Chip processing table for high-light-efficiency low-thermal-resistance high-power LED outdoor lamp

A technology for LED outdoor lights and LED lights, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of decreased welding quality, difficult adhesion of solder joints, and low light efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

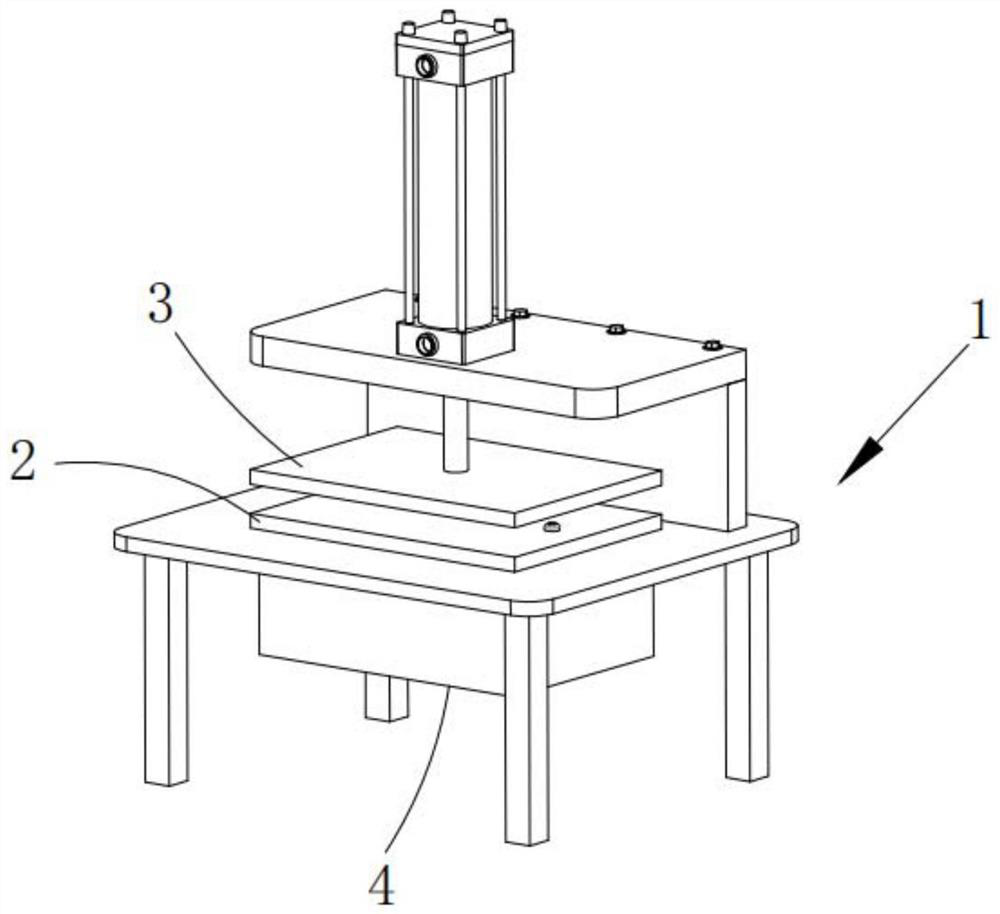

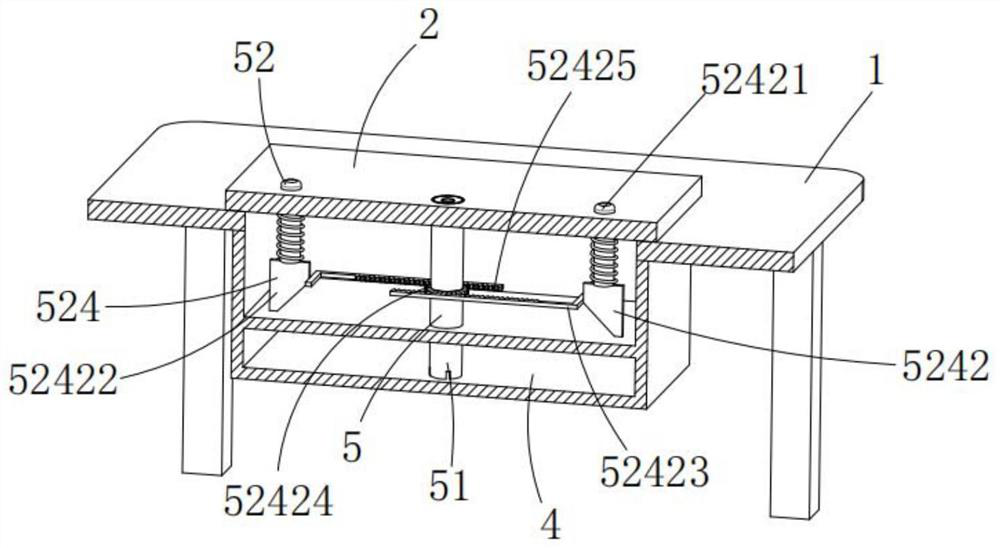

[0043] like figure 1 and figure 2 As shown in the figure, a chip processing table for LED outdoor lamps with high luminous efficiency, low thermal resistance and high power includes a worktable 1, a welding seat 2 arranged on the worktable 1, and a positive side that moves up and down and is arranged on the welding seat 2. The moving plate 3 above and forming a chip clamping station with the welding seat 2 is characterized in that, it also includes:

[0044] storage bin 4, the storage bin 4 is located below the welding seat 2, and the storage bin 4 is used to store tin;

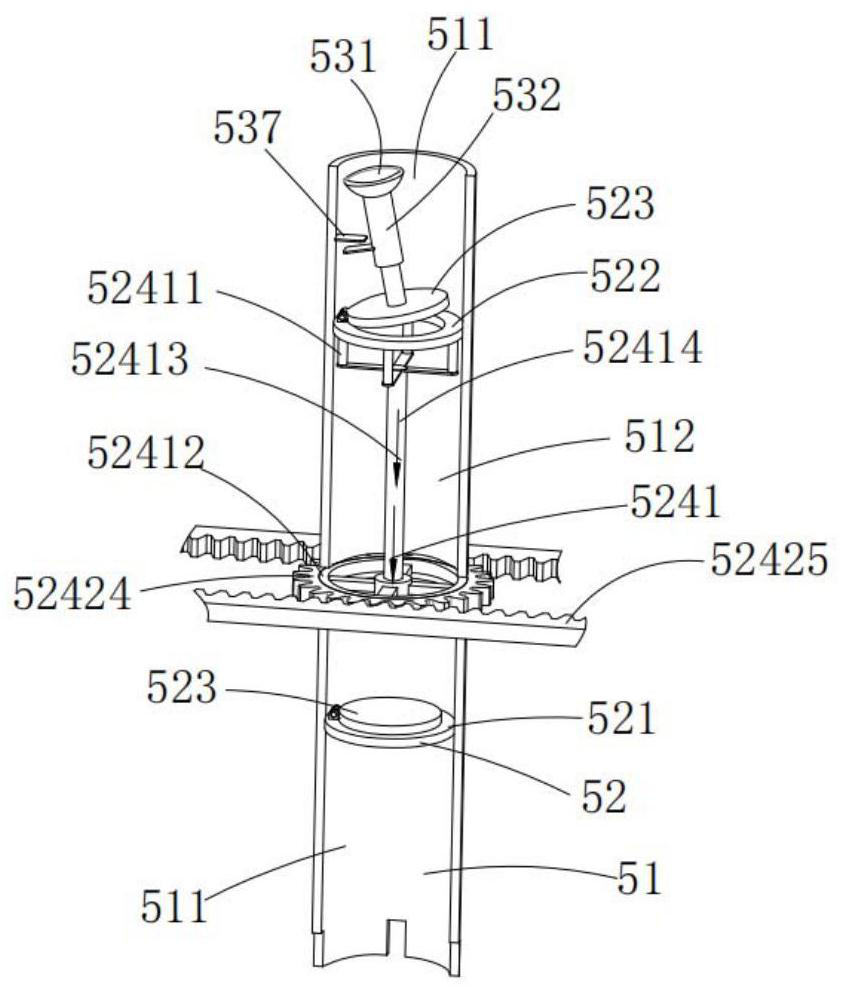

[0045] The feeding device 5 includes a feeding channel 51 extending through the welding seat 2 and extending downward into the storage bin 4 . The feeding channel 51 is arranged in the feeding channel 51 and can extract the tin in the storage bin 4 to the pumping component 52 in the feeding channel 51 and the feeding component 53 installed on the pumping component 52 and capable of sending the tin in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com