Patents

Literature

57results about How to "Improve soldering efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for establishing tin soldering process libraries and system applied to same

InactiveCN105729475AAvoid settingShorten the timeProgramme-controlled manipulatorMetal working apparatusJoints typesEngineering

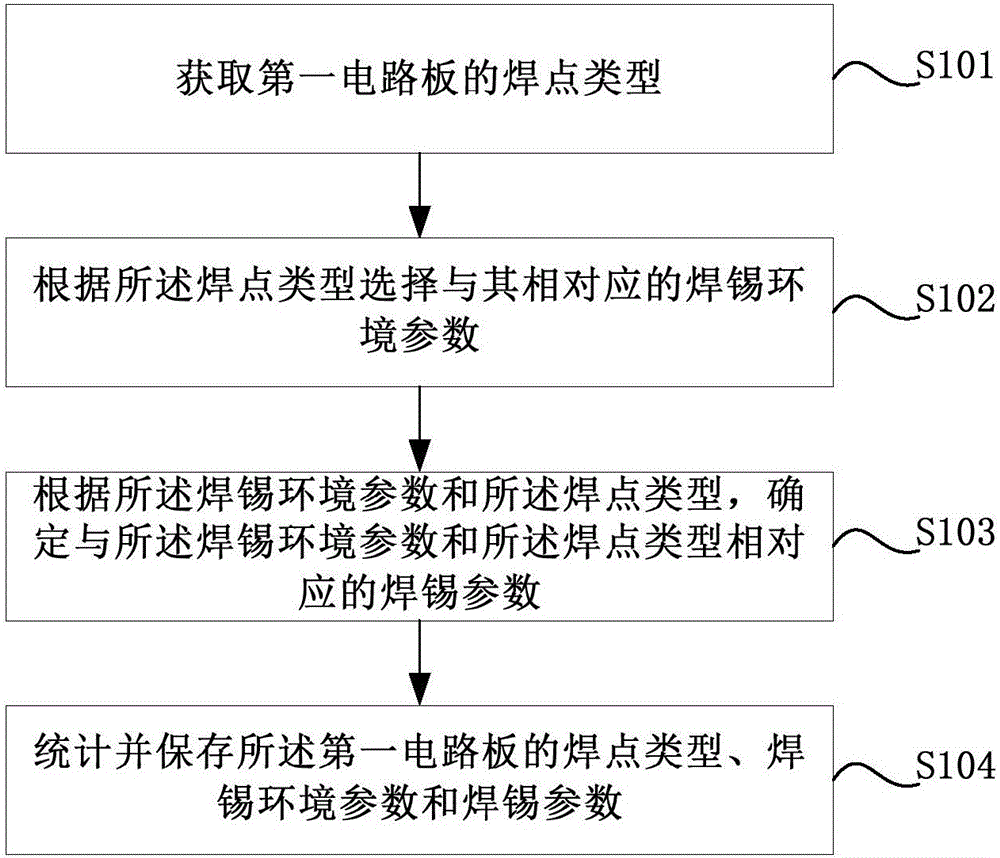

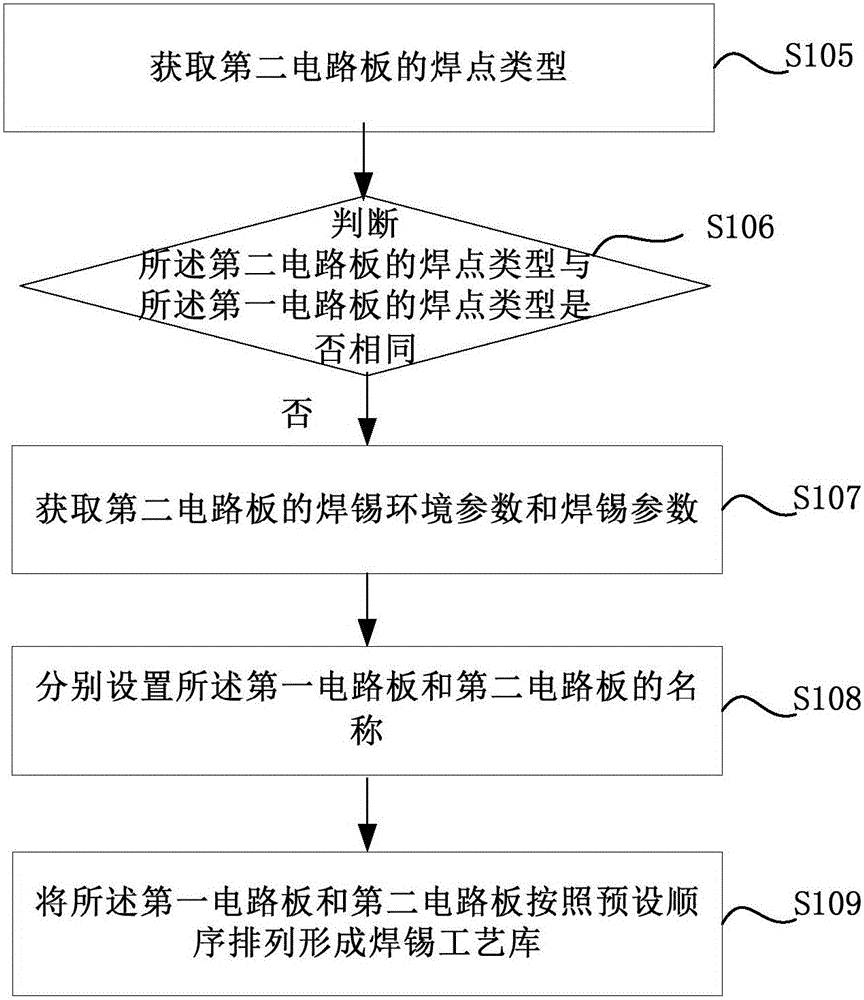

An embodiment of the invention discloses a method for establishing tin soldering process libraries and a system applied to the same. The method includes acquiring solder joint types of first circuit boards, selecting tin soldering environmental parameters according to the solder joint types and determining tin soldering parameters according to the tin soldering environmental parameters and the solder joint types; counting and storing the solder joint types of the first circuit boards, the tin soldering environmental parameters and tin soldering parameters. The solder joint types include pin parameters and pad parameters of components on the first circuit boards, and the tin soldering environmental parameters correspond to the solder joint types. The tin soldering parameters correspond to the tin soldering environmental parameters and the solder joint types and include tin feeding speeds, tin feeding lengths, preheating time and tin-soldered stagnation time. The method and the system have the advantages that tin soldering can be carried out by the aid of the tin soldering parameters in the tin soldering process libraries when the tin soldering process libraries contain the solder joint types of the circuit boards to be subjected to tin soldering and the tin soldering environmental parameters, accordingly, the tin soldering parameters do not need to be manually set one by one, and the tin soldering efficiency can be improved.

Owner:迈力(北京)机器人科技有限公司

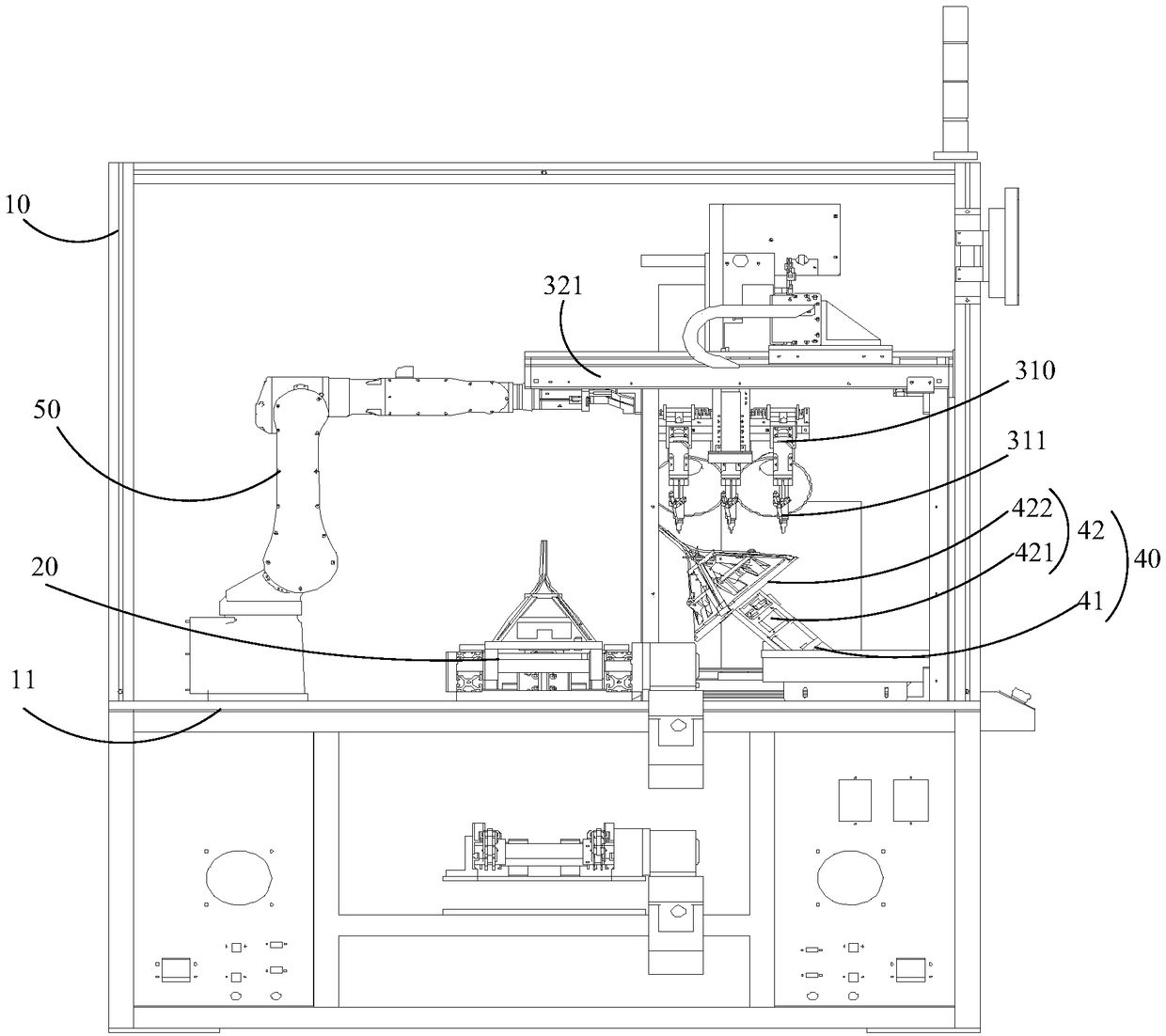

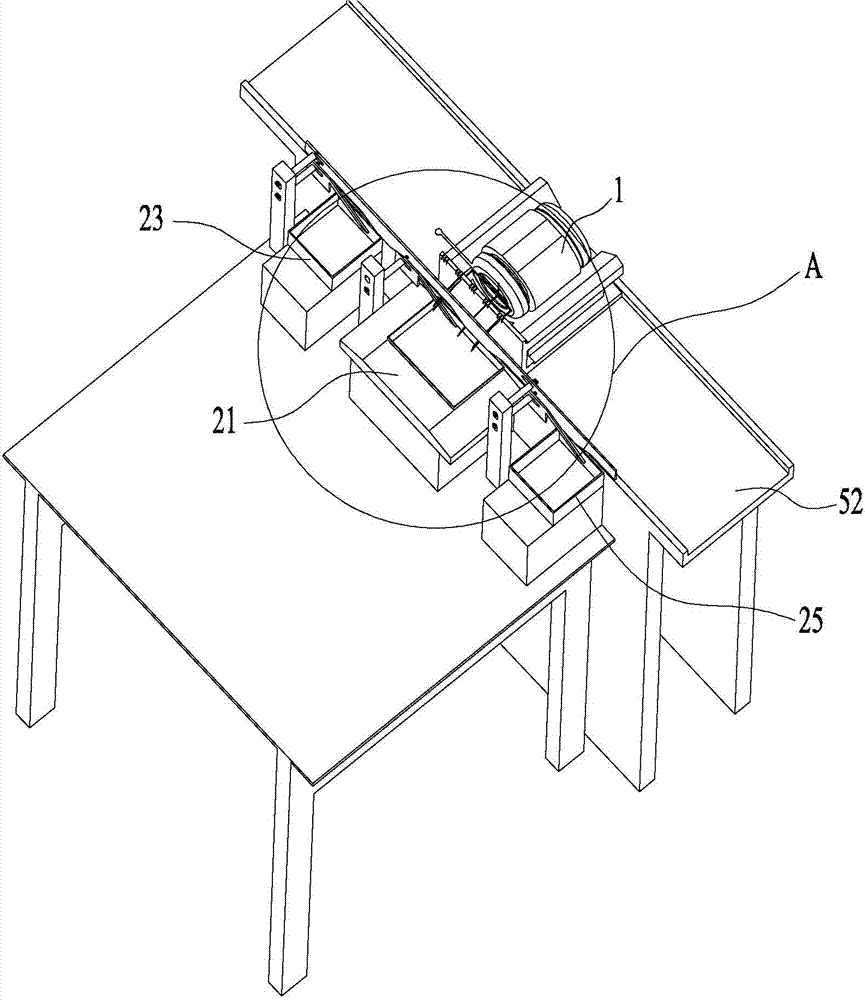

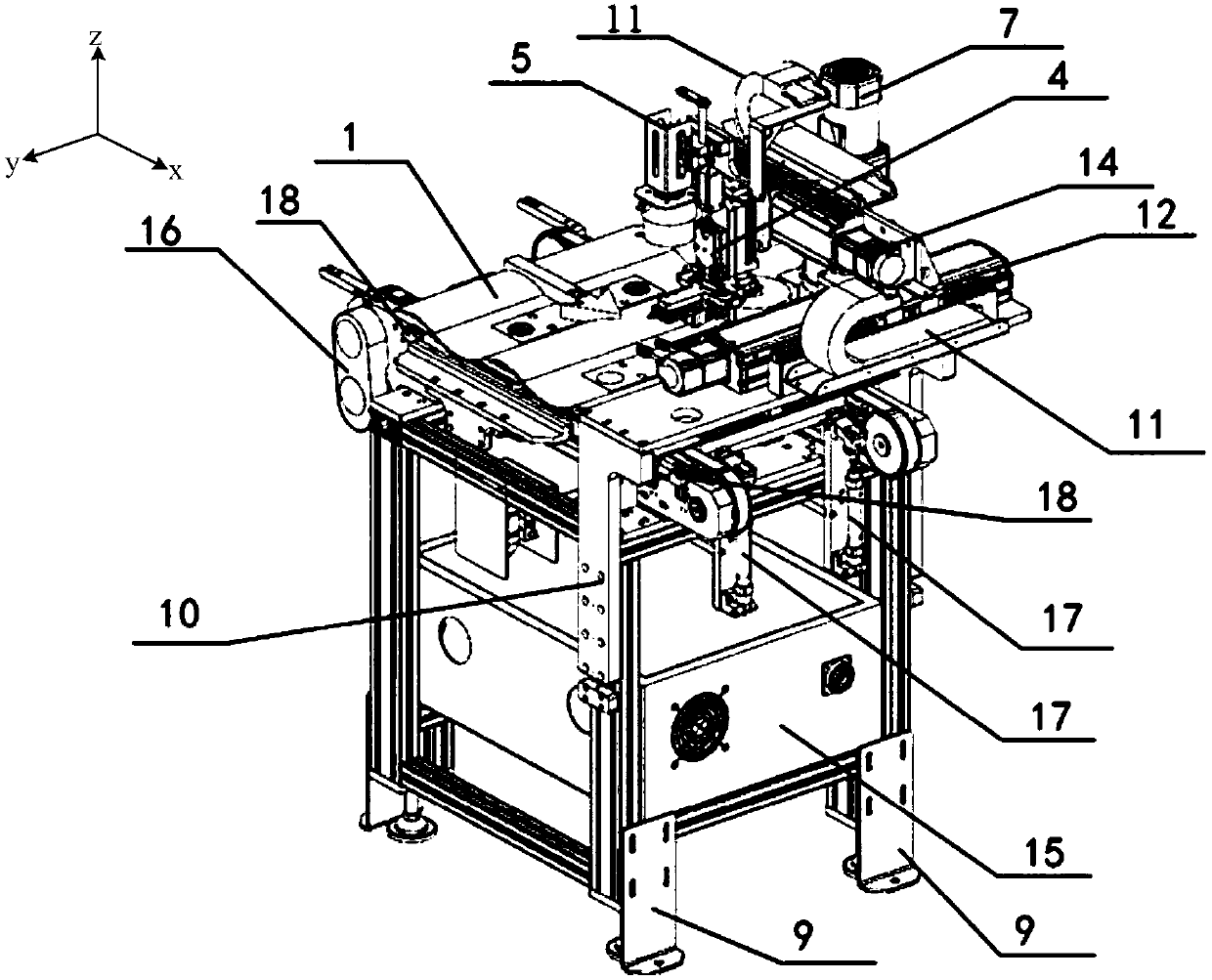

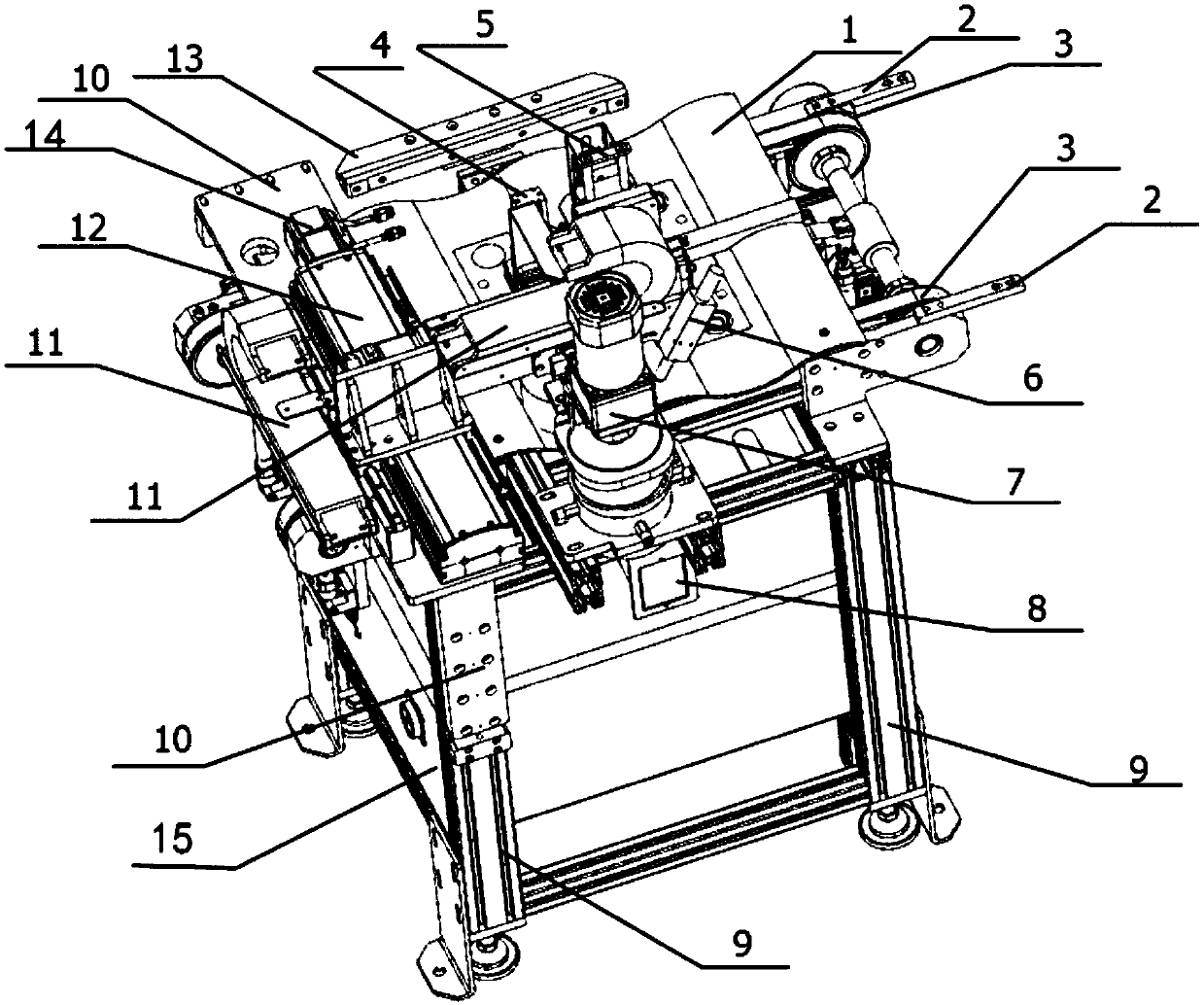

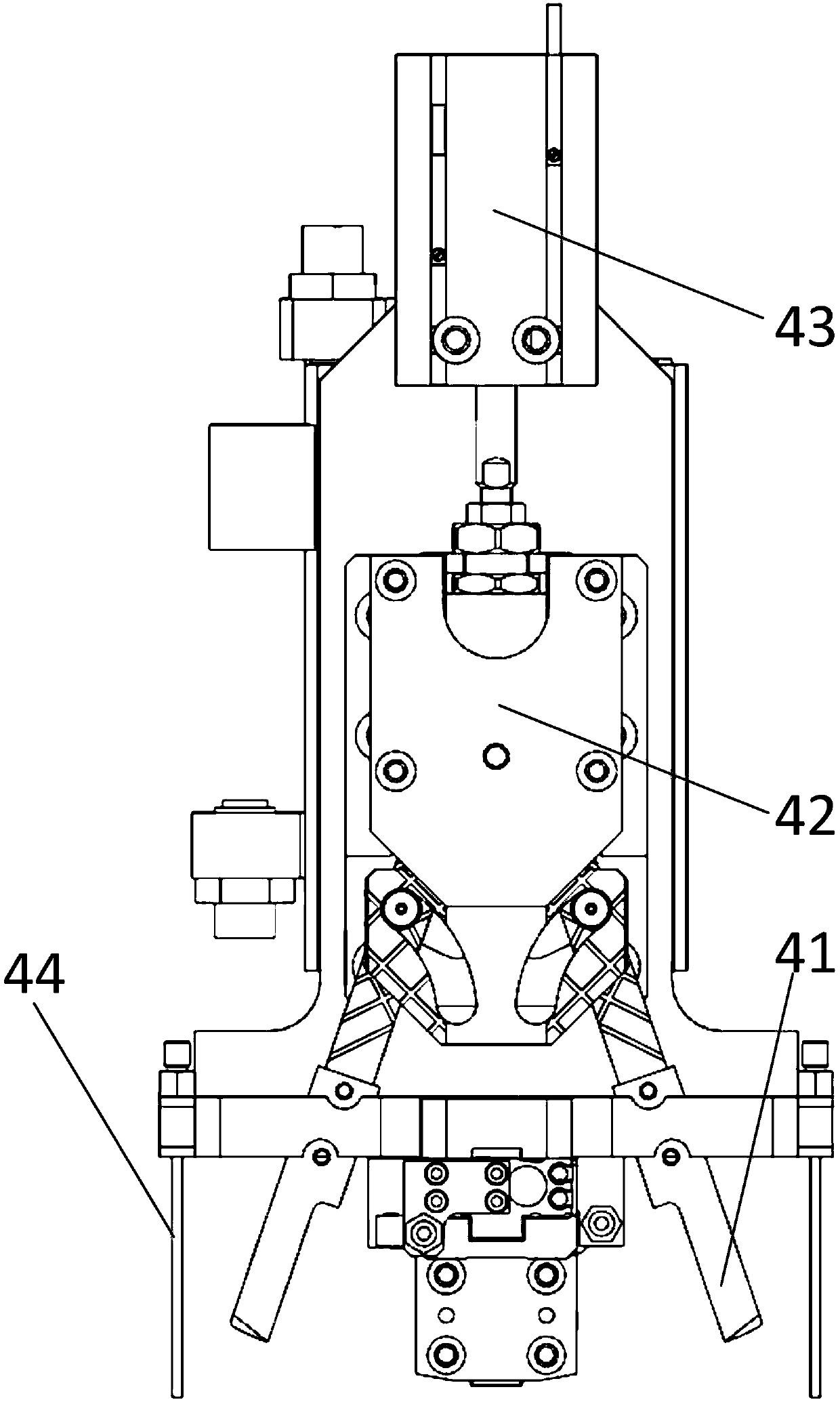

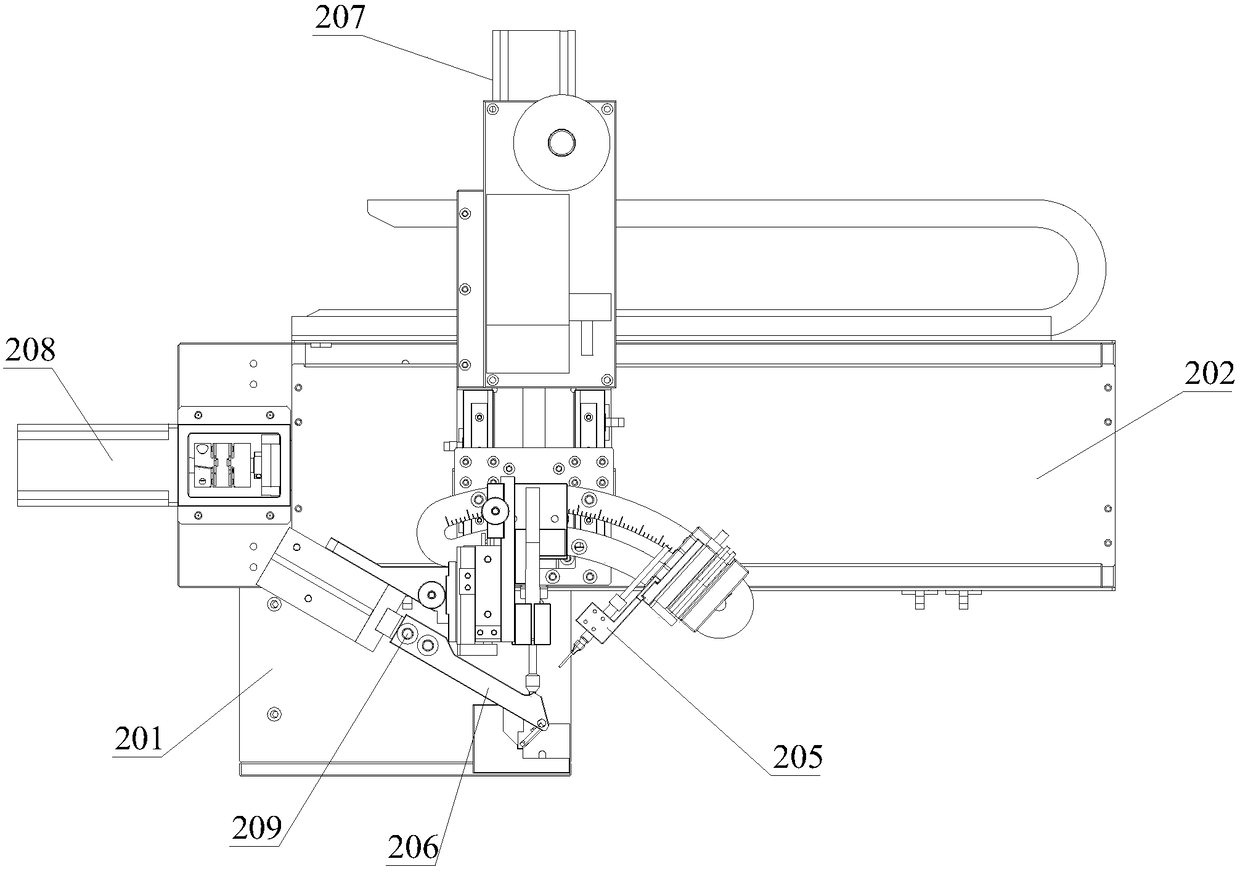

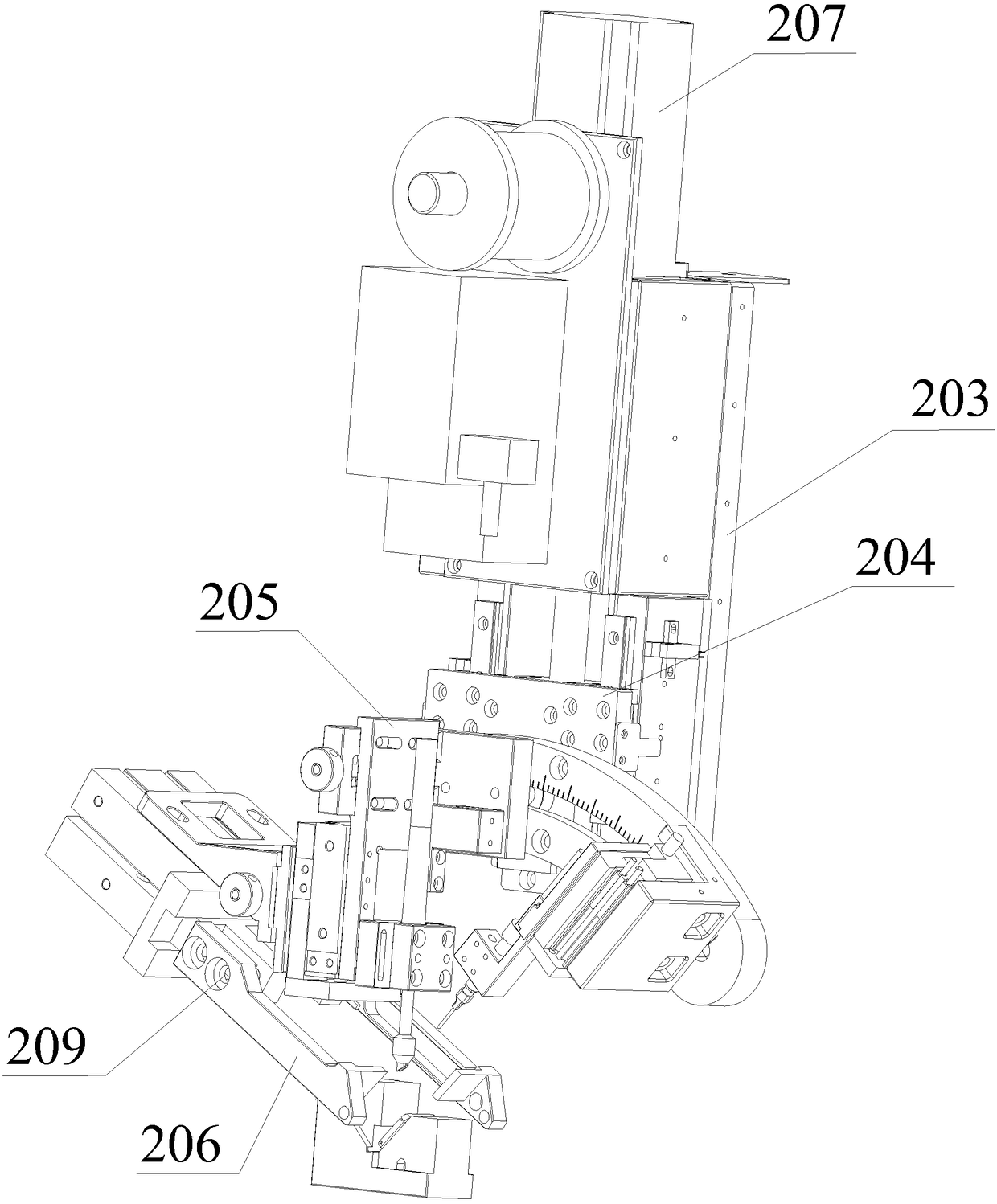

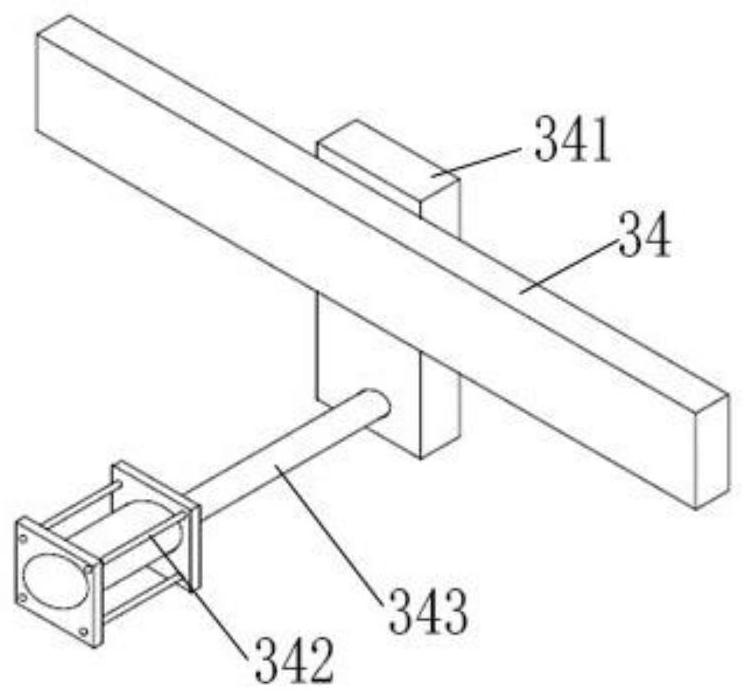

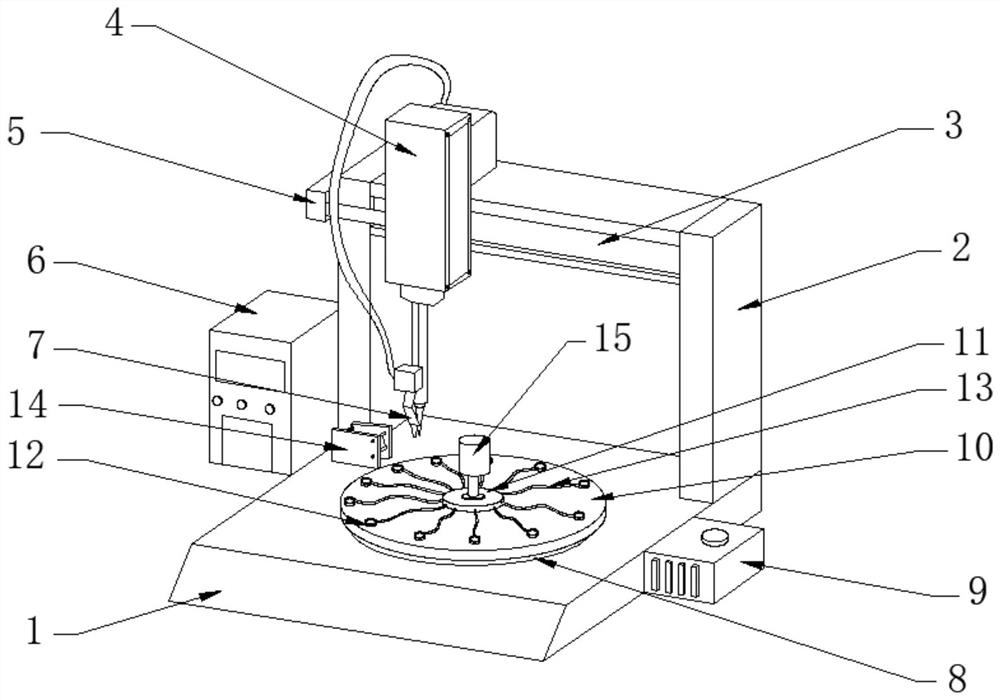

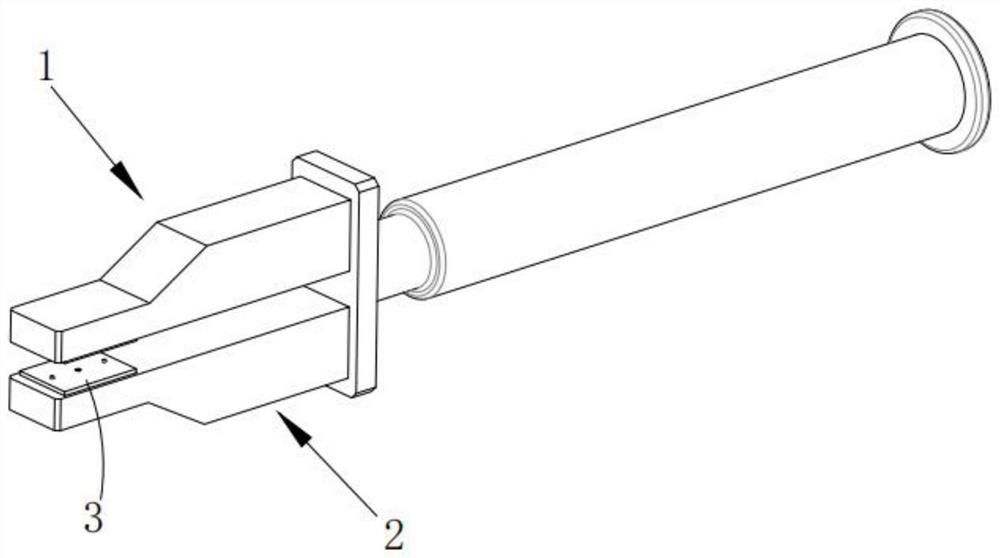

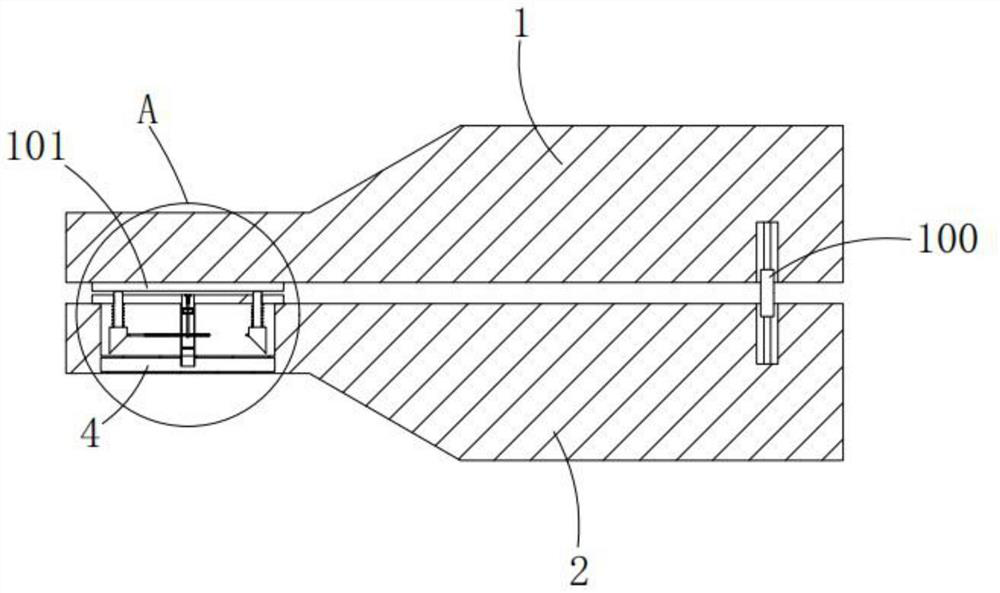

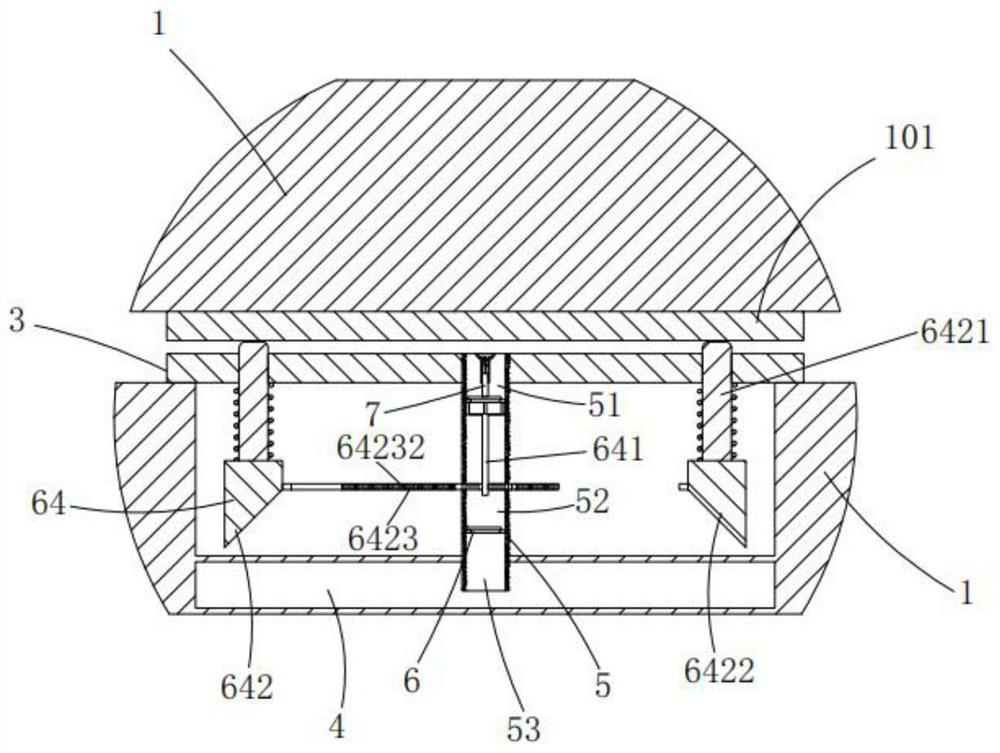

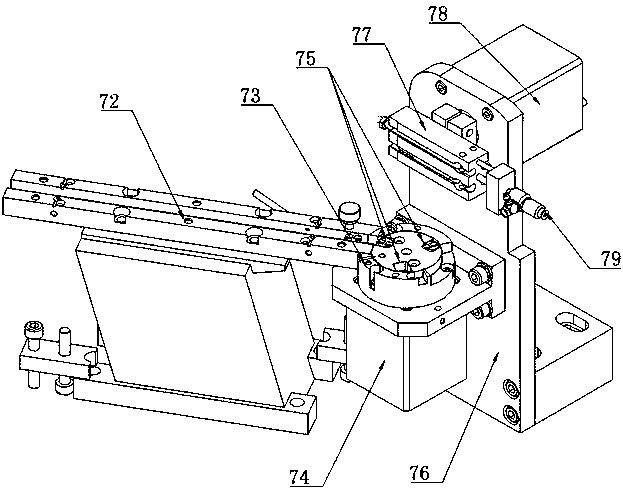

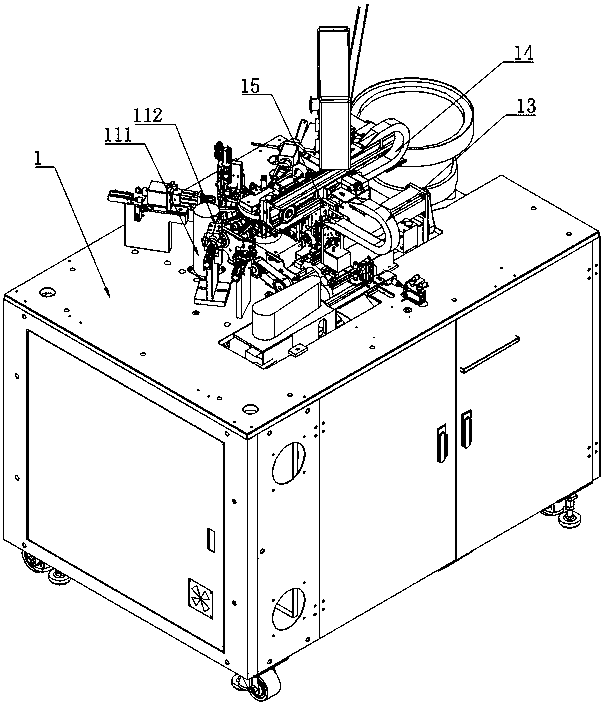

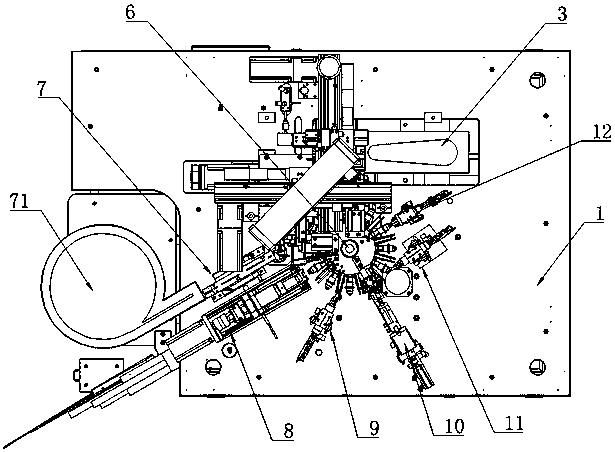

Ring vibrator automatic soldering robot and control method thereof

PendingCN108941826AMove preciselyImprove solder qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

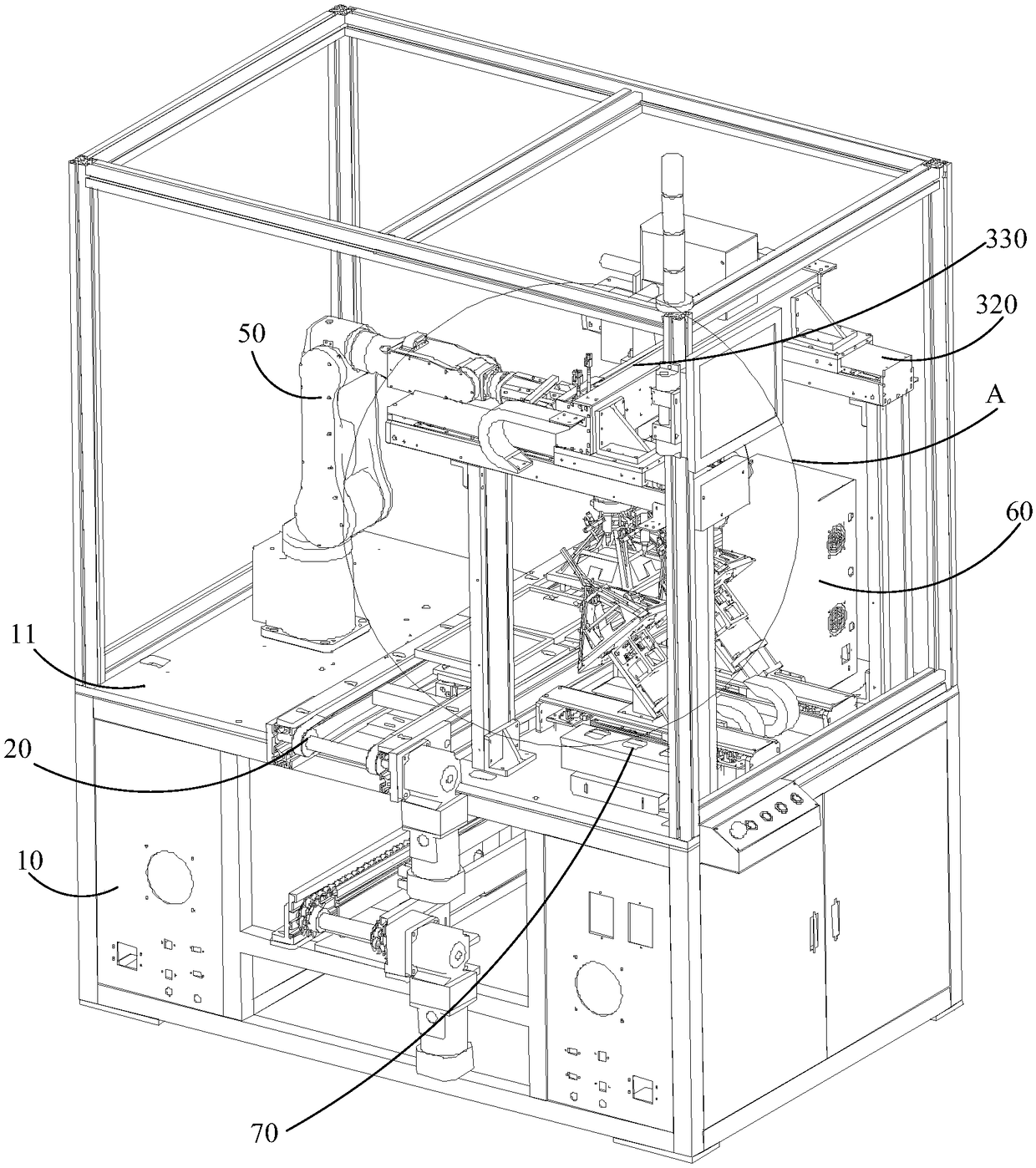

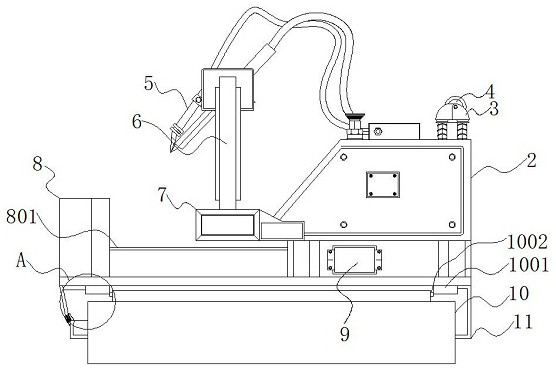

The invention discloses a ring vibrator automatic soldering robot and a control method thereof. The ring vibrator automatic soldering robot is characterized by comprising a rack, a conveying device, asoldering device, a workpiece fixing device and a manipulator, wherein a workbench is arranged on the rack; the conveying device is arranged on the workbench and used for conveying workpieces to be machined; the soldering device comprises a soldering assembly and a driving assembly for driving the soldering assembly to move; the soldering assembly is arranged on the driving assembly; the drivingassembly is arranged on the workbench; the workpiece fixing device comprises a supporting frame arranged on the workbench and a rotary support arranged on the supporting frame; the rotary support is used for rotating the workpieces to be machined; the manipulator is arranged on the workbench and used for grabbing the workpieces to be machined from the conveying device to the rotary support. Through the technical scheme, the ring vibrator automatic soldering robot achieves the functions of full-automatic feeding and discharging, locating and soldering and then improves the soldering quality andthe soldering efficiency of ring vibrators.

Owner:锐驰机器人(深圳)有限公司

Tin welding machine equipment

PendingCN110449685AHas a buffering effectDoes not affect soldering speedMetal working apparatusSoldering auxillary devicesEngineeringManipulator

The invention discloses tin welding machine equipment. The tin welding machine equipment comprises a loading buffer device, a wire material peeling mechanism, a tin dipping mechanism, a tin welding mechanism and a material receiving part from a charge end to a discharge end. According to the tin welding machine equipment, the loading buffer device adopts a stepper motor for intermittently feeding,and wire materials have a buffer function in the area, and do not influence a tin welding speed. The tin welding machine integrates manipulator feeding, wire material pre-cutting, wire material finish cutting, a laser cutting device used for cutting off the skins of the wire materials, and a double-sided peeling mechanism peeling the inner core wire skins of the wire materials and pulling out theinner core wire skins. According to the tin welding machine equipment, the wire skins do not need to be manually peeled, so that the labor cost is saved, and the peeling machining efficiency for thewire materials is increased. An assembly connector integrates material taking, flux bonding, tin bonding, wire arrangement and separation, and tin welding; and a clamping device is moved to a materialtaking station, a flux bonding station, a tin bonding station, a wire arrangement and separation station, and a tin welding station through a four-axis manipulator, so that the tin welding efficiencyis increased.

Owner:深圳市大圣神通机器人科技有限公司

Cantilever type soldering machine

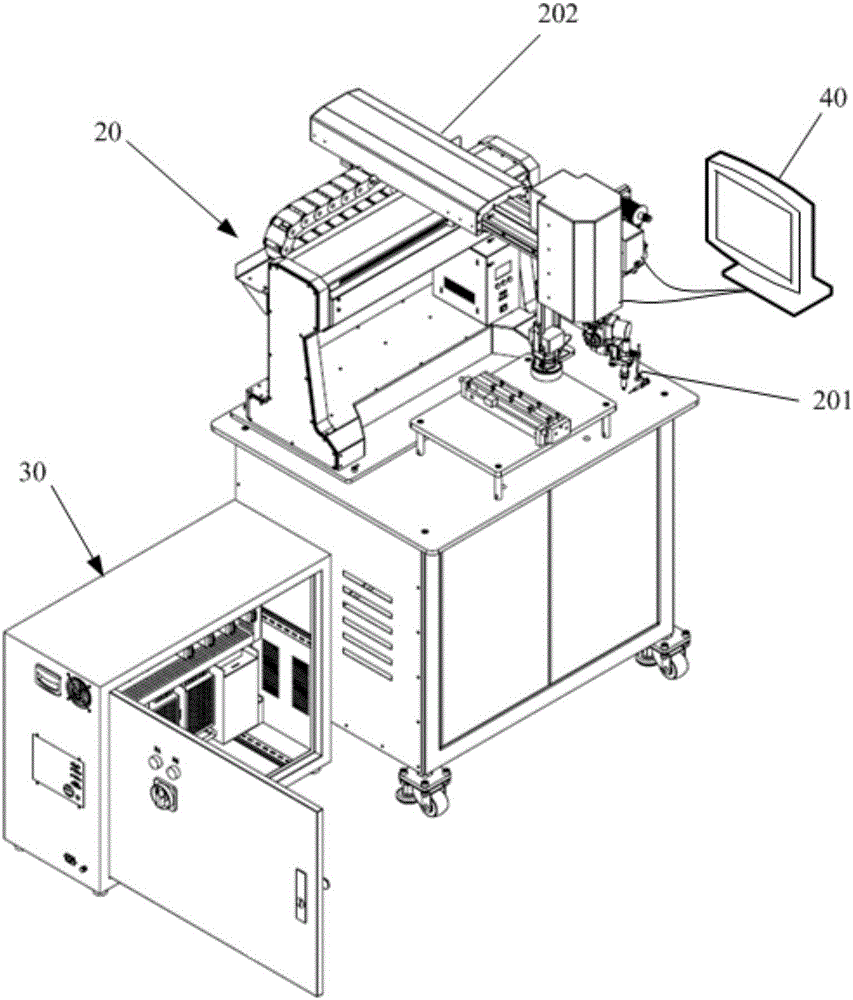

InactiveCN107363366AImprove soldering efficiencyShorten welding timePrinted circuitsMetal working apparatusEngineeringCantilever

The invention discloses a cantilever type soldering machine which comprises a rack, an electric cabinet, a first Y-direction sliding rail, a second Y-direction sliding rail, a front discharge station, a rear fetching station, an operating touch screen, an outer cover, a smoke exhaust outlet, a temperature controller, a first circuit board element jig, a second circuit board element jig, a soldering tip mechanism, an automatic solder splash cleaning box, a smoke collection hood, a Z-direction sliding rail, an X-direction sliding rail and a solder conveying machine. The full automatic loading, delivery and positioning of circuit boards as well as the horizontal, longitudinal and vertical adjustment and positioning to the soldering tip mechanism can be realized, the angle adjustment and positioning of the soldering tip mechanism can be conducted, so that the circuit boards can be welded and positioned through the soldering tip mechanism from different directions and different angles, the soldering precision is high and the soldering efficiency is high; in operation, products can be put from the front putting station, and taken from the rear taking station, so that workers which are specially configured to take and put products in each station traditionally can be decreased, and the labor cost of workers can be lowered and the productivity is high.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

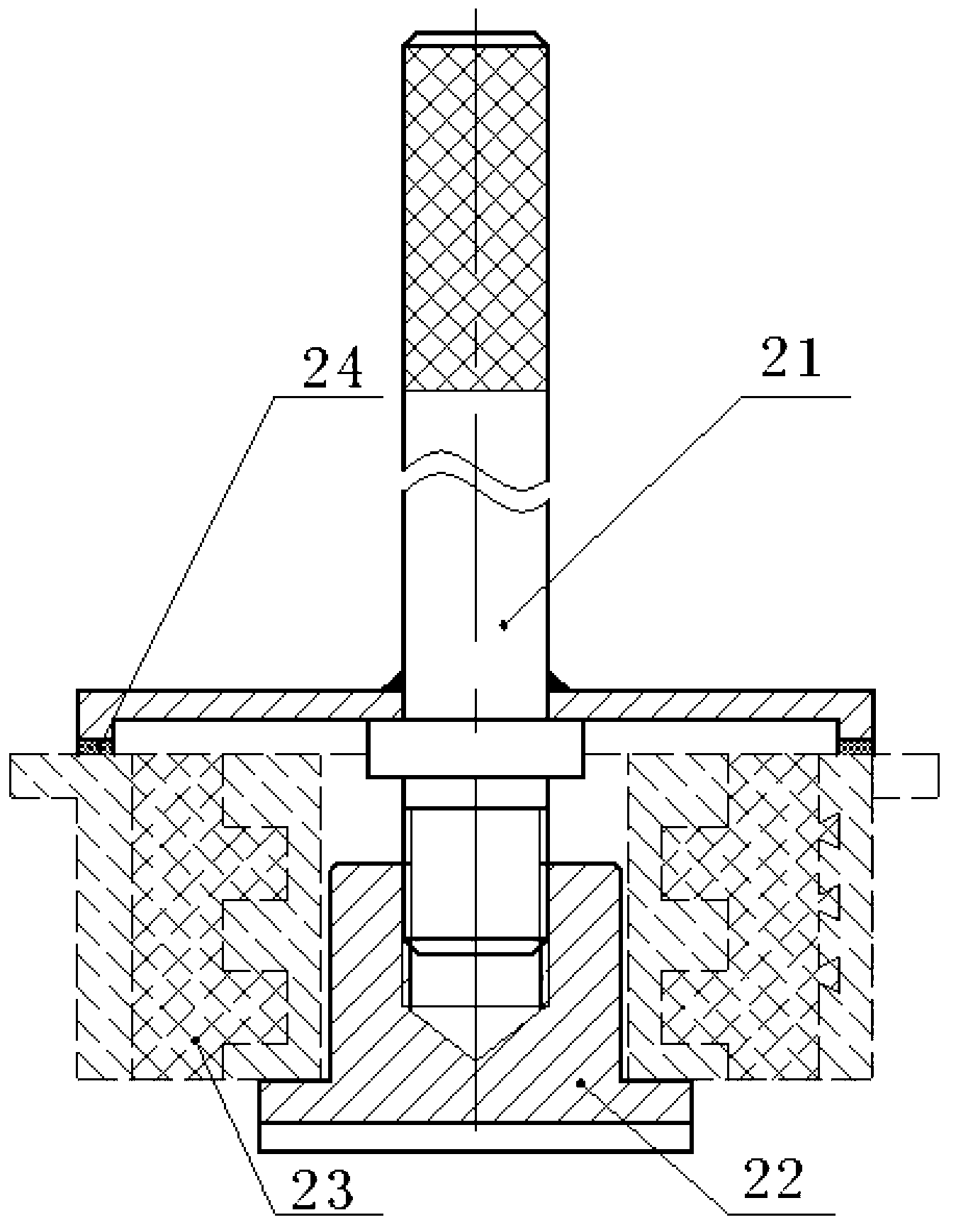

Process method for carrying out integral soldering on armature

InactiveCN102837094AImprove solder qualityImprove adhesionSoldering apparatusTinningTemperature control

The invention relates to a process method for carrying out integral soldering on an armature. Before the armature is subjected to integral soldering, a commutator pre-tinning process is added; a spiral wound gasket is used for replacing an asbestos cord; the spiral wound gasket is placed between a tin pan and the armature; the tin pan is made of titanium alloy; and a PID (Proportion Integration Differentiation) intelligent control instrument is adopted to carry out temperature control and maintenance. The commutator pre-tinning process is designed from the economy, the practicality and the manufacturability and takes an important effect in the process method for carrying out integral soldering on the armature. After the pre-tinning is carried out, the reliability of the integral soldering of the armature is improved, the pseudo soldering and the missing soldering are avoided, the repair rate of the armature is reduced and the motor quality is fundamentally improved. According to the method, the armature soldering efficiency is improved for dozens of times; the temperature control and constant temperature effects are good; the liquidity of molten tin, the welding strength and the welding reliability are improved; and the integral soldering quality of the armature is improved.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

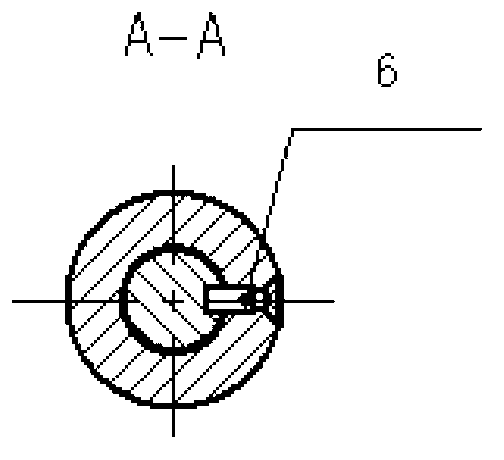

Auxiliary device for tin soldering for circuit board

InactiveCN107520518ARemove irritating odorTo achieve the role of auxiliary solderPrinted circuit assemblingSoldering bitsDip solderingEngineering

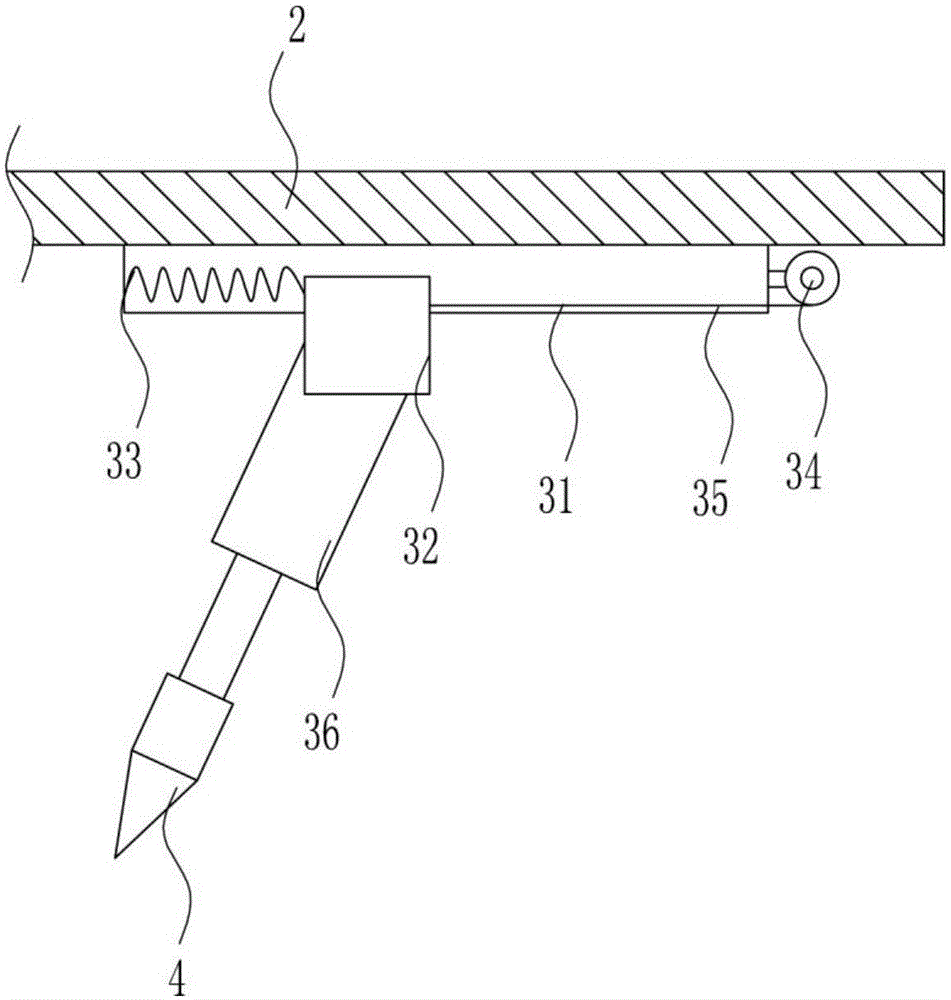

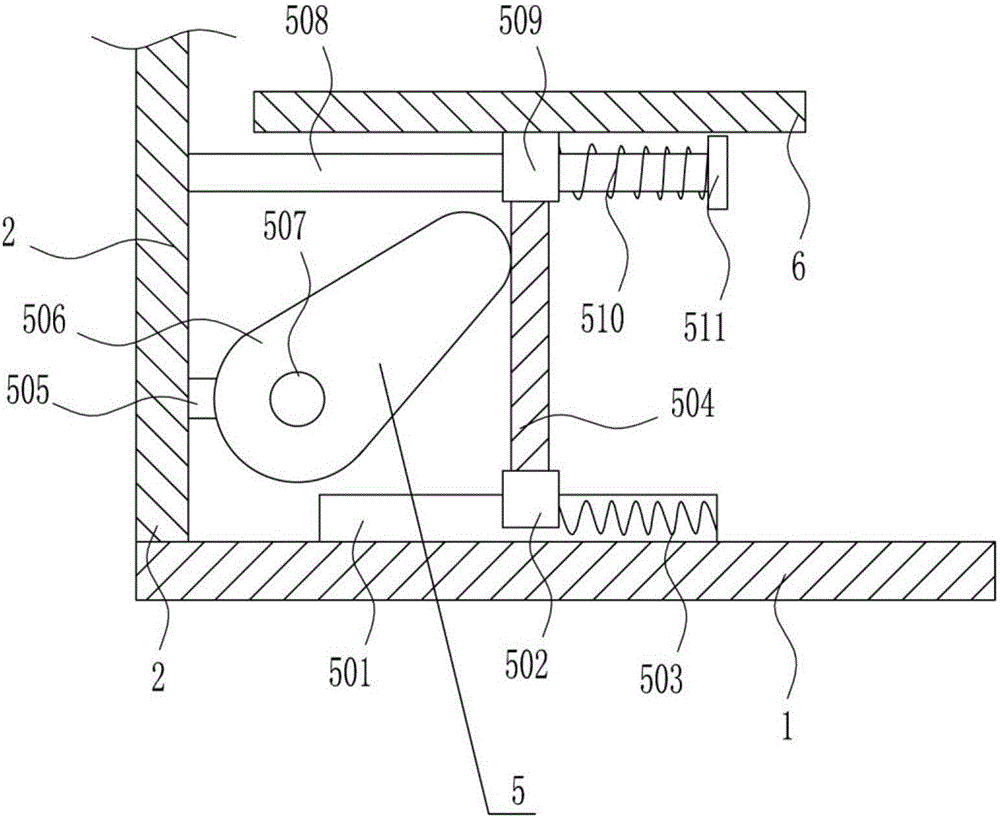

The invention relates to an auxiliary device for tin soldering, and particularly relates to an auxiliary device for tin soldering for a circuit board. The technical problem to be solved by the invention is to provide an auxiliary device for tin soldering for a circuit board, which is high in tin soldering speed, high in tin soldering efficiency, capable of carrying out front-rear tin soldering and left-right tin soldering on the circuit board, and further capable of removing a pungent odor. In order to solve the abovementioned technical problem, the invention provides an auxiliary device for tin soldering for a circuit board. The auxiliary device comprises a bottom plate and the like, wherein an L-shaped plate is arranged at the left side of the top of the bottom plate; an adjustment device is arranged at the top of the bottom plate; a placement table is arranged at the top of the adjustment device; a movement device is arranged at the inner top of the L-shaped plate; and a soldering bit is arranged at the bottom of the movement device. The auxiliary device disclosed by the invention achieves the effects of being high in tin soldering speed, high in tin soldering efficiency, and capable of removing the pungent odor. According to the device, the front-rear tin soldering is carried out on the circuit board through the movement device, the left-right tin soldering is carried out on the circuit board through the adjustment device, and therefore, tin soldering can be carried out on each orientation of the circuit board, and an odor removal device is capable of absorbing the pungent odor.

Owner:钟光文

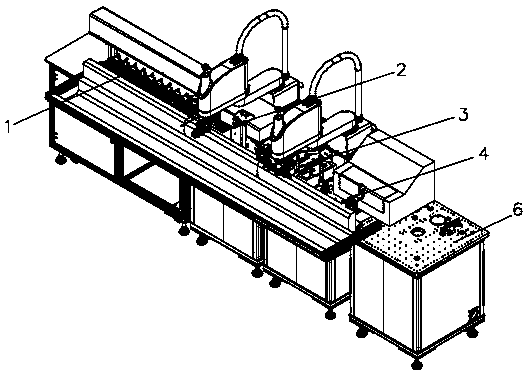

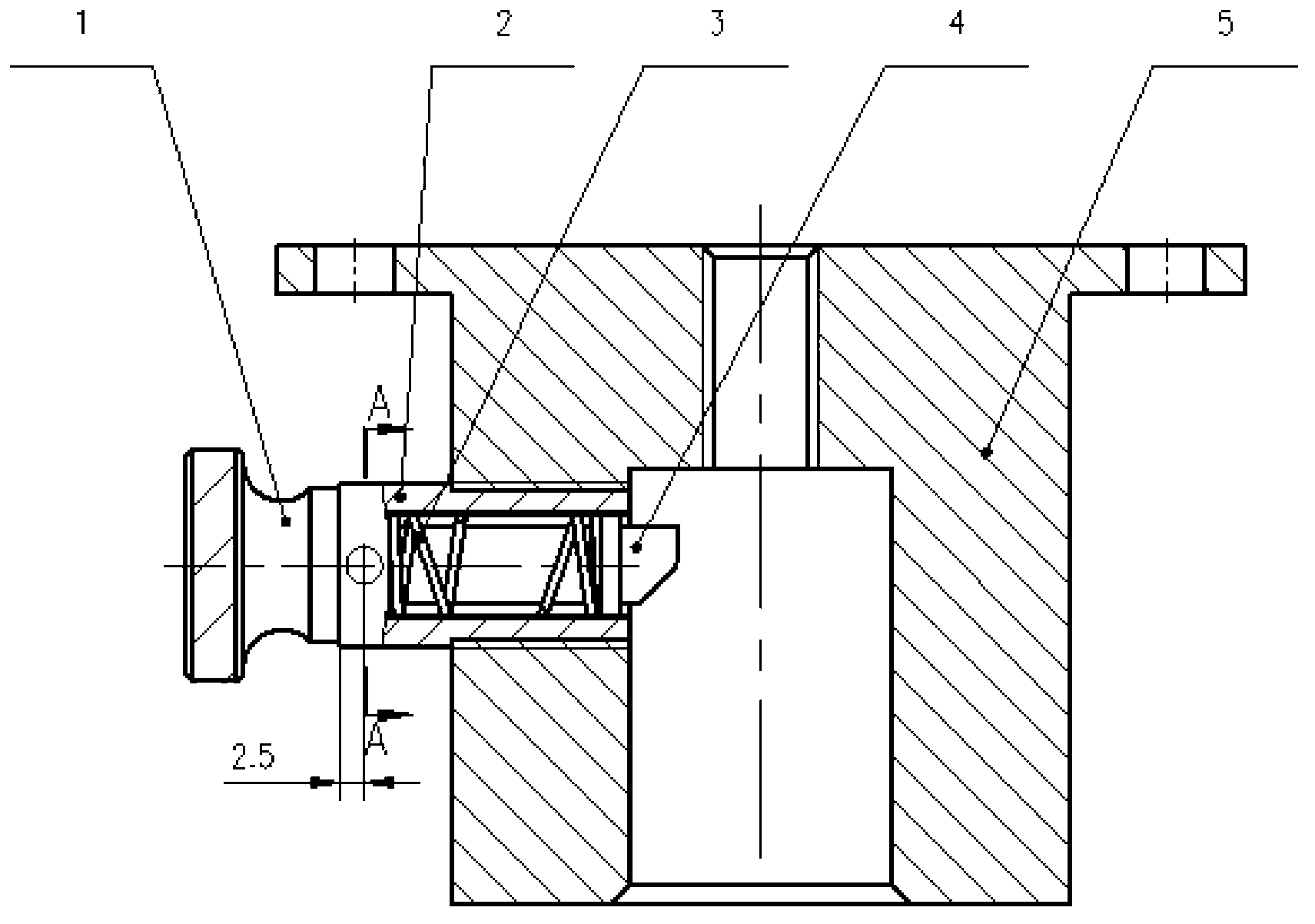

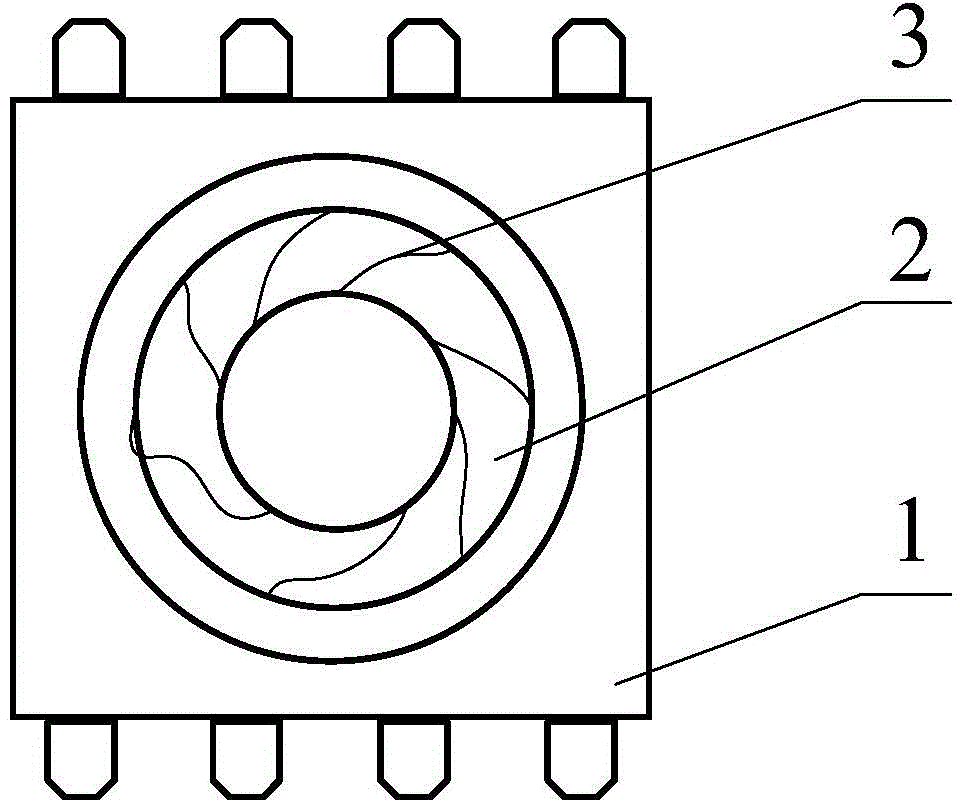

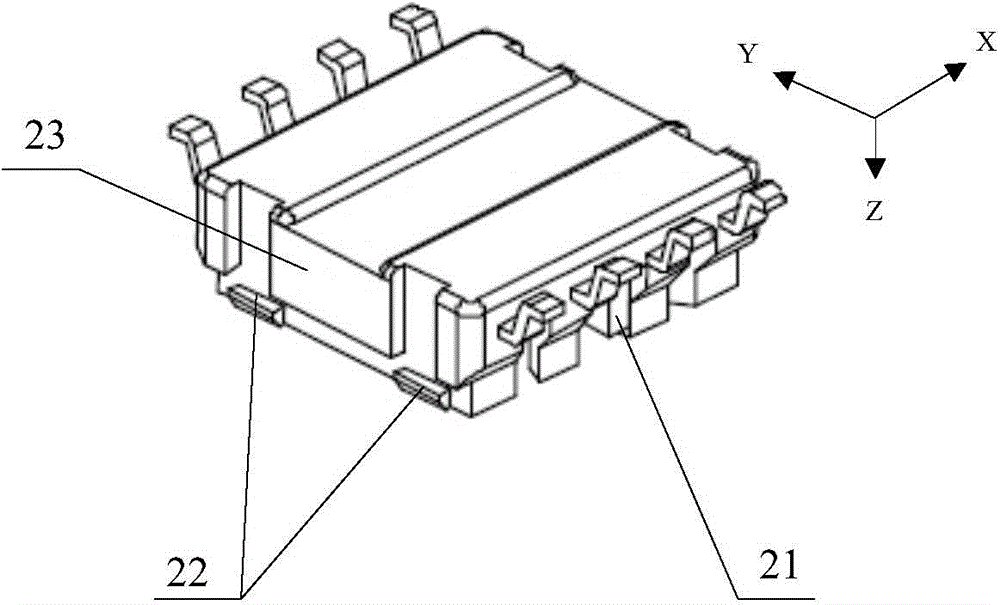

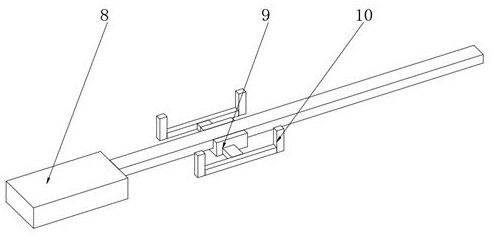

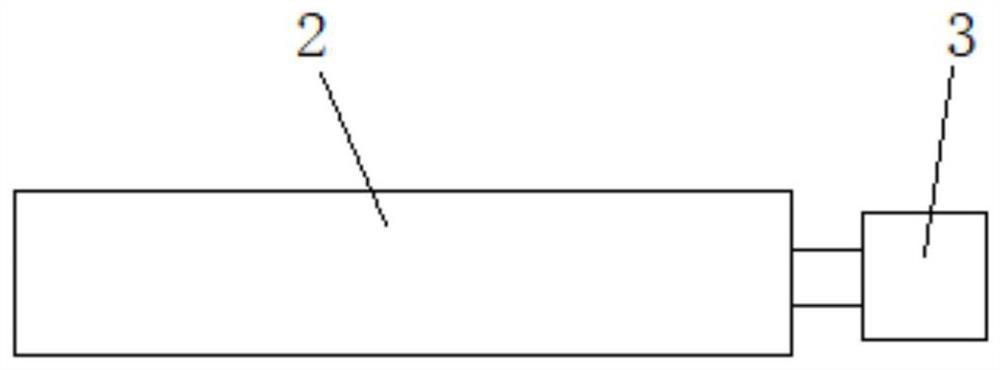

Six-axis tin soldering robot

ActiveCN105537714AAvoid occupyingRealize multi-angle free rotationMetal working apparatusFree rotationSoldering

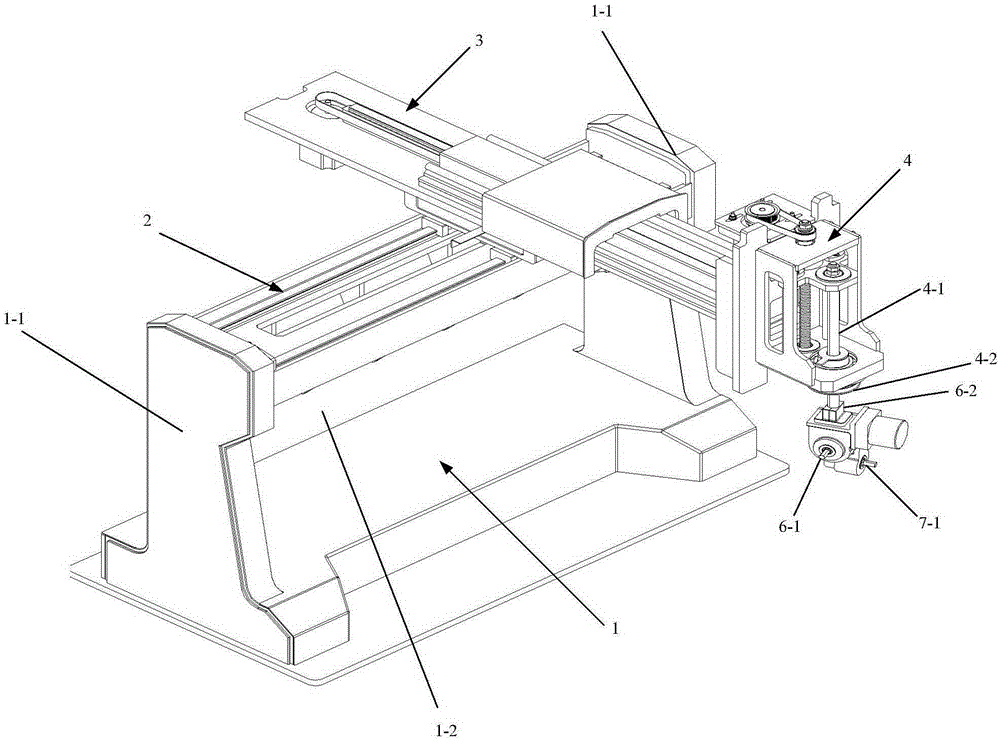

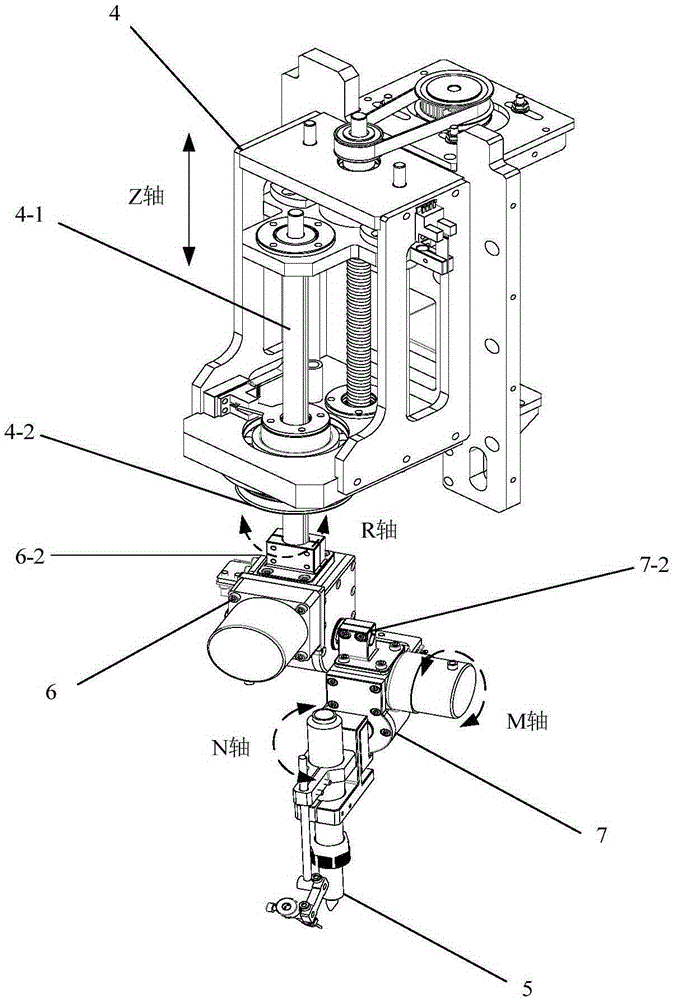

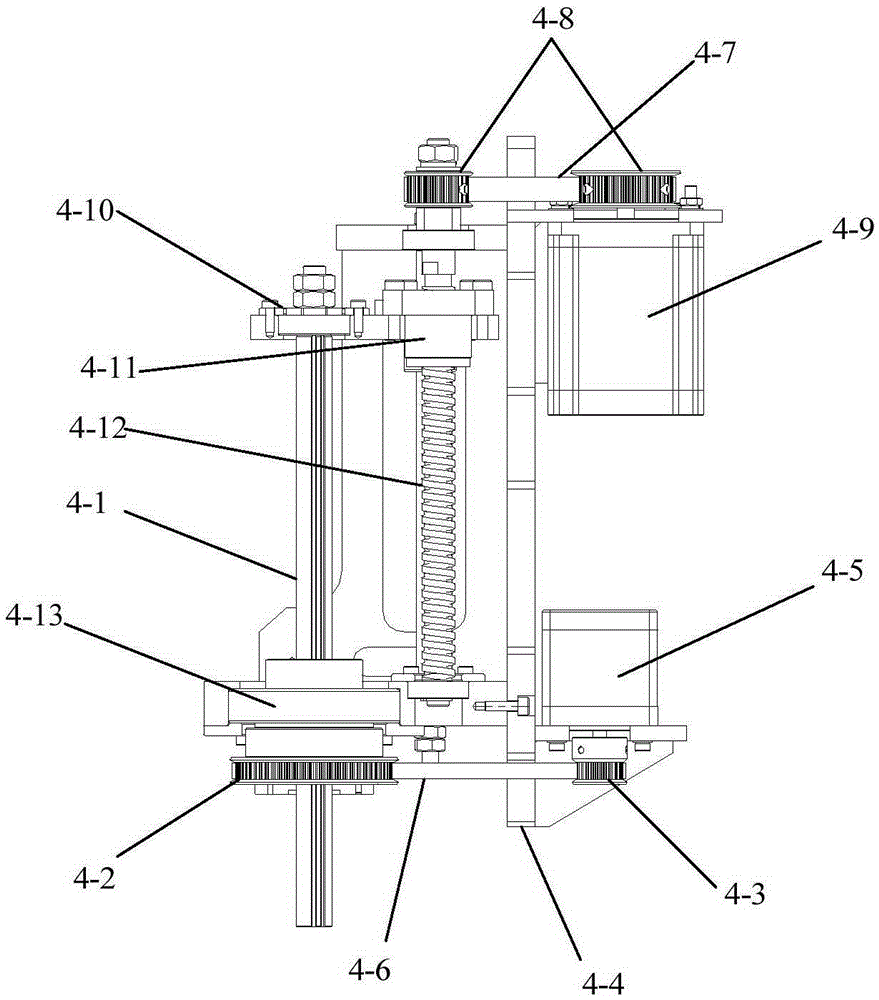

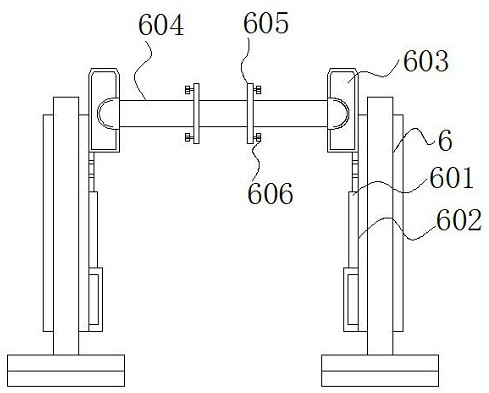

The invention provides a six-axis tin soldering robot comprising a rack (1), an X-axis assembly (2), a Y-axis assembly (3), a ZR-axis assembly (4) and a tin soldering head (5), wherein the ZR-axis assembly (4) comprises an R shaft (4-1) and a synchronous pulley (4-2) fixedly arranged at the lower end of the R shaft (4-1); the synchronous pulley (4-2) rotates around the R shaft (4-1). The six-axis tin soldering robot also comprises an M-axis assembly (6) and an N-axis assembly (7), wherein an M shaft (6-1) is vertical to the R shaft (4-1); and an N shaft (7-1) is vertical to the R shaft (4-1) and the M shaft (6-1). The robot is additionally provided with the R-axis, M-axis and N-axis assemblies on the basis of the existing X-axis assembly, Y-axis assembly and Z-axis assembly, so that the tin soldering head connected with the N-axis assembly can realize multi-angle free rotation in a space, the six-axis free movement of the tin soldering head is realized, various different soldering requirements can be met, and the problem of inapplicability caused by different welded products is solved.

Owner:迈力(北京)机器人科技有限公司

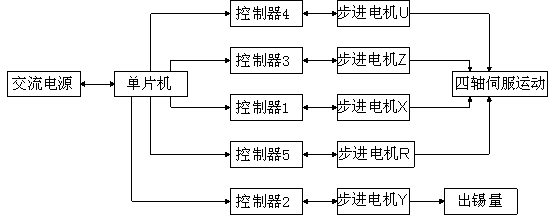

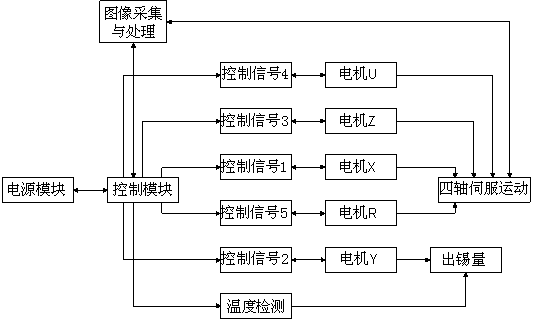

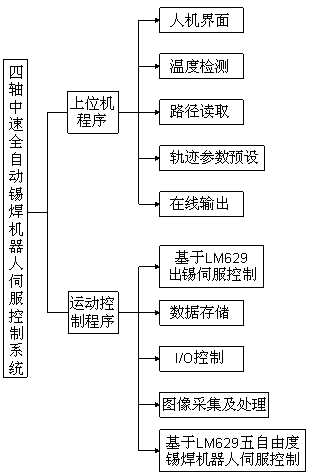

Servo control system for four-axis intermediate speed full-automatic soldering robot

InactiveCN103302670AHigh degree of automationImprove operation accuracyProgramme-controlled manipulatorMetal working apparatusDigital signal processingEngineering

The invention discloses a servo control system for a four-axis intermediate speed full-automatic soldering robot, which comprises a control module, four motors, a motion module and an image collecting module, wherein the control module comprises a digital signal processing chip and an LM 629 motion control chip; the digital signal processing chip is connected with point welding positions on the motion module through the image collecting module; the LM 629 motion control chip generates pulse-width modulation wave signals and sends the signals to the four motors; and the four motors are connected with the motion module respectively. According to the servo control system for the four-axis intermediate speed full-automatic soldering robot, provided by the invention, through the adoption of the scheme, the degree of automation and the operational precision are greatly improved, the positioning is extremely precise, the soldering efficiency of the robot can be greatly improved, the requirement for motion synchronous control of the four-axis servo motors is met, the all-digital control of a tin discharge system is realized, the space occupied by a special motion chip is reduced, and the micromation development is facilitated.

Owner:SUZHOU INDAL PARK INSTITUE OF VOCATIONAL TECH

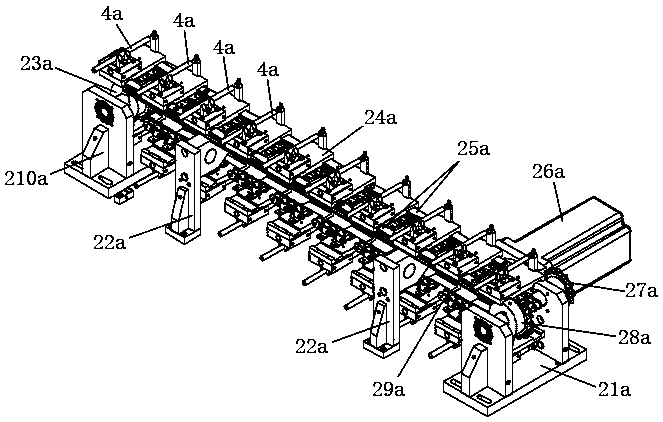

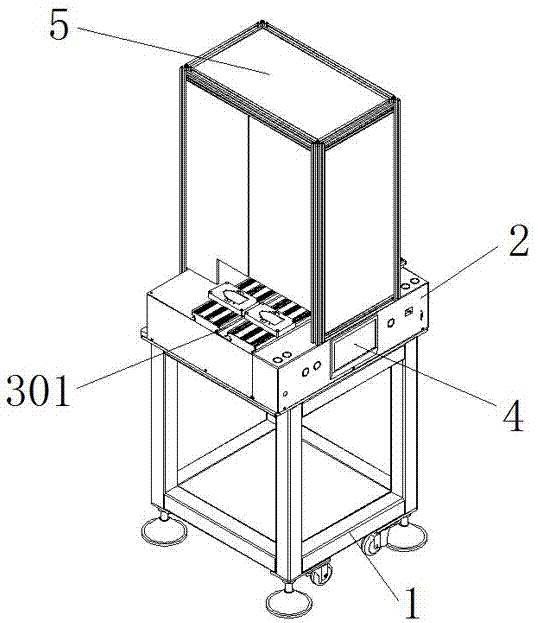

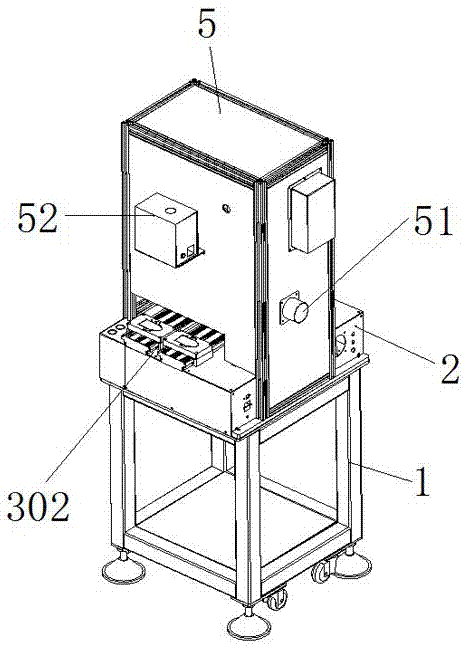

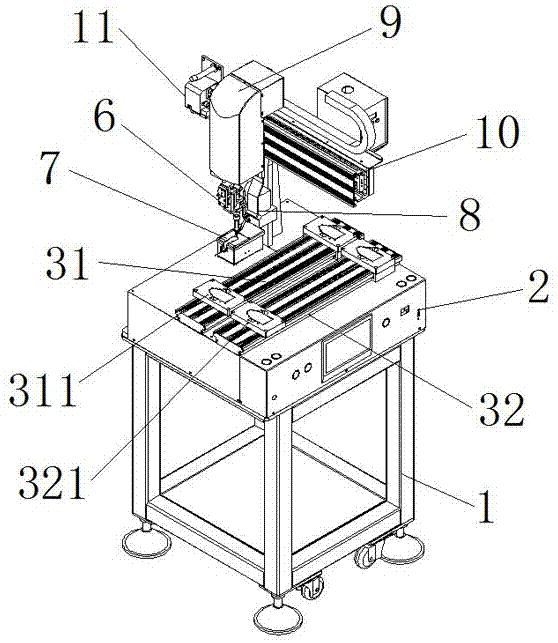

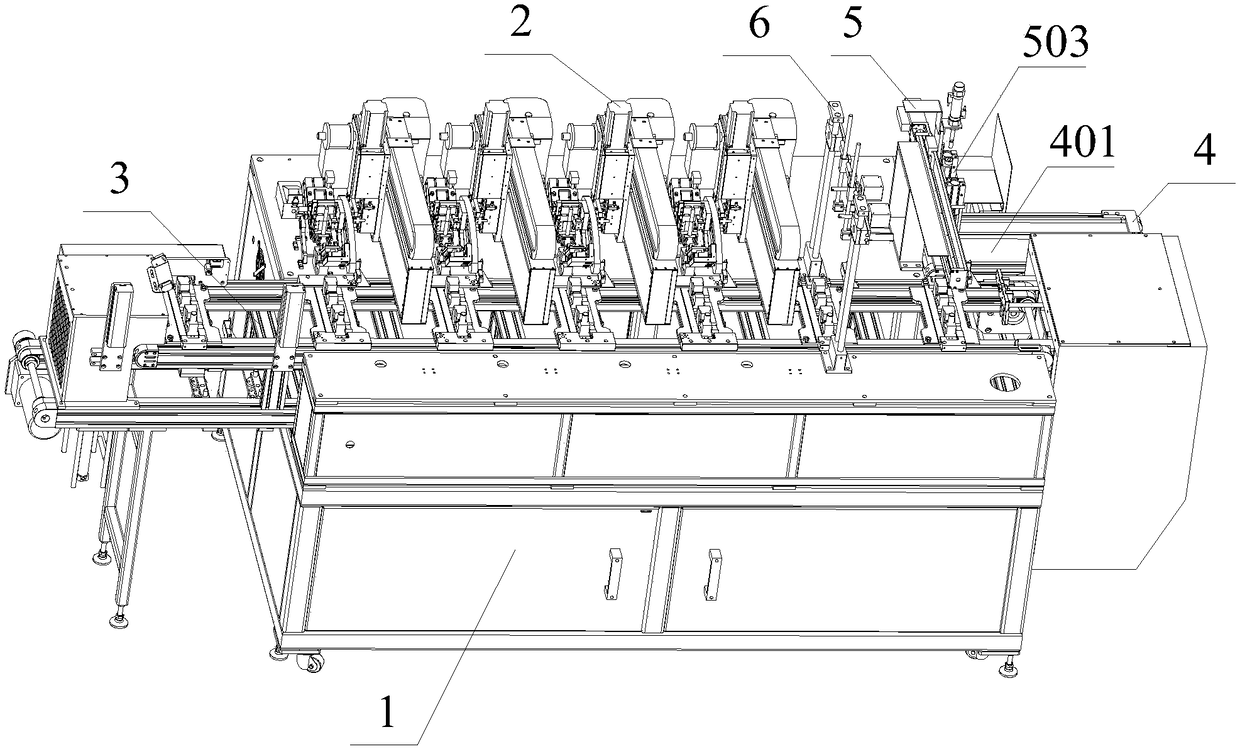

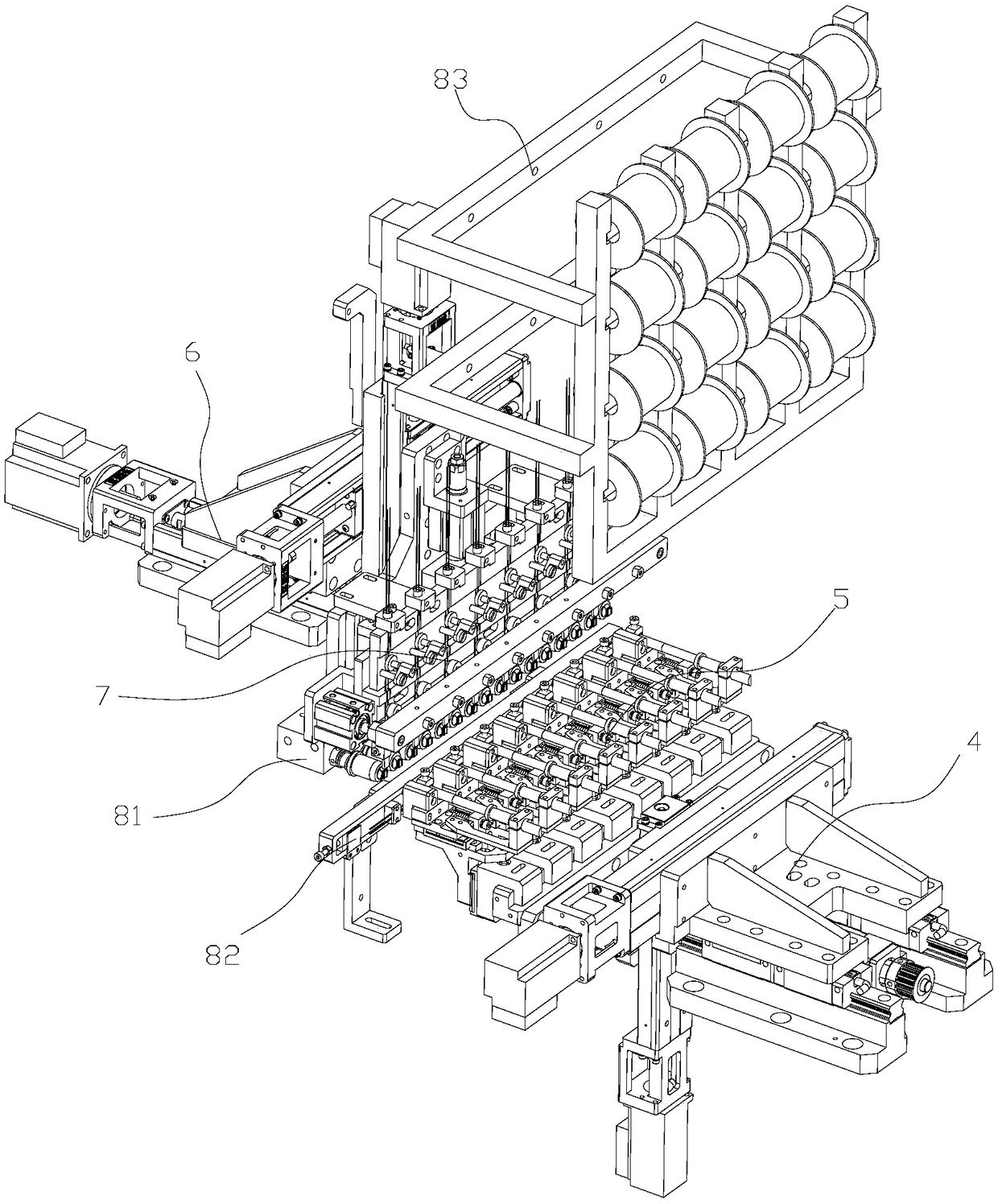

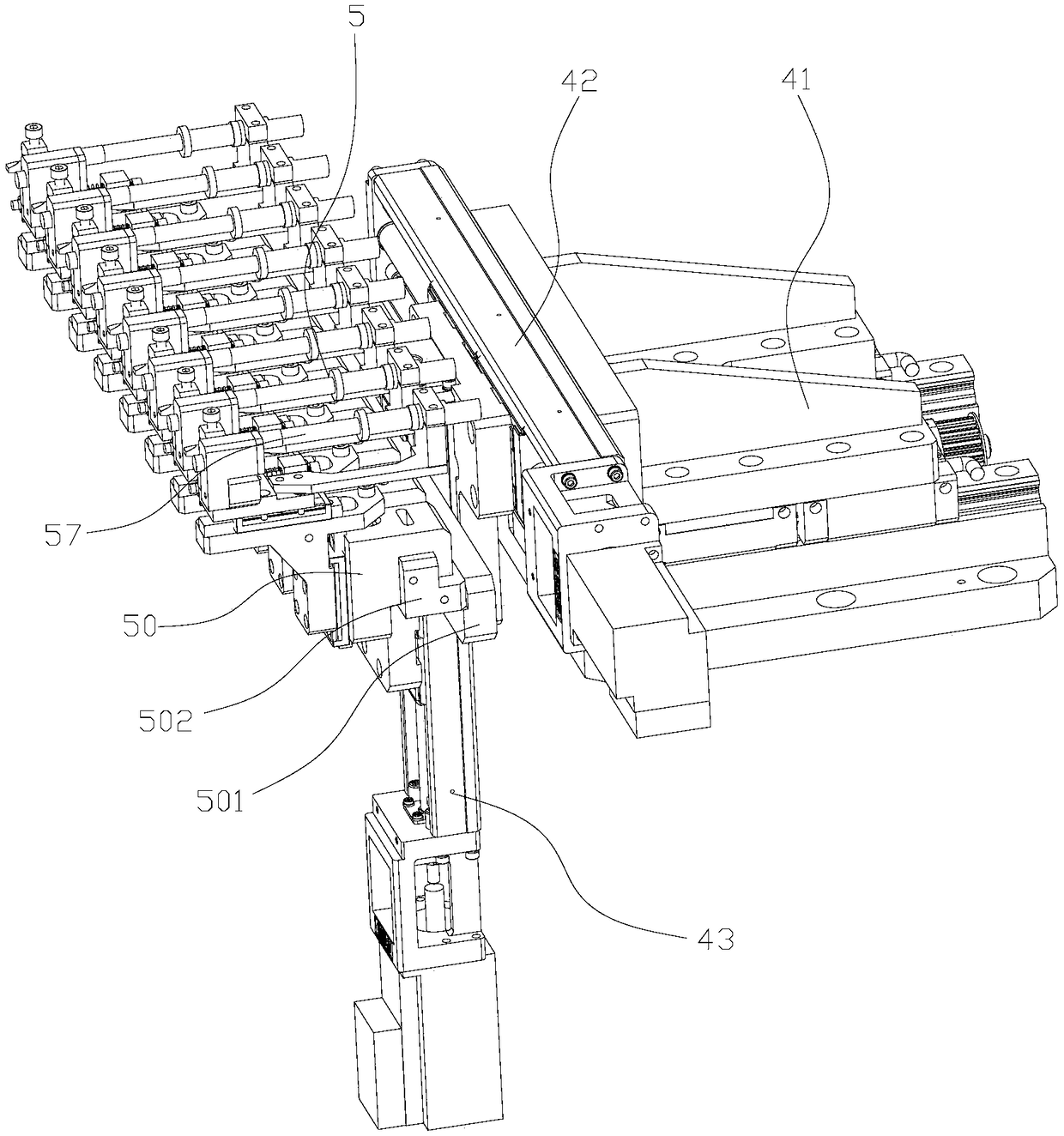

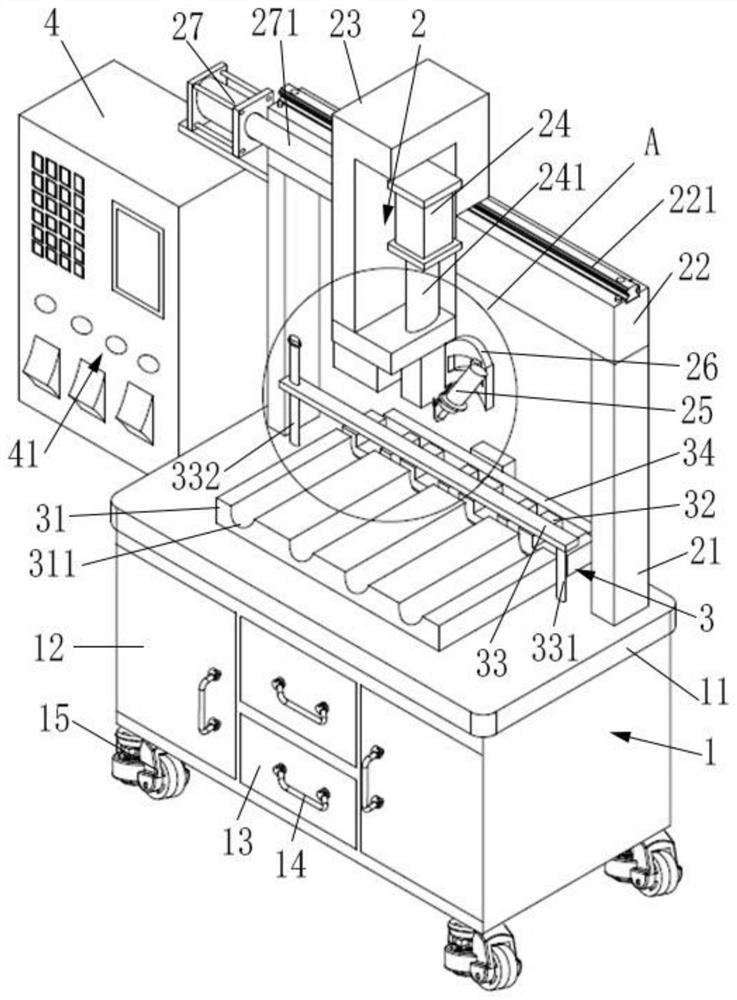

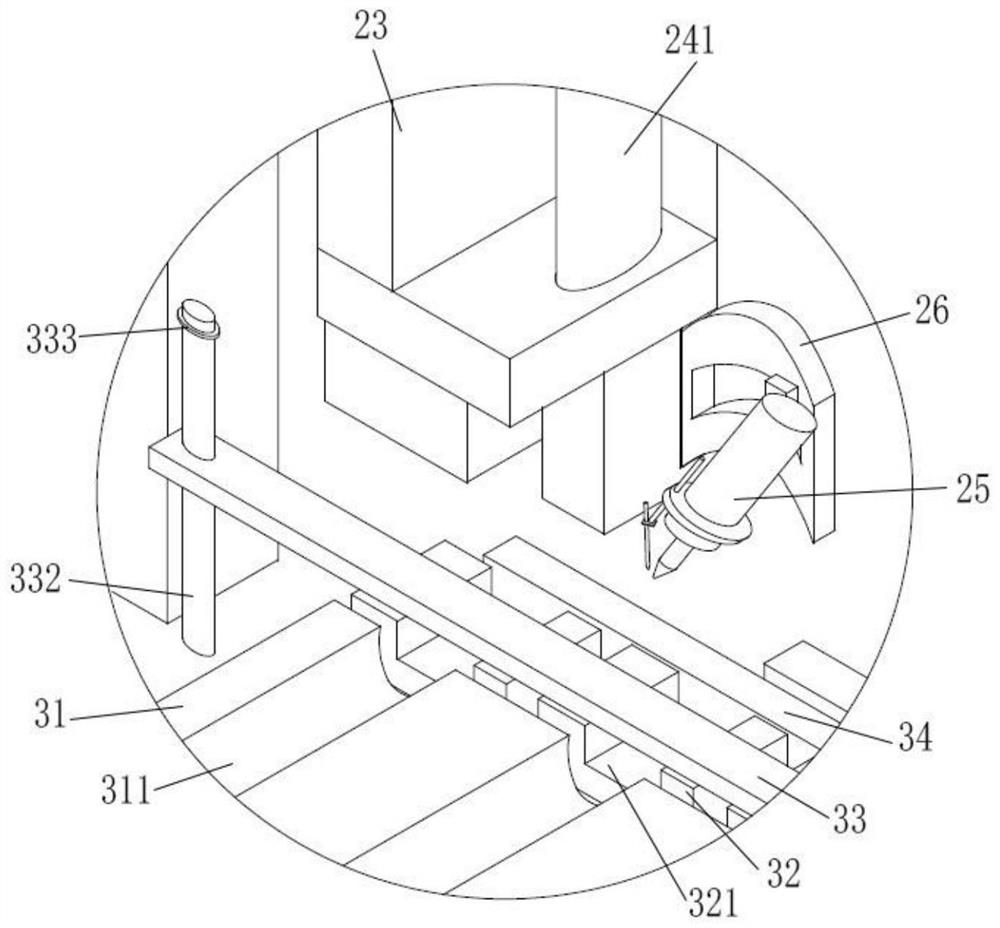

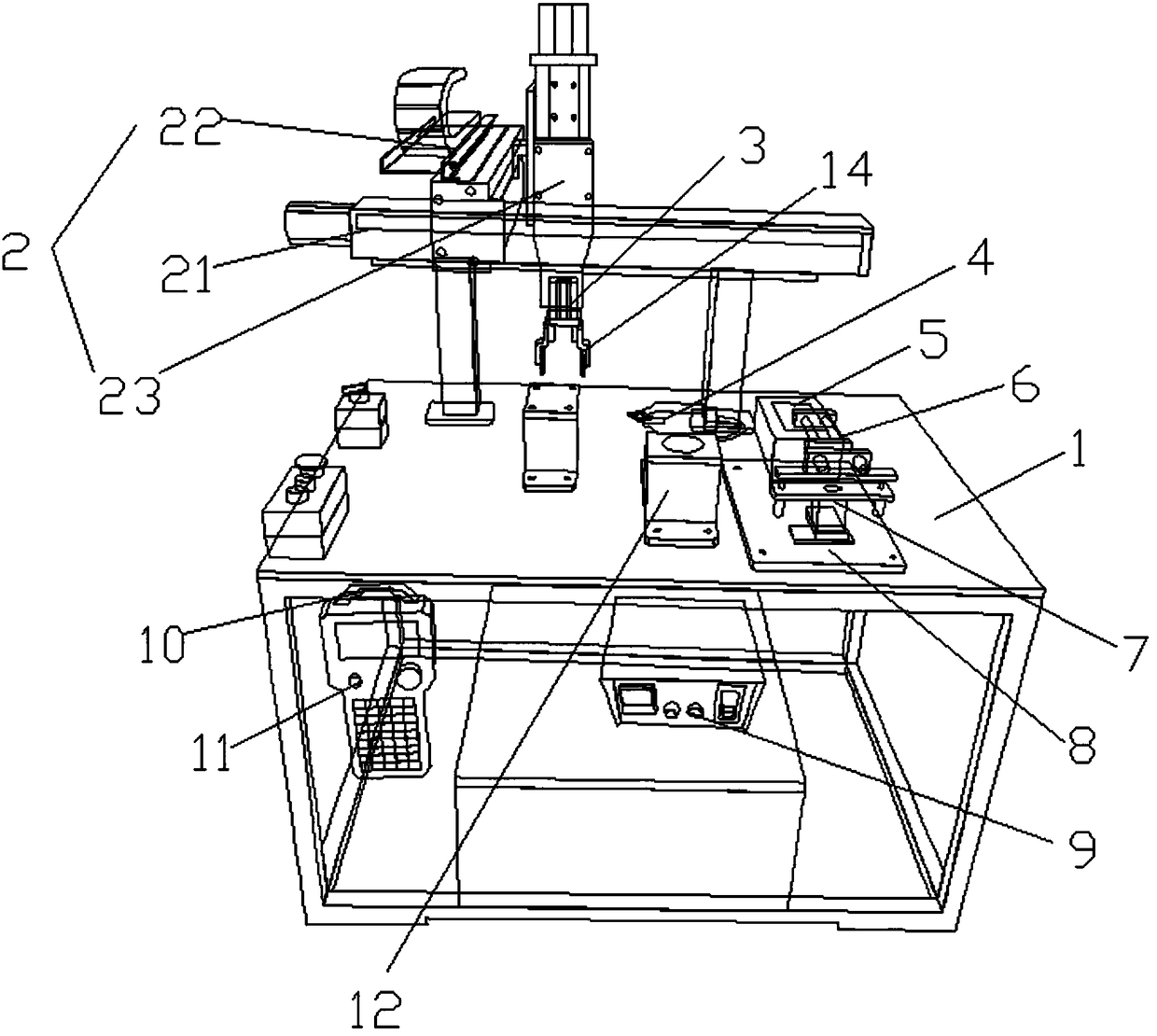

Automatic tin soldering machine assembly

ActiveCN108067699AReduce time consumptionReduce circulation proceduresWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

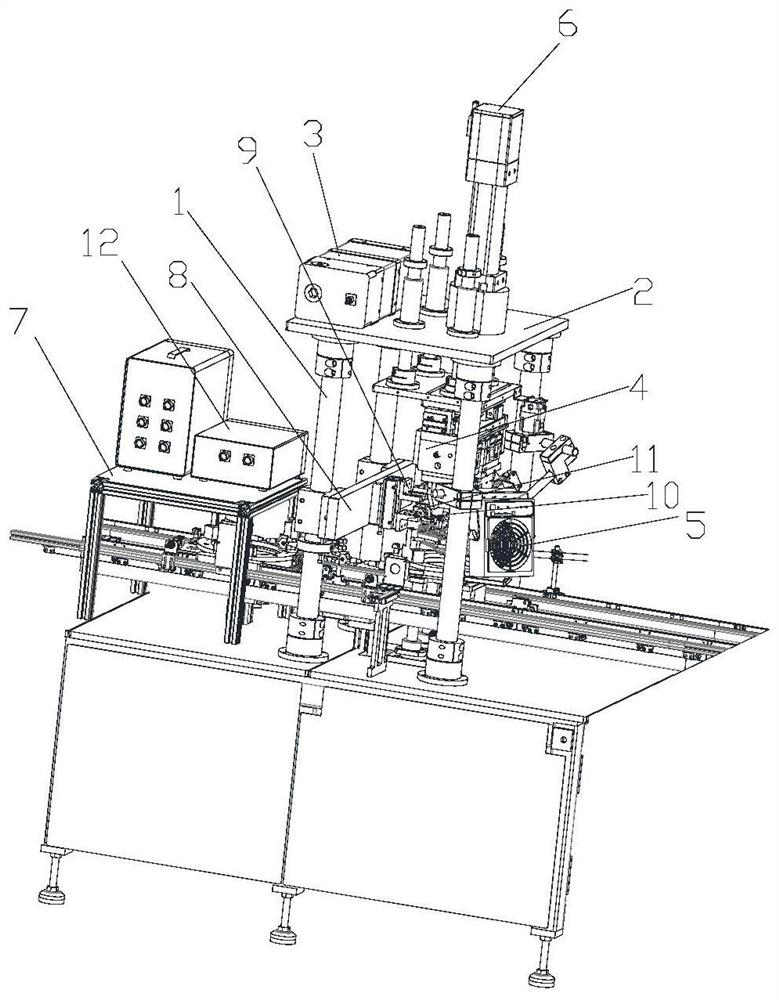

The invention provides an automatic tin soldering machine assembly. The automatic tin soldering machine assembly comprises a machine box. The machine box is provided with a plurality of welding cleaning modules which are used for carrying out soldering tin soldering on a workpiece, a conveying module for conveying and transferring the workpiece, a discharging module for discharging the workpiece and a material taking module for transferring the workpiece to the discharging module from the conveying module. The material taking module is arranged between the welding cleaning module and the discharging module. The automatic tin soldering machine assembly is high in automation degree, safety and precision are improved, the whole structure is compact, the space is saved, the tin soldering quality is high, and high-efficiency and high-quality soldering tin soldering work is further achieved while the production cost is reduced.

Owner:石超

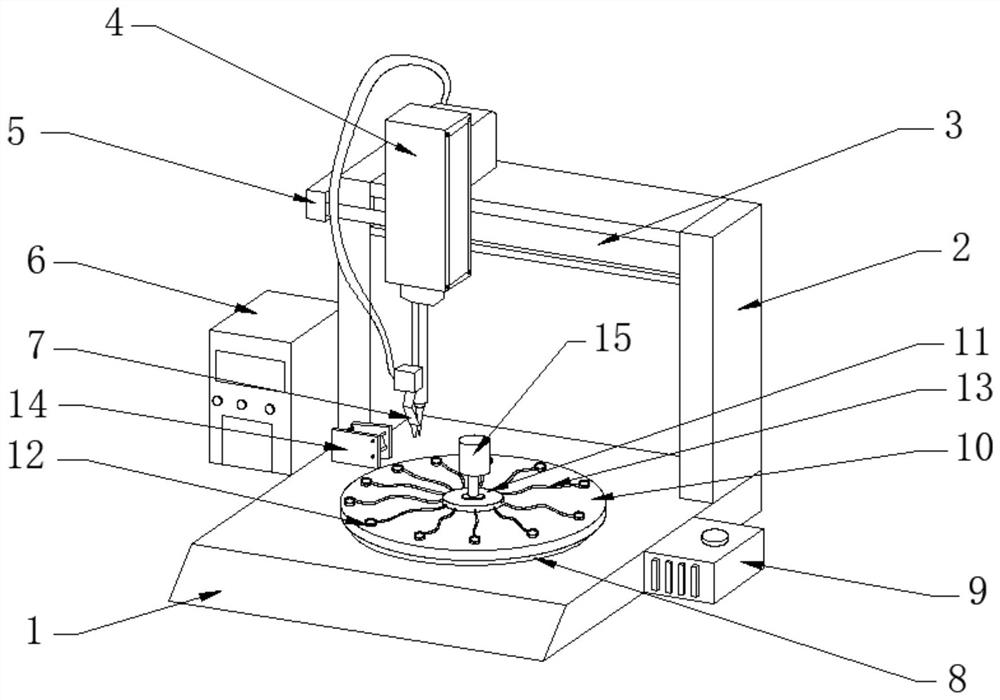

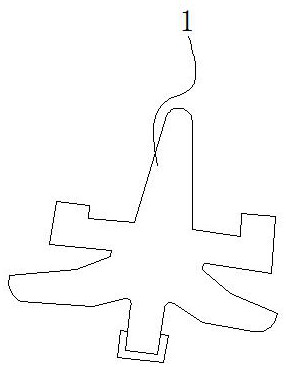

Automatic wire laser soldering machine

ActiveCN111702275AAvoid instant heatingAvoid Solder Quality ImpactSolder feeding devicesSoldering auxillary devicesEngineeringSpot welding

The invention discloses an automatic wire laser soldering machine. The automatic wire laser soldering machine comprises a machine base, wherein a fixed frame is fixedly arranged on the machine base; asliding rail is arranged on the fixed frame; a laser generator is arranged on the sliding rail in a sliding manner; a solder paste tank is arranged on the surface of the center of a workpiece tray; aplurality of welding spot grooves are formed in the edge of the workpiece tray and are connected to the solder paste tank through flexible pipes; a workpiece clamping plate is arranged on the outer side of the workpiece tray; a small-sized air cylinder is arranged on the top end of the solder paste tank; and a compression bar of the small-sized air cylinder is inserted in the solder paste tank. According to the automatic wire laser soldering machine, solder paste in the solder paste tank can be squeezed under the action of the compression bar at the bottom end of the small-sized air cylinder,and is transmitted to the interiors of the welding spot grooves through the flexible pipes, and the solder paste is in contact with the surfaces of workpieces, and thus, the effect of inputting the solder paste in advance can be achieved; then the workpieces are subjected to spot welding in batches by rotating a rotary table; and compared with a manual spot welding manner, the automatic wire laser soldering machine has the advantages that the soldering efficiency is relatively high, the instantaneous heating of the solder paste is avoided, and the solder paste can be placed at a room temperature firstly to prevent the soldering quality of the solder paste from being affected.

Owner:由力自动化科技(上海)有限公司

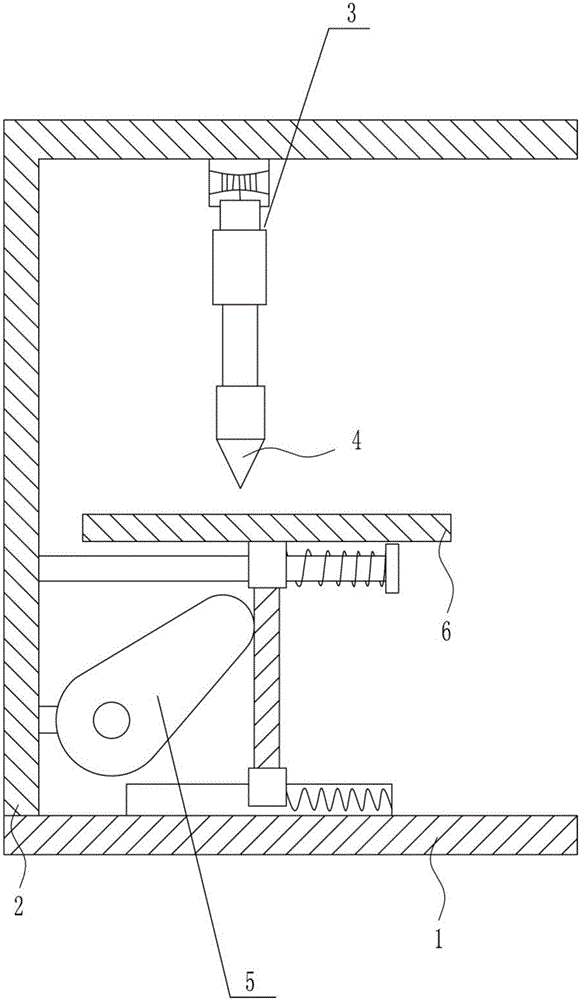

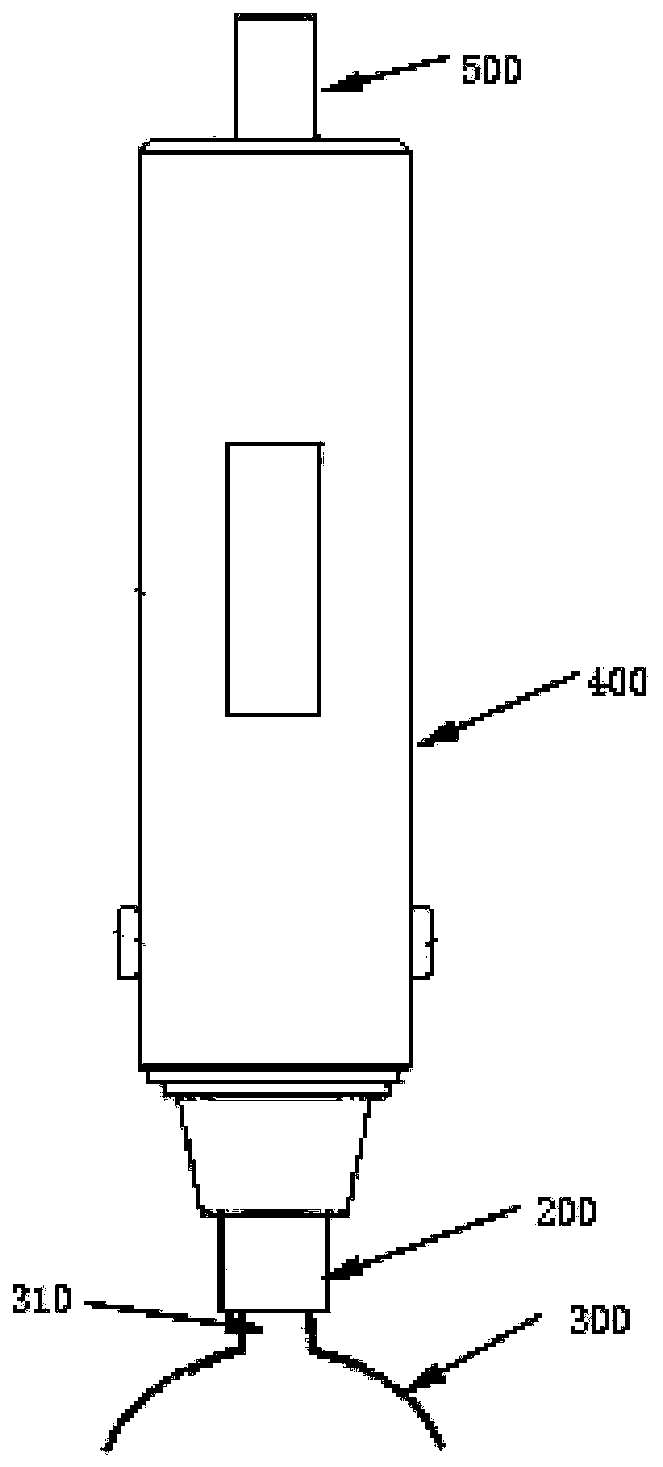

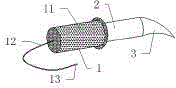

Tin soldering tool

ActiveCN103878463ATo achieve a fixed connectionAvoid instabilityWelding/cutting auxillary devicesAuxillary welding devicesSolderingMaterials science

The invention provides a tin soldering tool. The tin soldering tool comprises a wire positioning part (10), a tin melting device (21) and a wire guide part, wherein the wire positioning part (10) can move in the first direction and used for positioning a wire to be tin-soldered and driving the wire to be tin-soldered to move in the first direction; the tin melting device is provided with a first wire inlet and outlet (22); the wire guide part is located above the first wire inlet and outlet (22) and used for guiding the end to be tin-soldered of the wire to be tin-soldered moving in the first direction to stretch into the tin melting device (21) and be soaked into a soldering tin solution and leave from the soldering tin solution. By the adoption of the tin soldering tool, tin soldering efficiency of products is improved, labor intensity is relieved, and consistency of tin-soldered products is guaranteed.

Owner:HEFEI LINGDA COMPRESSOR +2

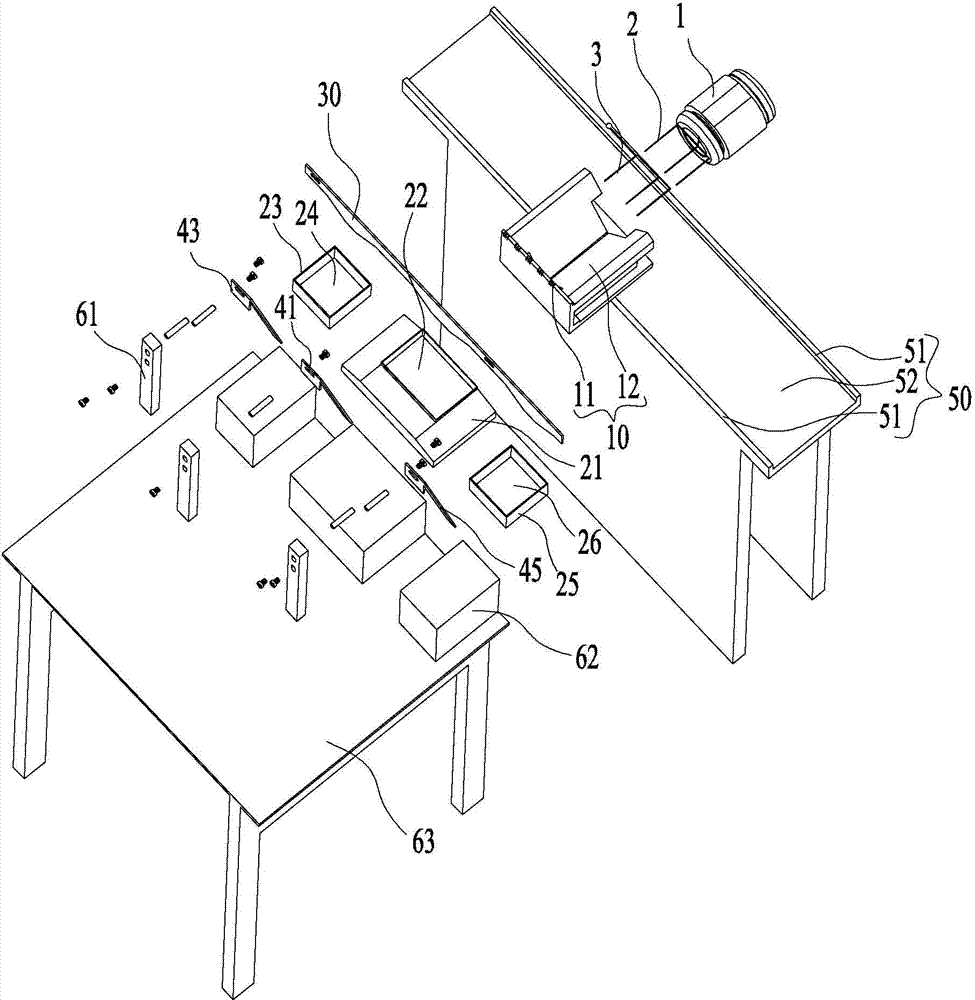

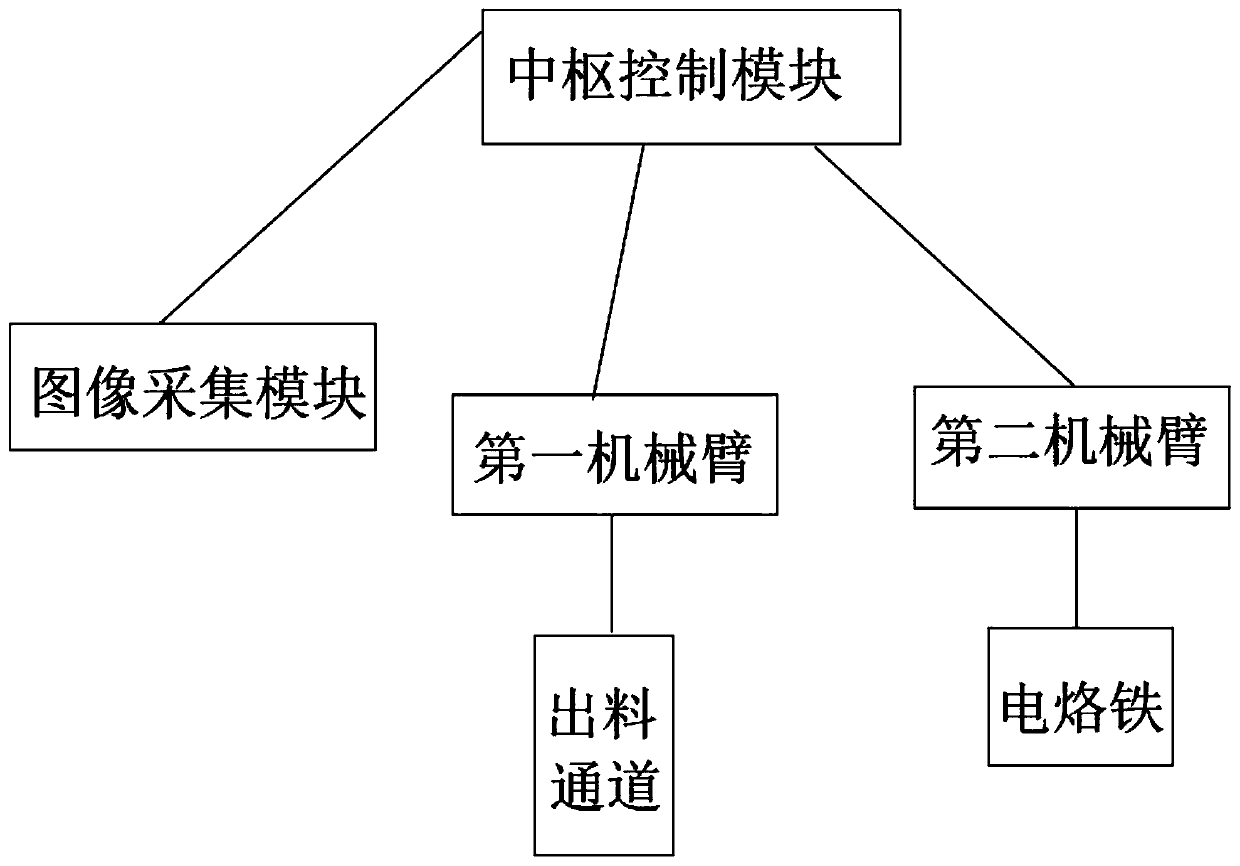

Electric soldering iron robot capable of realizing rapid tin soldering

InactiveCN110860759AImprove soldering efficiencyGuaranteed solder volumeSolder feeding devicesSoldering auxillary devicesEngineeringMechanical engineering

The invention discloses an electric soldering iron robot capable of realizing rapid tin soldering. The electric soldering iron robot capable of realizing rapid tin soldering comprises an image acquisition module, a central control module, a first mechanical arm and a second mechanical arm, wherein a discharge channel is formed in the head part of the first mechanical arm; a tin soldering materialis placed in the discharge channel; an electric soldering iron is arranged on the head part of the second mechanical arm; the image acquisition module acquires component pins on a circuit board, and transmits the acquired position information of the pins to the central control module; the central control module controls the first mechanical arm and the second mechanical arm to act; the first mechanical arm puts the tin soldering material at the positions of the pins; and the electric soldering iron of the second mechanical arm heats and melts the tin soldering material, so that soldering is realized. The electric soldering iron robot capable of realizing rapid tin soldering has the following advantages: tin soldering is automatically realized, and one-by-one correspondence with the component pins is facilitated, so that the tin soldering efficiency is increased; more uniform tin soldering is achieved while a tin soldering amount is ensured, so that the tin soldering efficiency is increased; and the beneficial effects of being simple, convenient and safe are achieved.

Owner:GUANGZHOU YIHUA ELECTRONICS EQUIP CO LTD

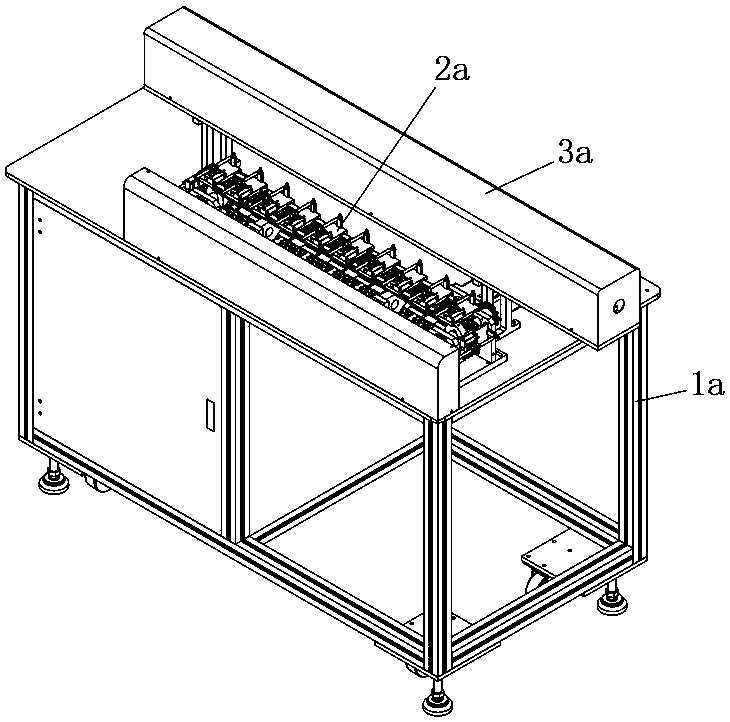

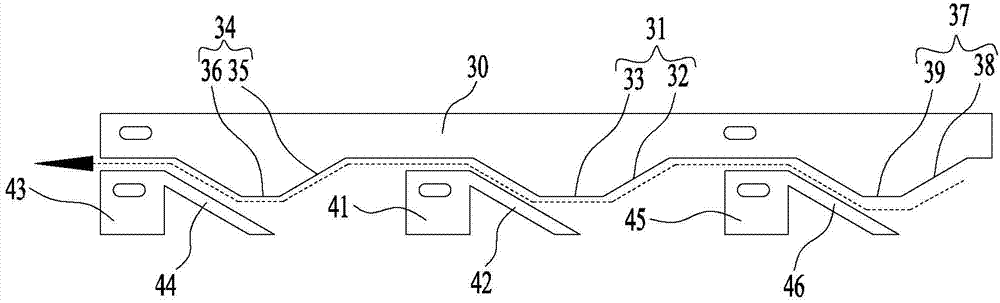

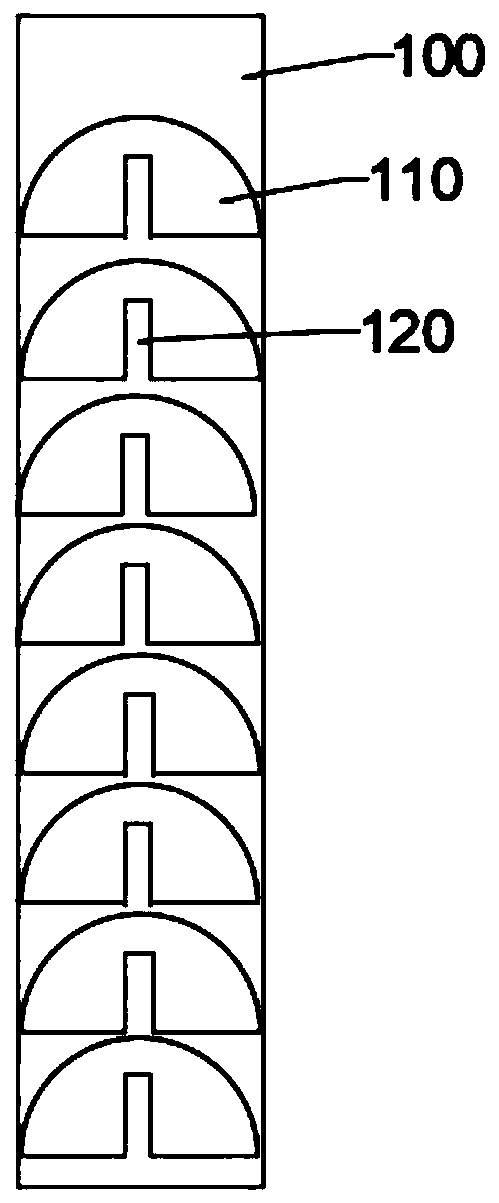

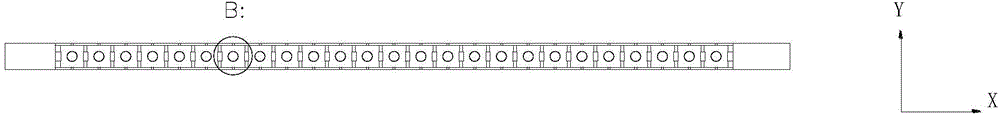

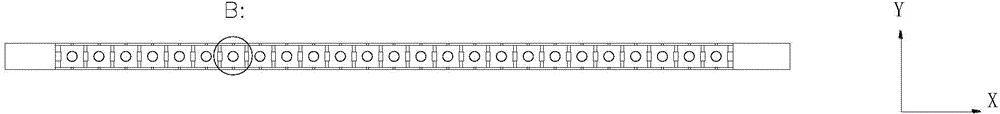

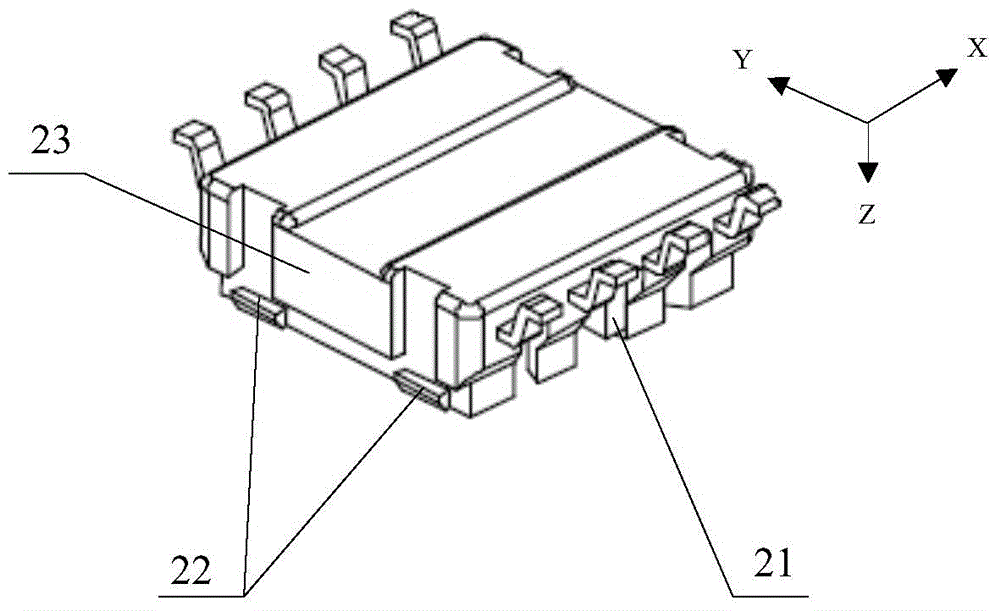

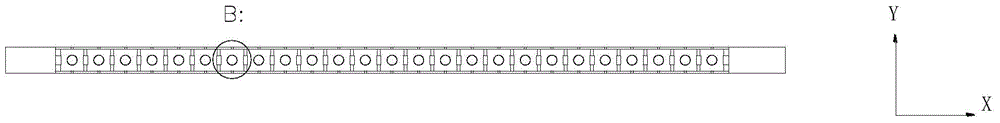

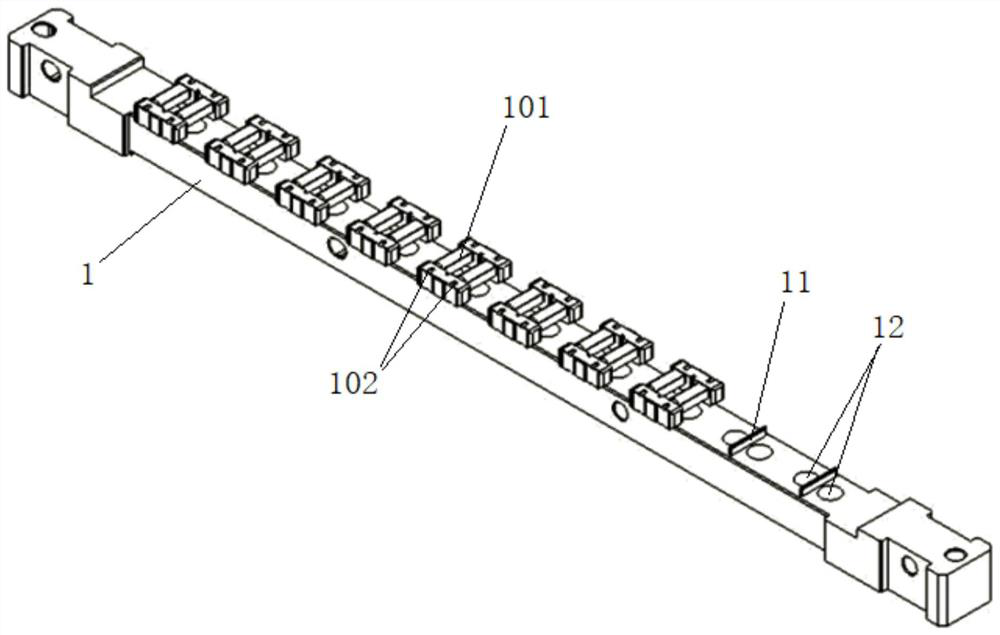

Tin-soldering tooling with strip-shaped heat dissipation holes

InactiveCN104551318ASimple structureEasy to processWelding/cutting auxillary devicesInductances/transformers/magnets manufactureAdhesiveInductor

The invention discloses a tin-soldering tooling of an automatic tin-soldering system of an inductor. The tin-soldering tooling can be used for providing a plurality of tin-soldering tooling positions of the inductor at a time, is provided with the heat dissipation design and can also be used for providing the basis for improving the tin-soldering working efficiency. A substrate of the tin-soldering tooling is a strip-shaped aluminum alloy plate, wherein a through groove is formed in one long side of the strip-shaped aluminum alloy plate; inverted T-shaped support tables are arranged in the groove at equal intervals; by designing the distance between two support tables, the inductor is erected between two adjacent support tables by using a boss; the height of the support table meets the condition that a circuit magnetic core in the inductor is not in contact with the bottom of the groove; partition positioning grooves matched with a middle partition of the inductor are distributed in the wall of the groove at equal intervals; circular magnetic steel used for absorbing a circular magnetic core of the inductor is embedded into the bottom of the groove; a plurality of rounded-corner strip-shaped holes penetrating through two large surfaces of the strip-shaped aluminum alloy plate are formed in the strip-shaped aluminum alloy plate; a ring of Teflon high-temperature adhesive tape is wound around one end provided with a groove on the strip-shaped aluminum alloy plate.

Owner:GUIYANG HIGH TECH KINGDA ELECTRONICS TECH

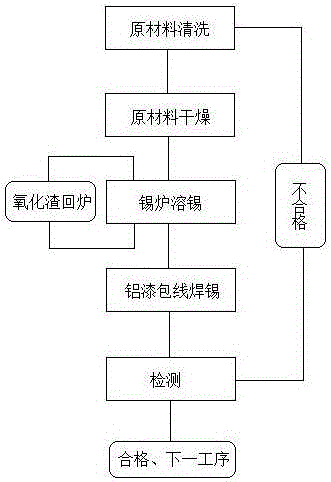

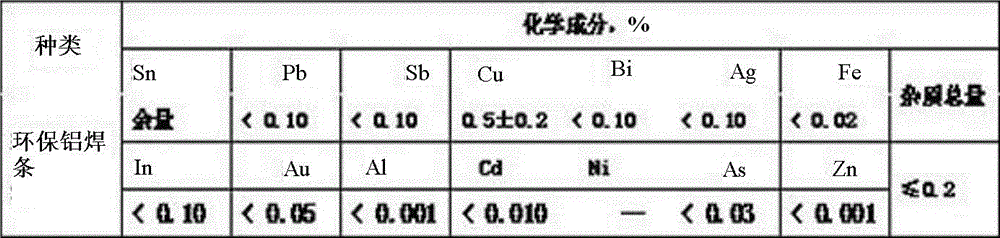

Tin soldering method for aluminum enameled wire

InactiveCN105855657AReasonable operationImprove soldering efficiencyWelding/cutting media/materialsSoldering mediaSoldering processMaterials science

The invention belongs to the technical field of application of aluminum enameled wires, and specifically discloses a tin soldering method for an aluminum enameled wire. The tin soldering method comprises the following steps: step 1) carrying out primary cleaning treatment on enameled wire raw materials; step 2) carrying out drying treatment on the enameled wire raw materials cleaned in the step 1); step 3) melting a tin bar by heating via a tin furnace, and carrying out tin soldering operation on the enameled wire raw materials subjected to the drying treatment in the step 2) by virtue of the molten tin bar in the tin furnace; and step 4) firstly detecting a tin-soldered finished product obtained in the step 3), and detecting whether a tin-soldered surface has solder skips, pseudo soldering, false soldering, excessive tin or tin holes or not. The tin soldering method for the aluminum enameled wire has the beneficial effect that the tin soldering process is reasonable in operation, the tin soldering efficiency is high, the quality is stable, phenomena such as insufficient soldering, false soldering, infirm connection or solder skips of the tin-soldered surface are solved, and the service life and the use safety of the assembled aluminum enameled wire tin-soldered finished product are effectively guaranteed.

Owner:XINGHUA ZHONGXING ELECTRIC APPLIANCE MFG CO LTD

Sheet lifting and cleaning device

PendingCN111375579AEasy to weldClean thoroughlyPhotovoltaicsCleaning using toolsStructural engineeringSoldering

The embodiment of the invention relates to photovoltaic product processing device, and particularly provides a sheet lifting and cleaning device. The sheet lifting and cleaning device comprises a sheet, a lifting mechanism and a cleaning mechanism, wherein one end of the sheet is fixed to a substrate, and the sheet comprises a fixed end and a free end; the lifting mechanism is used for bending thefree end of the sheet by a preset angle in the direction away from the substrate; and the cleaning mechanism is used for cleaning the surface of the substrate in the area near the sheet bent by the lifting mechanism. The free end of a bus bar is bent to be away from a photovoltaic panel, so that the bus bar is welded at a subsequent station conveniently, the tin soldering efficiency is improved,and bonding of a junction box is facilitated; and meanwhile, the cleaning mechanism is used for cleaning the photovoltaic panel at the bus bar, so that integration of lifting and cleaning of the bus bar is achieved, the integration level of the device is improved, manual cleaning is effectively replaced, the cleaning effect is good, and the efficiency is higher.

Owner:东君新能源有限公司

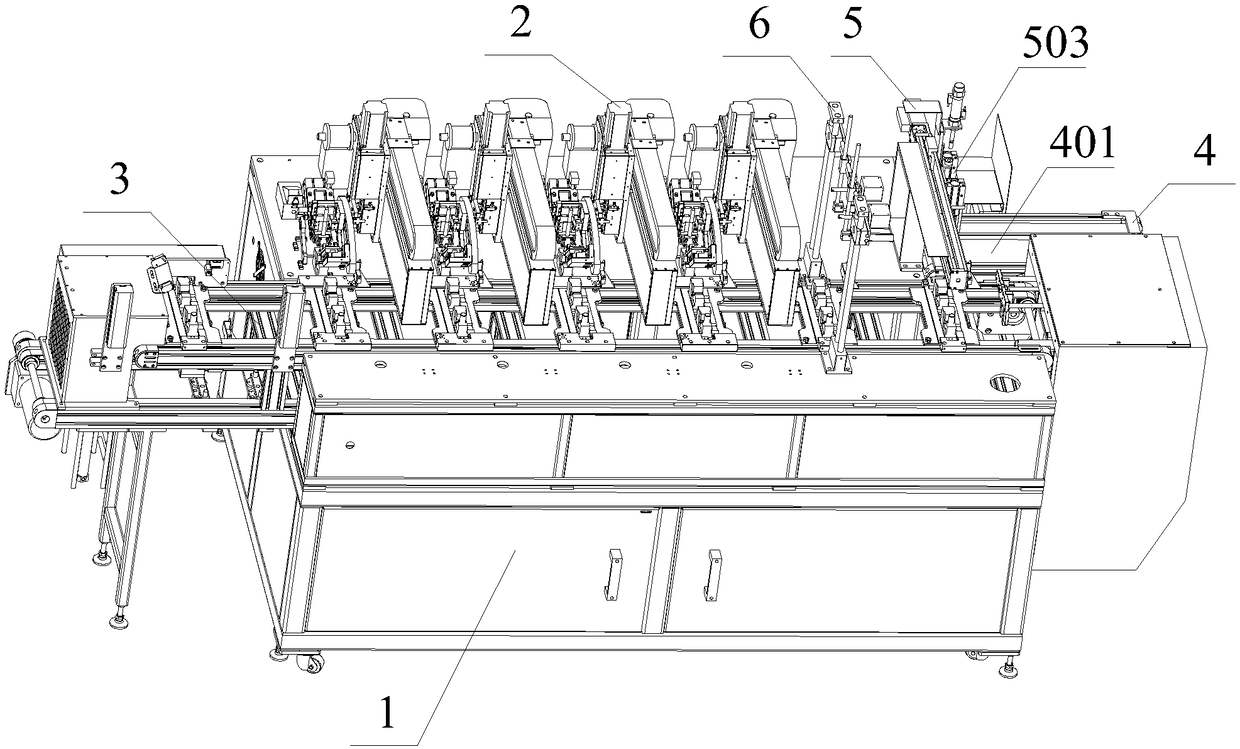

Fully-automatic inductance tin-soldering equipment

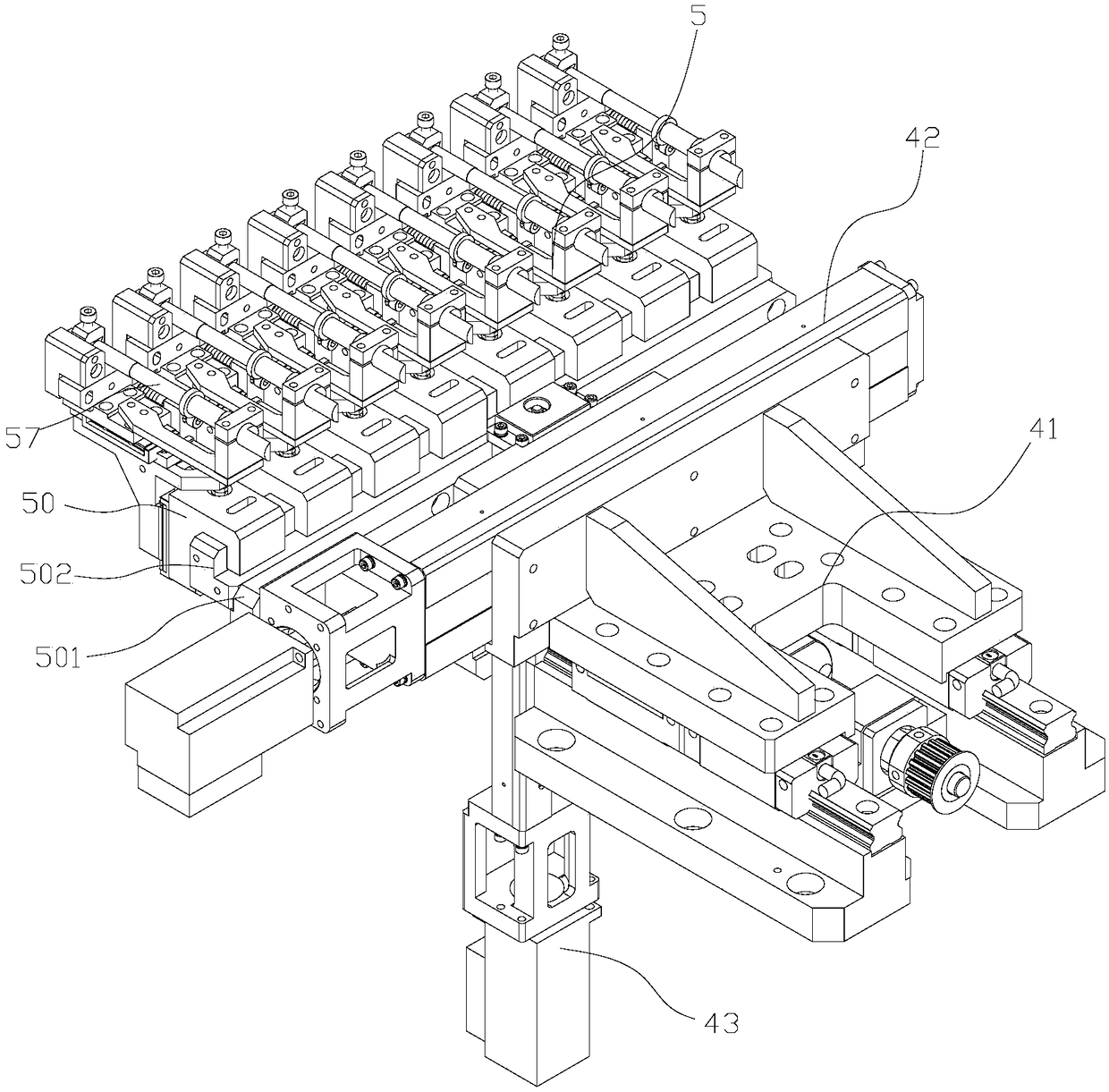

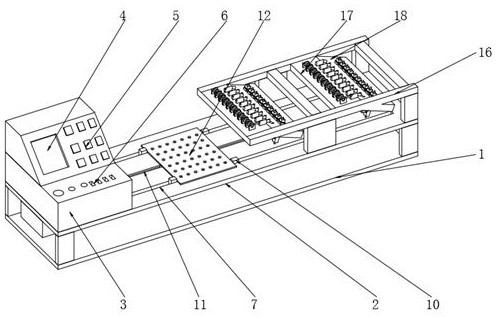

PendingCN108687420AIncrease production speedImprove product qualitySoldering ironSolder feeding devicesEngineeringInductance

The invention discloses fully-automatic inductance tin-soldering equipment. The fully-automatic inductance tin-soldering equipment comprises a multi-welding-head tin soldering mechanism, a tin outletline mechanism, a tin-soldering multi-shaft main shaft mechanism and a solder tip tin-scraping mechanism, wherein the multi-welding-head tin soldering mechanism comprises a tri-axial moving device ofthe tin soldering mechanism and a tin soldering assembly arranged on the tri-axial moving device of the tin soldering mechanism; the tin outlet line mechanism comprises a tri-axial moving device of the tin outlet line mechanism, and a tin outlet line assembly arranged on the tri-axial moving device of the tin outlet line mechanism. The fully-automatic inductance tin-soldering equipment has the advantages of being high in degree of automation, high in tin soldering efficiency, good in tin soldering quality, beneficial for improving inductance quality and increasing the yield, and the like, which are not achieved in the prior art.

Owner:GUANGXI BINYANG TIANXIANG ELECTRONICS

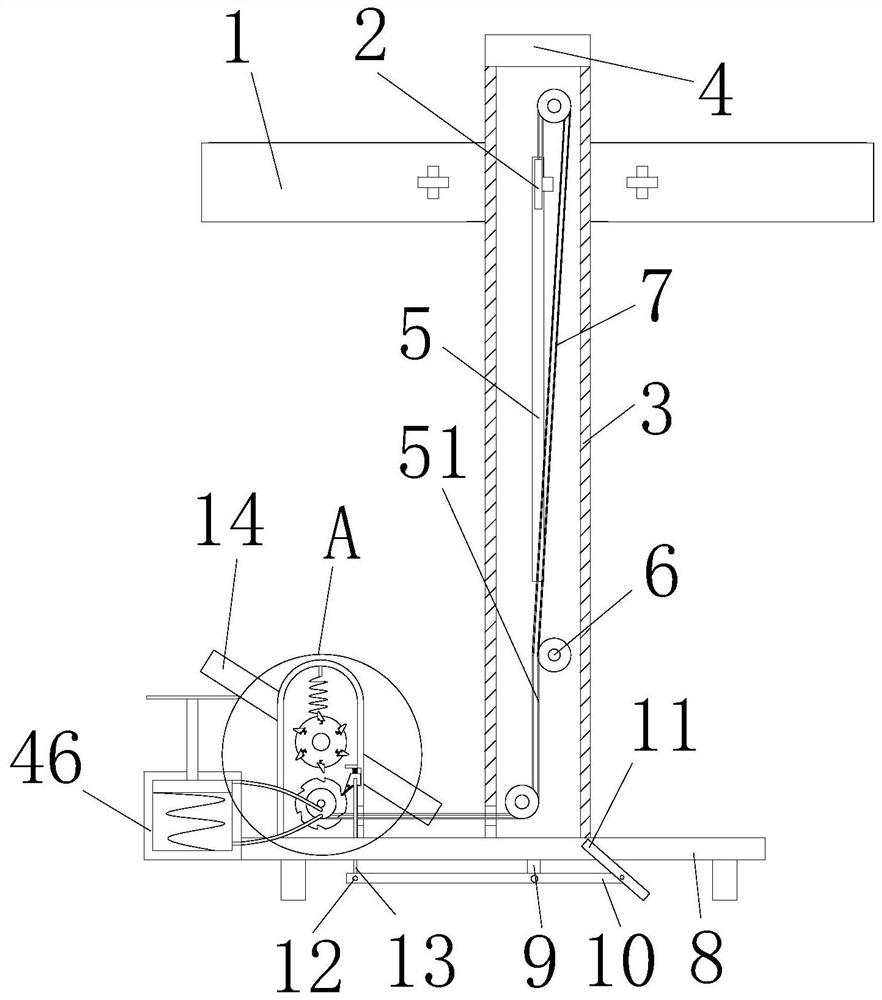

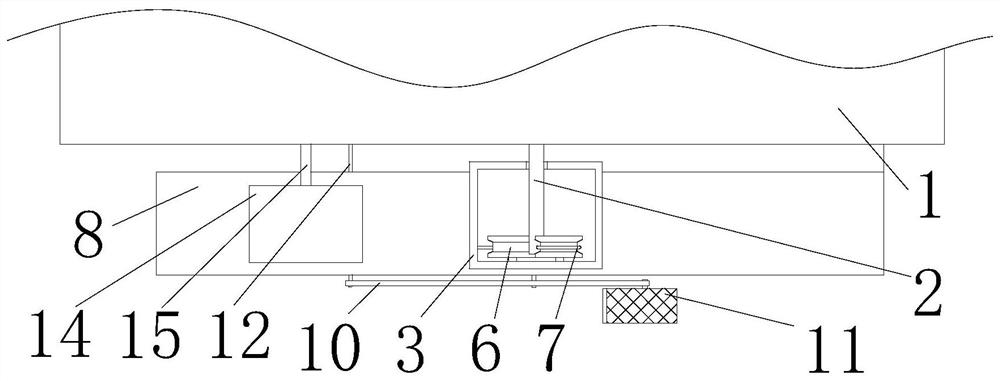

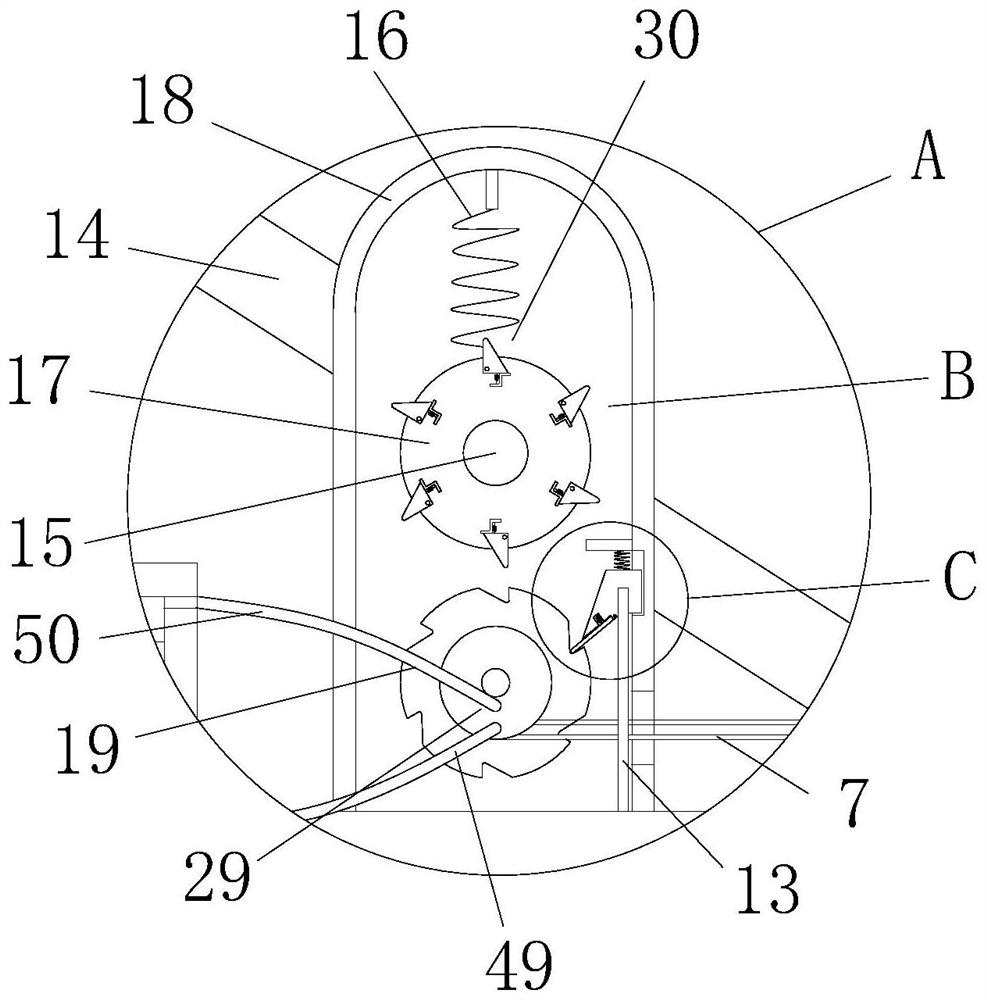

Tin soldering workbench capable of improving tin soldering efficiency

ActiveCN112872529AEasy height adjustmentMeet job needsMetal working apparatusSolder feeding devicesSolderingWorkbench

The invention relates to the technical field of tables, and discloses a tin soldering workbench capable of improving the tin soldering efficiency. The tin soldering workbench comprises a table board, a support frame, pulley blocks, a steel wire rope, a bottom frame, an auxiliary pedal and a main pedal, the rear inner wall of the support frame is provided with the three pulley blocks, the three pulley blocks are connected through the steel wire rope, the bottom surface of the support frame is fixedly connected with the bottom frame, a transmission box body is fixedly installed on the top face of the bottom frame, a movable hole is formed in the back face of the transmission box body, the front inner wall of the transmission box body is connected with a transmission wheel through a rotating shaft, the front face of the transmission wheel is fixedly connected with a wire coil, the outer wall of a connecting shaft is movably connected with a connecting rod in a sleeved mode, a fixing block is fixedly connected to the bottom face of the bottom frame, the fixing block is located at the front end of the bottom frame, the connecting rod is connected to the fixing block by means of a rotating shaft, the right end of the connecting rod is connected with the auxiliary pedal through a rotating shaft, the auxiliary pedal is located in front of the bottom frame, all structures arranged on the front face of the table board and the front face of the main pedal are arranged on the back faces of the table board and the main pedal in a mirroring mode, the structure is reasonable, and the height is convenient to adjust.

Owner:湖北卓茂智能科技有限公司

Tin soldering tooling for heat radiation by utilizing wave-shaped heat radiation hole and heat conducting holes

InactiveCN104551327ASimple structureEasy to processMetal working apparatusSoldering auxillary devicesAdhesiveHeat conducting

The invention discloses a tin soldering tooling for an inductor automatic tin soldering system. The tin soldering tooling has the advantages that a plurality of inductor tin soldering tooling positions can be provided in one step, and in addition, the heat radiation design is adopted, so that the basis is provided for improving the tin soldering work efficiency. A base body of the tin soldering tooling is a long-strip-shaped aluminum alloy plate, wherein one long side edge is provided with a penetrated groove, reverse T-shaped support tables are arranged in the groove at equal intervals, and the height of each support table is identical to the depth of the groove; separating baffle positioning grooves matched with middle separating baffles of an inductor are distributed on the groove wall of the groove at equal intervals, circular magnet steel used for adsorbing a round magnetic core of the inductor is embedded in the groove bottom, and a wave-shaped long-strip hole is formed in the long-strip-shaped aluminum alloy plate, and penetrates through two large surfaces of the long-strip-shaped aluminum alloy plate; a plurality of heat conducting holes communicated with the wave-shaped long-strip hole and the outside are formed inside the long-strip-shaped aluminum alloy plate; a circle of Teflon high-temperature adhesive tape is wound at one end, provided with the groove, on the long-strip-shaped aluminum alloy plate.

Owner:GUIYANG HIGH TECH KINGDA ELECTRONICS TECH

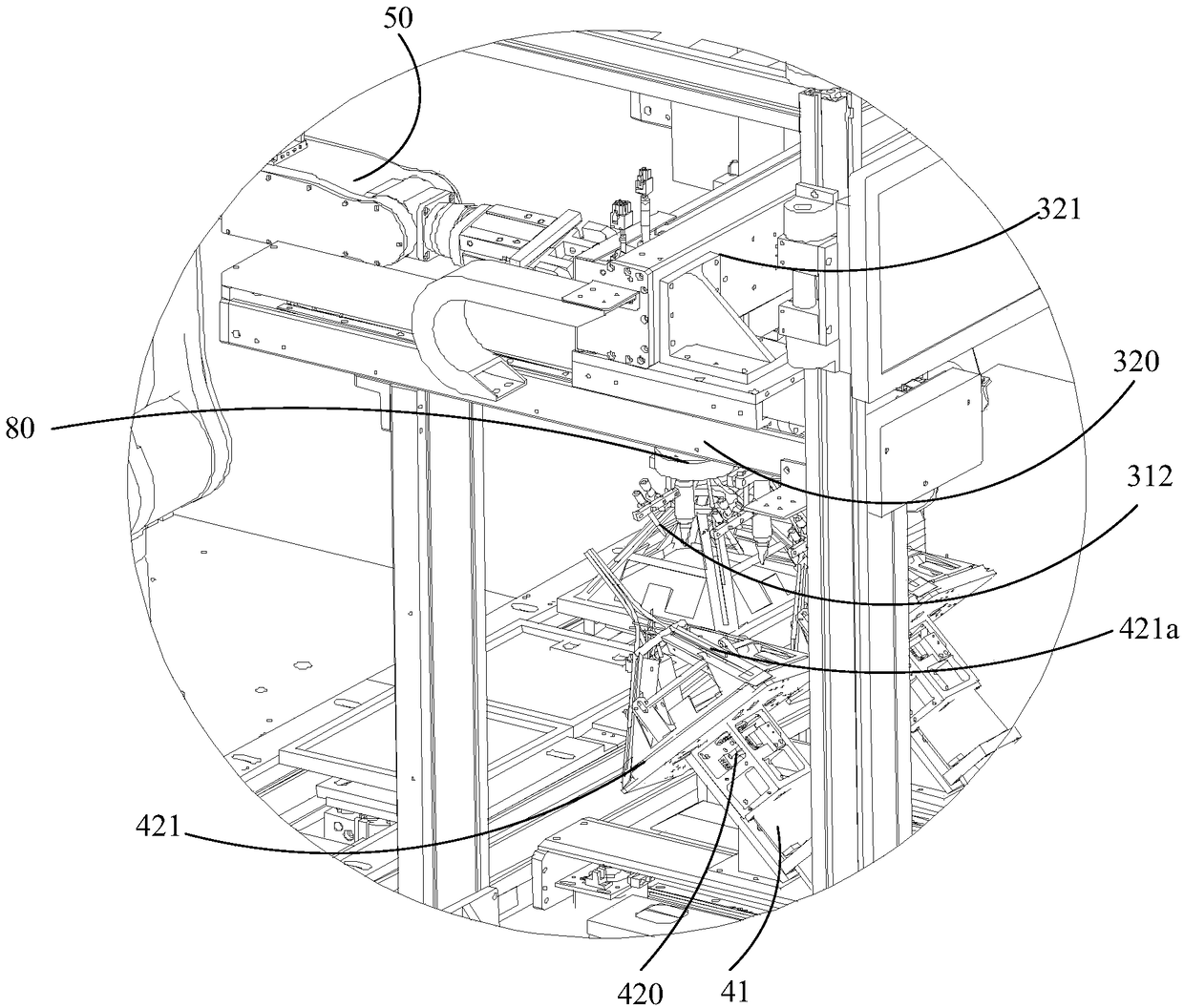

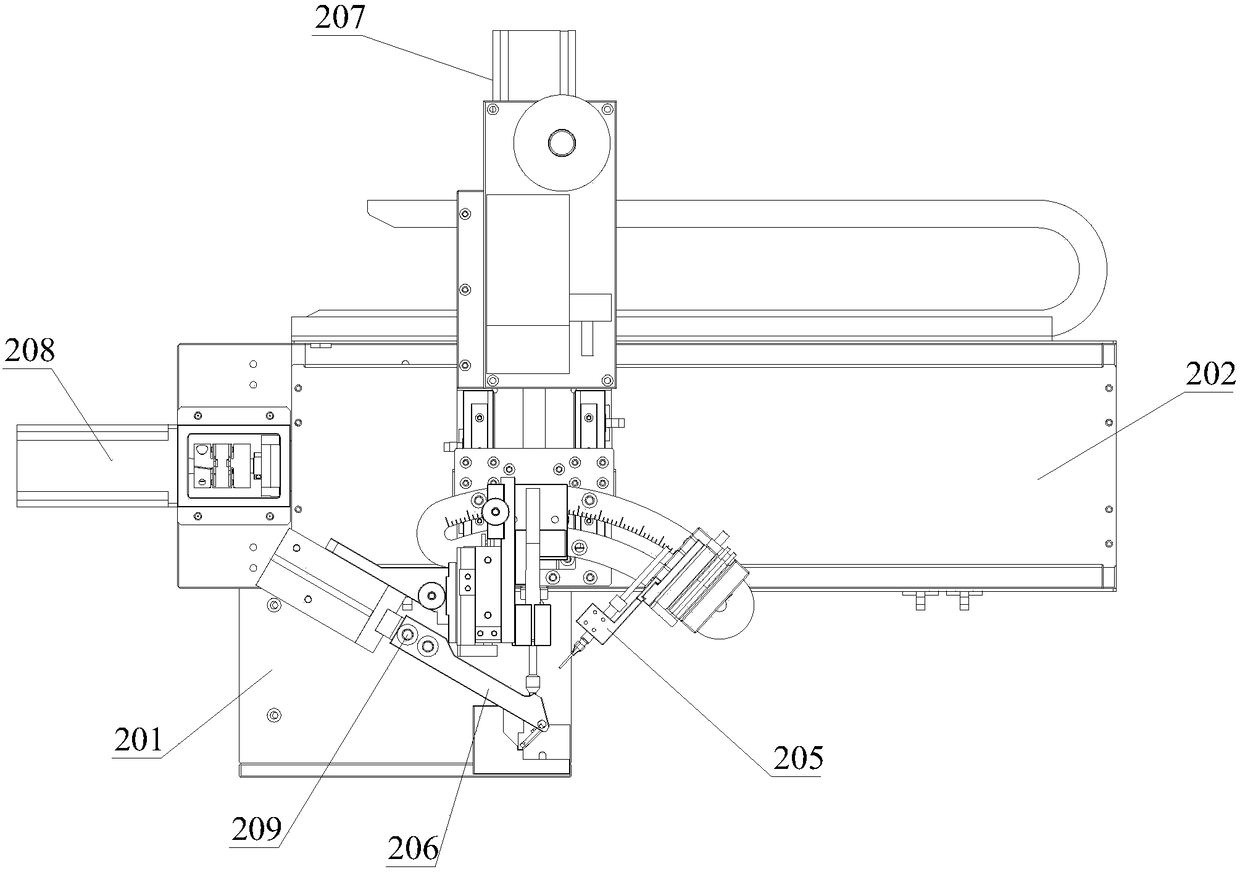

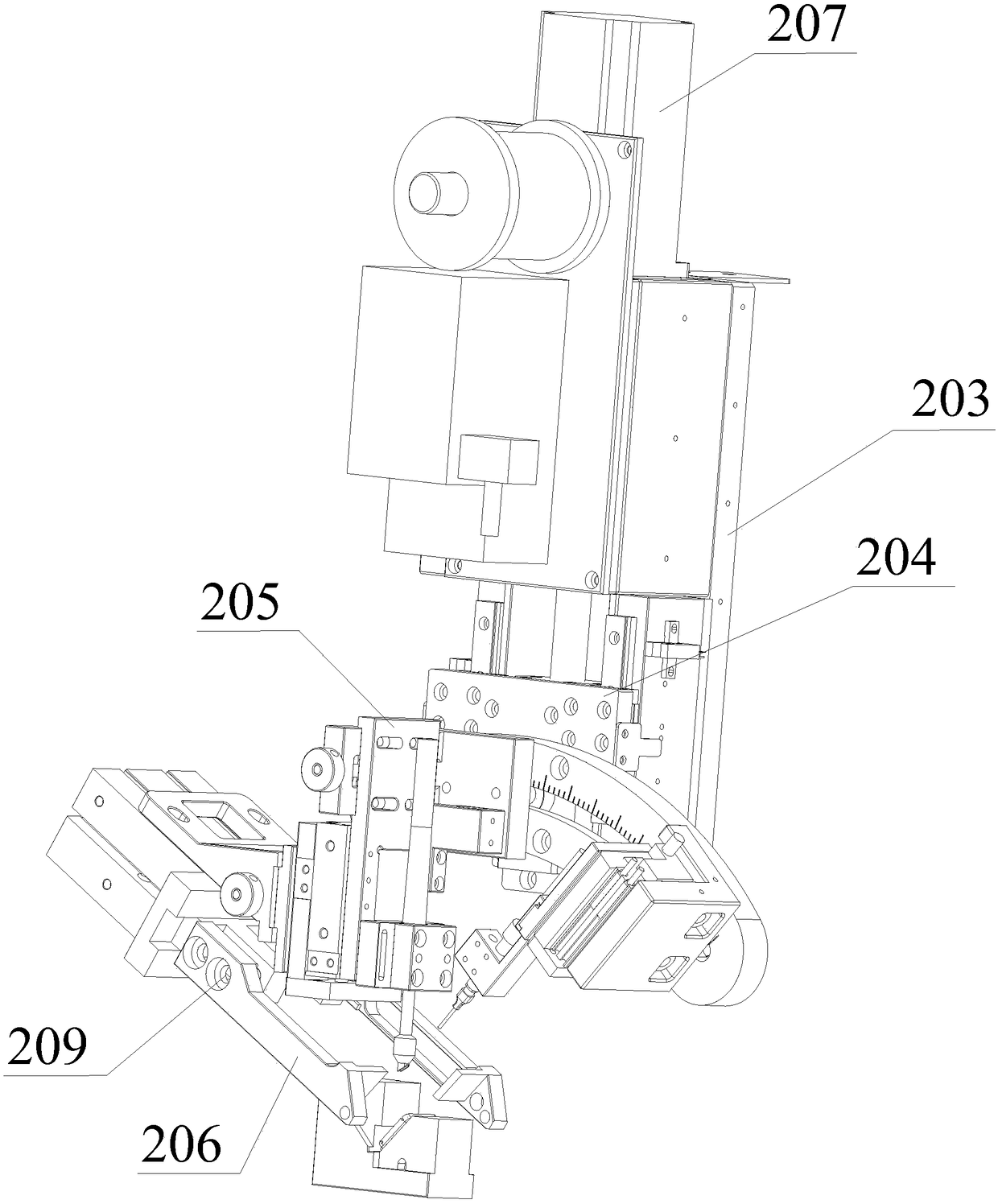

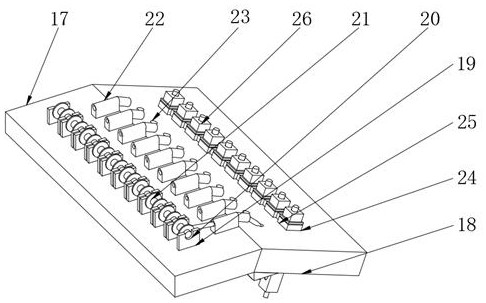

Welding cleaning module applied to soldering tin assembly and soldering tin assembly

ActiveCN108161164AReduce time consumptionReduce circulation proceduresSoldering auxillary devicesEngineeringTin

The invention provides a welding cleaning module applied to a soldering tin assembly and the soldering tin assembly. The welding cleaning module applied to the soldering tin assembly comprises a soldering machine used for conducting soldering tin and welding on workpieces, and a workpiece fine adjusting device used for clamping the workpieces and transferring the workpiece to a preset position andcooperating with the soldering machine for the soldering tin and welding; and the soldering machine comprises a welding head, an electric soldering iron used for conducting soldering tin and weldingcooperating operation on the workpieces and an adjusting frame, wherein the adjusting frame is used for limiting, connecting and cooperating the welding head and the electric soldering iron, and for enabling the welding head and the electric soldering iron to cooperate with each other to form an inclined included angle. The plurality of welding cleaning modules and conveying modules cooperate witheach other so as to finish accurate cooperation between the soldering tin and welding work of the workpieces and the workpiece conveying, the conveying modules can carry out circulating conveying onthe workpieces so as to guarantee the integrity of the tin soldering and welding work, the production efficiency and the product utilization rate are improved, all stations are arranged on the machinebox, and the soldering tin and welding and conveying work of the workpieces are completed in a collaborative mode.

Owner:石超

Automatic tin soldering device for multimedia interface line and working method for automatic tin soldering device

InactiveCN112872530AEasy to operateImprove processing efficiencyMetal working apparatusSoldering auxillary devicesMetallurgyEngineering

The invention provides an automatic tin soldering device for a multimedia interface line and a working method for the automatic tin soldering device and belongs to the field of interface line tin soldering technical equipment. The automatic tin soldering device comprises a rack, a tin soldering portion and a placement portion, wherein the tin soldering portion comprises a pair of supporting columns, a fixed strip, a connecting block, a first air cylinder, a second air cylinder and a tin soldering pen, the pair of supporting columns are oppositely arranged at the two ends of the top of the rack respectively, the fixed strip is arranged between the tops of the pair of supporting columns, the connecting block is slidably connected with the top of the fixed strip, the second air cylinder is arranged on the side surfaces of the supporting columns and is in driving connection with the connecting block, the first air cylinder is arranged on the other side of the connecting block, and the tin soldering pen is in driving connection with the first air cylinder; and the placement portion is arranged at the position, close to the soldering tin pen, of a workbench. The automatic tin soldering device for the multimedia interface line is capable of conducting tin soldering on multiple interface lines and improving the tin soldering efficiency of the interface lines and is easy to operate, high in machining efficiency, low in equipment maintenance cost and suitable for industrial large-scale popularization.

Owner:新沂市宏展电子科技有限公司

Automatic wire shearing and soldering tin device for varnished wires

The invention discloses an automatic wire shearing and soldering tin device for varnished wires. The automatic wire shearing and soldering tin device comprises a workbench, wherein a moving mechanismis arranged on the workbench; the moving mechanism is provided with a pneumatic manipulator used for moving and clamping an antenna; the workbench is further provided with a pneumatic shear clamp anda constant-temperature tin furnace in sequence; a constant-temperature controller used for controlling the constant-temperature tin furnace is arranged below the workbench, the constant-temperature controller is connected to the constant-temperature tin furnace, and a pneumatic de-ashing rake used for removing sundries in the constant-temperature tin furnace is arranged below the constant-temperature tin furnace; and the moving mechanism comprises an X-axis screw rod, a Y-axis screw rod and a Z-axis screw rod, wherein the Y-axis screw rod is arranged on the X-axis screw rod, the Z-axis screw rod is arranged on the Y-axis screw rod, and the pneumatic manipulator is arranged on the Z-axis screw rod. According to the automatic wire shearing and soldering tin device for the varnished wires, the pneumatic manipulator shearing and soldering tin, the length of a shearing line is accurately controlled through a mechanical arm, the length of the varnished wires is consistent, the problem of leakage shearing and the leakage soldering tin are avoided, and the yield of the soldering tin is improved; and the pneumatic manipulator is driven in three directions, so that the varnished wires are convenient to move.

Owner:SUZHOU SIPULANDI ELECTRONICS CO LTD

Tin soldering tool with strip-shaped heat radiation holes and heat conduction holes

InactiveCN104625300ASimple structureEasy to processMetal working apparatusSoldering auxillary devicesInductorSoldering

The invention discloses a tin soldering tool for an inductor automatic tin soldering system. The tin soldering tool can provide tin soldering tool positions of a plurality of inductors at a time, heat radiation design is achieved, and therefore a foundation is provided for improving the tin soldering work efficiency. A strip-shaped aluminum alloy plate serves as a base body of the tin soldering tool, a through groove is formed in one long side edge of the strip-shaped aluminum alloy plate, and inverted-T-shaped supporting tables are arranged in the grooves at equal intervals. Partition locating grooves matched with middle partitions of the inductors are formed in the wall of the groove at equal intervals, and round magnetic steel is embedded into the bottom of the groove. Circular bead strip-shaped holes are formed in the strip-shaped aluminum alloy plate, every four circular bead strip-shaped holes form a group, 2n+1 groups are totally formed, and n is set according to the length of the strip-shaped aluminum alloy plate. The circular bead strip-shaped holes in the same group are the same in the length direction, and are distributed in the strip-shaped aluminum alloy plate with the group as the unit in the direction X. A circle of Teflon high-temperature tape is wound at the end, with the groove, of the strip-shaped aluminum alloy plate.

Owner:GUIYANG HIGH TECH KINGDA ELECTRONICS TECH

An automatic wire laser soldering machine

ActiveCN111702275BAvoid instant heatingAvoid Solder Quality ImpactSolder feeding devicesSoldering auxillary devicesEngineeringSpot welding

The invention discloses an automatic wire laser soldering machine, which comprises a machine base, a fixing frame is fixedly installed on the base, a sliding rail is arranged on the fixing frame, a laser generator is slidably installed on the sliding rail, and a central surface of a rotating workpiece disc is installed There is a solder paste tank, a number of solder joint grooves are arranged on the edge of the workpiece plate, the solder joint groove and the solder paste tank are connected by a hose, a workpiece clamping plate is arranged on the outside of the workpiece plate, and a top of the solder paste tank is installed Small cylinder, the pressure rod of the small cylinder is inserted into the solder paste tank. The invention can squeeze the solder paste in the solder paste tank through the hose and conduct it into the solder joint slot under the action of the pressing rod at the bottom end of the small cylinder, and the solder paste contacts the surface of the workpiece, which can play the role of pre-injecting the solder paste in advance. Compared with manual spot welding, the soldering efficiency is higher, and the instant heating of the solder paste is avoided, so that the solder paste can be kept at room temperature at first, and the quality of the solder paste can be avoided.

Owner:由力自动化科技(上海)有限公司

Tin soldering device with pressing-holding fixing structure for automobile key contact piece assembly

InactiveCN112091355AAdjustable angleEasy to operateMetal working apparatusSoldering auxillary devicesMachine partsEngineering

The invention discloses a tin soldering device with a pressing-holding fixing structure for automobile key contact piece assembly, and relates to the technical field of automobile key contact piece assembly machining. The tin soldering device comprises a machining part and a fixing spring, a placement bottom plate is arranged outside the machining part, a pressing-holding device is installed at one end of the exterior of the placement bottom plate, a linking base is arranged at the upper end of the exterior of the pressing-holding device, and the top of the linking base is provided with a supporting device. According to the tin soldering device, by arranging the supporting device, the vertical height of a side block connected with the supporting device can be adjusted under the action of an electric push rod according to the tin soldering requirement of a spot-welding workpiece needing to be subjected to spot welding, a user can perform flexible adjustment according to the thickness ofthe machining part, the position of a tin soldering head can be fixed by manually adjusting the distance between two mounting side plates, the angle of the tin soldering head can be conveniently adjusted by the user, meanwhile, the tin soldering head can be disassembled and stored after using by the user is finished, the structure is simple, and operation by the user is facilitated.

Owner:广州市金点子机电科技发展有限公司

Tin soldering method for workpiece

InactiveCN112247299ANo manual operation requiredNo risk of manual operationPrinted circuitsMetal working apparatusAssembly lineManual handling

The invention discloses a tin soldering method for a workpiece. The tin soldering method comprises the following steps that (1) the workpiece provided with a PCB cover plate slides to the position below a tin soldering mechanism of an auxiliary device for workpiece tin soldering along an assembly line groove; (2) a conductive unit of the auxiliary device for workpiece tin soldering is connected with a conductive block of the workpiece so as to power on the workpiece; (3) a tin soldering head of the tin soldering mechanism is moved to any position, to be subjected to tin soldering, facing the workpiece, and the tin soldering head is powered on for tin soldering; and (4) tin soldering is carried out on the multiple positions, to be subjected to tin soldering, of the workpiece in sequence. According to the tin soldering method, manual operation is not needed, manual operation risks are avoided, the tin soldering process is automatically completed, and tin soldering efficiency is high.

Owner:长沙全时智联科技有限公司

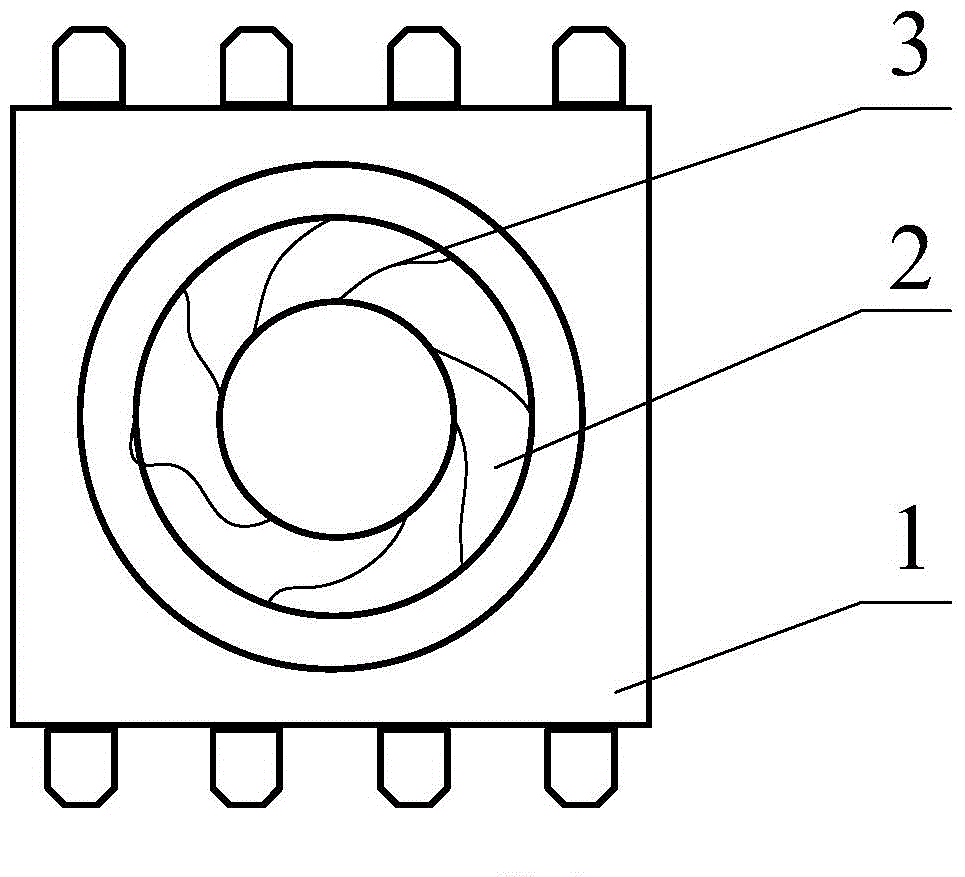

Integrated circuit processing method and processing equipment

PendingCN113690165AAvoid welding inaccurate positionsPrevent lack of weldingSolid-state devicesSemiconductor/solid-state device manufacturingSolderingMechanical engineering

The invention discloses an integrated circuit processing method and equipment, and the equipment comprises a pedestal, the top of the pedestal is fixedly provided with a positioning plate through a support, one side of the top of the positioning plate is fixedly provided with a console, and the top of the positioning plate is fixedly provided with two solder wire fixing plates through a support. Two tin soldering plates are fixedly arranged on the inner walls of the two tin wire fixing plates, a downward-inclined tin soldering plate is fixedly arranged on the outer wall of one side of each tin soldering plate, a fixing groove is formed in the outer wall of the top of each tin soldering plate, and a fixing sleeve is fixedly arranged on the inner wall of each fixing groove. The top of the integrated circuit board is welded through cooperation of the multiple lead sleeves and the laser tin melting spotlight, after the integrated circuit board moves on the tin soldering plate and the bottom of the tin soldering plate, top tin soldering of the integrated circuit board is completed, the tin soldering efficiency of the top of the integrated circuit board is greatly improved, the using effect is good, and large-scale batch processing of integrated circuit boards in existing factories is met.

Owner:谢利洪

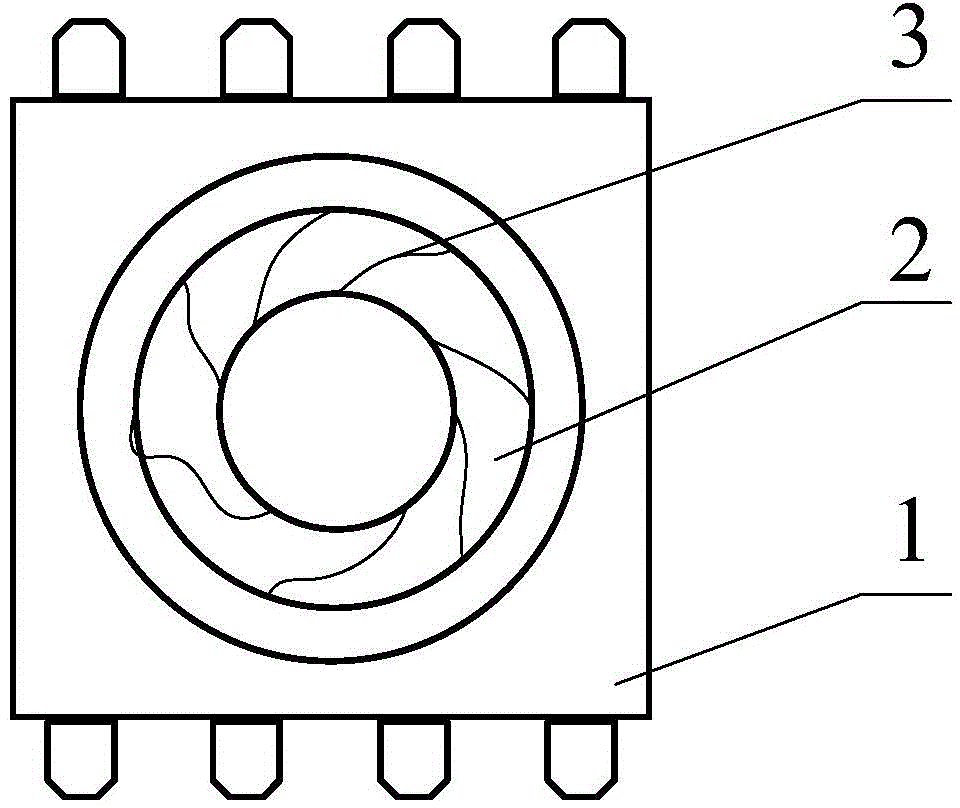

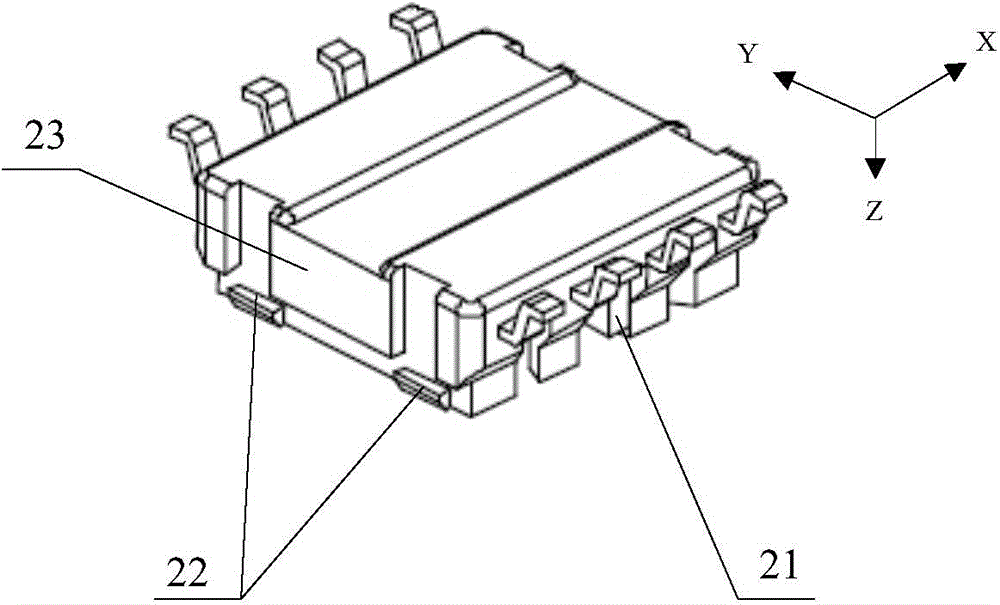

Efficient automatic soldering process for patch common-mode inductors

PendingCN111604562ARealize soldering automationPrecision SprayingPrinted circuit assemblingMetal working apparatusEngineeringInductor

The invention discloses an efficient automatic soldering process for patch common-mode inductors. The process comprises the following steps that (1) patch common-mode inductors are placed on a jig strip at interval, wherein the upper surface of the jig strip is provided with limiting protrusions inserted into the patch common-mode inductors for positioning and adsorption magnetic blocks located onthe two sides of the limiting protrusions and adsorbing the patch common-mode inductor; (2) the jig strip is biased to a set angle, so that the surface of the welding feet PIN on one sides of the patch common-mode inductors is exposed upwards; (3) flux spraying is performed on the exposed surfaces of the welding feet PIN on the side by using precision spraying equipment; (4) the step 2 and the step 3 are repeated, flux spraying of the welding feet PIN on the other side is completed, and then the jig strip is restored to an initial state; (5) hot air is blown; (6) selective wave crest weldingis carried out; (7) cleaning is carried out; and (8) CCD detection is carried out. According to the process, automatic soldering operation can be realized, the soldering efficiency, the soldering precision and the soldering effect are greatly improved.

Owner:苏州恊合自动化科技有限公司

A high-efficiency LED lamp chip soldering equipment based on digital linear dimming technology

ActiveCN113319398BConvenient and accurate fixationReduce wasteSolder feeding devicesSoldering auxillary devicesSolderingEngineering physics

The invention relates to a high-efficiency LED lamp chip soldering device based on digital linear dimming technology. A tin storage chamber is arranged below, and also includes a tin conveying channel, a conveying device and a tin conveying device. The tin conveying channel runs through the welding table and extends downward to the tin storage chamber; It is divided into a storage section, a temporary storage section and a conveying section. The conveying device makes the tin in the tin storage room enter the storage section through the conveying section and the temporary storage section in turn; the tin feeding device sends the tin in the storage section to the solder joints of the chip. The invention solves the technical problem that the molten tin is difficult to be sent to the welding point in the prior art.

Owner:浙江凯友照明科技有限公司

Winding Soldering Machine

ActiveCN105047392BRealize integrationImprove soldering efficiencyInductances/transformers/magnets manufactureWelding/soldering/cutting articlesEngineeringSoldering

Owner:中山捷航自动化科技有限公司

Electric soldering iron device capable of avoiding shielding operation visual field

InactiveCN104690391AReduce blockingConvenient welding operationSoldering ironMetal working apparatusVisual field lossElectricity

The invention discloses an electric soldering iron device capable of avoiding shielding an operation visual field. The electric soldering iron device comprises an insulation handle (1), an electric soldering rod (2) is arranged in the front of the insulation handle; an electric soldering head (3) is arranged on one end, opposite to the insulation handle, of the electric soldering rod. The electric soldering iron device is characterized in that the axis of the electric soldering head (3) and the center axis of the electric soldering rod (2) form a 0 degree-30 degree radian curve. During soldering tin operation, the blockage of the electric soldering rod (2) for the visual field is effectively reduced, and thus the soldering tin operation is facilitated. A hole (31) is formed in the electric soldering head (3), thus a section of electrode wire is blended in a spherical space (32) of the electric soldering head, the electrode wire does not need to be attached to the electric soldering head all the time in the soldering tin process, the operation is simplified, and the efficiency is improved.

Owner:朱妍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com