Patents

Literature

32results about How to "Solder joints are full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

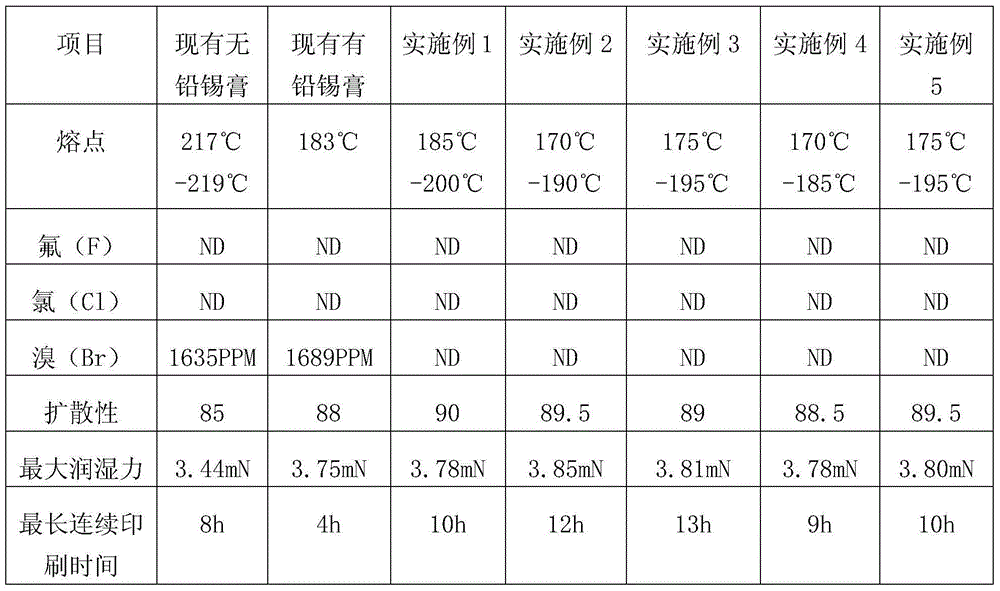

Lead-free halogen-free tin paste and production process thereof

InactiveCN104923952ALow melting pointLow soldering temperatureWelding/cutting media/materialsSoldering mediaOrganic acidSolvent

The invention relates to the technical field of electronic welding, in particular to lead-free halogen-free tin paste which comprises, in weight percent, 88%-90% of tin powder and 10%-12% of paste flux. The tin powder is made of alloys including 88-94.5% of Sn, 0.2-1.2% of Ag, 0.3-0.8% of Cu and 5-10% of Bi. The paste flux comprises rosin, solvents, corrosion inhibitors, activators, thixotropic agents and thickening agents, wherein the activators comprise organic acid and organic amine. The paste flux is prepared by an emulsion dispersion high-speed shearing process. A preparation method of the tin paste includes the steps: placing the tin powder and the paste flux into a sealed stirrer for stirring according to the proportion; pumping vacuum; releasing the vacuum; finishing preparation of the tin paste. The lead-free halogen-free tin paste is low in melting point, fine in weldability, full in welding spot and fine in reliability, achieves fine welding effects and meets environmental protection requirements, and the service life of the tin paste is prolonged.

Owner:广西南宁迈点装饰工程有限公司

Sn0.3Ag0.7Cu lead-free solder paste and preparation method thereof

InactiveCN104785948AGood adhesionNon stickyWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

The invention discloses Sn0.3Ag0.7Cu lead-free solder paste. The Sn0.3Ag0.7Cu lead-free solder paste particularly comprises, by mass, 9-11% of scaling powder and 89-91% of soldering tin powder. The scaling powder comprises, by mass, 20-25% of rosin, 15-20% of film-forming agent, 15-20% of active agent, 5-10% of thixotropic agent, 1-3% of acidity regulator and the balance solvent. The invention further discloses a preparation method of the Sn0.3Ag0.7Cu lead-free solder paste. The method comprises the steps that the solvent and the film-forming agent are stirred at 75 DEG C to be transparent, and the mixture is cooled to be at the temperature of 65 DEG C, added with the film-forming agent, cooled to be at the temperature of 55 DEG C and added with the active agent to be stirred to be transparent; the mixture is cooled to be at 55 DEG C and added with the thixotropic agent to be stirred to be transparent; the mixture is cooled to be at normal temperature and added with the acidity regulator to be stirred for 15 min, and then the mixture and solder powder are mixed and stirred to obtain the Sn0.3Ag0.7Cu lead-free solder paste. The solder paste is good in printing technology and welding performance, residues left after welding evenly cover the surface welding spots, and the effects of electrical insulation, welding spot protection and the like are achieved.

Owner:XIAN UNIV OF TECH

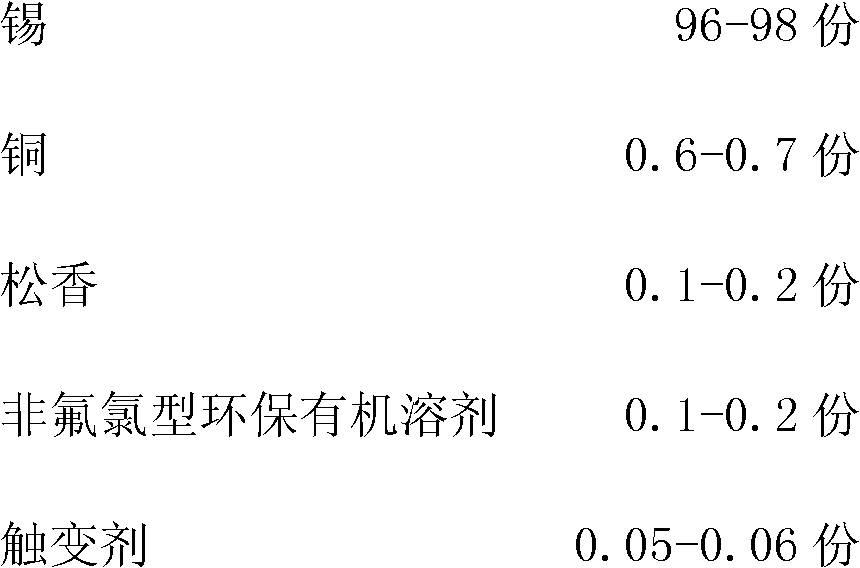

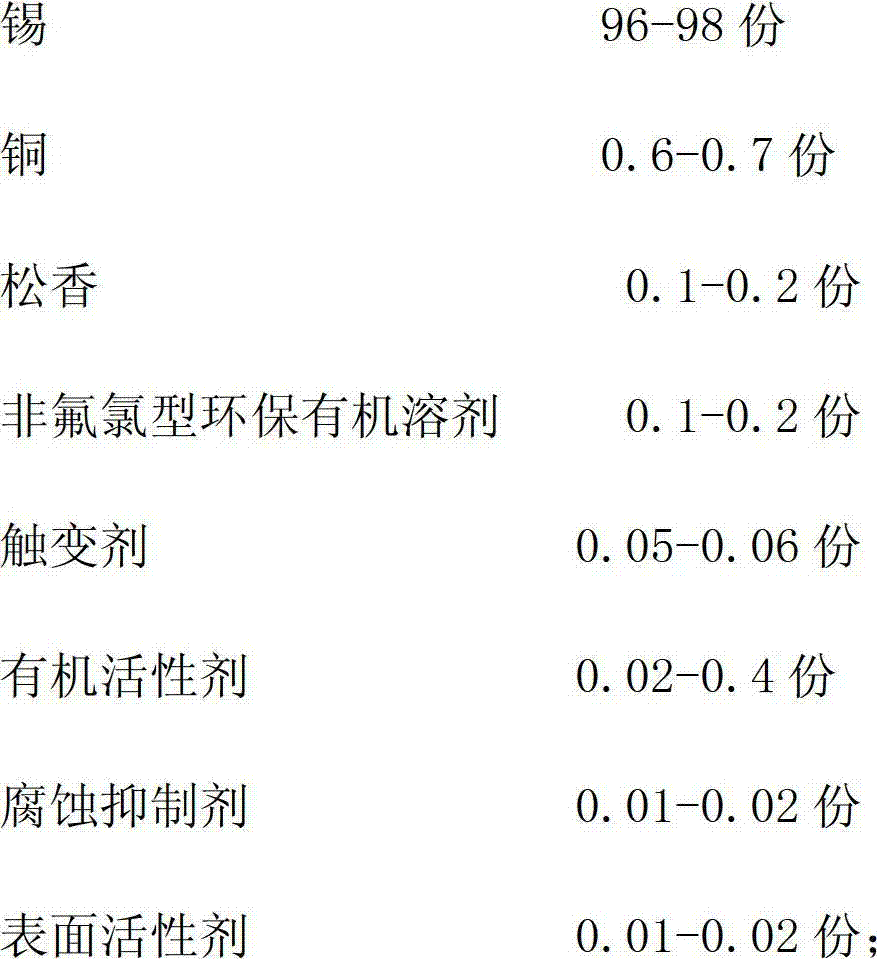

Halogen-free lead-free tin wire

InactiveCN102248317AImprove reliabilitySolder joints are fullWelding/cutting media/materialsSoldering mediaOrganic solventHalogen

The invention relates to the technical field of tin wires, in particular to a composite halogen-free lead-free tin wire in line with the EU (European Union) directive. The tin wires comprise the following components in parts by per unit mass: 96-98 parts of tin, 0.6-0.7 part of copper, 0.1-0.2 part of resin, 0.1-0.2 part of non-fluorochloro environmentally-friendly organic solvent, 0.05-0.06 part of thixotropic agnet, 0.02-0.4 part of organic active agent, 0.01-0.02 part of corrosion inhibitor, and 0.01-0.02 part of surfactant, wherein the tin and the copper are the solder of the tin wire, and others are soldering flux. By using said technical scheme in the invention, the product is in line with relative directive of the EU and free from lead and relative halogen. Furthermore, the reliability of the welding is high, bad welding spot cannot be formed, and the welding spot is full and bright.

Owner:JIANGXI UNIV OF SCI & TECH +1

Lead free tin cream and preparation process

InactiveCN1565790AGood surface activityUniform pasteWelding/cutting media/materialsSoldering mediaOrganic acidRosin

The invention provides a lead-free solder paste comprising the tin base alloy welding powder and the pewter. The components of the tin base alloy welding powder are as follows (in % by weight): Sn 91-99, Cu 0.5-3, Ag 0.5-6; the components of the pewter are as follows (in % by weight): mixed alcohol ether 25-40, natural colophony 50-70, natural vegetable oil thixotropic agent 5-15, organic acid 0.5-2.0, additives. The lead-free solder paste preparing process includes the following steps: mixing the components of the pewter in proportion, standing to room temperature, putting the pewter in a refrigerating chamber with the temperature of 1 C. to 10 C. for 48 hours; mixing the pewter and the tin base alloy welding powder in the ratio of 1 to 9 in the vacuum dispersion machine, putting the mixture in the package bottle and storing hermetically with the temperature of between 5 C. and 10 C.. The lead-free solder paste is characterized by good surface activity, moderated viscosity, and no smell.

Owner:倪潮春

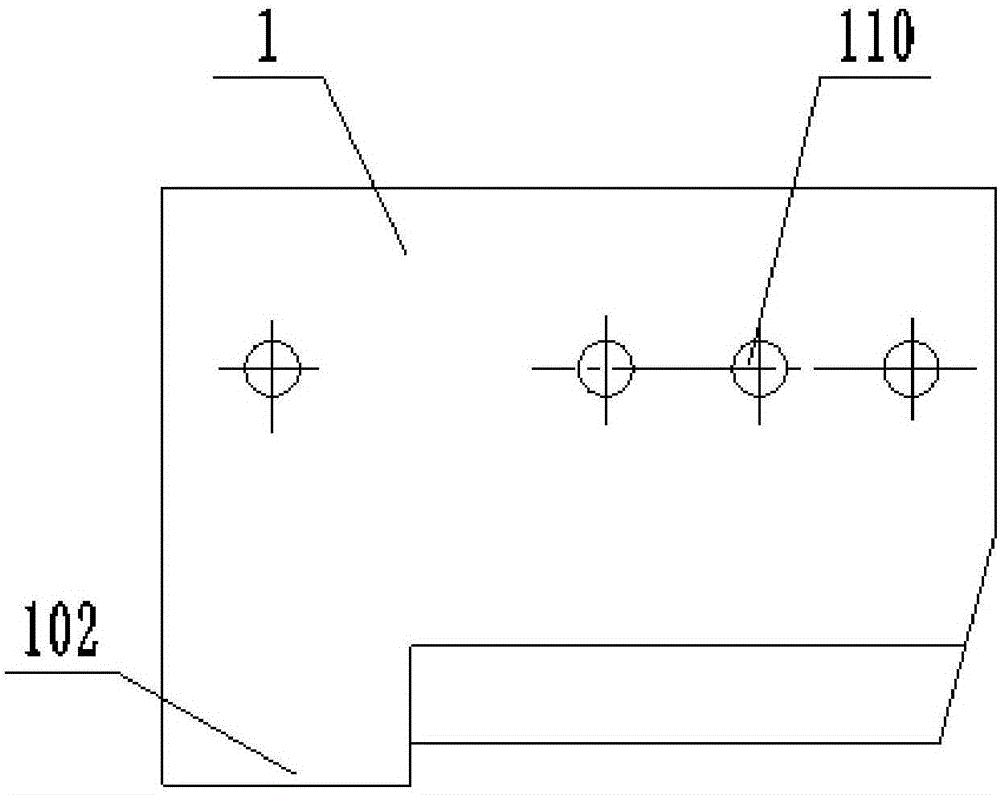

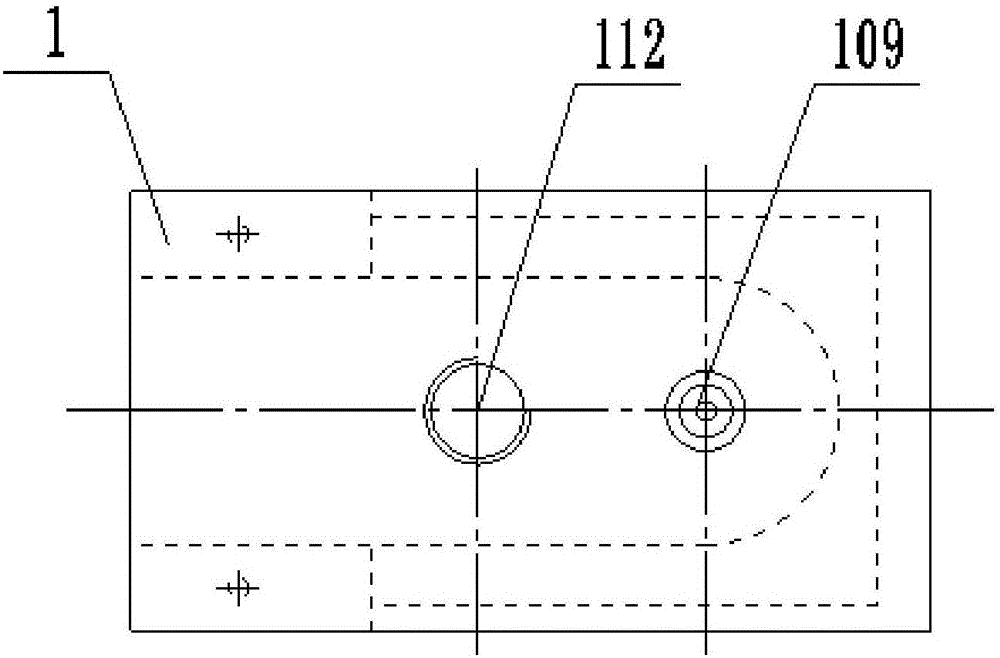

Air conditioner liquid storage device welding protection device and application method thereof

ActiveCN106270915AAvoid oxidation and blackeningAvoid contactGas flame welding apparatusSurface oxidationEngineering

The invention discloses an air conditioner liquid storage device welding protection device and an application method thereof, and belongs to the technical field of welding. The air conditioner liquid storage device welding protection device comprises an outer ventilation block and an inner ventilation block. The outer ventilation block is of a rectangular block-shaped structure and is provided with a transverse air blowing hole and longitudinal air blowing holes and connected with an air source through an outer ventilation connecting hole. An inner air blowing hole is formed in the inner ventilation block and connected with the air source through an inner ventilation connecting hole. According to the method, a cylinder is inflated with protection air through the inner ventilation block in the welding process, the welding position is immediately inflated with the protection air through the outer ventilation block after welding is finished, and air is prevented from making contact with a welding line. By means of the air conditioner liquid storage device welding protection device and the application method thereof, the surface of a welded part can be prevented from being oxidized during liquid storage device welding, the connecting strength of the welding line is improved, the quality of a finished product is improved, and the production cost is reduced.

Owner:ANHUI ZHONGHUI REFRIGERATION

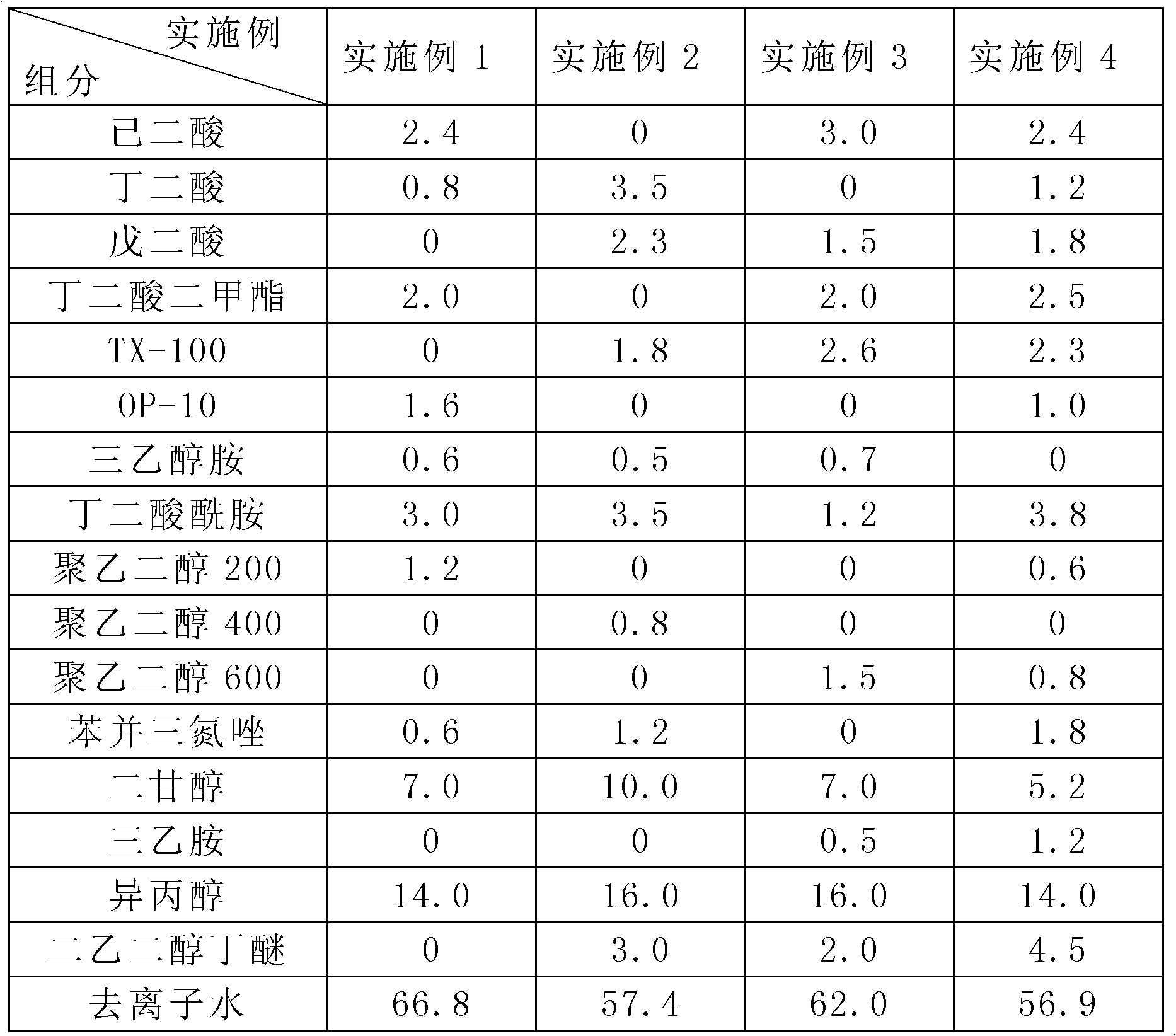

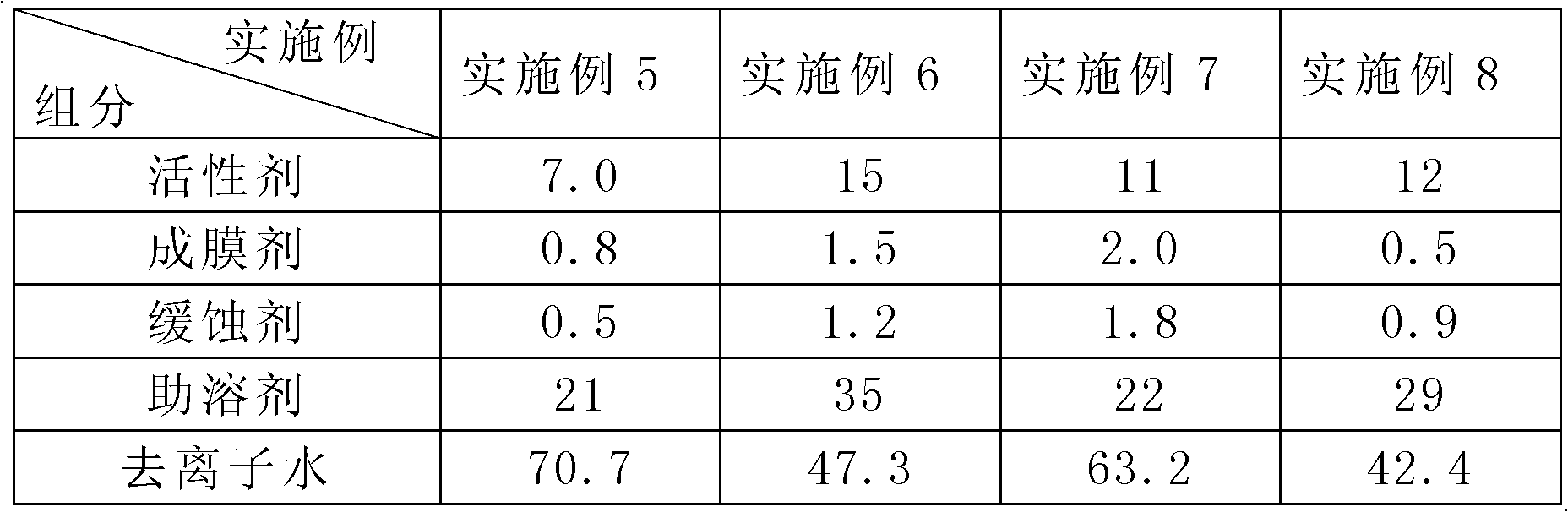

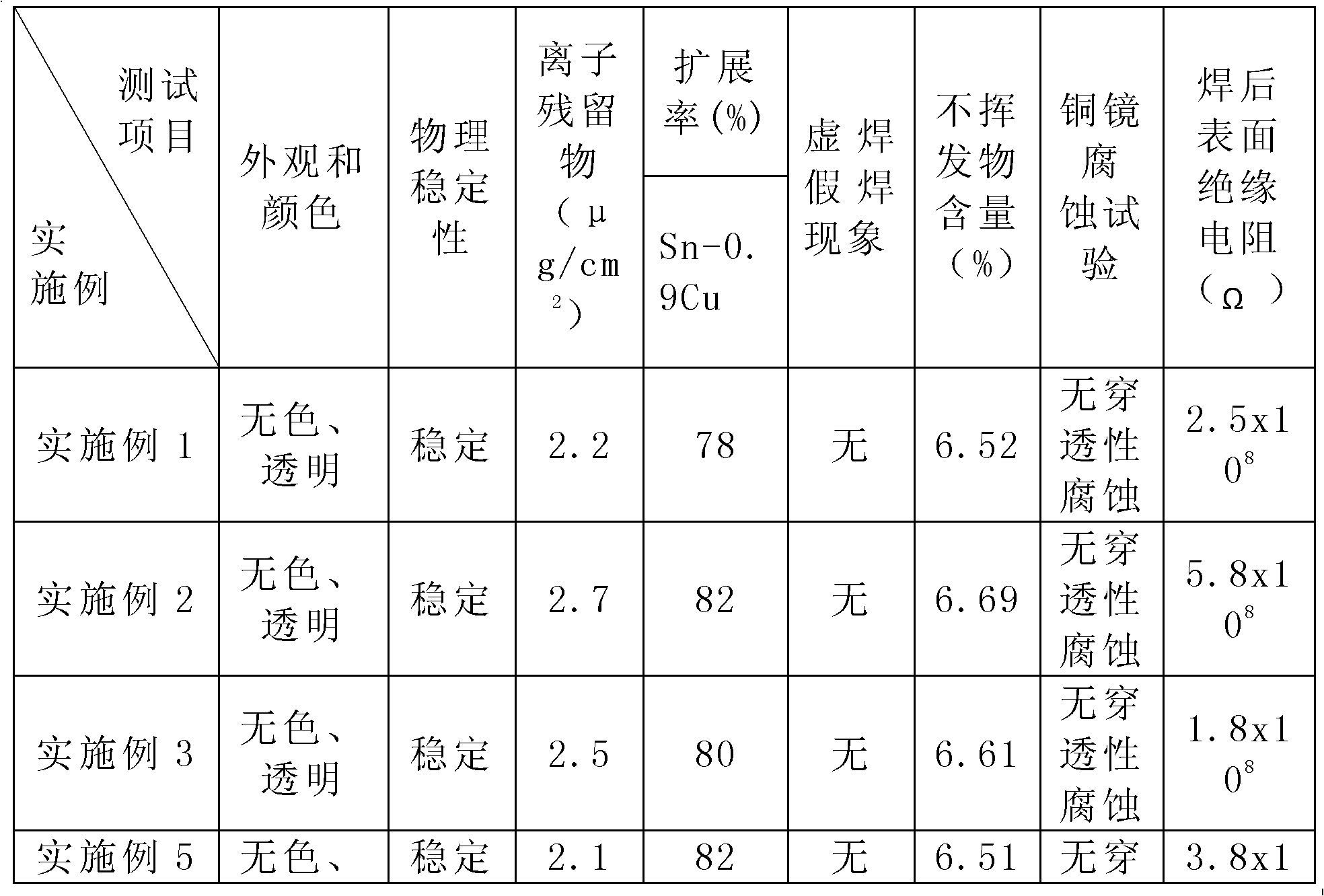

Alcohol and water mixed-base cleaning-free soldering flux for wire connection

InactiveCN102303200AImprove adaptabilitySolder joints are fullWelding/cutting media/materialsSoldering mediaSolventSoldering

The invention discloses an alcohol and water mixed-base cleaning-free soldering flux for wire connection, belonging to the technical field of soldering materials. The soldering flux comprises the raw materials by weight percent: 7.0-15 percent of activating agent, 0.5-2.0 percent of film-forming agent, 0.3-1.8 percent of corrosion inhibitor, 18-35 percent of cosolvent and the balance of deionized water. The soldering flux has the advantages of effectively removing oxides and dirt on the surfaces of various leads or pins and improving assembly adaptability of different components, and has the characteristics of stronger activity, high postwelding quality, full welding spots, no poor soldering or cold soldering, less corrosive residues, no need of cleaning, and long service life.

Owner:YIYUAN ELECTRONICS TECH

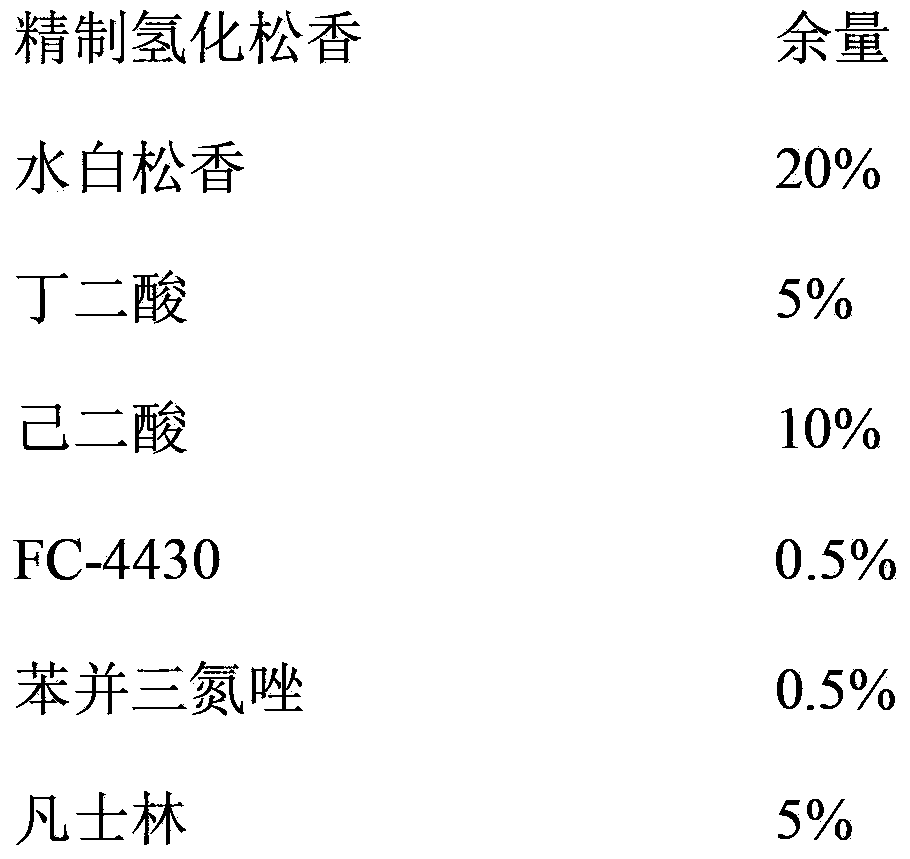

Low-splash and halogen-free welding agent for tin wires and preparation method thereof

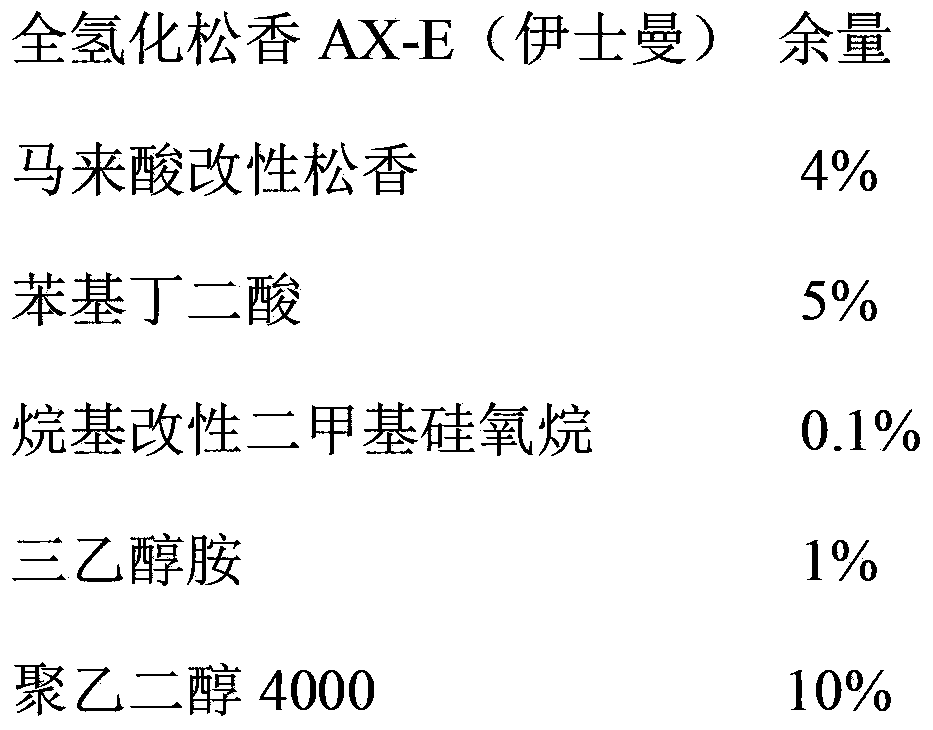

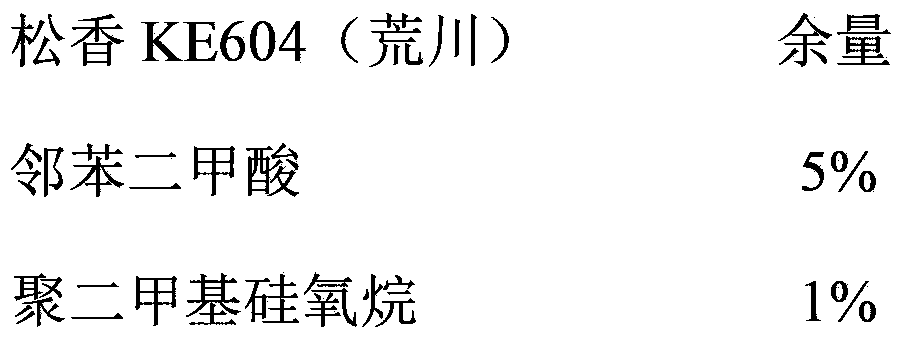

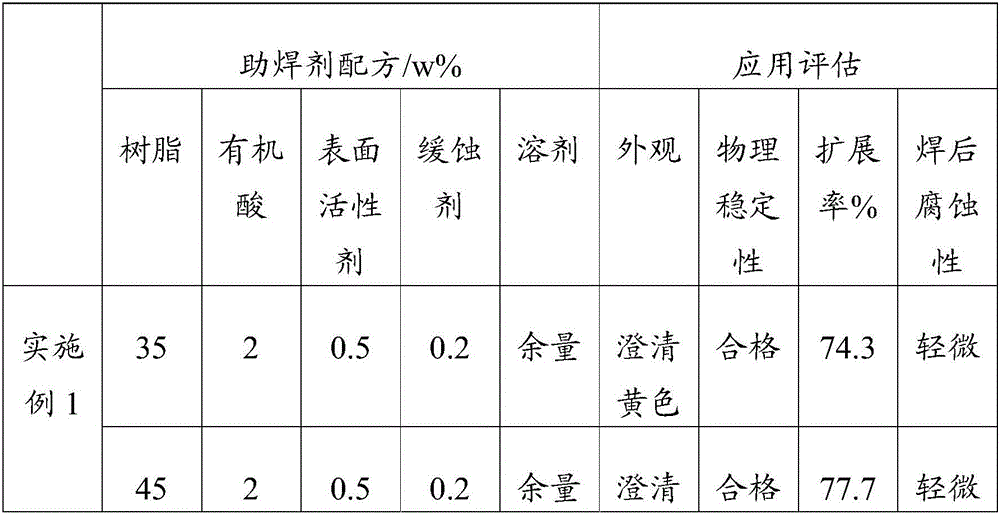

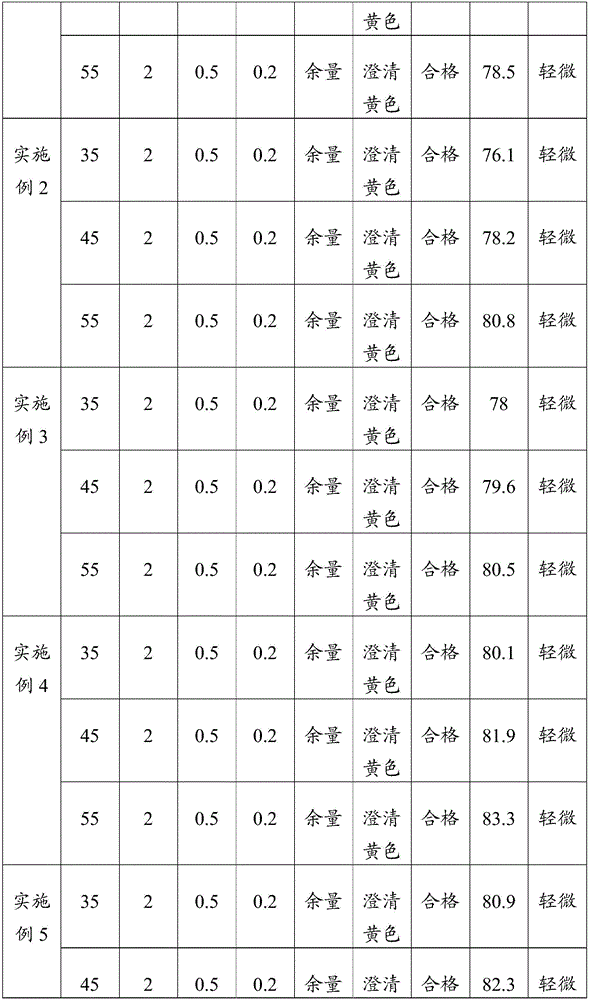

InactiveCN103394824AHigh surface insulation resistanceImprove wettabilityWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention discloses a low-splash and halogen-free welding agent for tin wires and a preparation method thereof. The welding agent is mainly used for agent cores of tin-based alloy tin wires. The welding agent is composed of, by weight, 80-90% of rosin and rosin derivatives, 5-15% of active agents, 0.1-2% of efficient surface active agents, 0.5-2% of corrosion inhibitors and 3-10% of viscosity modifiers. The prepared halogen-free welding agent for the tin wires is needless of any halogen element, is little in splash and smoke when welding is conducted, has high activity, is high in surface insulation resistance, and can be used for preparing tin-lead series tin wires, tin-copper series tin wires and tin-silver-copper series tin wires. The prepared tin wires are good in wetting performance, high in reliability after being welded, and light and full in welding point.

Owner:BEIJING COMPO ADVANCED TECH

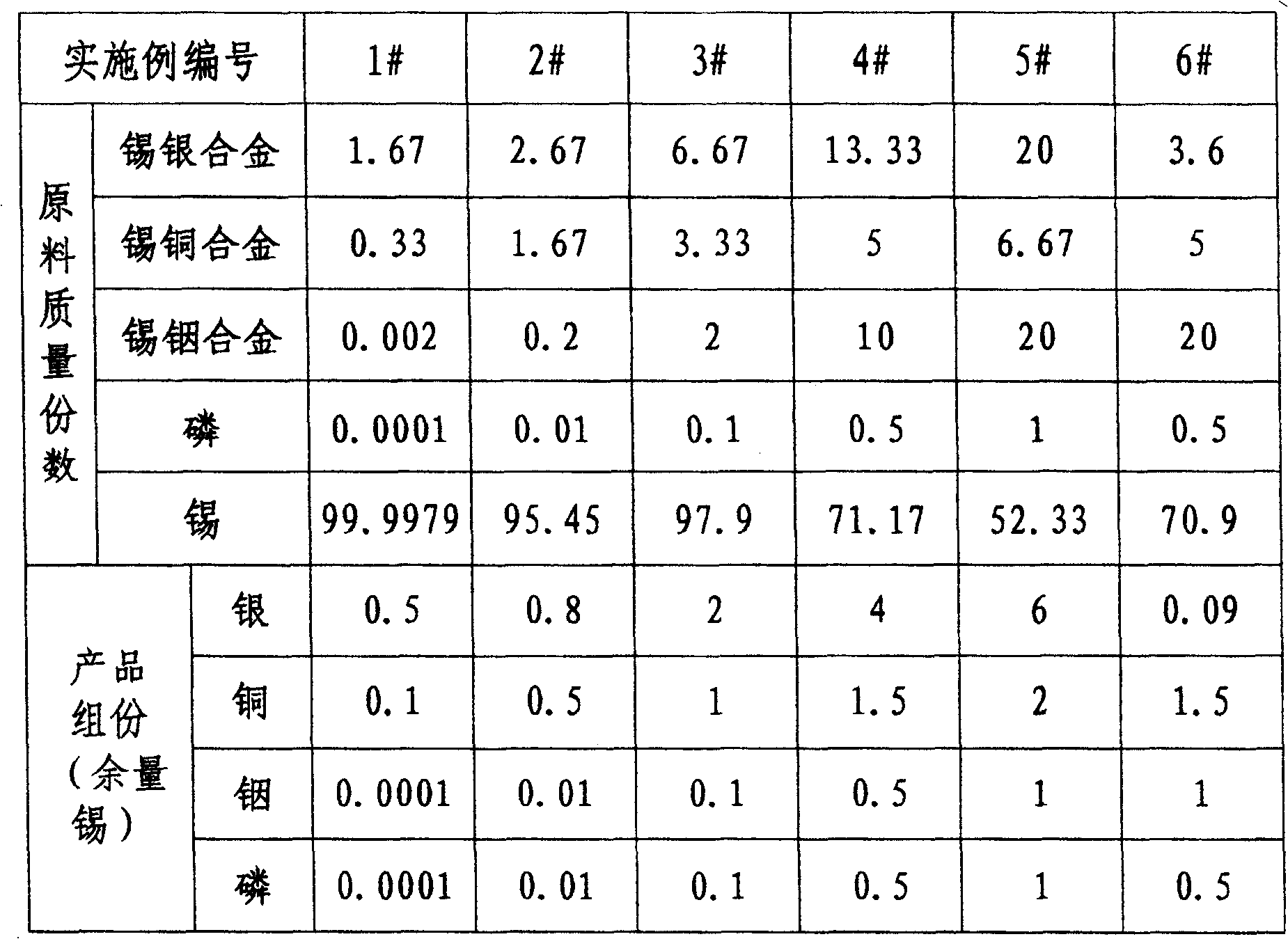

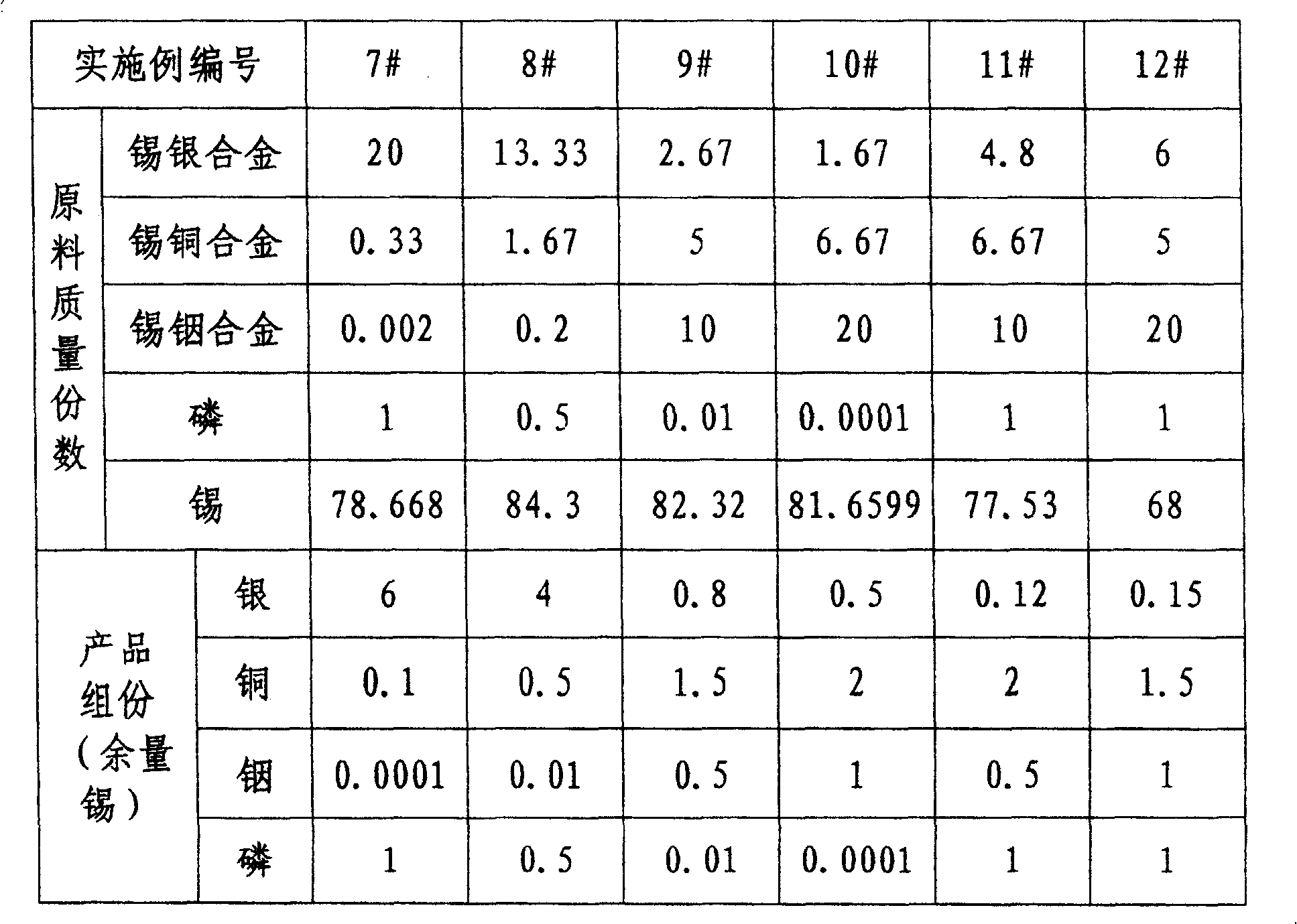

Lead-free solder

InactiveCN1806998AUniform metallographicMetallographic refinementWelding/cutting media/materialsSoldering mediaIndiumIntermediate frequency

The invention relates to a leadless tin soldering material which comprises the constituents (by mass ratio) of Ag 0.5-6%, Cu 0.1-2%, In 0.0001-1%, P 0.0001-1%, and balancing Sn. The preparing process of the soldering material comprises weighing 1.67-20 parts of Sn-Ag intermediate alloy ingot containing Ag 30%, 1-20 parts of Sn-Cu intermediate alloy ingot containing Cu 30%, 0.002-20 parts of Sn-In intermediate alloy ingot containing In 5%, P 0.0001-1 part, and balancing Sn in the whole 100 parts, charging the raw materials into manganese alloy crucible, smelting in intermediate frequency furnaces, evacuating and filling in nitrogen, elevating the temperature to 450 deg. C, agitating 1 hour, cooling down slowly and homogeneously to 340 deg C, charging weighed P and stirring homogeneously, finally pouring the melted liquid into dies.

Owner:THOUSAND ISLAND METAL FOIL

Rosin used for scaling powder as well as preparation method and application

ActiveCN106634612AImprove solubilityHigh flux activityWelding/cutting media/materialsNatural resin chemical modificationSolubilityHeat stability

The invention relates to rosin used for scaling powder as well as a preparation method and application, belonging to the field of basic resin used for the scaling powder. Rosin which contains mercusicacid is taken as a raw material to prepare the rosin used for the scaling powder. The rosin used for the scaling powder has excellent solubility and crystallization resistance in a scaling powder solvent system, is high in weld-aid activity and low in corrosivity, and has very good wettability for brazing filler metal free of lead; and the rosin used for the scaling powder is good in both heat stability and film-forming property, and the formed welding spot is full, bright and regular.

Owner:广东科茂林产化工股份有限公司 +2

Lead-free low-temperature solder and preparation method thereof

InactiveCN107877031AImprove liquidityImprove wettabilityWelding/cutting media/materialsSoldering mediaIndiumSlag

The invention belongs to the technical field of solder, and particularly relates to a lead-free low-temperature solder. The solder comprises, by mass, 0.001-58.0% of bismuth, 0.001-1.0% of silver, 0.001-2.0% antimony, 0.001-0.1% of indium, 0.001-0.15% of phosphorus, 0.001-0.08% of germanium, 0.001-0.015% of beryllium, 0.001-0.015% of cerium and the balance tin. Compared with the prior art, when welding is carried out at the temperature of 139DEG C to 200DEG C, little oxidation slag is generated, the surface of a tin furnace can be kept bright basically without oxidation at the temperature, thesolder can not be oxidized within 50 seconds at 200-260 DEG C, so that the welding efficiency is greatly improved, and the damage to electronic components of a PCBA board is reduced; the low-temperature solder is good in oxidation resistance; and in the welding process, compared with a common Sn-Ag-Cu system, the solder has fewer welding defects, the surfaces of welding spots are very light-bright, the welding spots are full, continuous welding does not occur, so that the welding quality is effectively improved, and the solder and the method are environment-friendly and safe.

Owner:THOUSAND ISLAND METAL FOIL

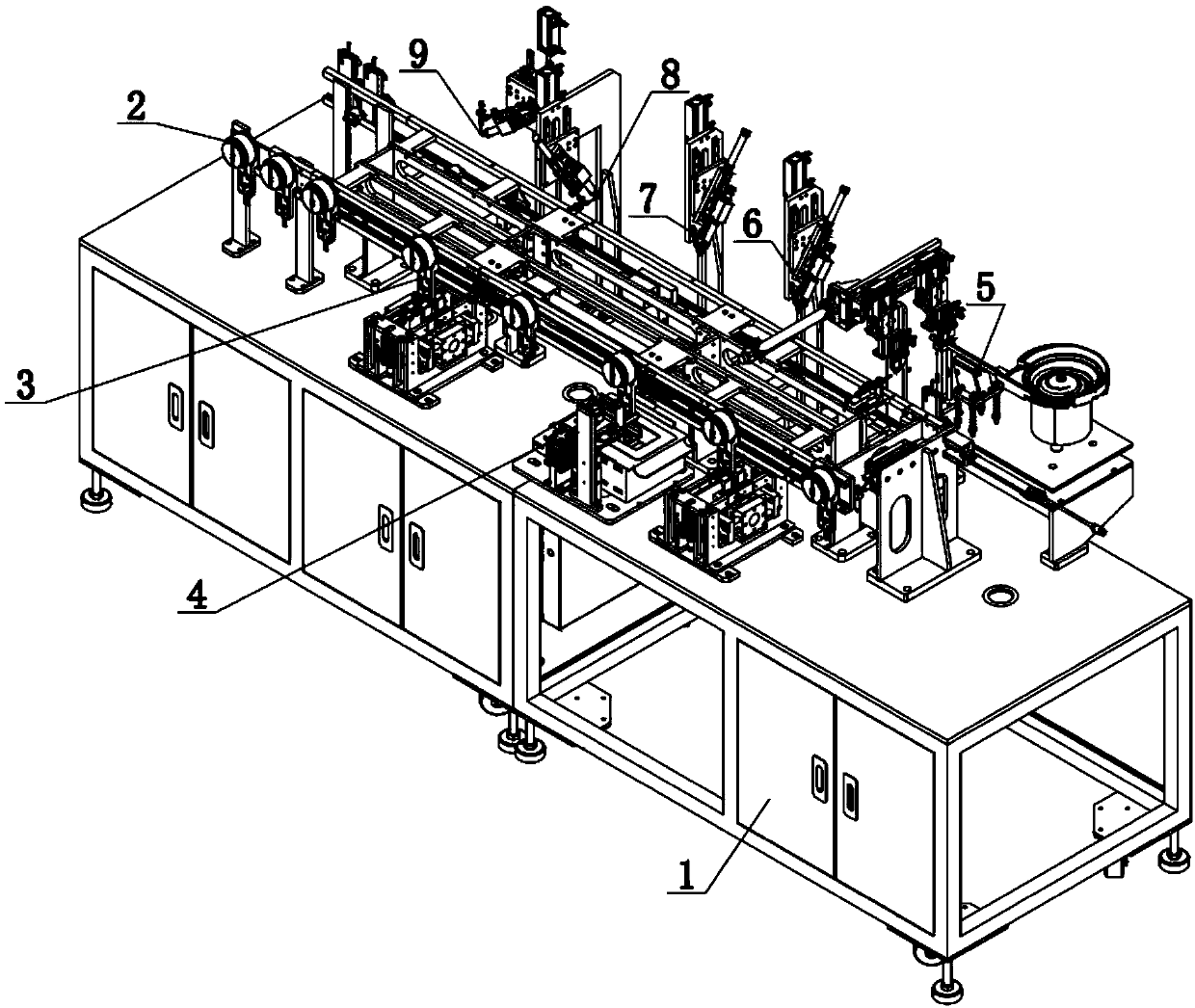

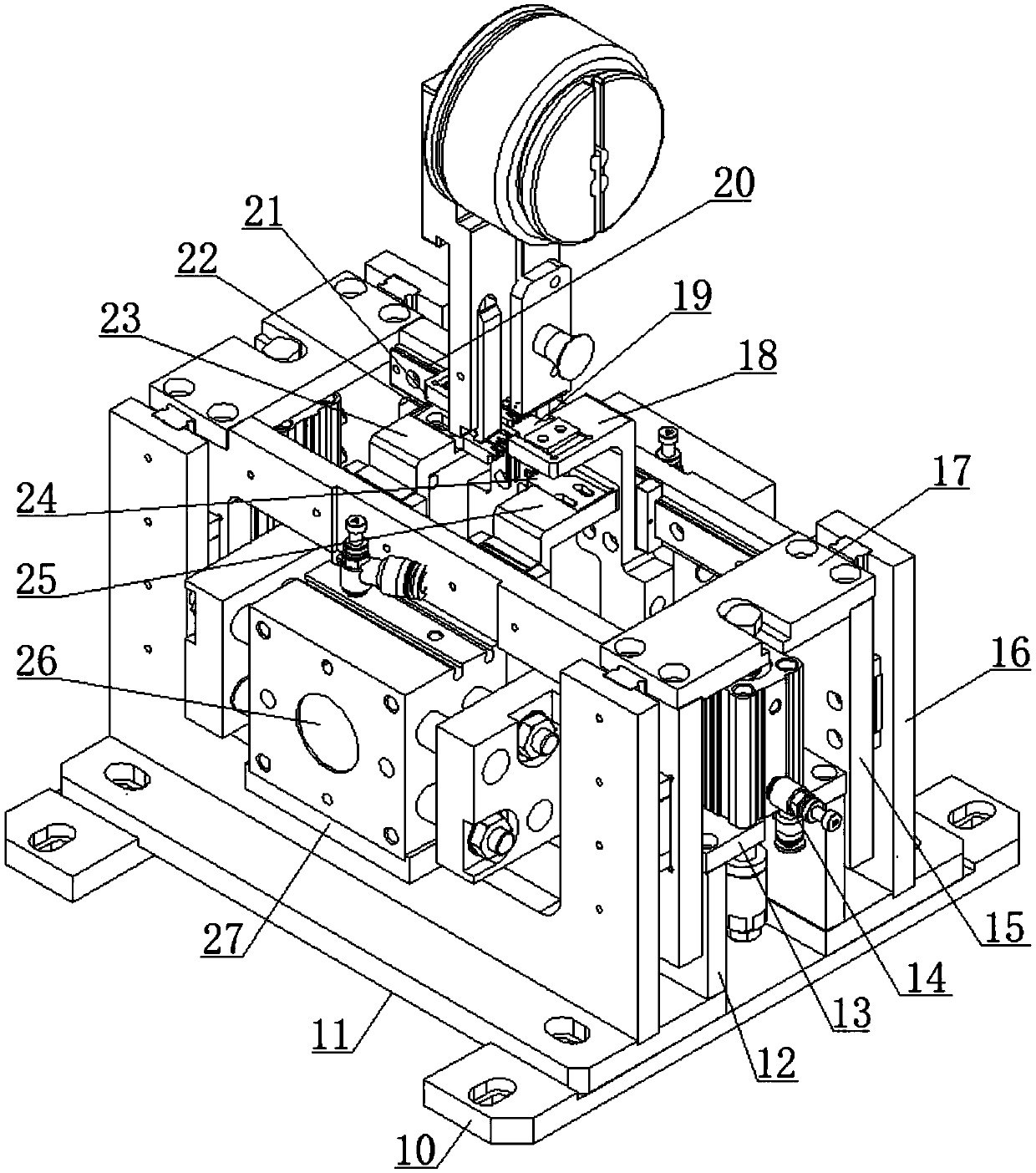

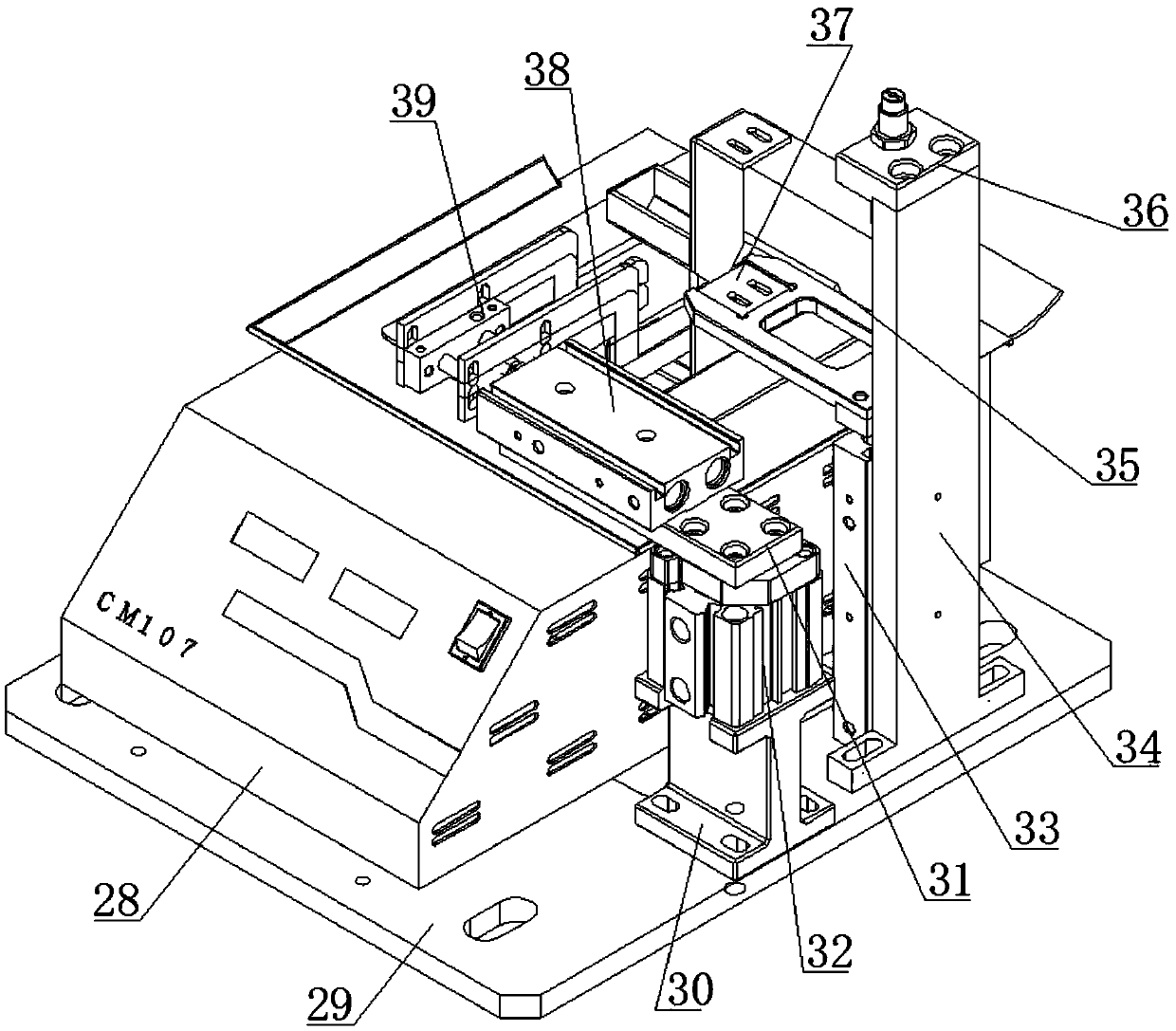

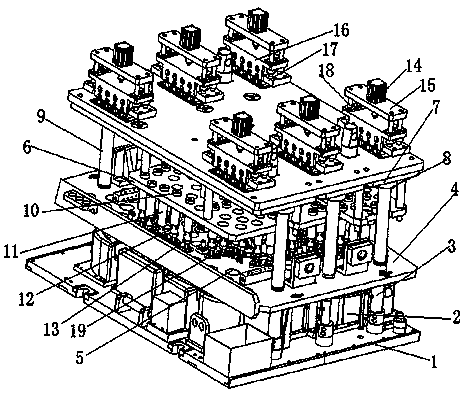

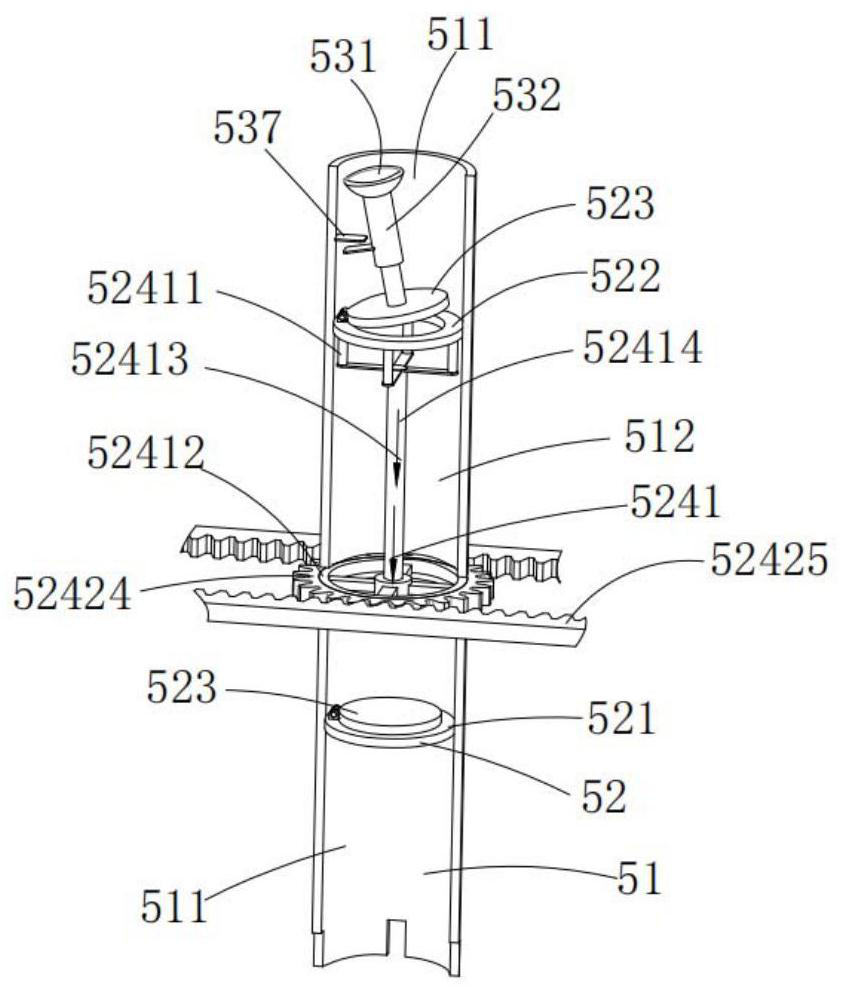

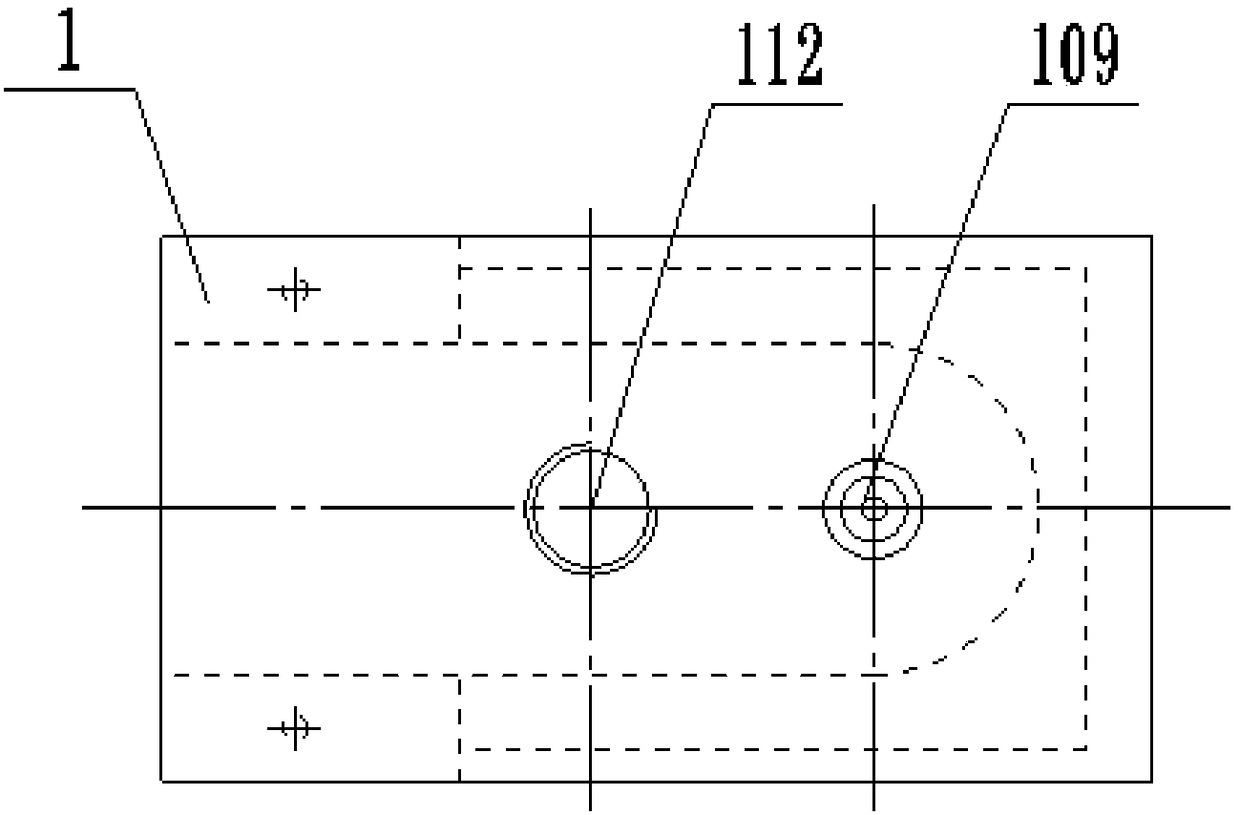

Multi-wire automatic shearing tin pick-up treatment device

InactiveCN109514026AGood compatibilityAvoid uneven solderingConductorsWelding/soldering/cutting articlesPre treatmentEngineering

The invention discloses a multi-wire automatic shearing tin pick-up treatment device, and relates to the technical field of industrial automation. The device comprises a machine body, a loading mechanism, a peeling device and a tin pick-up treatment device are sequentially arranged on one side of the top of the machine body from left to right, a position sensor, a first welding gun, a second welding gun, a third welding gun and a fourth welding gun are sequentially arranged on the other side of the machine body from right to left, the peeling device comprises a left and right adjusting base plate, the top of the left and right adjusting base plate is provided with a front and back adjusting base plate, the top of the front and back adjusting base plate is provided with a jacking air cylinder supporting plate. According to the electronic line welding pretreatment device, the peeling device and the tin pick-up treatment device, trimming tin pick-up pretreatment before welding of the electronic connecting line can be achieved, the rear face and a terminal are better in compatibility during welding, the phenomenon that after line cutting, direct welding is carried out, tin pick-up is not uniform, and welding spots are not full is solved, and the welding quality is improved.

Owner:广东霏碧智能制造有限公司

Lead-free paste welding material and preparation method thereof

InactiveCN106475703AReduce contact resistanceImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMass ratioPositive pressure

The invention proposes a lead-free paste welding material and a preparation method thereof. The lead-free paste welding material is prepared by mixing lead-free solder alloy powder with a flux according to a mass ratio of 10-11: 0.9-1.2; the lead-free solder alloy powder is prepared by the following raw materials: 5-10 wt% of Zn, 0.1-0.2 wt% of Ti, 0.6-2.4 wt% of graphene, and the balance of Sn; and the flux has the following components: 40-50 wt% of adhesive film forming agent, 3-12 wt% of activating agent, 2-8 wt% of thixotropy anti-sinking slipping agent, and the balance of solvent. The preparation method comprises the following steps: the lead-free solder alloy powder and the flux are mixed according to the mass ratio of 10-11: 0.9-1.2; the flux is firstly put in a synthesizer; then, solder powder of the lead-free solder alloy powder is added; the synthesizer is sealed; then, a vacuum system is started for vacuumizing to fill nitrogen to reach positive pressure; a stirring system is started for stirring; the stirring is stopped; and the discharge is performed to obtain the lead-free paste welding material. The lead-free paste welding material is excellent in welding point combination strength; and meanwhile, the flux is better in oxidation resistance without needing to add antioxidant.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

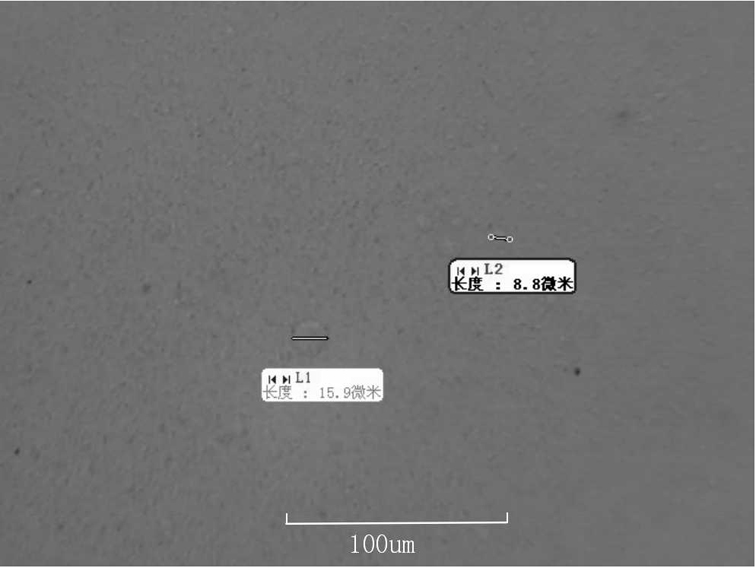

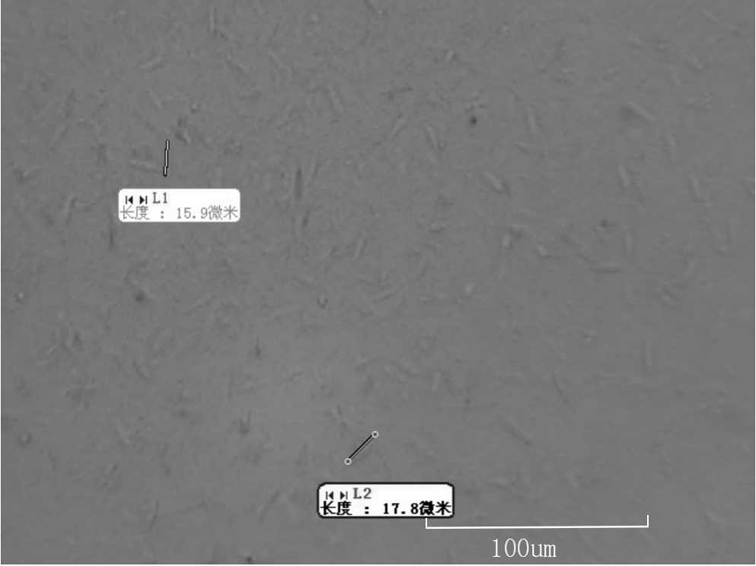

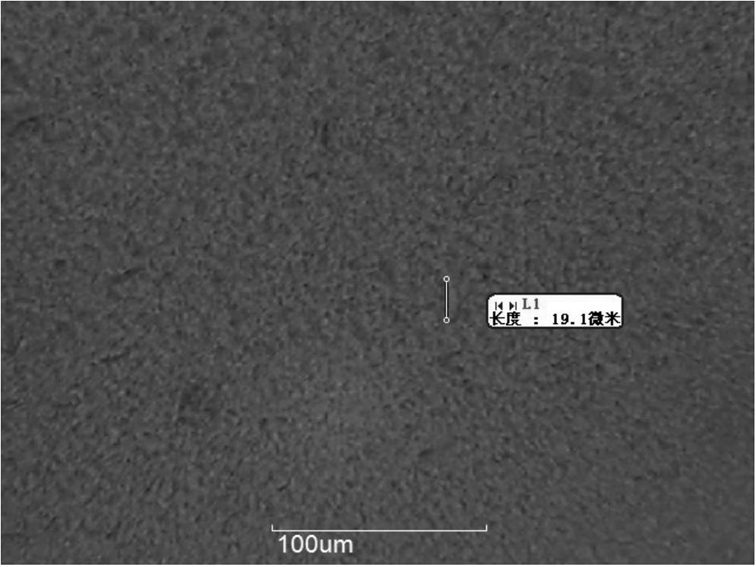

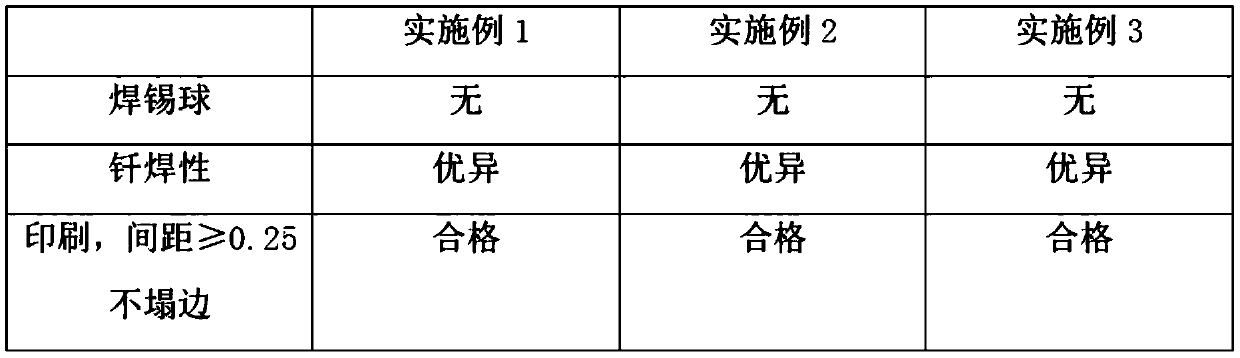

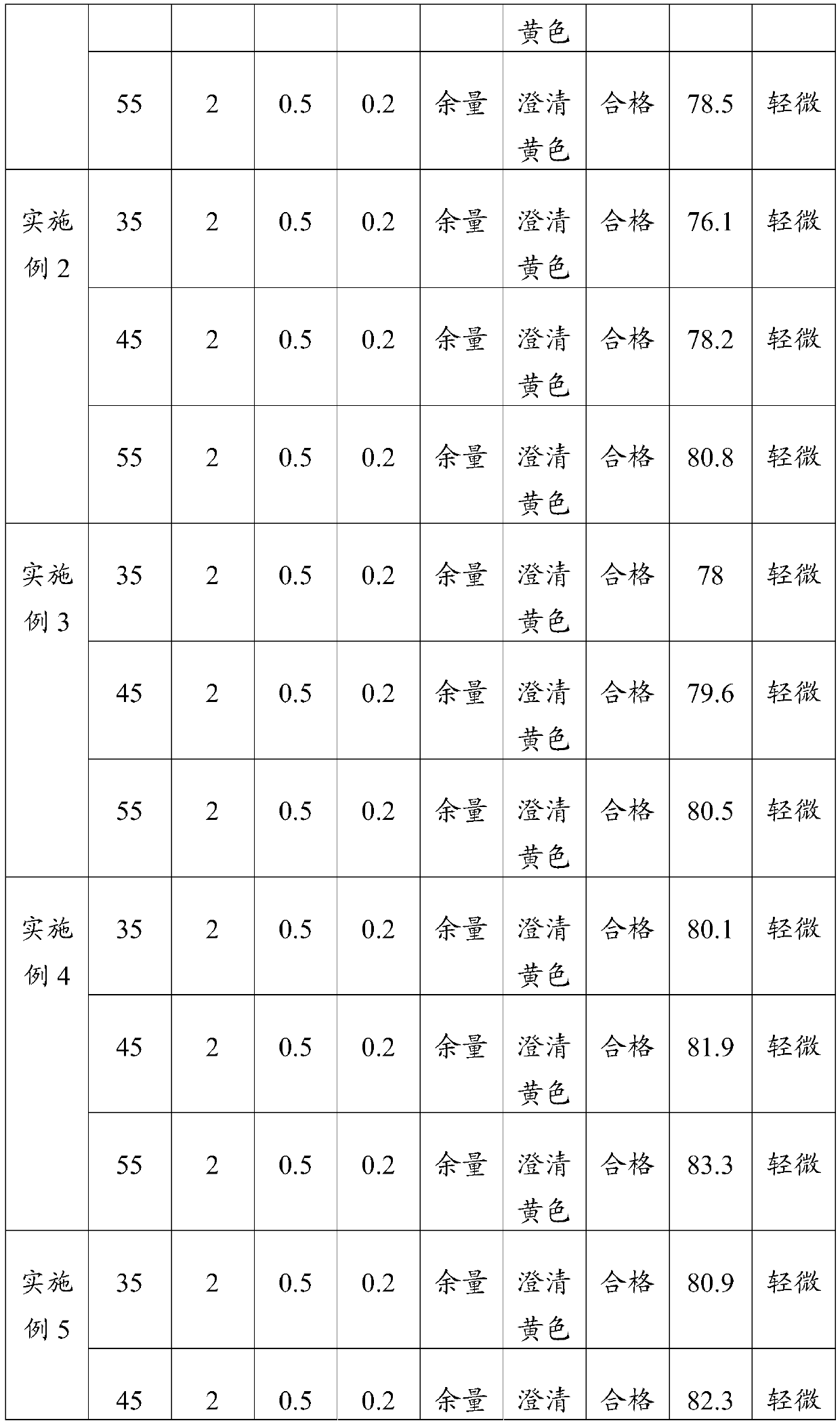

A kind of preparation method of solder paste

ActiveCN108788537BSolder joints are fullLess tin beadsWelding/cutting media/materialsSoldering mediaProcess engineeringGrain distribution

The invention relates to a preparation method of paste flux. The preparation method comprises the following steps: putting basic raw materials for preparing the paste flux in a reaction container to be heated to 80-120 DEG C and to be uniformly stirred to prepare an initial reactant of the paste flux; in a constant temperature condition of 80-120 DEG C, applying ultrasonic waves to the initial reactant of the paste flux for dispersing treatment to prepare a paste flux intermediate; and cooling the paste flux intermediate to the room temperature, and continuously using ultrasonic waves in the cooling process for dispersing treatment to prepare the paste flux. The method provided by the invention is simple and convenient to operate and high in work efficiency. The particle sizes of crystalsin the paste flux prepared through the method provided by the invention are smaller than 20 [mu]m, and the paste flux is more uniform in grain distribution and superior in comprehensive performance.

Owner:SHENZHEN FITECH

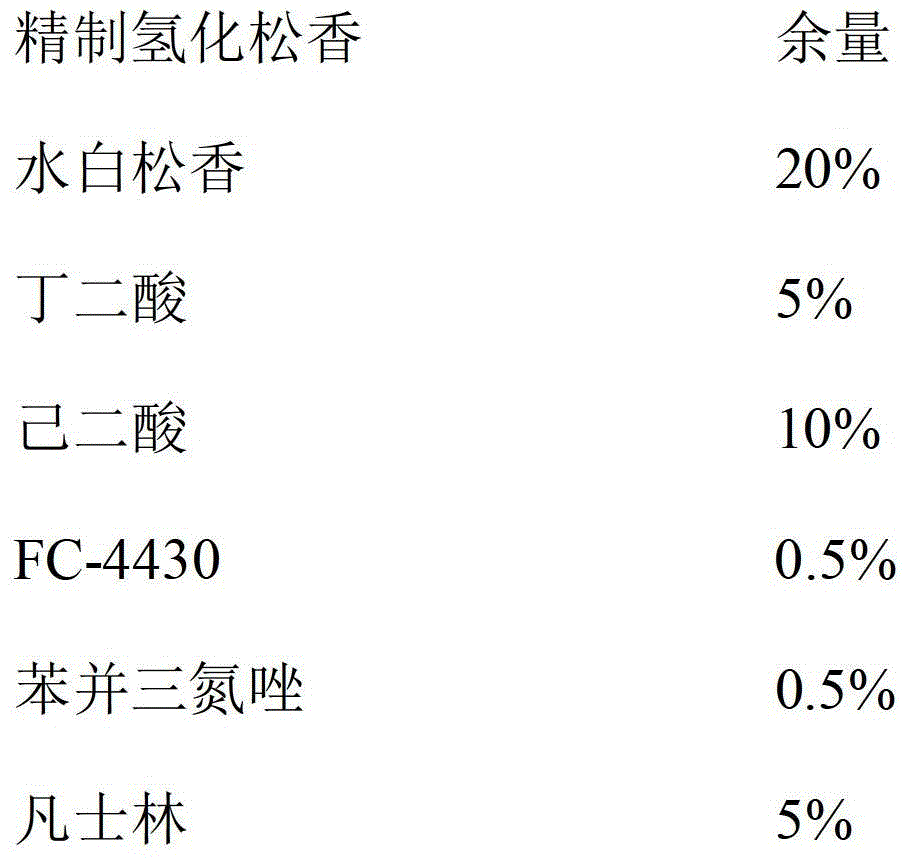

Low-carbon low-volatility water-based flux and preparation method thereof

PendingCN109530971ASolder joints are fullRound solder jointsWelding/cutting media/materialsSoldering mediaBenzoic acidWater based

The invention provides a low-carbon low-volatility water-based flux and a preparation method thereof. The low-carbon low-volatility water-based flux is prepared from the following components, by mass:2-4.5% of an active agent, 1.5-4% of a surface active agent, 0-0.4% of a film-forming agent, 0.01-0.3% of an antioxidant, 0.01-0.4% of a corrosion inhibitor and the balance a solvent, specifically, the active agent is prepared by mixing at least two of succinic acid, benzoic acid, DL-malic acid and adipic acid at the mass ratio of greater than 0% respectively at the temperature of 30-60 DEG C; and the surface active agent is any one of AEC-9NA or TX-10 phosphate, or the surface active agent is prepared by mixing both of the AEC-9NA and TX-10 phosphate at the mass ratio of greater than 0% respectively. The flux has low solid residue content, no halogen, no rosin, low carbon, no volatile organic compound, no irritating odor, little corrosion to a circuit board, and round and bright solder joints. Besides, the flux is easy to manufacture, quite low in cost, convenient to store and transport, free of solder explosion, stable in chemical property, free of influence on physical health of operators and environmentally friendly.

Owner:CHONGQING UNIV OF TECH

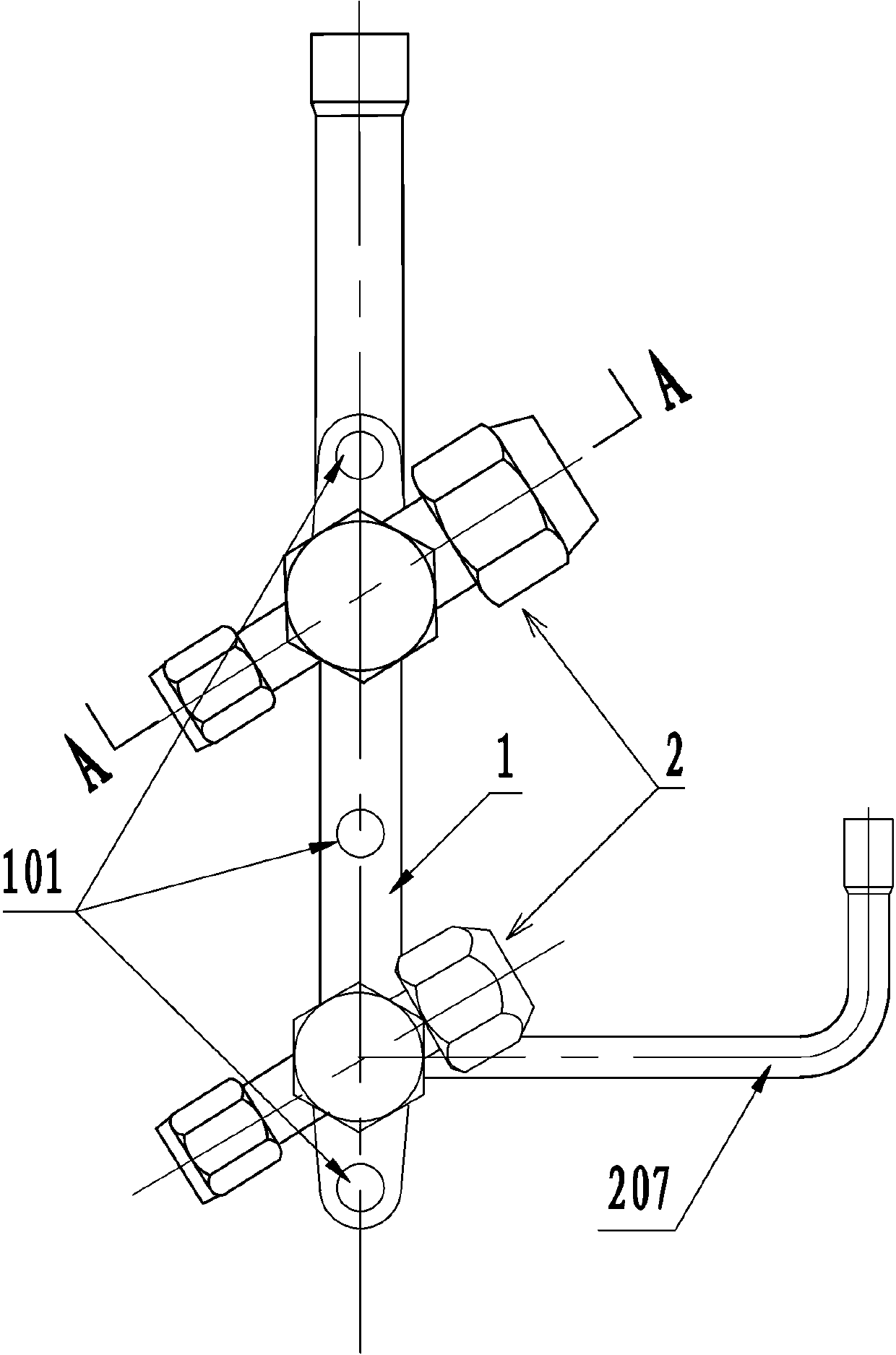

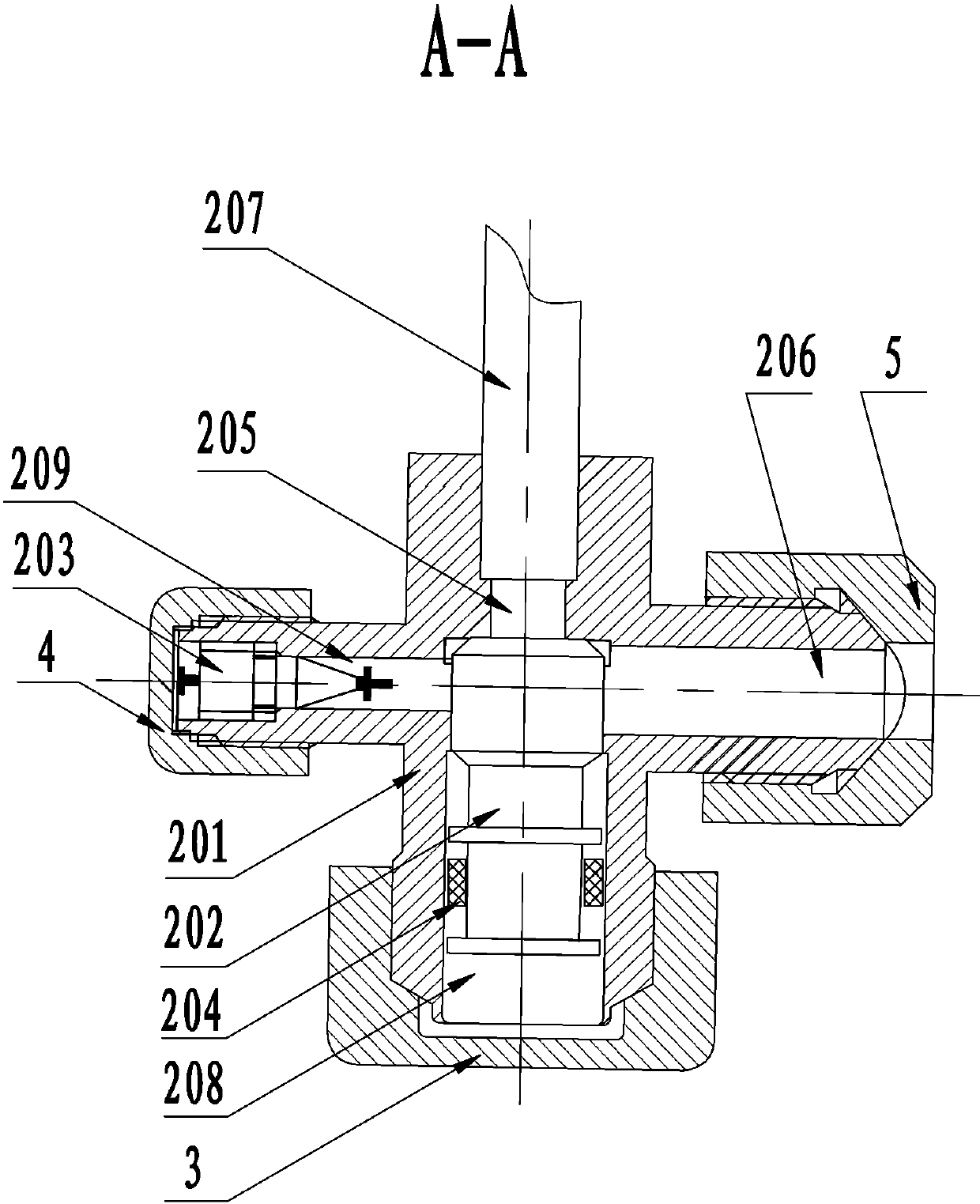

Check valve for air conditioner

InactiveCN104006200AEasy to installEasy to fixLighting and heating apparatusSpace heating and ventilation detailsEngineeringCopper

The invention provides a check valve for an air conditioner. The check valve for the air conditioner comprises a valve seat and N valve body assemblies arranged on the valve seat, wherein N is larger than or equal to 2. Each valve body assembly comprises a valve body, a valve element, an air valve core, an O-shaped seal ring located in a seal ring groove of the valve element and a connecting pipe which is connected with an air inlet and an air outlet in the valve body, wherein the valve element is installed in a main hole formed in the valve body, the air valve core is installed in an auxiliary hole formed in the valve body, the main hole is sealed through a copper cap with internal threads, the auxiliary hole is sealed through a copper air valve core nut, and the air outlet is sealed through a copper nut. When the check valve, with the structure, of the air conditioner is installed, a worker just needs to conduct installation operation once, and then the demand for use of a plurality of valve bodies of the connecting pipe of an outdoor unit can be met.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Lead free tin cream and preparation process

InactiveCN1264640CImprove surface activityIncrease stickinessWelding/cutting media/materialsSoldering mediaOrganic acidVegetable oil

The invention provides a lead-free solder paste comprising the tin base alloy welding powder and the pewter. The components of the tin base alloy welding powder are as follows (in % by weight): Sn 91-99, Cu 0.5-3, Ag 0.5-6; the components of the pewter are as follows (in % by weight): mixed alcohol ether 25-40, natural colophony 50-70, natural vegetable oil thixotropic agent 5-15, organic acid 0.5-2.0, additives. The lead-free solder paste preparing process includes the following steps: mixing the components of the pewter in proportion, standing to room temperature, putting the pewter in a refrigerating chamber with the temperature of 1 C. to 10 C. for 48 hours; mixing the pewter and the tin base alloy welding powder in the ratio of 1 to 9 in the vacuum dispersion machine, putting the mixture in the package bottle and storing hermetically with the temperature of between 5 C. and 10 C.. The lead-free solder paste is characterized by good surface activity, moderated viscosity, and no smell.

Owner:倪潮春

Halogen-free lead-free tin wire

InactiveCN102248317BImprove reliabilitySolder joints are fullWelding/cutting media/materialsSoldering mediaHalogenOrganic solvent

The invention relates to the technical field of tin wires, in particular to a composite halogen-free lead-free tin wire in line with the EU (European Union) directive. The tin wires comprise the following components in parts by per unit mass: 96-98 parts of tin, 0.6-0.7 part of copper, 0.1-0.2 part of resin, 0.1-0.2 part of non-fluorochloro environmentally-friendly organic solvent, 0.05-0.06 part of thixotropic agnet, 0.02-0.4 part of organic active agent, 0.01-0.02 part of corrosion inhibitor, and 0.01-0.02 part of surfactant, wherein the tin and the copper are the solder of the tin wire, and others are soldering flux. By using said technical scheme in the invention, the product is in line with relative directive of the EU and free from lead and relative halogen. Furthermore, the reliability of the welding is high, bad welding spot cannot be formed, and the welding spot is full and bright.

Owner:JIANGXI UNIV OF SCI & TECH +1

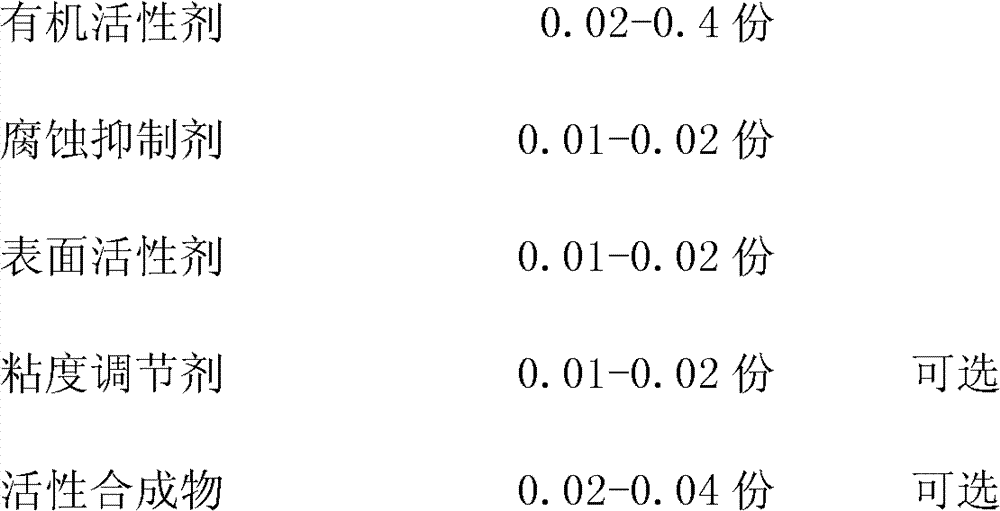

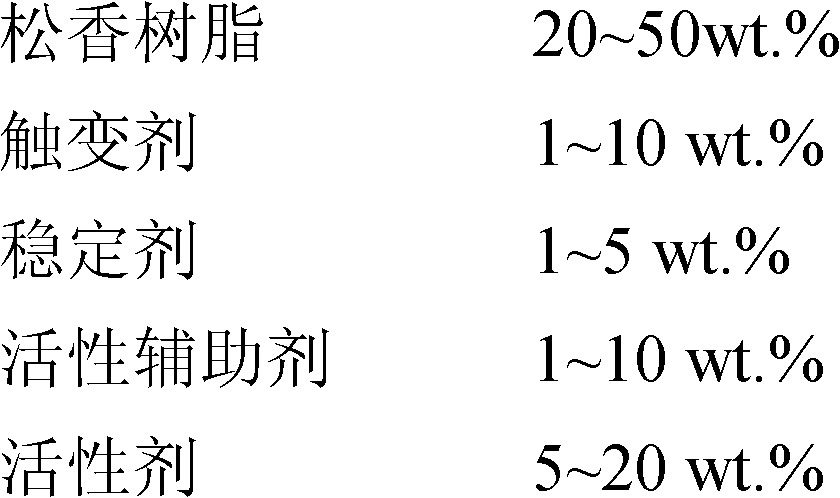

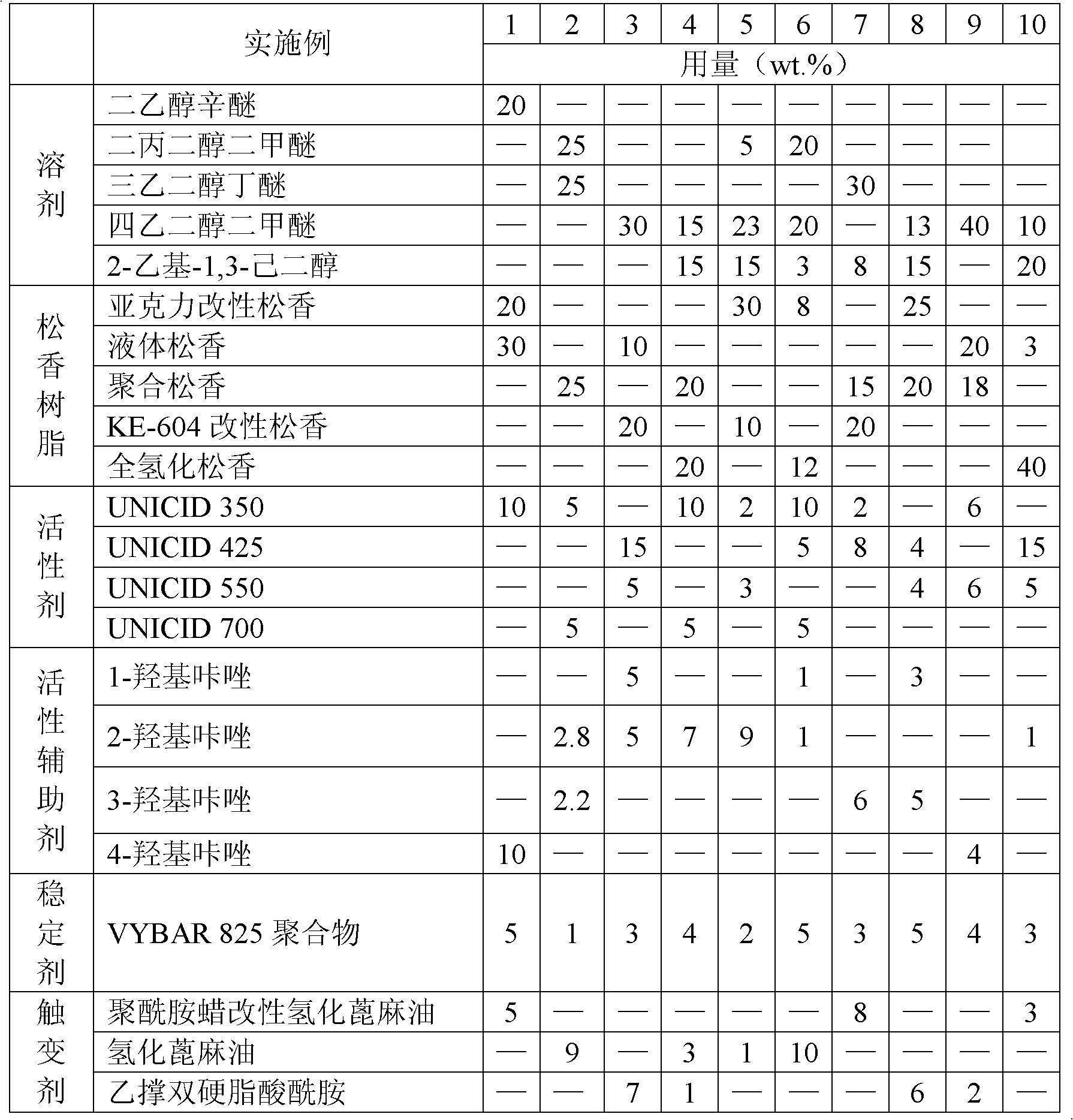

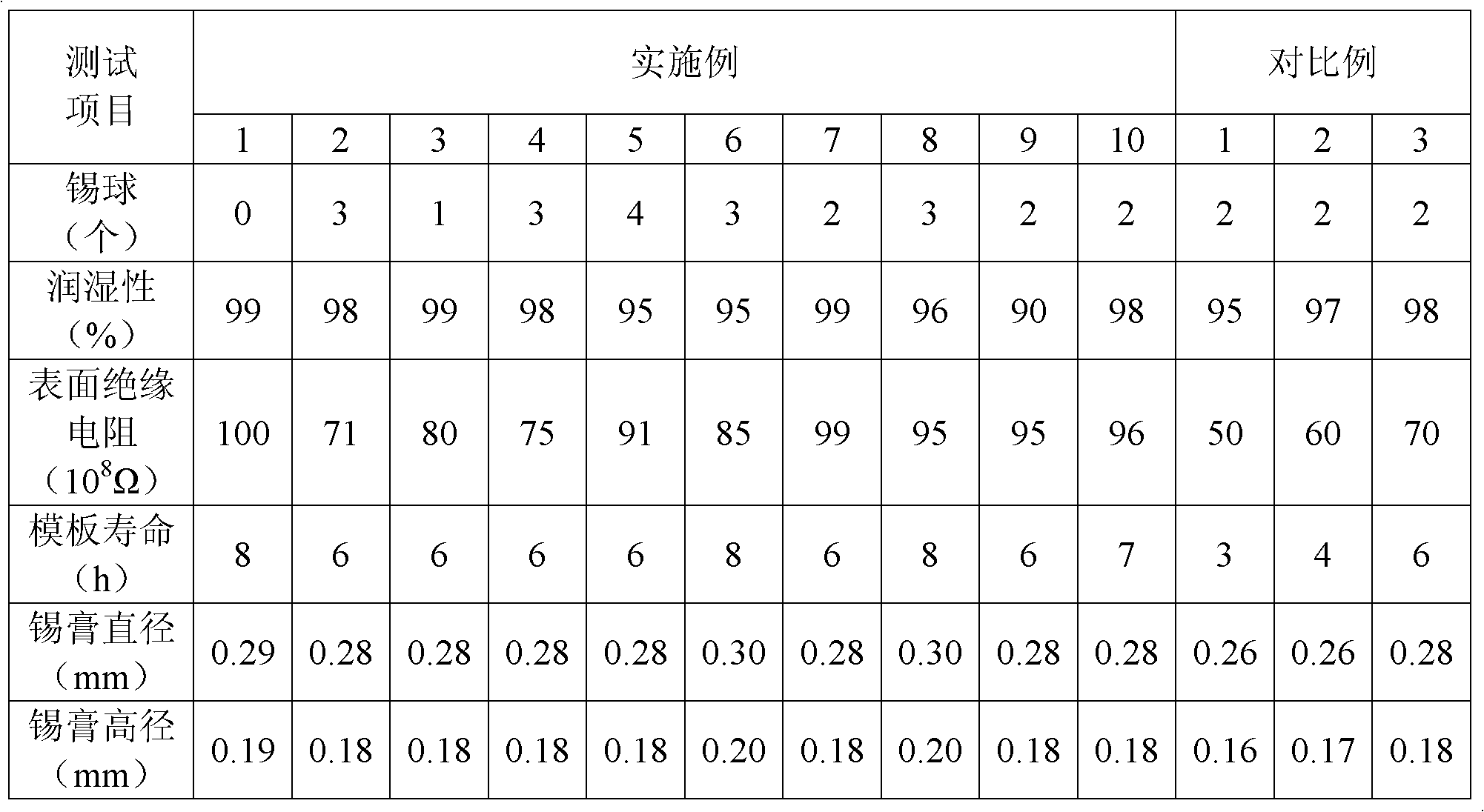

Low-silver lead-free flux paste and preparation method thereof

ActiveCN102489898BEasy to prepareNot easy to form a short circuitWelding/cutting media/materialsSoldering mediaAdjuvantActive agent

The invention discloses a low-silver lead-free flux paste, which comprises abietic resin 20-50wt.%, a thixotropic agent 1-10 wt.%, a stabilizing agent 1-5 wt.%, active adjuvant 1-10 wt.%, an active agent 5-20 wt.%, and the balance solvent. The stabilizing agent is poly-alpha-olefin with ultrahigh branches, the number-average molecular weight is 2800-2900, the distribution index of degree of polymerization is 1.6-1.7, and the viscosity measured at the temperature of under 37.8 DEG C according to American Society for Testing and Materials (MSTM) D-3236 is 530cP. The active agent is long-chain linear carboxylic acid which contains 26-50 carbon atoms, the acid value is 61-115mgKOH / g, and the number-average molecular weight is 390-720. The active adjuvant is hydroxy carbazole. The flux paste and lead-free flux paste with low-silver lead-free materials can be prepared into the lead-free flux paste which has small solder balls, good welding effects and high surface insulating resistance so that a short circuit does not happen to a circuit board after welding, wettability is good, welding spots are full, and welding effects are good. In addition, corrosivity is small, and service life of a template is greatly improved. Besides, the preparation method of the flux paste is simple and easy to implement in industries in a large-scale mode.

Owner:昆山成利焊锡制造有限公司

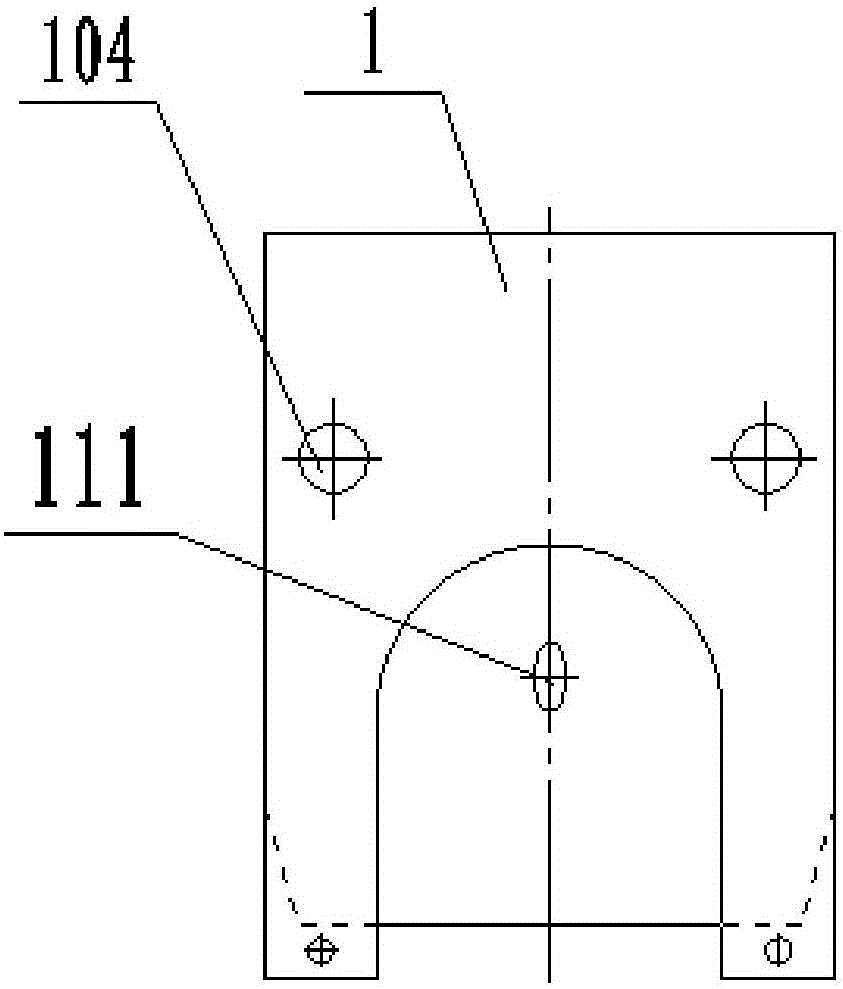

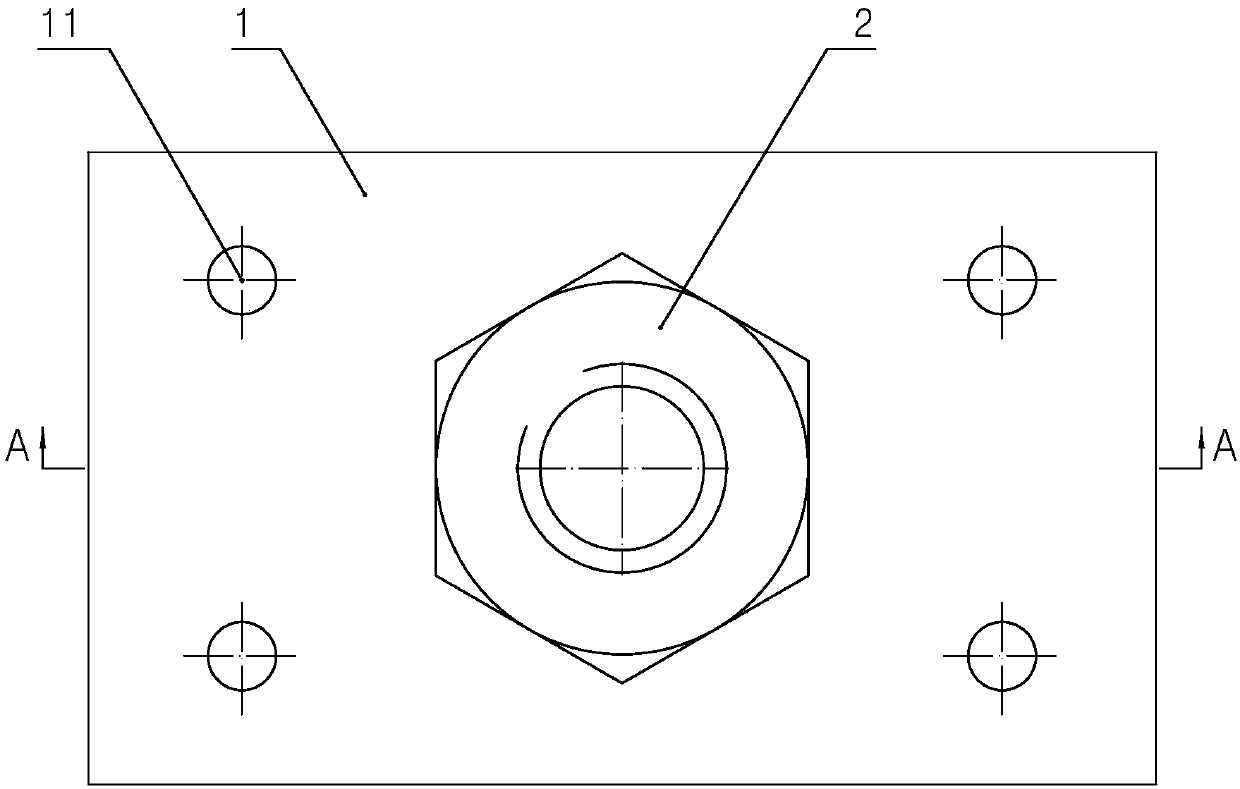

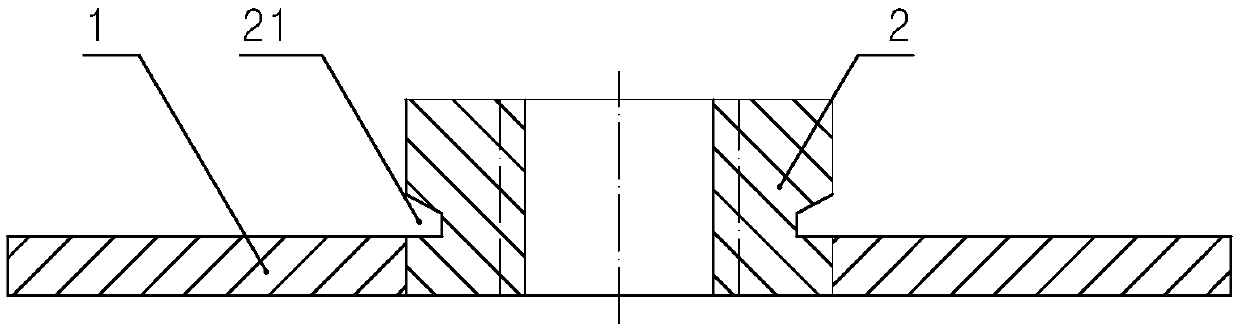

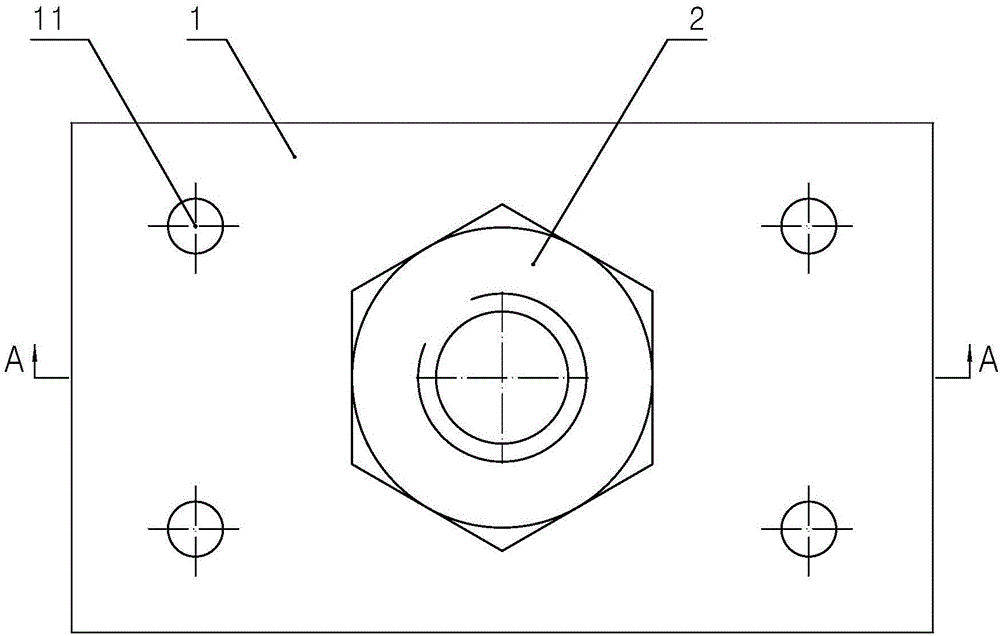

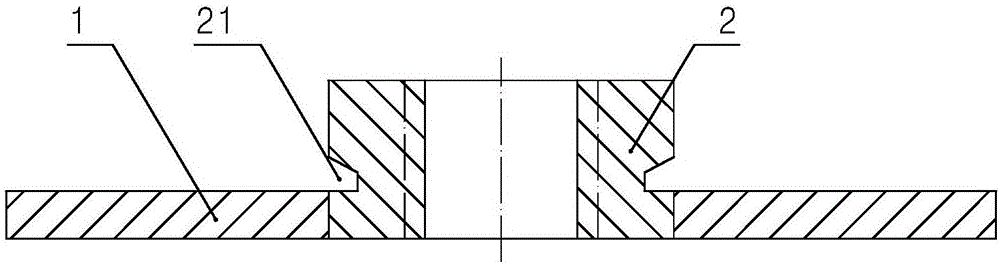

A kind of welding method of embedded nut connector

The invention discloses a welding method for an embedded nut connecting piece, and by the adoption of the welding method, the nut can be reliably welded to a mounting bottom plate. The embedded nut connecting piece comprises the mounting bottom plate and a containing hole which is formed in the mounting bottom plate and matched with the nut. The welding method comprises the following steps that 1), a circle of annular trench is formed in the side face of the nut to be welded in the peripheral direction, and the distance between the lower side face of the trench and the bottom face of the nut is equal to the thickness of the mounting bottom plate; 2), the nut is put into the mounting hole of the mounting bottom plate, and at least three welding points are selected for welding with the center line of a threaded hole of the nut as the center in the circumferential direction; and 3), the welded embedded nut connecting piece is subjected to post-heat treatment. The welding method is extremely wide in application range.

Owner:张家港市锦力标准件制造有限公司

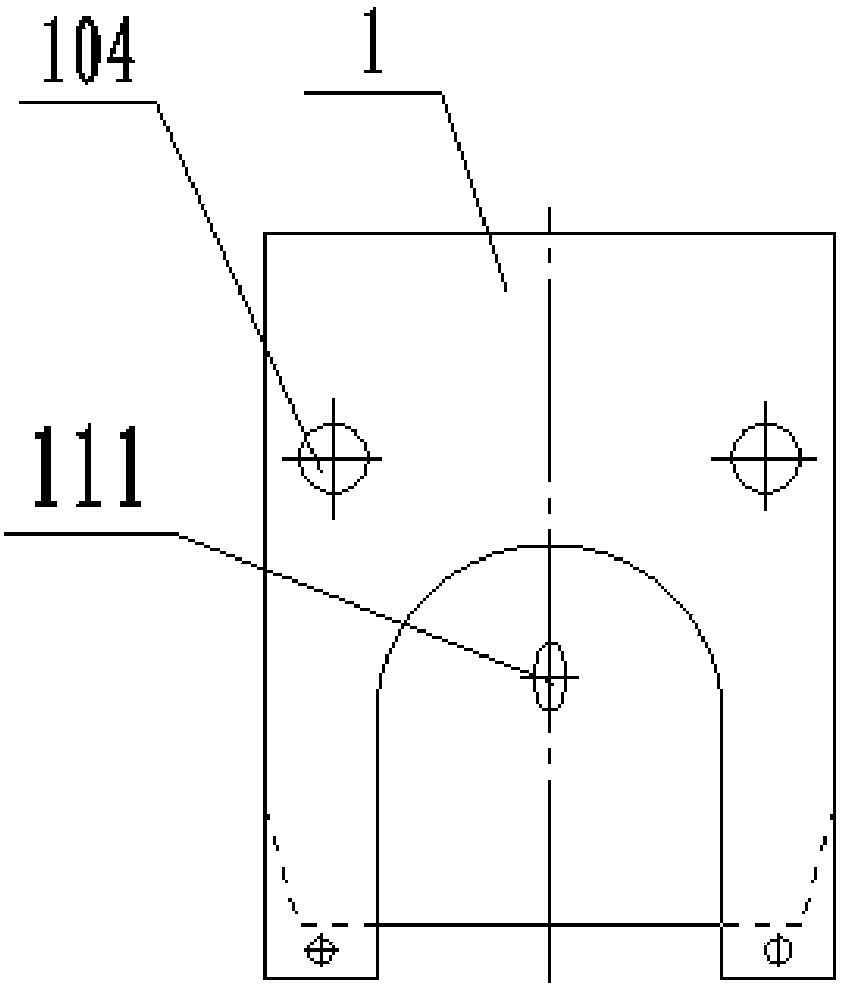

Ultrasonic welding base structure

PendingCN109175674AHigh speedImprove welding qualityNon-electric welding apparatusUltrasonic weldingConnection table

The invention provides an ultrasonic welding base structure. The ultrasonic welding base structure comprises a bottom plate, a bottom support block set arranged on the bottom plate, synchronous connecting rod sets connected with four corners of the upper portion of the bottom plate, a membrane plate structure penetrating through the synchronous connecting rod sets, and an upper guide plate structure arranged on the upper portion of the membrane plate structure and connected with the synchronous connecting rod sets, wherein the membrane plate structure includes a membrane connection plate and guide holes formed in the membrane connection plate. The ultrasonic welding base structure is characterized in that the lower portion of the upper guide plate is movably provided with a welding connection pedestal; and the welding connection pedestal comprises edge locking blocks arranged at the lower portion of the upper guide plate structure, connection lock sleeves arranged on the edge locking blocks, locking rods, a welding tool connection table and a welding tool connection block set. By adoption of the movable arrangement of the welding connection pedestal, the speed of changing a membrane and the welding quality are improved.

Owner:WUHU XINBAO ULTRASONIC EQUIP

A special solder paste for aluminum welding and its preparation method and use method

ActiveCN108213766BHigh strengthImprove plasticityWelding/cutting media/materialsSoldering mediaActive agentSurface-active agents

Owner:中山翰华锡业有限公司

Welding method for embedded nut connecting piece

The invention discloses a welding method for an embedded nut connecting piece, and by the adoption of the welding method, the nut can be reliably welded to a mounting bottom plate. The embedded nut connecting piece comprises the mounting bottom plate and a containing hole which is formed in the mounting bottom plate and matched with the nut. The welding method comprises the following steps that 1), a circle of annular trench is formed in the side face of the nut to be welded in the peripheral direction, and the distance between the lower side face of the trench and the bottom face of the nut is equal to the thickness of the mounting bottom plate; 2), the nut is put into the mounting hole of the mounting bottom plate, and at least three welding points are selected for welding with the center line of a threaded hole of the nut as the center in the circumferential direction; and 3), the welded embedded nut connecting piece is subjected to post-heat treatment. The welding method is extremely wide in application range.

Owner:张家港市锦力标准件制造有限公司

A kind of smokeless solder wire and preparation method thereof

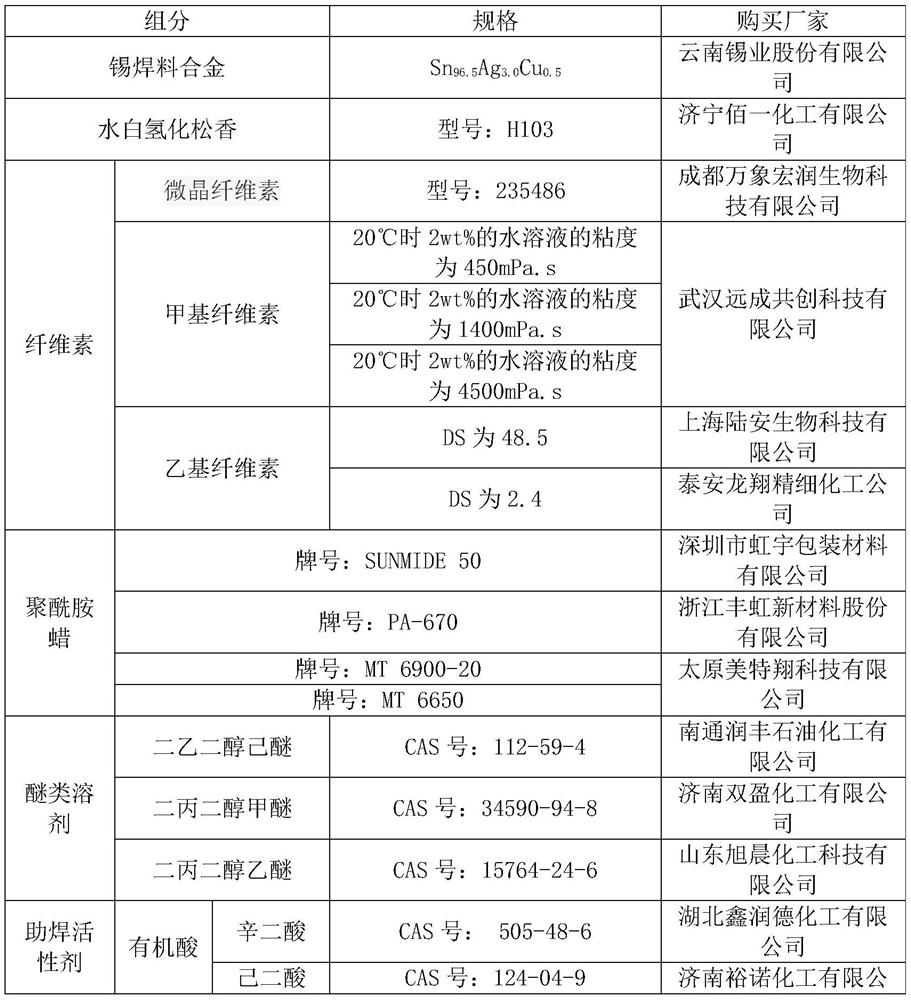

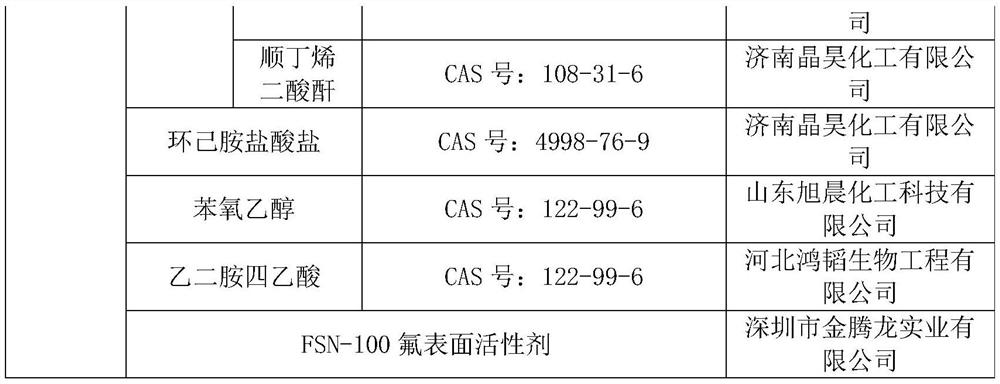

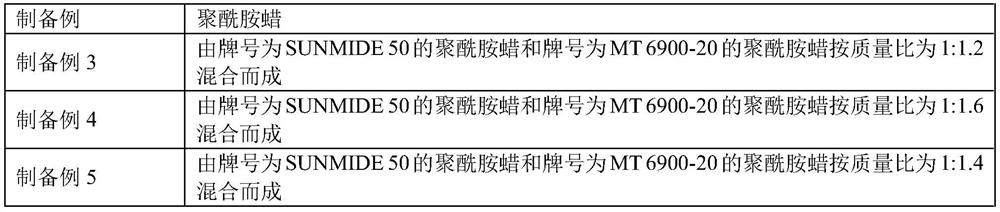

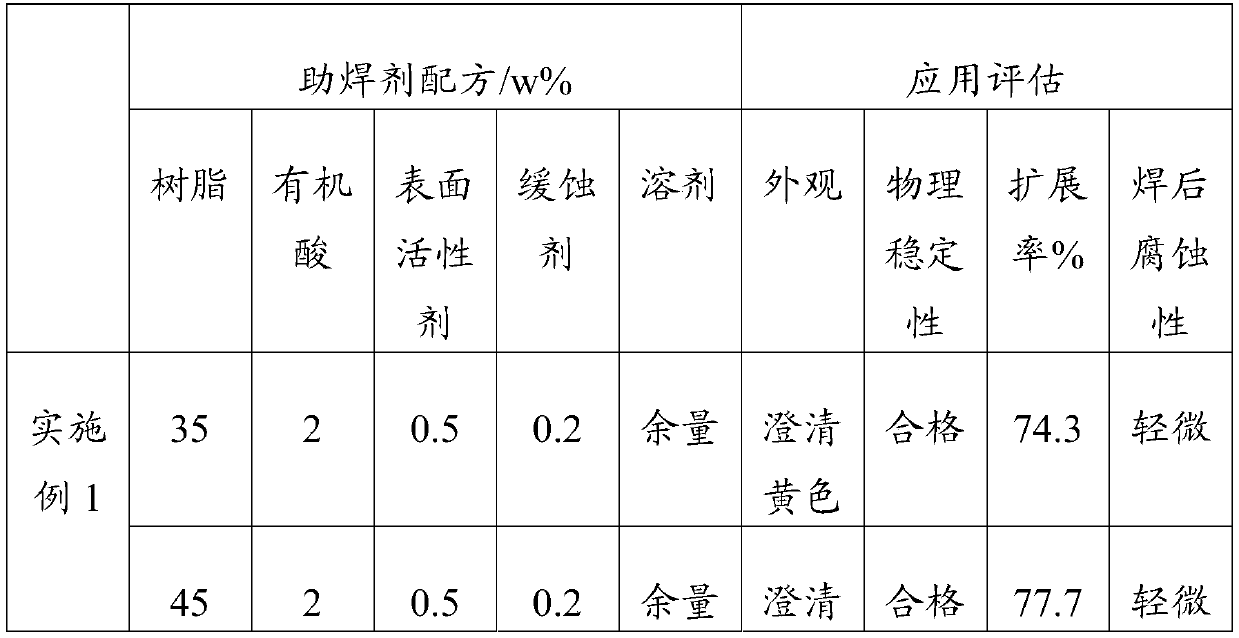

ActiveCN112775587BImprove thermal stabilityImprove thermoplasticityWelding/cutting media/materialsSoldering mediaCellulosePolymer science

The application relates to solder technology, in particular to a smokeless solder wire and a preparation method thereof. A smokeless solder wire, comprising a tin solder alloy and smokeless flux filled in the tin solder alloy, the mass ratio of the tin solder alloy to the smokeless flux is (97-98):(2-3 ), the smokeless flux includes a smokeless carrier and a flux activator, and the mass ratio of the smokeless carrier to a flux activator is (94-96): 5; the smokeless carrier consists of the following parts by weight Made of raw materials: 40-60 parts of cellulose, 20-30 parts of polyamide wax, 10-15 parts of ether solvent; the polyamide wax is a polyamide wax with an acid value less than 10mgKOH / g and a density of 0.88-0.9g / cm 3 A mixture of modified polyamide waxes. The smokeless solder wire provided by this application does not produce smoke during soldering, eliminates toxic and harmful gases, and the welded parts are clean and tidy after soldering.

Owner:SHENZHEN XINGHONGTAI TIN

A kind of rosin for soldering flux and its preparation method and application

ActiveCN106634612BImprove solubilityHigh flux activityWelding/cutting media/materialsNatural resin chemical modificationPolymer scienceHigh flux

The invention relates to rosin for flux, a preparation method and application, and belongs to the field of basic resin for flux. The rosin for soldering flux of the present invention is prepared by using the rosin containing nanasinic acid as a raw material. The rosin for flux of the present invention has excellent solubility and anti-crystallization performance in the flux solvent system, has high flux activity and low corrosiveness, and has good wetting performance for lead-free solder; and has good thermal stability, Good film formation, the formed solder joints are full, bright and regular.

Owner:广东科茂林产化工股份有限公司 +2

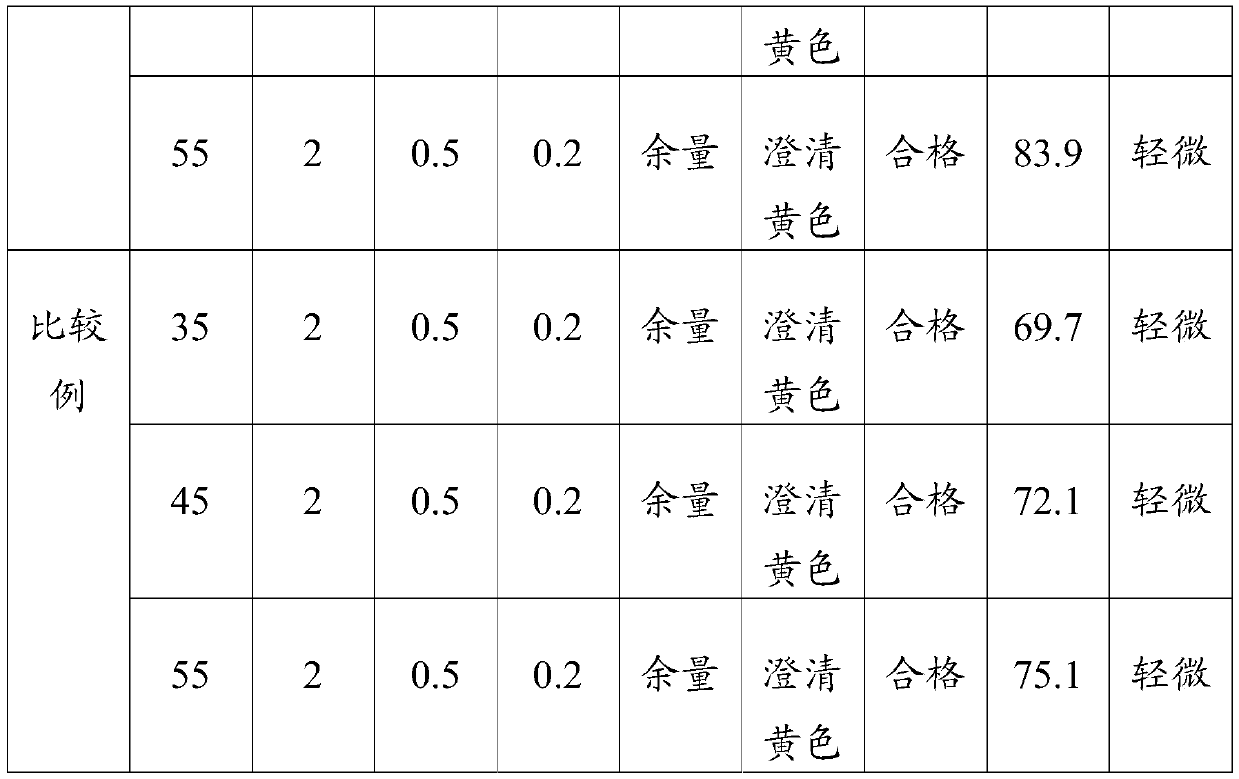

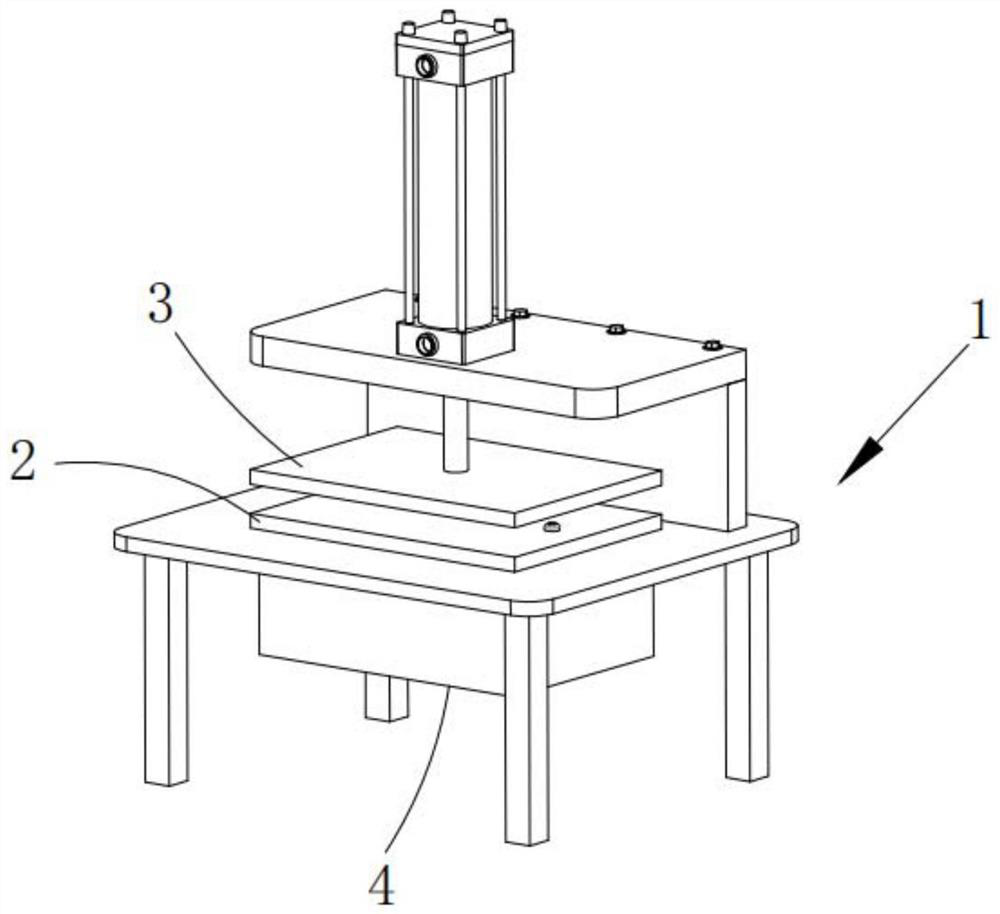

Chip processing table for high-light-efficiency low-thermal-resistance high-power LED outdoor lamp

ActiveCN113351956AFast attachmentWell mixedSolder feeding devicesSemiconductor devicesWorkbenchElectrical and Electronics engineering

The invention relates to a chip processing table for a high-light-efficiency low-thermal-resistance high-power LED outdoor lamp. The chip processing table comprises a workbench, a welding base arranged on the workbench, and a moving plate which is arranged over the welding base in an up-down moving mode and forms a chip clamping station with the welding base. The chip processing table further comprises a storage bin and a feeding device, wherein the storage bin is located below the welding base and used for storing tin; the feeding device comprises a feeding channel penetrating through the welding base and extending downwards into the storage bin, a pumping assembly arranged in the feeding channel and capable of pumping tin in the storage bin into the feeding channel, and a feeding assembly installed on the pumping assembly and capable of feeding tin in the feeding channel to a chip welding spot; and the feeding assembly comprises a containing bowl used for containing tin, a stirring mechanism rotationally installed in the containing bowl, and a feeding mechanism arranged in the stirring mechanism and capable of conveying scaling powder into the containing bowl. The technical problem that in the prior art, tin is not prone to being attached to a welding spot, and consequently the welding quality is reduced is solved.

Owner:苏州伦可新材料技术有限公司

Lead-free solder

InactiveCN100478115CUniform metallographicMetallographic refinementWelding/cutting media/materialsSoldering mediaIntermediate frequencyManganese

The invention relates to a leadless tin soldering material which comprises the constituents (by mass ratio) of Ag 0.5-6%, Cu 0.1-2%, In 0.0001-1%, P 0.0001-1%, and balancing Sn. The preparing process of the soldering material comprises weighing 1.67-20 parts of Sn-Ag intermediate alloy ingot containing Ag 30%, 1-20 parts of Sn-Cu intermediate alloy ingot containing Cu 30%, 0.002-20 parts of Sn-In intermediate alloy ingot containing In 5%, P 0.0001-1 part, and balancing Sn in the whole 100 parts, charging the raw materials into manganese alloy crucible, smelting in intermediate frequency furnaces, evacuating and filling in nitrogen, elevating the temperature to 450 deg. C, agitating 1 hour, cooling down slowly and homogeneously to 340 deg C, charging weighed P and stirring homogeneously, finally pouring the melted liquid into dies.

Owner:THOUSAND ISLAND METAL FOIL

A low-splash halogen-free solder for tin wire and preparation method thereof

InactiveCN103394824BHigh surface insulation resistanceImprove wettabilityWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention discloses a low-splash and halogen-free welding agent for tin wires and a preparation method thereof. The welding agent is mainly used for agent cores of tin-based alloy tin wires. The welding agent is composed of, by weight, 80-90% of rosin and rosin derivatives, 5-15% of active agents, 0.1-2% of efficient surface active agents, 0.5-2% of corrosion inhibitors and 3-10% of viscosity modifiers. The prepared halogen-free welding agent for the tin wires is needless of any halogen element, is little in splash and smoke when welding is conducted, has high activity, is high in surface insulation resistance, and can be used for preparing tin-lead series tin wires, tin-copper series tin wires and tin-silver-copper series tin wires. The prepared tin wires are good in wetting performance, high in reliability after being welded, and light and full in welding point.

Owner:BEIJING COMPO ADVANCED TECH

Loudspeaker voice coil wire welding soldering flux and preparation method thereof

InactiveCN102049633BLow costWeld firmlyWelding/cutting media/materialsSoldering mediaEngineeringRosin

The invention discloses a loudspeaker voice coil wire welding soldering flux and a preparation method thereof, and aims to solve the problems that a rosin water soldering flux for welding the voice coil wire has low soldering performance, extremely low welding productivity and dark and lusterless welding spots and that phenomena of loose welded voice coil wire, insufficient welding and cold solder easily occur after welding so as to cause a soundless loudspeaker or intermittent sound of the loudspeaker. The soldering flux comprises soldering fluid consisting of the following components: 3.8 to 4.8 weight percent of ammonium chloride, 0.07 to 0.12 weight percent of anhydrous sodium carbonate, 38 to 46 weight percent of glycerol and 50 to 58 weight percent of absolute ethyl alcohol; and thesoldering flux also comprises rosin water which accounts for 70 to 80 percent of the total weight of the soldering flux. The soldering flux has good soldering performance, high welding productivity and saturated and bright welding spots, so that the voice coil wire is welded firmly. Therefore, the stable acoustical property of a loudspeaker is guaranteed.

Owner:ZHEJIANG ANYALL AUDIO TECH CO LTD

Lead-free paste soldering material and preparation method thereof

InactiveCN106475703BReduce contact resistanceImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaFilm-forming agentGraphite

The invention proposes a lead-free paste welding material and a preparation method thereof. The lead-free paste welding material is prepared by mixing lead-free solder alloy powder with a flux according to a mass ratio of 10-11: 0.9-1.2; the lead-free solder alloy powder is prepared by the following raw materials: 5-10 wt% of Zn, 0.1-0.2 wt% of Ti, 0.6-2.4 wt% of graphene, and the balance of Sn; and the flux has the following components: 40-50 wt% of adhesive film forming agent, 3-12 wt% of activating agent, 2-8 wt% of thixotropy anti-sinking slipping agent, and the balance of solvent. The preparation method comprises the following steps: the lead-free solder alloy powder and the flux are mixed according to the mass ratio of 10-11: 0.9-1.2; the flux is firstly put in a synthesizer; then, solder powder of the lead-free solder alloy powder is added; the synthesizer is sealed; then, a vacuum system is started for vacuumizing to fill nitrogen to reach positive pressure; a stirring system is started for stirring; the stirring is stopped; and the discharge is performed to obtain the lead-free paste welding material. The lead-free paste welding material is excellent in welding point combination strength; and meanwhile, the flux is better in oxidation resistance without needing to add antioxidant.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

A method of using a welding protection device for an air-conditioning liquid reservoir

ActiveCN106270915BAvoid oxidation and blackeningAvoid contactGas flame welding apparatusSurface oxidationEngineering

The invention discloses an air conditioner liquid storage device welding protection device and an application method thereof, and belongs to the technical field of welding. The air conditioner liquid storage device welding protection device comprises an outer ventilation block and an inner ventilation block. The outer ventilation block is of a rectangular block-shaped structure and is provided with a transverse air blowing hole and longitudinal air blowing holes and connected with an air source through an outer ventilation connecting hole. An inner air blowing hole is formed in the inner ventilation block and connected with the air source through an inner ventilation connecting hole. According to the method, a cylinder is inflated with protection air through the inner ventilation block in the welding process, the welding position is immediately inflated with the protection air through the outer ventilation block after welding is finished, and air is prevented from making contact with a welding line. By means of the air conditioner liquid storage device welding protection device and the application method thereof, the surface of a welded part can be prevented from being oxidized during liquid storage device welding, the connecting strength of the welding line is improved, the quality of a finished product is improved, and the production cost is reduced.

Owner:ANHUI ZHONGHUI REFRIGERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com