Low-silver lead-free flux paste and preparation method thereof

A technology of flux paste and active auxiliary agent, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of low surface insulation resistance, shortened template life, easy to produce solder balls, etc., to achieve high surface insulation resistance, improve Template life, the effect of not easy to short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

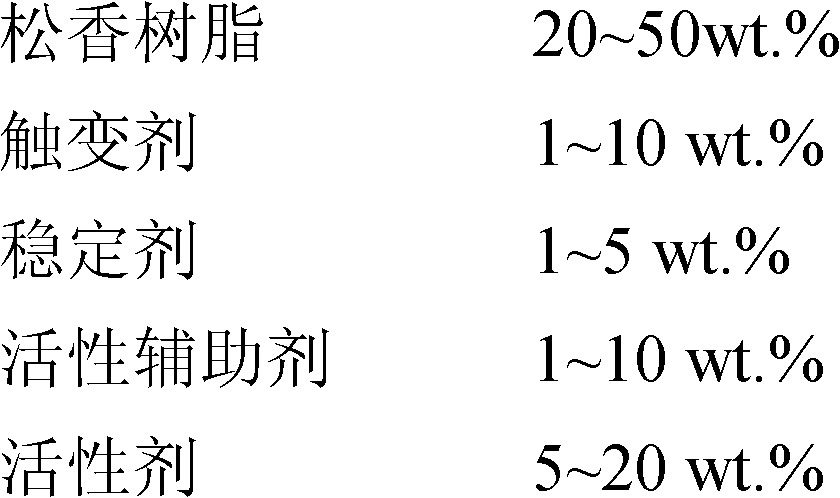

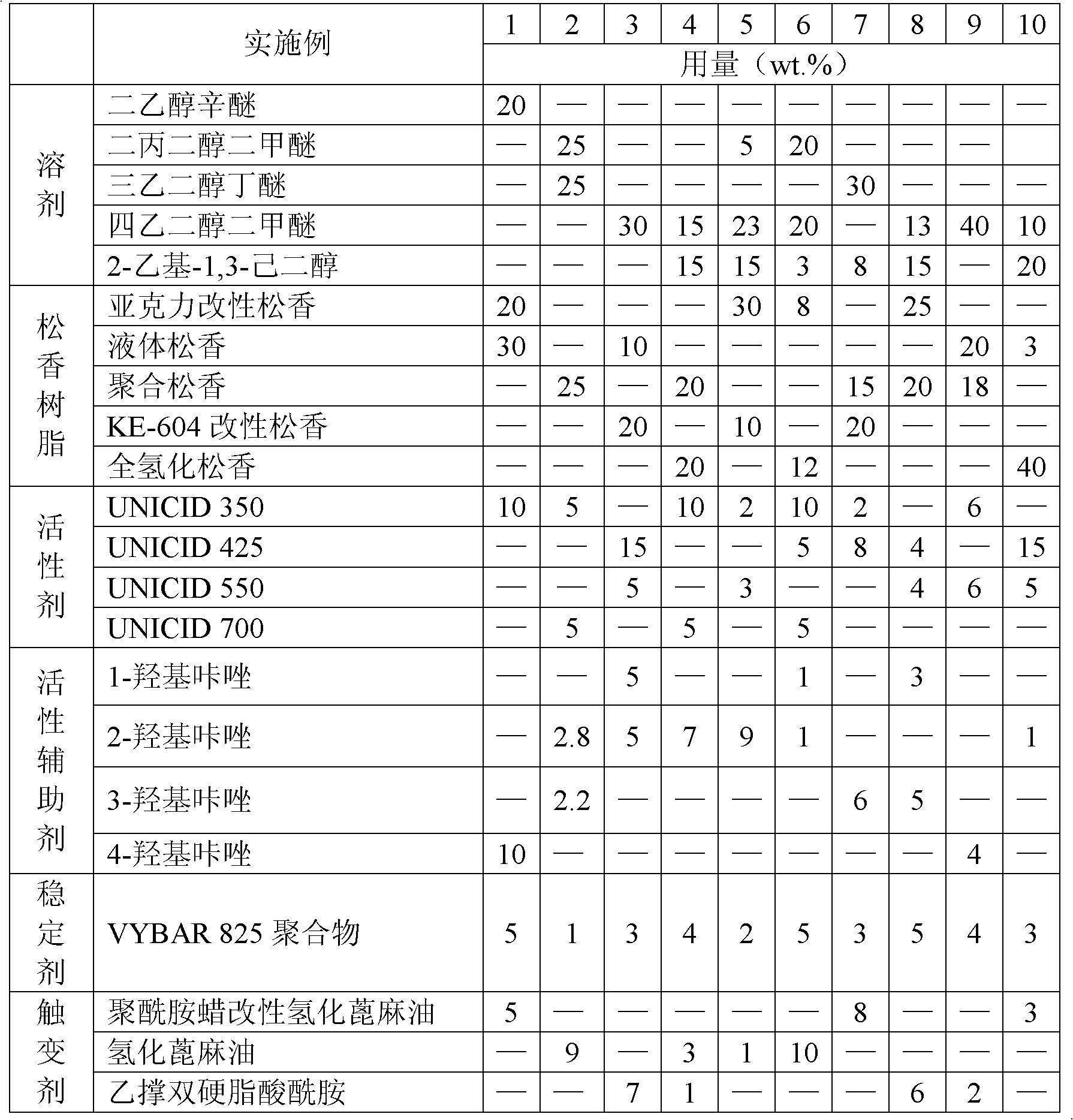

[0022] The present invention will be further described in detail below in conjunction with specific embodiments. See Table 1 for specific examples. The solder paste prepared by using the lead-free flux paste and solder powder of the technical scheme of the present invention is composed of 85-91wt.% solder powder and 9-15wt.% flux paste, preferably 11.5% by weight. In the example, the low-silver lead-free solder paste and 88.5 wt.% tin powder were prepared into a solder paste and the lead-free solder paste sold in the market was used for a comparative test. The composition of the tin powder was 99Sn / 0.3Ag / 0.7Cu.

[0023] Table 1 Specific Examples

[0024]

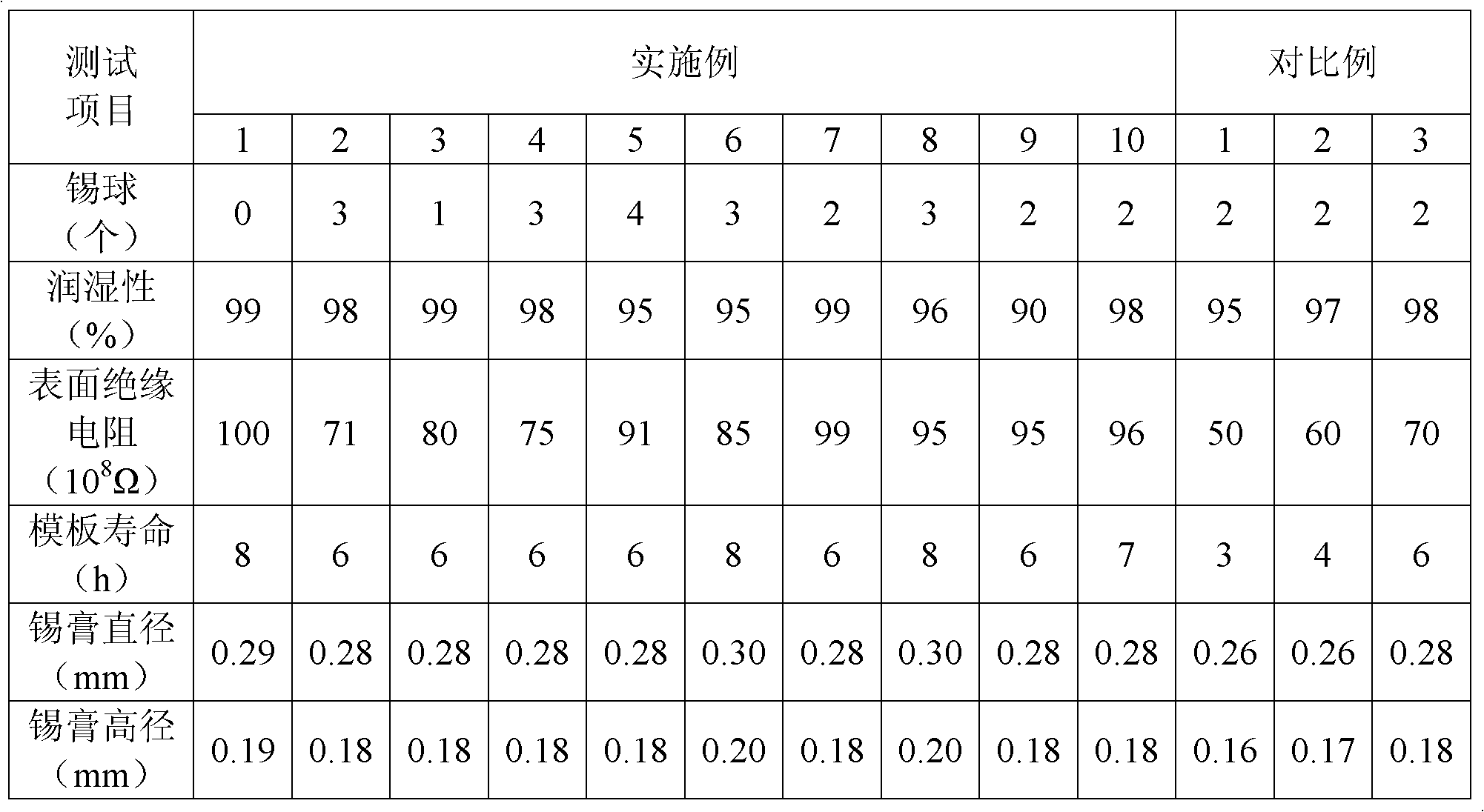

[0025] Refer to the method of ICP TM 6502.4.43 to test the tin balls and observe the condition of the tin balls on the alumina test board; refer to the method of ICP TM 6502.6.3.3B to measure the surface insulation resistance; refer to the method of ICP TM 6502.4.45 to measure the wettability.

[0026] Print on the automatic prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com