Auxiliary device for tin soldering for circuit board

A technology for auxiliary devices and circuit boards, applied in auxiliary devices, assembling printed circuits with electrical components, welding positions, etc., can solve the problems of low soldering efficiency, slow soldering speed, and physical harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

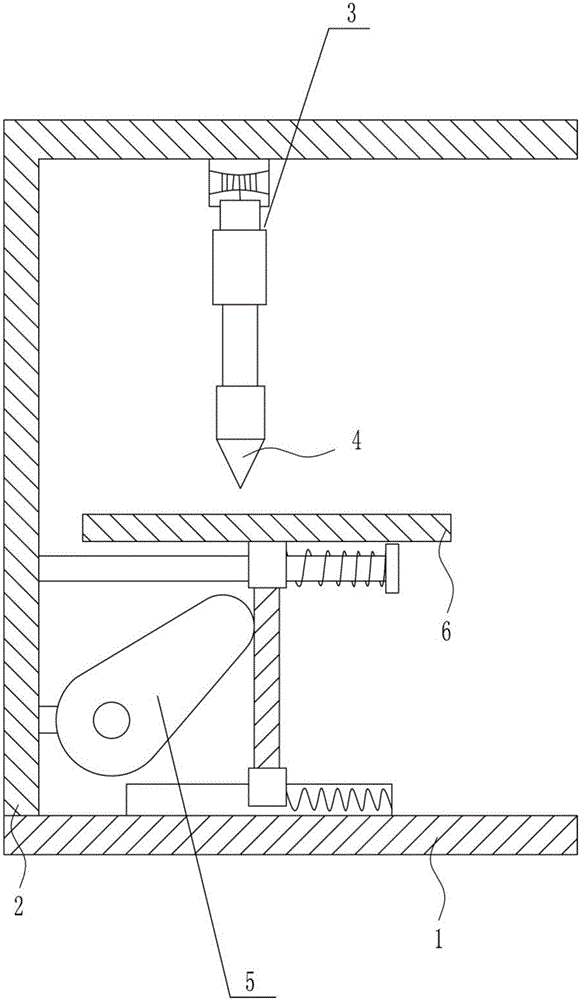

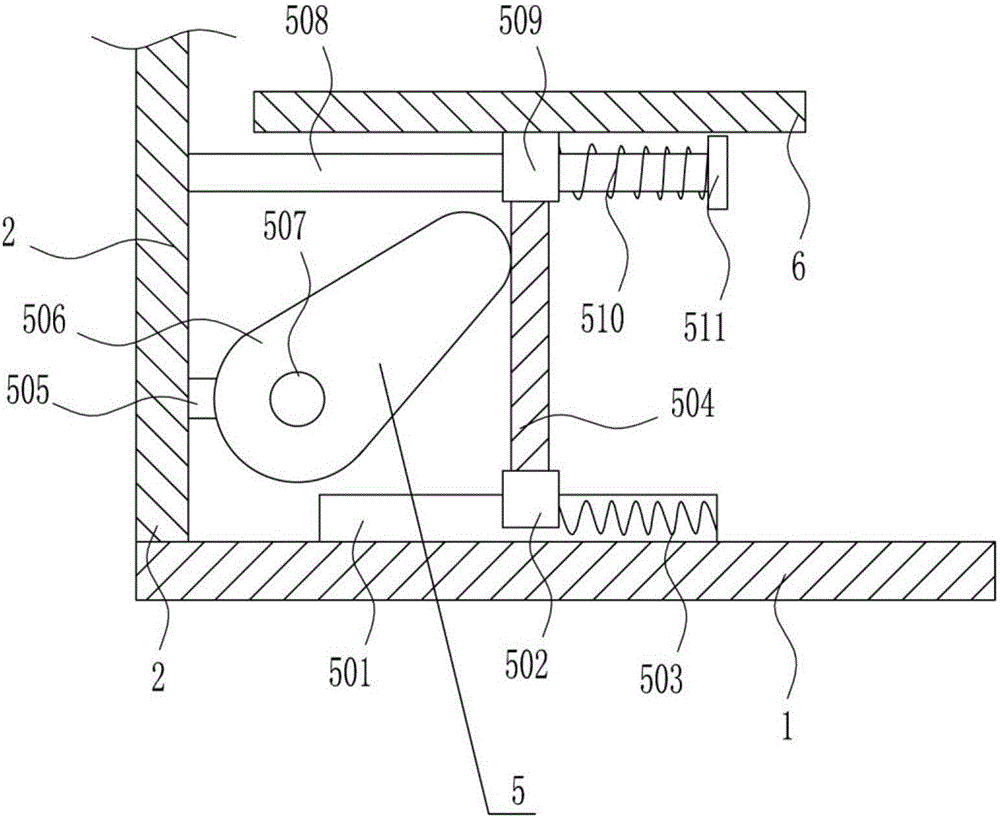

[0040] A circuit board soldering auxiliary device, such as Figure 1-9 As shown, it includes a base plate 1, an L-shaped plate 2, a moving device 3, a soldering iron tip 4, an adjustment device 5, and a placement table 6. The left side of the top of the base plate 1 is provided with an L-shaped plate 2, and the top of the base plate 1 is provided with an adjustment device 5. The top of the adjusting device 5 is provided with a placing platform 6 , the inner top of the L-shaped plate 2 is provided with a moving device 3 , and the bottom of the moving device 3 is provided with a soldering iron tip 4 .

Embodiment 2

[0042] A circuit board soldering auxiliary device, such as Figure 1-9 As shown, it includes a base plate 1, an L-shaped plate 2, a moving device 3, a soldering iron tip 4, an adjustment device 5, and a placement table 6. The left side of the top of the base plate 1 is provided with an L-shaped plate 2, and the top of the base plate 1 is provided with an adjustment device 5. The top of the adjusting device 5 is provided with a placing platform 6 , the inner top of the L-shaped plate 2 is provided with a moving device 3 , and the bottom of the moving device 3 is provided with a soldering iron tip 4 .

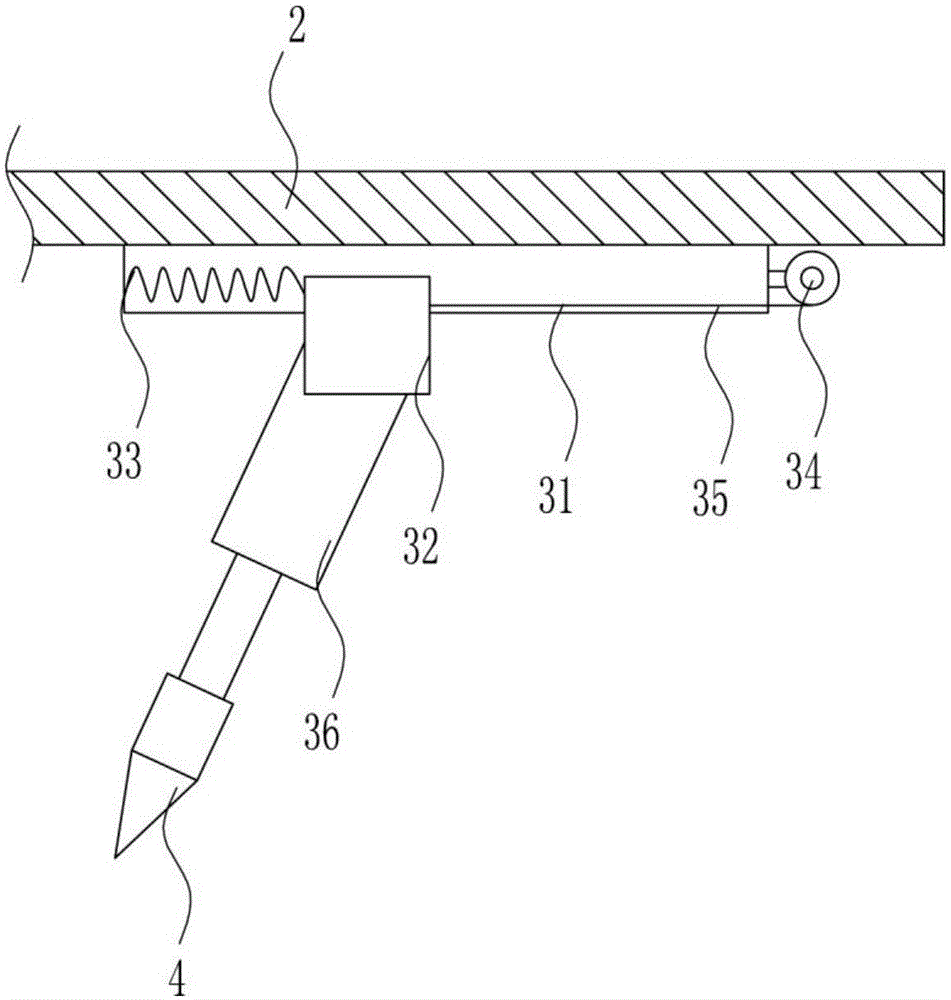

[0043] Mobile device 3 comprises the first slide rail 31, the first slide block 32, the first spring 33, the first electric reel 34, the first backguy 35 and the first electric push rod 36, and the inner top of L-shaped plate 2 is provided with A first slide rail 31 is arranged, and a first slide block 32 is slidably provided on the first slide rail 31. A first spring 33 is conne...

Embodiment 3

[0045] A circuit board soldering auxiliary device, such as Figure 1-9 As shown, it includes a base plate 1, an L-shaped plate 2, a moving device 3, a soldering iron tip 4, an adjustment device 5, and a placement table 6. The left side of the top of the base plate 1 is provided with an L-shaped plate 2, and the top of the base plate 1 is provided with an adjustment device 5. The top of the adjusting device 5 is provided with a placing platform 6 , the inner top of the L-shaped plate 2 is provided with a moving device 3 , and the bottom of the moving device 3 is provided with a soldering iron tip 4 .

[0046] Mobile device 3 comprises the first slide rail 31, the first slide block 32, the first spring 33, the first electric reel 34, the first backguy 35 and the first electric push rod 36, and the inner top of L-shaped plate 2 is provided with A first slide rail 31 is arranged, and a first slide block 32 is slidably provided on the first slide rail 31. A first spring 33 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com