Automatic wire shearing and soldering tin device for varnished wires

An enameled wire, automatic technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as difficulty in meeting modern needs, uneven lengths of wire trimming, affecting soldering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

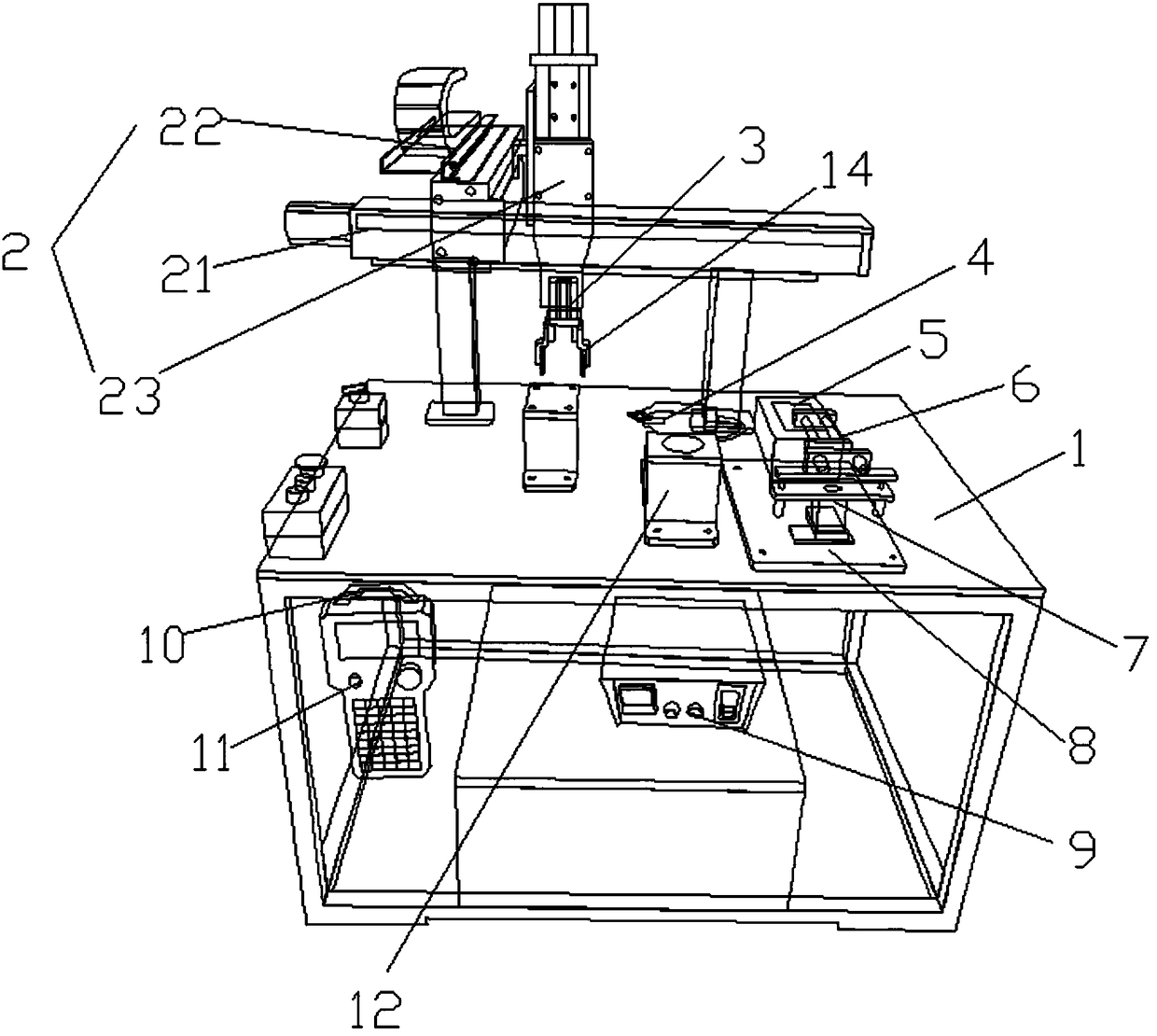

[0019] like figure 1 As shown, the enameled wire automatic trimming and soldering equipment includes a workbench 1, the stud of the workbench 1 is connected with a moving mechanism 2, and the stud of the moving mechanism 2 is connected with a pneumatic manipulator 3 for moving and clamping the antenna. 1. The studs are connected with the pneumatic cutters 4 and the constant temperature tin furnace 5 in turn. The lower part of the workbench 1 is connected with the constant temperature controller 9 through the bracket studs. The constant temperature controller 9 is electrically connected with the constant temperature tin furnace 5. The stud below the constant temperature tin furnace 5 is connected with a pneumatic ash removal rake 6 for removing sundries in the constant temperature tin furnace 5 .

[0020] When in use, the pneumatic manipulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com