Alcohol and water mixed-base cleaning-free soldering flux for wire connection

A flux, mixed-based technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of unsuitable flux and low activity, and achieve full solder joints, high qualified rate of finished products, and improved adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

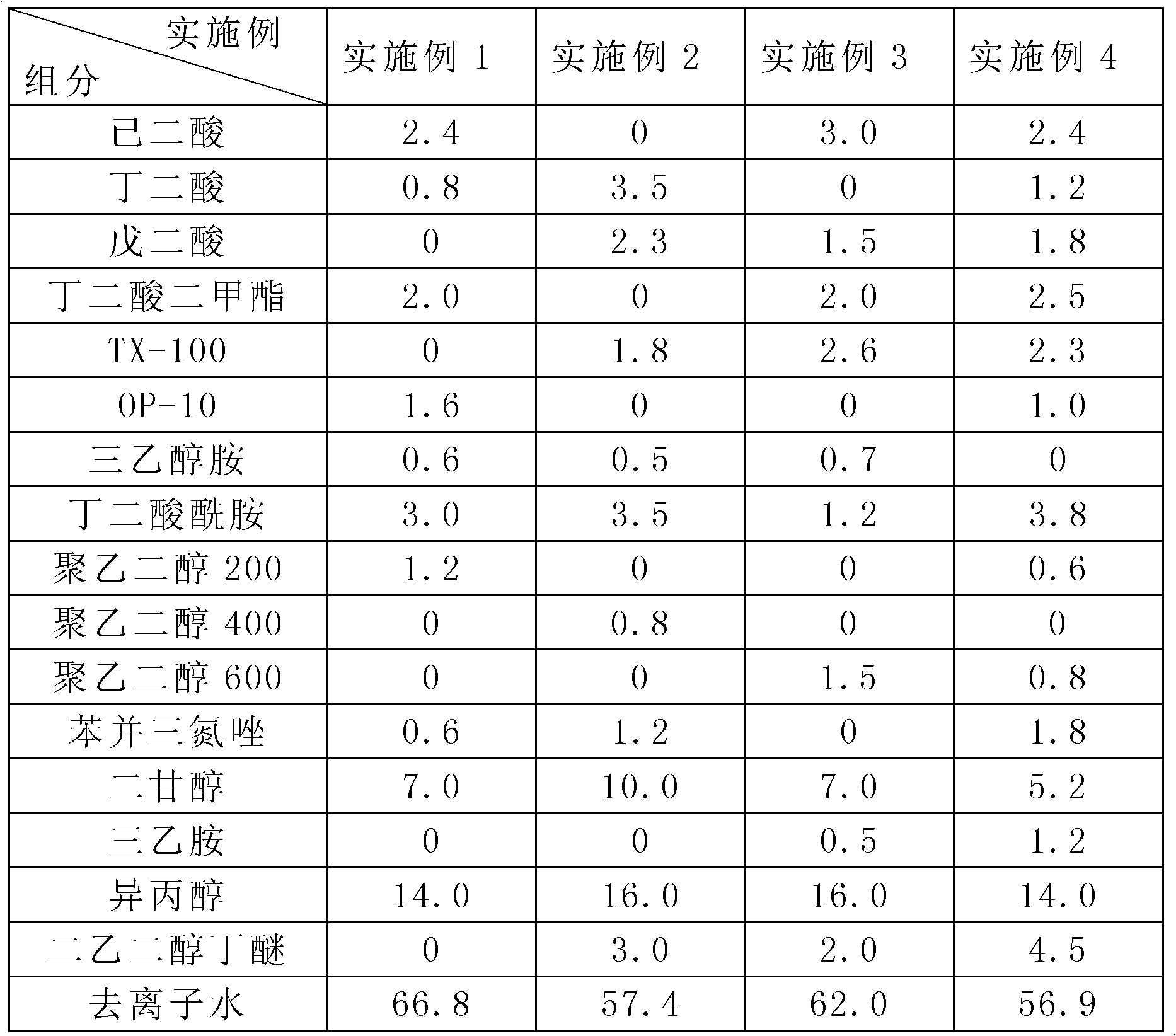

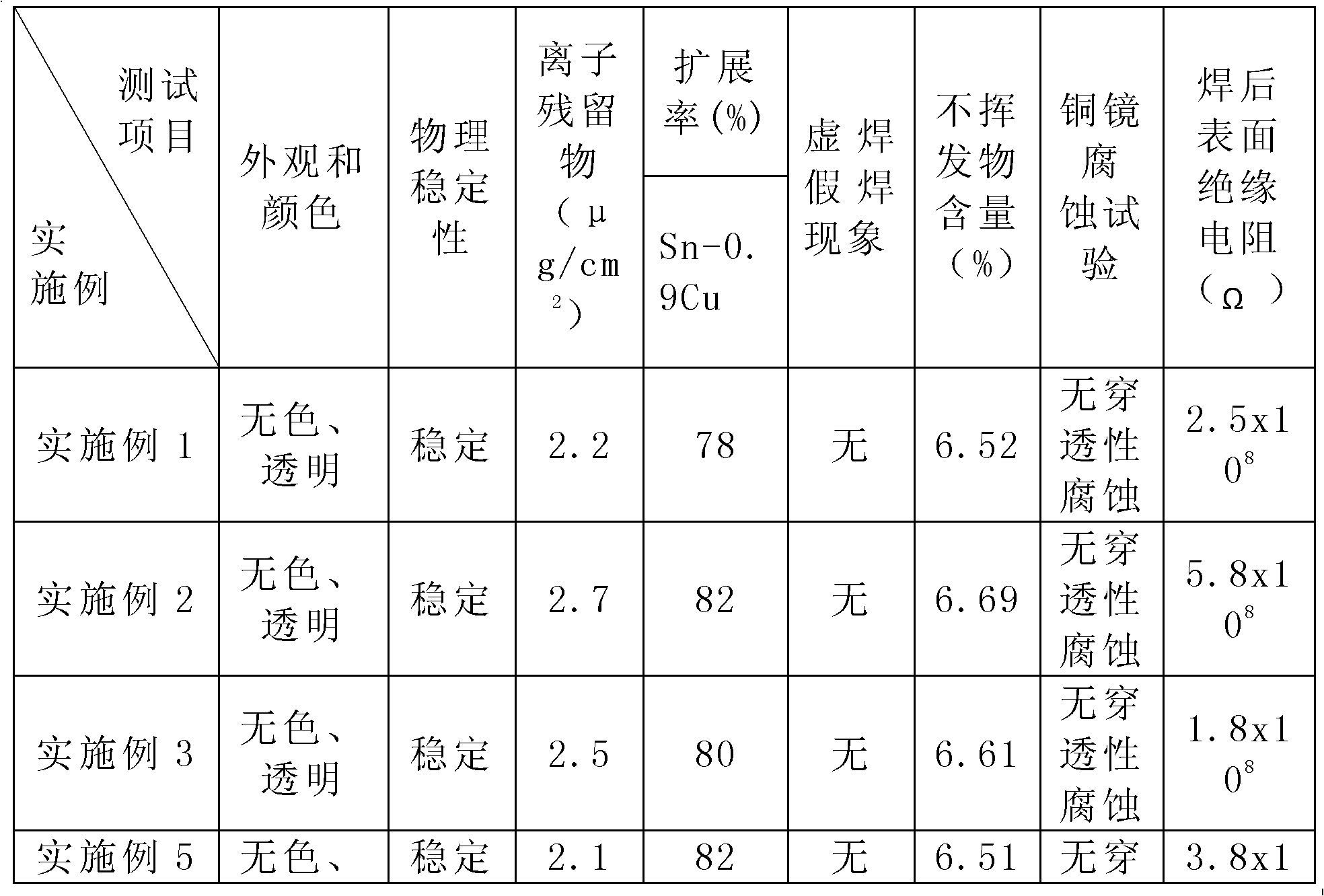

Examples

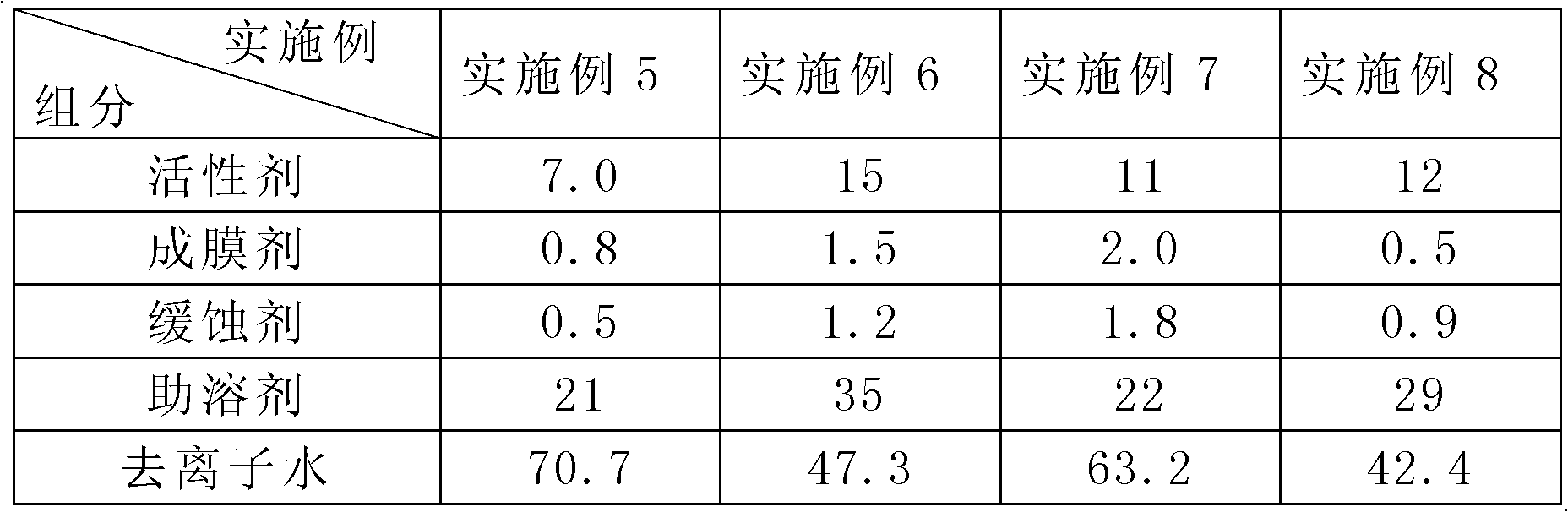

Embodiment 6

[0031] The active agent described in embodiment 6 is adipic acid, succinic acid diester, succinic acid amide and TX-100, and their weight ratio is 1: 3: 2: 1; Described film forming agent is poly Ethylene glycol 200, polyethylene glycol 300 and polyethylene glycol 600, their weight ratio is 3: 1: 2; Described corrosion inhibitor is benzotriazole; Described cosolvent is diethylene glycol and Diethylene glycol butyl ether, the weight ratio of the two is 1:3.

Embodiment 7

[0032] The active agent described in embodiment 7 is succinic acid amide; Described film-forming agent is polyethylene glycol 400 and polyethylene glycol 600, and their weight ratio is 3: 2; Described corrosion inhibitor is Ethylene glycol benzoazole; Described cosolvent is diethylene glycol butyl ether.

Embodiment 8

[0033] The described active agent described in embodiment 8 is succinic acid amide; Described film-forming agent is polyethylene glycol 400 and polyethylene glycol 300, and their weight ratio is 1: 2; Etching agent is ethylene glycol benzoxazole and benzotriazole, and the weight ratio of the two is 2: 3; Described auxiliary solvent is diethylene glycol butyl ether and diethylene glycol, and the weight ratio of the two is 4: 1.

[0034] After selecting raw materials according to the weight parts of all components in the above-mentioned Examples 1-8, firstly add the co-solvent and part of deionized water into the reaction kettle, then add the film-forming agent, stir until dissolved, then add the active agent and buffer etchant and the remaining deionized water, stir until all the components are dissolved, mix the materials evenly, and then filter and remove the filter residue. The obtained filtrate is the alcohol water used for wire bonding as described in Embodiments 1-8 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com