Underfill adhesive with high surface insulation resistance and preparation method thereof

An underfill and insulation resistance technology, applied in the field of underfill with high surface insulation resistance and its preparation, can solve the problems of low surface insulation resistance, poor high temperature adhesion, poor high and low temperature resistance, etc. High transition temperature, high surface insulation resistance, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

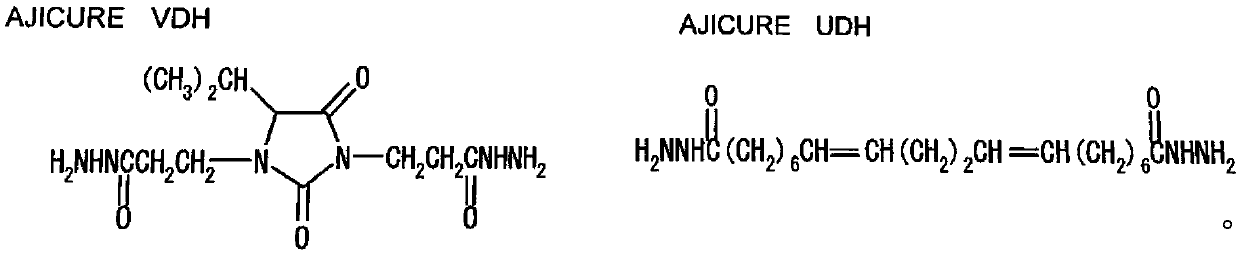

[0026] An underfill adhesive with high surface insulation resistance. Its components include bisphenol F epoxy resin EXA-830LVP 620g, dicyclopentadiene phenol epoxy resin HP-7200 50g, polydimethyl silicon 8 g of oxane compound, 6 g of γ-glycidoxypropyltrimethoxysilane, 6 g of carbon black, and 310 g of bishydrazine compound VDH-J.

[0027] The method for preparing the underfill with high surface insulation resistance is as follows:

[0028] (1) Weigh 620g of bisphenol F epoxy resin EXA-830LVP, HP-720050g of dicyclopentadiene phenol epoxy resin and 6g of carbon black, put them into the reactor and heat up to 90°C, stir at high speed for 1 hour, and mix well;

[0029] (2) Weigh 8g of polydimethylsiloxane compound and 6g of γ-glycidoxypropyltrimethoxysilane under the condition of 30°C, put them into the reactor, stir at high speed for 1.5h, and mix well;

[0030] (3) Weigh 310g of the bishydrazine compound VDH-J under 22°C, put it into the reaction kettle and evacuate it, stir at low spe...

Embodiment 2

[0033] An underfill adhesive with high surface insulation resistance. Its components in parts by weight include: bisphenol F epoxy resin EXA-835LV 600g, biphenol epoxy resin NC-3000 60g, polydimethylsiloxane Compound 8g, γ-glycidoxypropyltrimethoxysilane 6g, carbon black 6g, bishydrazine compound VDH-J 200g, and bishydrazine compound UDH-J 120g.

[0034] The method for preparing the underfill with high surface insulation resistance is as follows:

[0035] (1) Weigh 600g of bisphenol F epoxy resin EXA-835LV, 60g of biphenol-type epoxy resin NC-3000 and 6g of carbon black, put them into the reactor and heat up to 95℃, stir at high speed for 1h, and mix well;

[0036] (2) Weigh 8g of polydimethylsiloxane compound and 6g of γ-glycidoxypropyltrimethoxysilane at 35°C, put them into the reactor and stir at high speed for 1h, and mix well;

[0037] (3) Under the condition of 24°C, weigh 200g of bishydrazine compound VDH-J and 120g of bishydrazine compound UDH-J, put them into the reaction ket...

Embodiment 3

[0040] An underfill adhesive with high surface insulation resistance. Its components include, in parts by weight: bisphenol F epoxy resin EXA-830LVP 620g, biphenol epoxy resin NC-3000 40g, polydimethylsiloxane Compound 8g, γ-glycidoxypropyltrimethoxysilane 6g, carbon black 6g, bishydrazine compound VDH-J 160g, and bishydrazine compound UDH-J 160g.

[0041] The method for preparing the underfill with high surface insulation resistance is as follows:

[0042] (1) Weigh 620g of bisphenol F epoxy resin EXA-830LVP, 40g of biphenol-type epoxy resin NC-3000 and 6g of carbon black, put them into the reactor and heat up to 98°C, stir at high speed for 0.8h, and mix well;

[0043] (2) Weigh 8g of polydimethylsiloxane compound and 6g of γ-glycidoxypropyltrimethoxysilane under the condition of 25℃, put them into the reactor and stir at high speed for 1h, and mix well;

[0044] (3) Under the condition of 24°C, weigh 160g of bishydrazine compound VDH-J and 160g of bishydrazine compound UDH-J, put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com