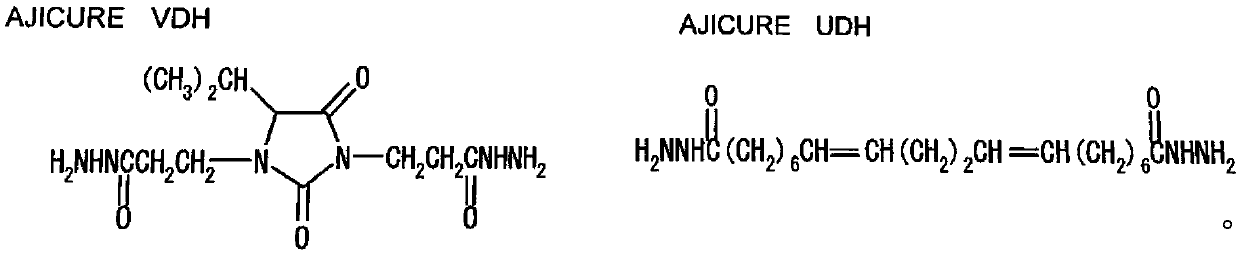

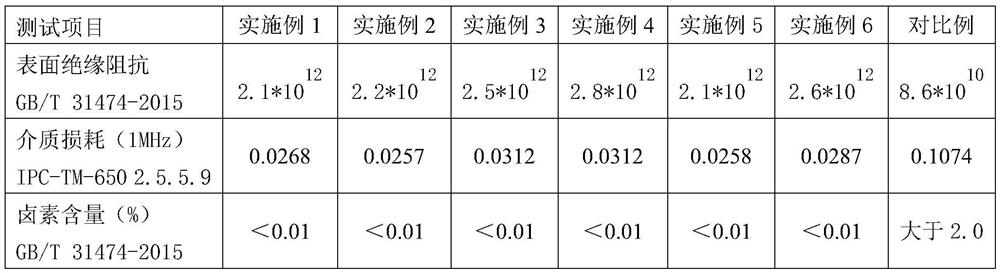

Underfill adhesive with high surface insulation resistance and preparation method thereof

Belonging to the technical field of filling adhesive preparation, the invention particularly relates to an underfill adhesive with high surface insulation resistance and a preparation method thereof.The underfill adhesive disclosed by the invention does not adopt any flexibilizer or plasticizer, has the characteristics of low storage modulus, high glass-transition temperature, low hygroscopicity,good high and low temperature resistance, high surface insulation resistance under the conditions of high temperature and high humidity, etc., and ensures long-term reliable use of micro-sized densely packaged components in various environments.

Owner:YANTAI DARBOND TECH

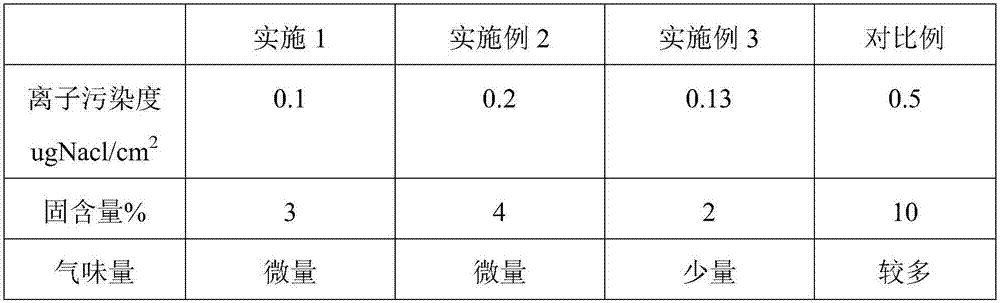

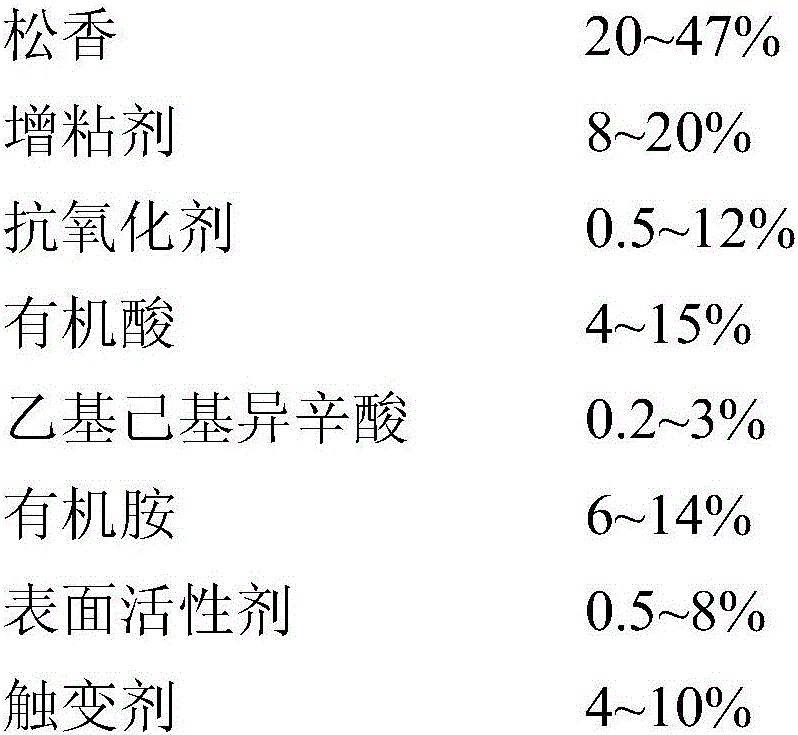

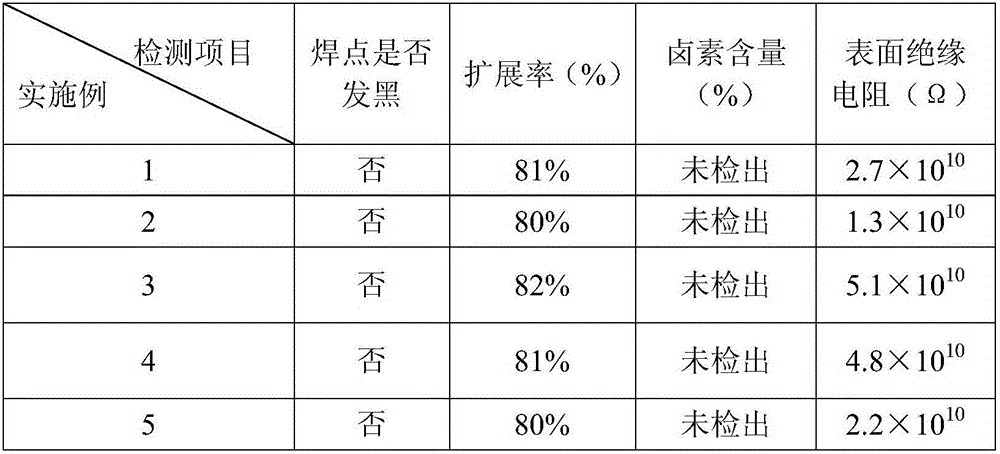

A kind of halogen-free flux for tin-bismuth series lead-free solder paste and preparation method thereof

ActiveCN104858571BSolder joints are less corrosiveHigh surface insulation resistanceWelding/cutting media/materialsSoldering mediaAntioxidantSolvent

The invention provides a halogen-free soldering agent for tin bismuth system unleaded tin paste and a preparation method thereof. The halogen-free soldering agent for the tin bismuth system unleaded tin paste consists of 20-47% of rosin, 8-20% of thickening agent, 0.5-12% of antioxidant, 4-15% of organic acid, 0.2-3% of ethylhexyl isocaprylic acid, 6-14% of organic amine, 0.5-8% of surface active agent,4-10% of thixotropic agent and the balance solvent. By optimizing selection of an active system of the soldering agent, the halogen-free soldering agent for the tin bismuth system unleaded tin paste enables the tin paste prepared from the halogen-free soldering agent for the tin bismuth system unleaded tin paste and tin bismuth system unleaded tin powder to not only contain no halogen element such as fluorine, chlorine, bromine, iodine and astatine, but also have good welding ability in soldering, and then generates full and bright soldering spots, does not generate black oxides, and is high in surface insulation resistance after the soldering, and is specially suitable for assembly welding of electronic parts and components, which require low soldering temperature.

Owner:深圳市同方电子新材料有限公司 +1

Lead-free solder tin wire applicable to drag soldering technology

InactiveCN107498208AEvenly distributedPrevent splashWelding/cutting media/materialsSoldering mediaOrganic solventBoiling point

The invention discloses a lead-free solder tin wire applicable to the drag soldering technology. The lead-free solder tin wire comprises the following components in percentage by weight: 96.0%-98.5% of lead-free solder and 4.0%-1.5% of scaling powder, wherein the scaling powder comprises the following components in percentage by weight: 1-4% of an organic solvent with a low boiling point, 4-10% of an activator, 0-0.5% of corrosion inhibitor and the balance of modified rosin. The lead-free solder tin wire can rapidly weld a component on a base plate, is high in tin breaking performance, does not cause the continuous tin phenomenon during the continuous application process, greatly improves the working efficiency, lowers the cost, does not contain the forbidden substances including RoHS2.0, REACH and the like, does not cause harm to the environment and meets the environmental protection requirement.

Owner:广东中实金属有限公司

Method for preparing polytetrafluoroethylene copper-clad plate

InactiveCN102173172BHigh surface insulation resistanceImprove flexural strengthLamination ancillary operationsLaminationDielectricGlass fiber

The invention discloses a method for preparing a polytetrafluoroethylene copper-clad plate, which comprises the following steps of: pretreating glass fiber cloth, preparing impregnation liquid, preparing dielectric cloth by impregnating the glass fiber cloth, and cladding copper and aluminum on the dielectric cloth, wherein the step of cladding copper and aluminum on the dielectric cloth comprises the following sub-steps of: a, cutting the dielectric cloth, copper foils and aluminum foils according to required sizes; and b, staking on a template in a sequence of an aluminum foil, a copper foil, the dielectric cloth, a copper foil and an aluminum foil, putting into a hot press, raising the temperature in a mode of wave bands, applying pressure of 6-9MPa when the temperature is between 360 and 380DEG C, cooling, and quenching when the temperature is reduced to be 200DEG C to obtain the modified polytetrafluoroethylene copper-clad plate. The dielectric cloth copper-clad plate has the dielectric loss factor reduced from 1*10<-3> to 7*10<-4>, the surface insulation resistance improved from 1*10<10> to the average 10<15>, the bending strength improved from 80MPa to average 140MPa, and the peel strength from 1.5kN / m to average 3kN / m.

Owner:禹胜林

Welding flux agent of solder with no lead and free from cleaning

ActiveCN1290662CDesign scienceReasonable preparationWelding/cutting media/materialsSoldering mediaOrganic acidBoiling point

A non-lead solder flux without cleaning contains organic acid as activating agent, improved resin, surfactant, high-boiling-point solvent, wetting agent and isopropanol or deionized water instead of VOC solvent.

Owner:深圳市唯特偶新材料股份有限公司

A kind of high-performance halogen-free lead-free solder paste and preparation method thereof

ActiveCN110202293BHigh activityEfficient removalWelding/cutting media/materialsSoldering mediaPhosphoric acidSolder paste

The invention discloses a high-performance halogen-free lead-free solder paste and a preparation method thereof. The halogen-free lead-free solder paste includes the following components in mass percentage: 80-90% of tin-based alloy powder, 2-5% of metal salt of hydroxy acid, 1-2% of acidic alkyl phosphate, hydroxyethylene 0.2-1% of diphosphonic acid, 0.5-1.5% of polyaniline, 0.1-0.5% of amine antioxidant, 0.5-2% of rheological additive, 2-4% of film forming agent and 3-8% of cosolvent. The solder paste of the present invention has high activity, low corrosiveness, and less residue, which can well solve the common problems of current low-temperature lead-free solder paste such as blackening of the periphery after soldering, a large number of tin beads, and a large number of residues, and can greatly reduce Reduce the defective rate of printing and improve the reliability of welding.

Owner:深圳市可为锡业有限公司

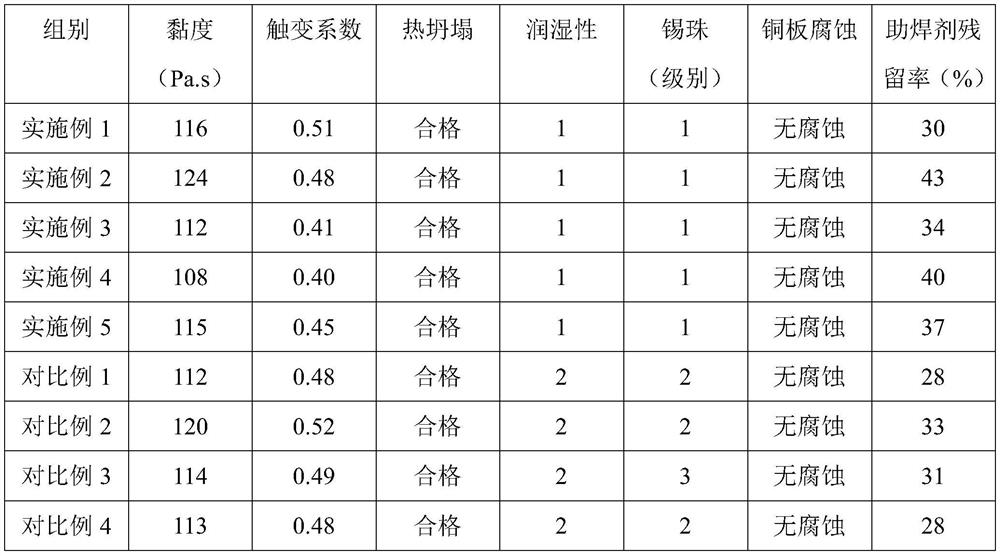

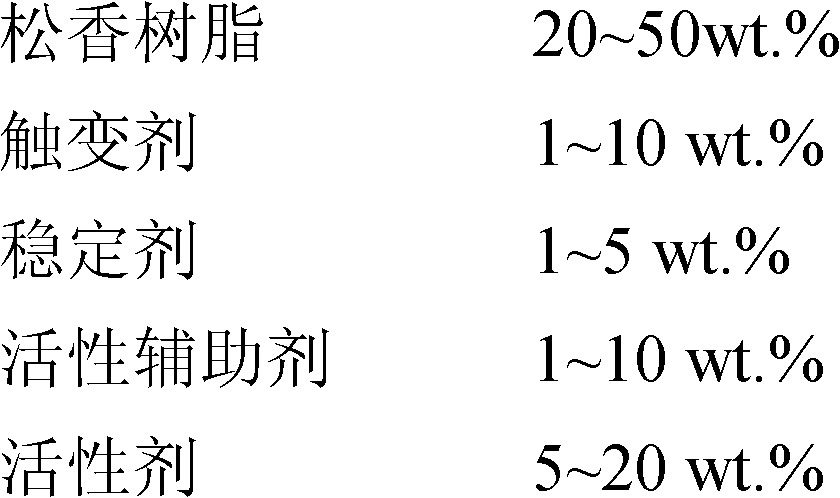

Low-silver lead-free flux paste and preparation method thereof

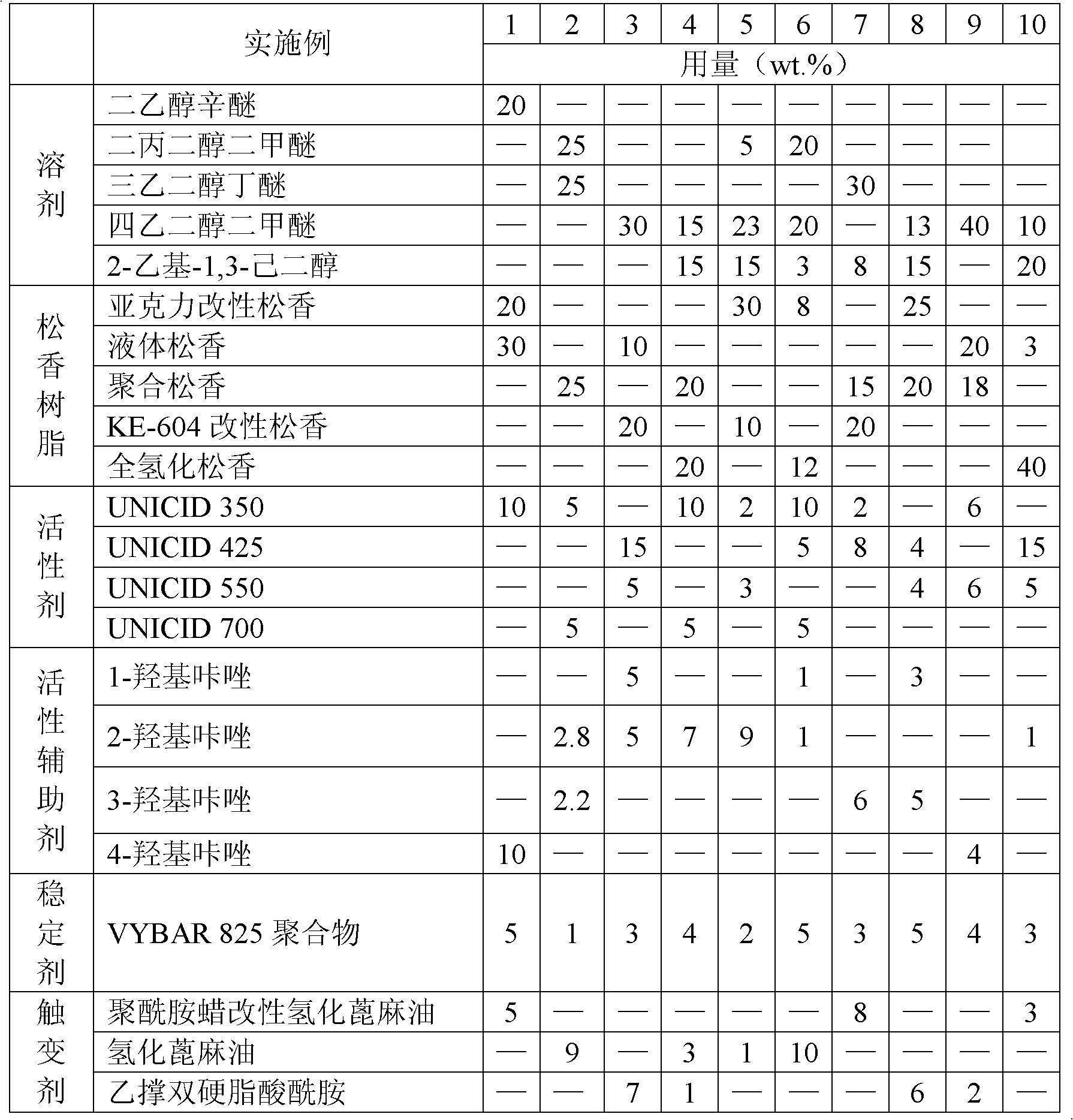

ActiveCN102489898BEasy to prepareNot easy to form a short circuitWelding/cutting media/materialsSoldering mediaAdjuvantActive agent

The invention discloses a low-silver lead-free flux paste, which comprises abietic resin 20-50wt.%, a thixotropic agent 1-10 wt.%, a stabilizing agent 1-5 wt.%, active adjuvant 1-10 wt.%, an active agent 5-20 wt.%, and the balance solvent. The stabilizing agent is poly-alpha-olefin with ultrahigh branches, the number-average molecular weight is 2800-2900, the distribution index of degree of polymerization is 1.6-1.7, and the viscosity measured at the temperature of under 37.8 DEG C according to American Society for Testing and Materials (MSTM) D-3236 is 530cP. The active agent is long-chain linear carboxylic acid which contains 26-50 carbon atoms, the acid value is 61-115mgKOH / g, and the number-average molecular weight is 390-720. The active adjuvant is hydroxy carbazole. The flux paste and lead-free flux paste with low-silver lead-free materials can be prepared into the lead-free flux paste which has small solder balls, good welding effects and high surface insulating resistance so that a short circuit does not happen to a circuit board after welding, wettability is good, welding spots are full, and welding effects are good. In addition, corrosivity is small, and service life of a template is greatly improved. Besides, the preparation method of the flux paste is simple and easy to implement in industries in a large-scale mode.

Owner:昆山成利焊锡制造有限公司

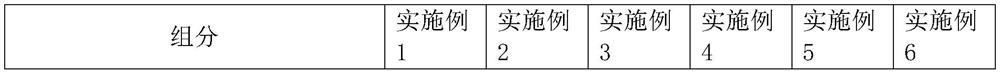

A kind of solder paste with low dielectric loss and high reliability and preparation method thereof

ActiveCN111590235BImprove adhesionExcellent dielectric propertiesWelding/cutting media/materialsSoldering mediaIndiumOrganosolv

The invention discloses a solder paste with low dielectric loss and high reliability and a preparation method thereof. The technical solution is: 85.4-91.6wt% solder alloy powder, 8.4-14.6wt% flux, wherein the tin powder includes 2.5-4.1 wt% silver, 0.5‑2.6wt% copper, 6.5‑8.7wt% indium, 3.1‑4.7wt% zinc, 0.11‑0.25wt% molybdenum, 0.09‑0.19wt% vanadium, 0.08‑0.21wt% lutetium and the rest of tin, the flux includes 35.4‑42.6wt% rosin, 8.4‑14.6wt% organic acid, 1.8‑4.6wt% organic amine, 3.3‑6.1wt% thixotropic agent, 3.5‑6.8 wt% of thermosetting resin, 1.4-3.2wt% of antioxidant and the balance of organic solvent, the thermosetting resin is composed of 48-56wt% of cyanate resin and 44-52wt% of epoxy resin. There will be no corrosive residue on the board, and the prepared solder paste has low residue, low dielectric loss, high surface insulation resistance after soldering, and high reliability solder paste, which is suitable for use in 5G-related application scenarios.

Owner:中山翰华锡业有限公司

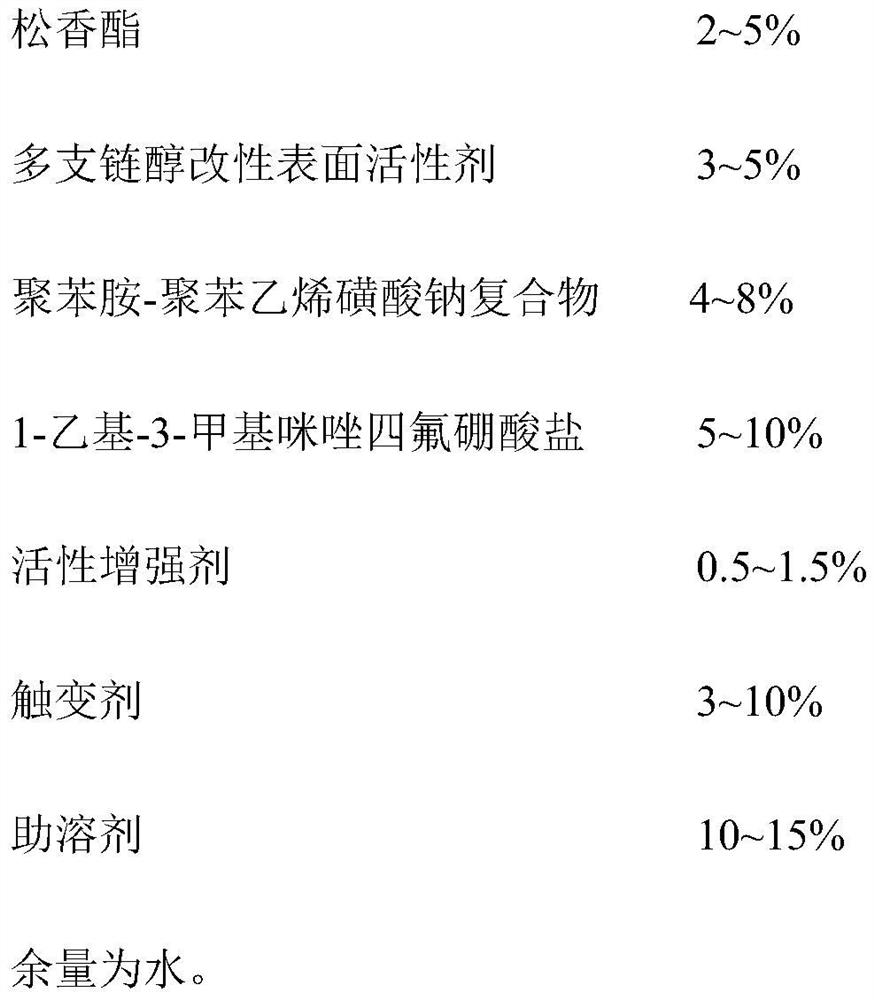

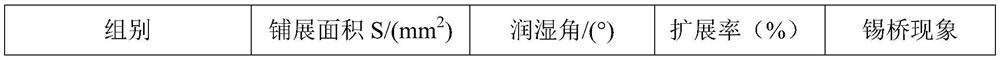

A kind of flux and preparation method thereof

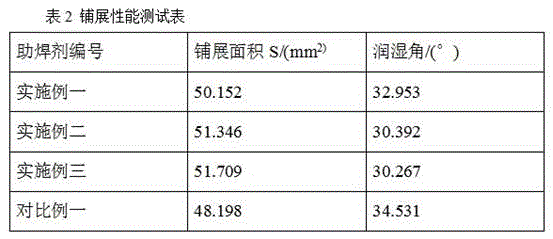

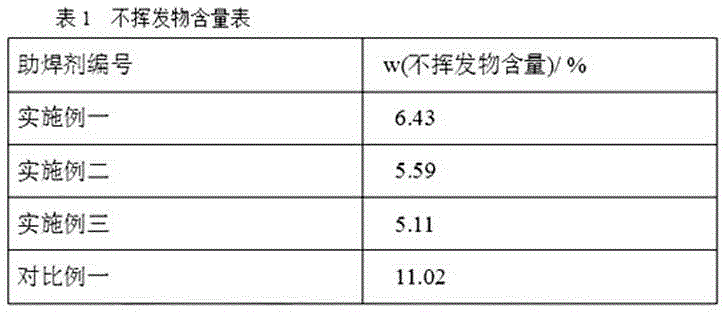

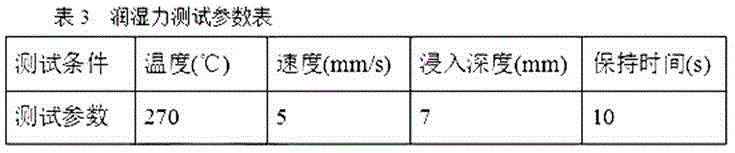

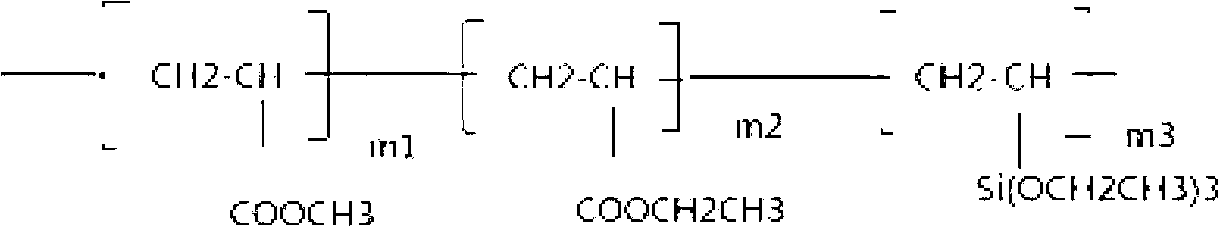

ActiveCN110328467BImprove wetting rateLarge spreading areaWelding/cutting media/materialsSoldering mediaTetrafluoroborateActive agent

The invention discloses a flux and a preparation method thereof. The flux includes the following components in terms of mass percentage: rosin ester 2-5%, polybranched alcohol modified surfactant 3-5%, polyaniline-polystyrene sodium sulfonate compound 4-8% , 5-10% of 1-ethyl-3-methylimidazolium tetrafluoroborate, 0.5-1.5% of activity enhancer, 3-10% of thixotropic agent, 10-15% of co-solvent, and the balance is water. The flux overcomes the defect that the existing water-based no-cleaning flux cannot inhibit the formation of solder bridges, and has the characteristics of high soldering activity, strong solderability, less residue, and high surface insulation resistance. Low corrosion, good storage stability, good applicability to lead-free soldering, meet the requirements of no-cleaning.

Owner:浙江强力控股有限公司

Lead-free solder environmental-protection scaling powder used for soldering capacitor with film adhered on surface

ActiveCN101745760BHigh activityReduce surface tensionWelding/cutting media/materialsSoldering mediaHigh surfaceSurface-active agents

The invention discloses a lead-free solder environmental-protection scaling powder used for soldering a capacitor with a film adhered on a surface, which contains 4-17 percent of rosin and derivates thereof, 3-9 percent of organic acid activating agent, 1.5-3.5 percent of diethylamine hydrochloride and / or cyclohexylamine hydrochloride, 0.3-0.7 percent of surface active agent and 70-90 percent of dissolvant. Firstly, the rosin and the derivate thereof, the organic acid activating agent and the diethylamine hydrochloride and / or the cyclohexylamine hydrochloride are added to the dissolvant to bestirred evenly; then the surface active agent is added to be continuously stirred evenly; and finally, the solution is filtered by gauze so as to remove solid impurities, and finally, light yellow clear and transparent liquid is obtained. The solder has the advantages of strong wetting power and superior solderability and can improve the soldering performance of the lead-free solder; the solderedsoldering tin has even spreading, bright and smooth surface, high surface insulation resistance and superior electrical property and meets the environmental protection requirements.

Owner:XIAMEN FARATRONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com