Halogen-free sulfur-free and lead-free solder paste

A sulfur lead-free solder paste and solder paste technology, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem that the solder paste on the pad is not full enough, it is easy to enter the blood and accumulate, and the stencil is not released from the mold. Clean and other problems, to achieve the effect of strong wettability, high expansion rate, no penetrating corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

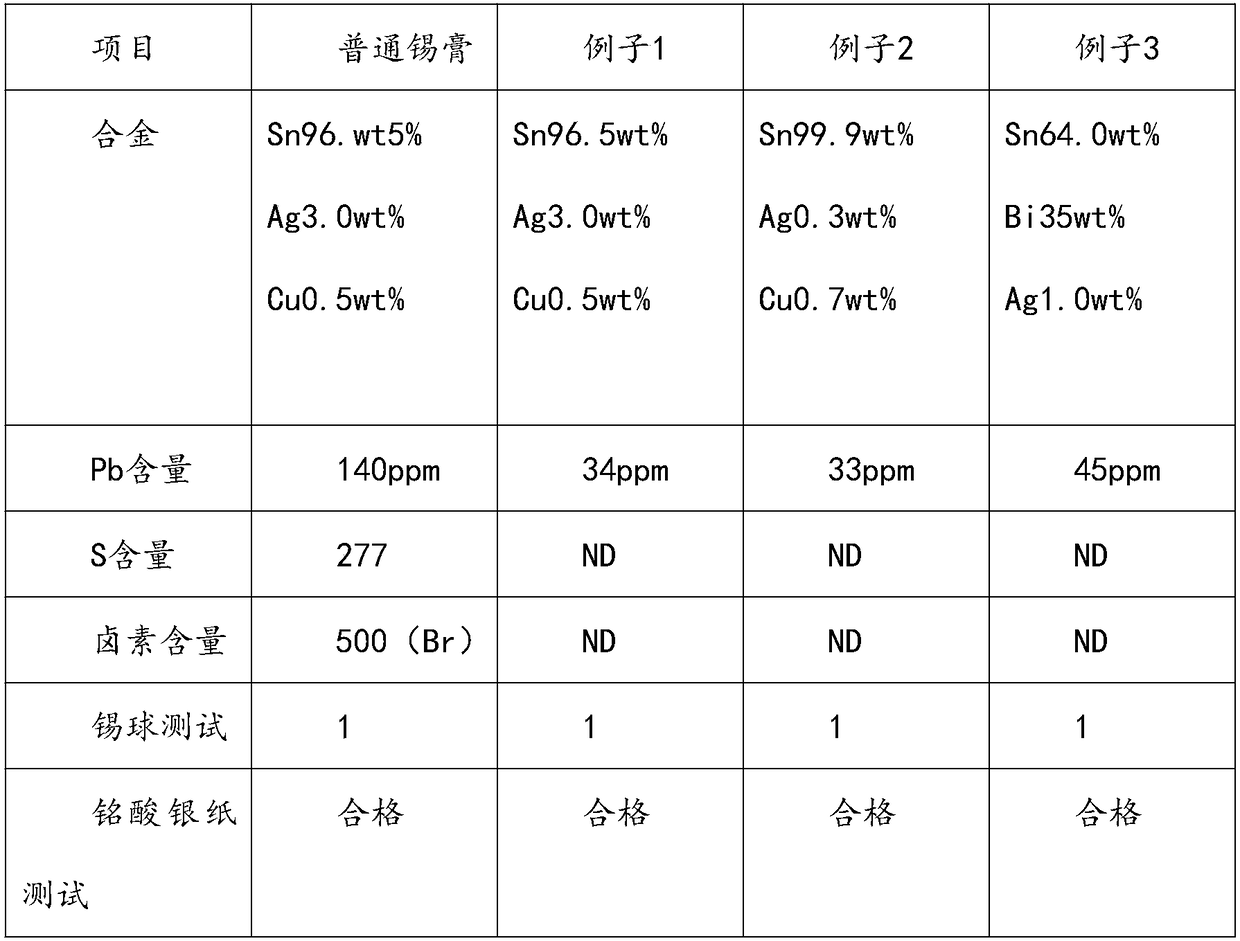

[0025] Embodiment 1, a kind of halogen-free sulfur-free lead-free solder paste, is the solder paste that is formed by mixing 87.5%-90.5wt% lead-free metal powder and 9.5%-12.5wt% solder paste body material, its characteristic That is, the lead-free metal powder is composed of Sn96.5wt%, Ag3.0wt%, Cu0.5wt%, hydrogenated rosin 20wt%, polymerized rosin 20wt%, water white rosin 5wt%, diethylene glycol diethylene glycol Butyl ether 10wt%, dioctyl adipate 25wt%, adipic acid wt5%, maleic acid 4wt%, octylphenol polyoxyethylene ether 2wt%, polyethylene glycol monoester 0.5wt%; thixotropic Agent 65003wt%, ethylene bis stearic acid amide 1.5wt%, 2,6-di-tert-butyl-4-methylphenol 1wt%, paraffin 0.5wt%, hydrogenated castor oil 2.5wt%.

[0026] Preferably, the ratio of solder paste: metal powder is =11:89;

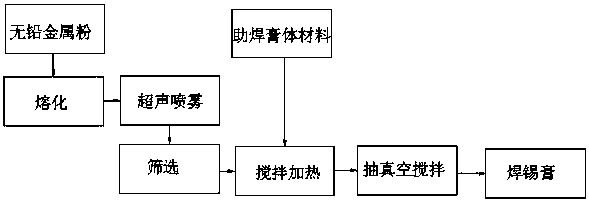

[0027] Preferably, the lead-free metal powder is melted to form tin alloy tin balls by ultrasonic spraying, and then screened to obtain lead-free metal powder with a suitable particle s...

Embodiment 2

[0033] Embodiment 2, a kind of halogen-free, sulfur-free and lead-free solder paste is a solder paste formed by mixing 87.5%-90.5wt% lead-free metal powder and 9.5%-12.5wt% solder paste material, and its characteristics That is, Sn99.9wt%, Ag0.3wt%, Cu0.7wt% in lead-free metal powder, hydrogenated rosin 20wt%, polymerized rosin 20wt%, water white rosin 5wt%, diethylene glycol dibutyl ether in the solder paste material 10wt%, dioctyl adipate 25wt%, adipic acid wt5%, maleic acid 4wt%, octylphenol polyoxyethylene ether 2wt%, polyethylene glycol monoester 0.5wt%; thixotropic agent 65003wt %, ethylene bis stearic acid amide 1.5wt%, 2,6-di-tert-butyl-4-methylphenol 1wt%, paraffin 0.5wt%, hydrogenated castor oil 2.5wt%.

[0034] Preferably, the ratio of flux paste: metal powder is =11.3:88.7;

[0035] Preferably, the lead-free metal powder is melted to form tin alloy tin balls by ultrasonic spraying, and then screened to obtain lead-free metal powder with a suitable particle size, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com