Impregnation liquid used in copper clad plate preparation process

A preparation process and impregnating liquid technology, applied in layered products, metal layered products, glass/slag layered products, etc., can solve problems such as high loss factor, low peel strength, and small surface insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] An immersion solution used in the preparation of copper clad laminates, the immersion solution includes a first immersion solution and a second immersion solution, the first immersion solution is composed of perfluoroalkoxy concentrated dispersion solution and distilled water in a volume ratio of 1:1.4 When mixing, put the two into a stirrer, stir at a speed of 200r / min for 30 minutes, filter with EW60 glass fiber cloth, and obtain the first impregnating liquid; the second impregnating liquid is made of perfluoroalkoxy Concentrated dispersion liquid, polytetrafluoroethylene concentrated dispersion liquid and distilled water are mixed uniformly at a volume ratio of 1:12:6. When mixing, put the three substances into the stirrer and stir at 200r / min for 30-90 Minutes, filter with EW60 glass fiber cloth to get the second impregnation solution.

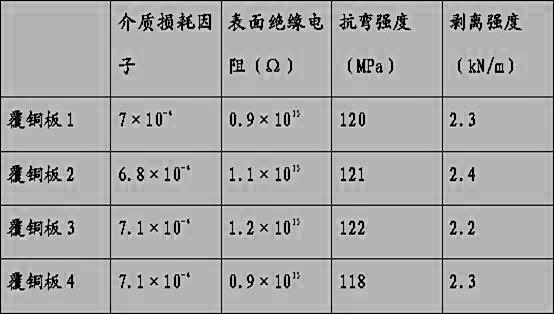

[0016] Each material performance index described in the present invention is as follows:

[0017] Perfluoroalkoxy concentrated di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com