Patents

Literature

61results about How to "Short filter time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel technique for extracting L-tryptophan from fermentation broth

ActiveCN101812009AThorough decontaminationShort filter timeOrganic chemistryAnimal feeding stuffIon exchangeUltrafiltration

The invention discloses a novel technique for extracting L-tryptophan from fermentation broth, which includes the following steps that: fermentation broth is pretreated, and the treated liquid is pumped into a ceramic microfiltration membrane filter, so that tryptophan microfiltrate without mycelium and mycoprotein are obtained; the tryptophan microfiltrate is pumped into an ultrafiltration membrane filter, so that tryptophan ultrafiltrate and concentrated liquid containing pigment and protein are obtained; the tryptophan ultrafiltrate is pumped into a nanofiltration membrane filter, so that concentrated tryptophan liquid and permeate containing salt are obtained; waste filtrate is comprehensively utilized to produce protein feed; industrial ethylic acid is used for promoting low-temperature crystallization, crystallization mother liquid is treated by the ion exchange method and used, and after crystals are centrifugally dehydrated and dried, the L-tryptophan product is obtained. The invention solves the problem on how to recover industrial ethylic acid, and greatly increases the extraction rate of L-tryptophan; and since the filtrate and the mycoprotein are comprehensively utilized, the product profit is maximized. The total extraction rate of L-tryptophan is 85.2 percent, and the refined product meets the standards of Chinese Pharmacopoeia edition 2005.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

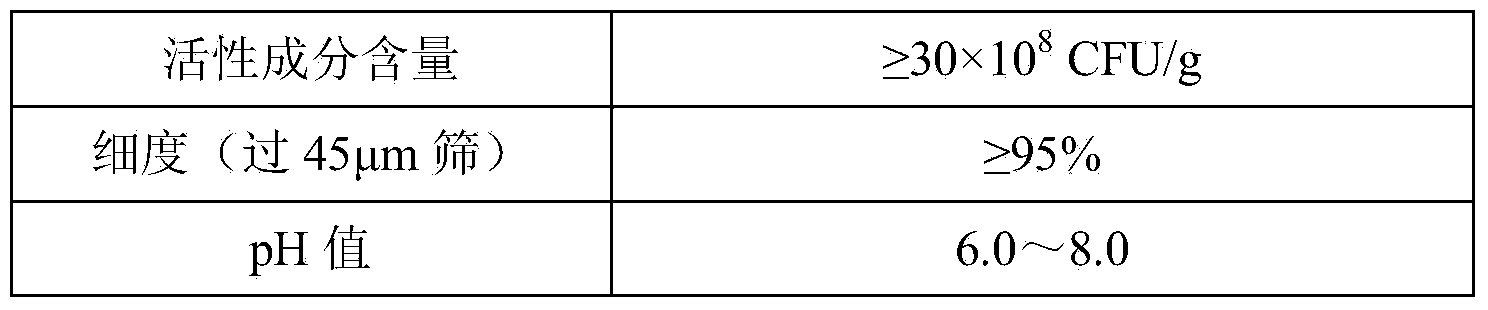

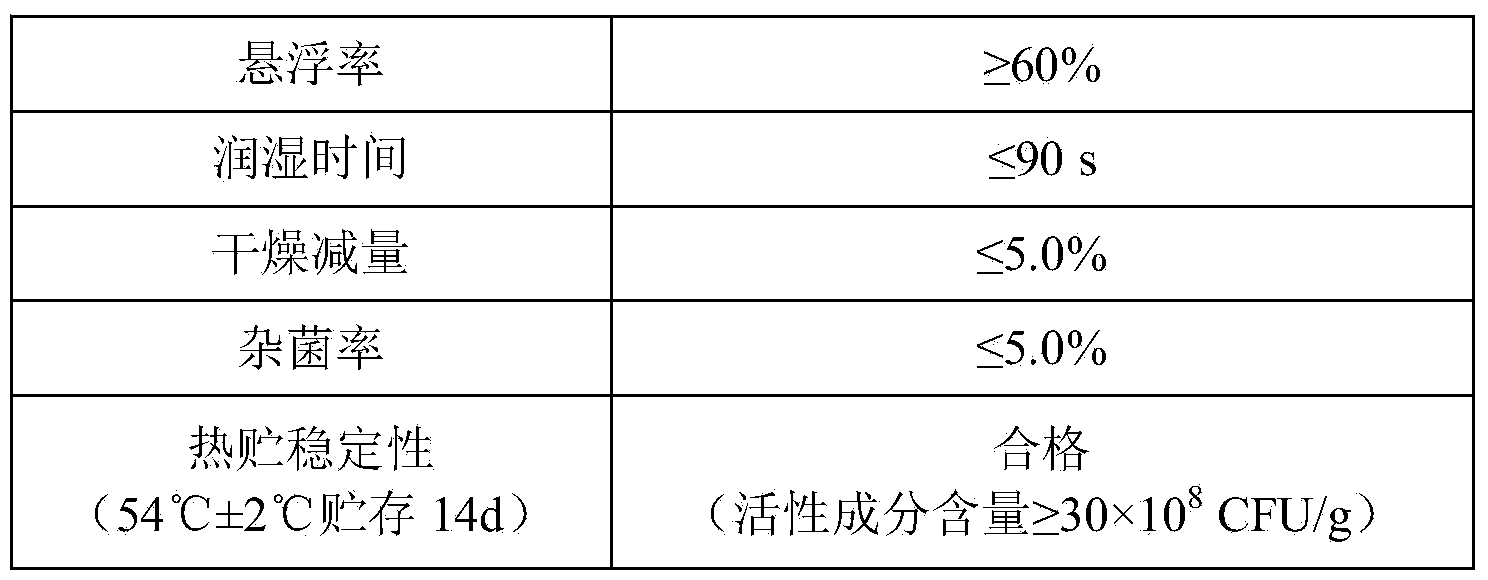

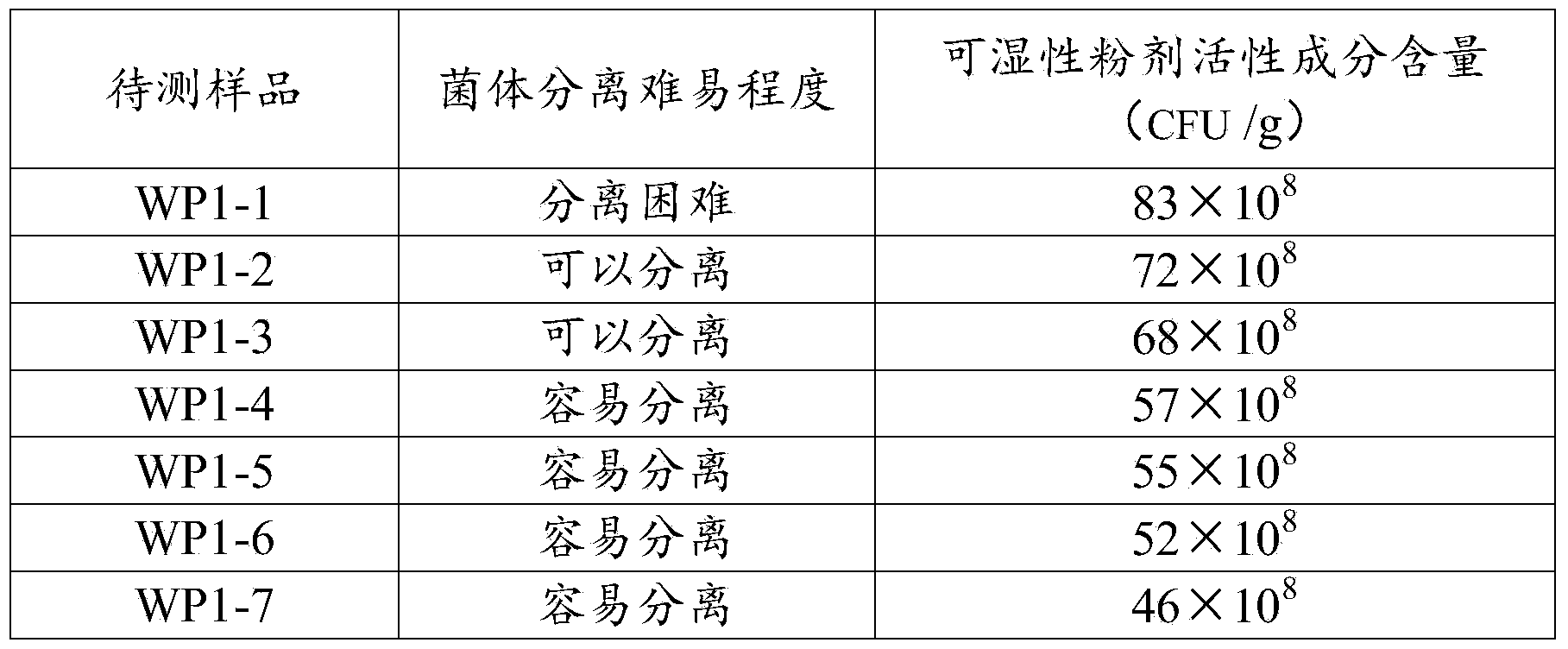

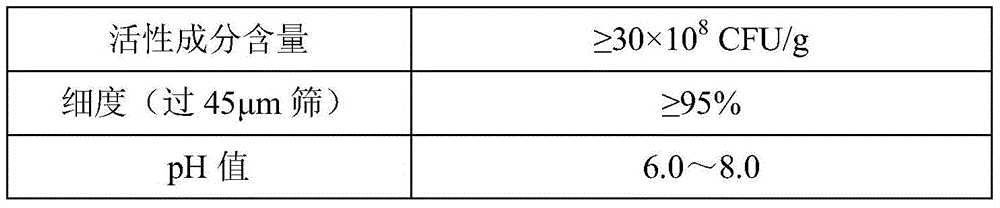

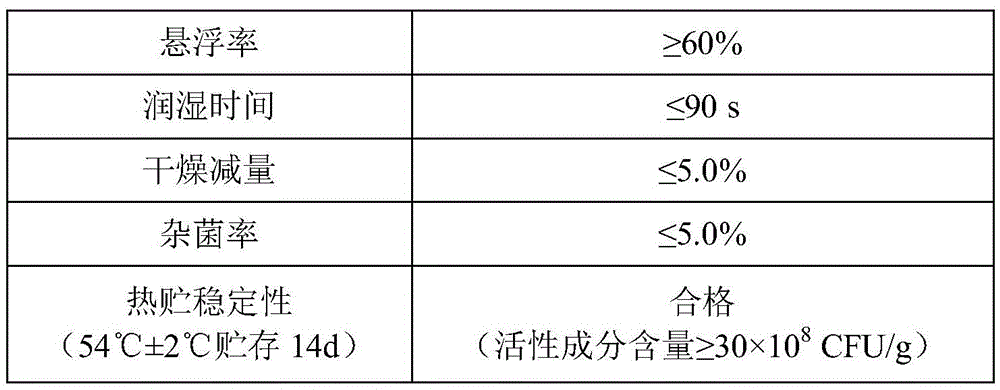

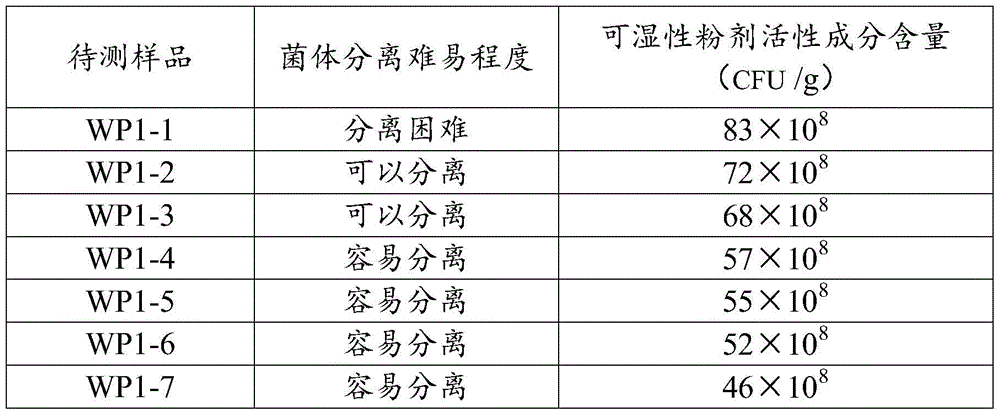

Bacillus methylotrophicus wettable powder and preparation method and application thereof

ActiveCN104222076AGuaranteed control effectQuality improvementBiocideFungicidesSide effectPesticide residue

The invention discloses bacillus methylotrophicus wettable powder which comprises 100 parts by mass of bacillus methylotrophicus active components, 4-10 parts by mass of a wetting agent and 4-10 parts by mass of a dispersing agent. A method for preparing the bacillus methylotrophicus wettable powder comprises the following steps: weighing the bacillus methylotrophicus active ingredients, the wetting agent and the dispersing agent according to a ratio, and uniformly mixing; and milling through a jet mill, thereby obtaining the bacillus methylotrophicus wettable powder. The wettable powder is stable in quality and convenient to preserve and use for a long time, has good effects of preventing and treating cucumber gray mold and apple rot, solves the problems such as environmental toxic and side effects and pesticide residues brought by chemical agents, has the characteristics of high efficiency, no toxicity, safety and no residue, is a safe, effective, low-residue and environment-friendly microbial pesticide and has wide application prospects in the field of microbial control.

Owner:NORTH CHINA PHARMA GROUP AINO

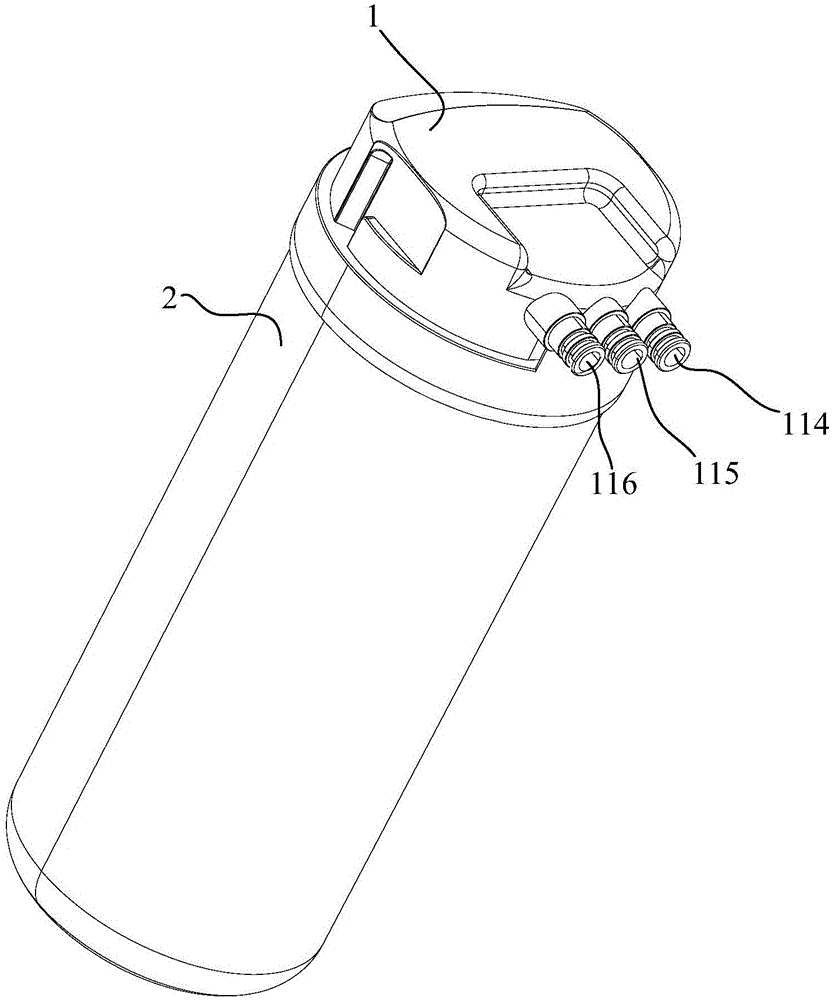

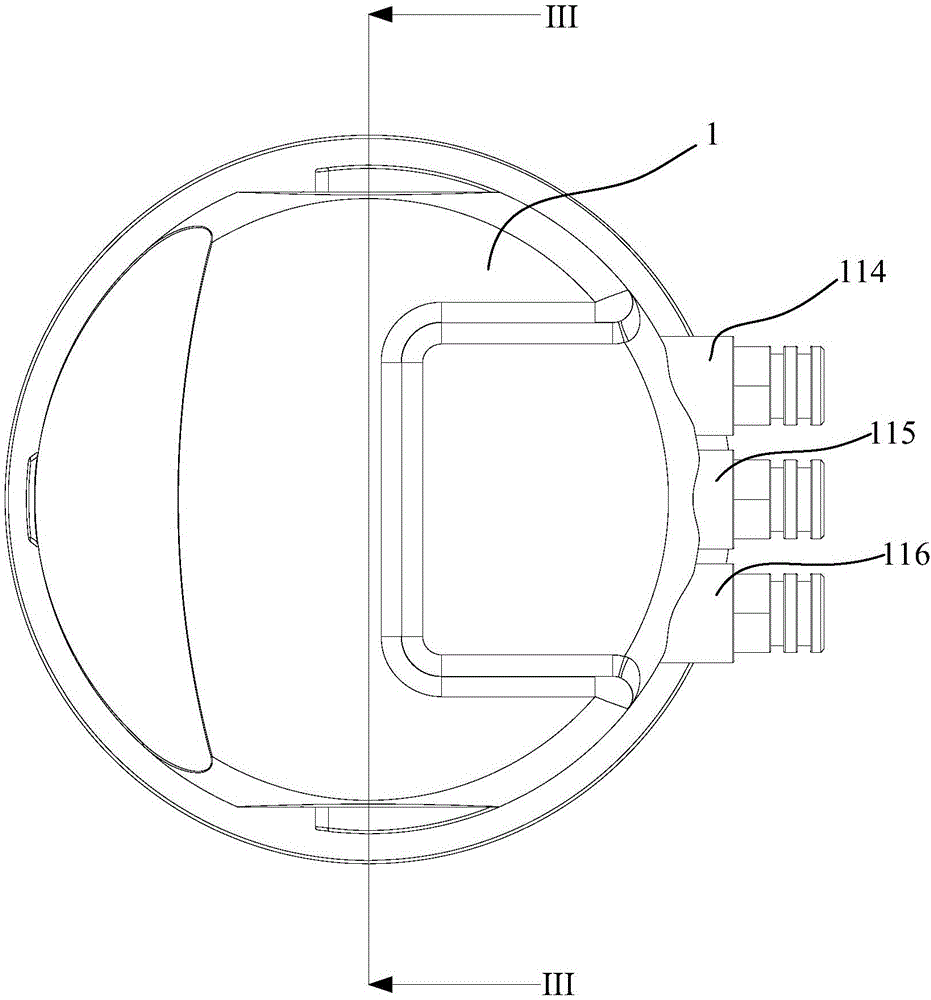

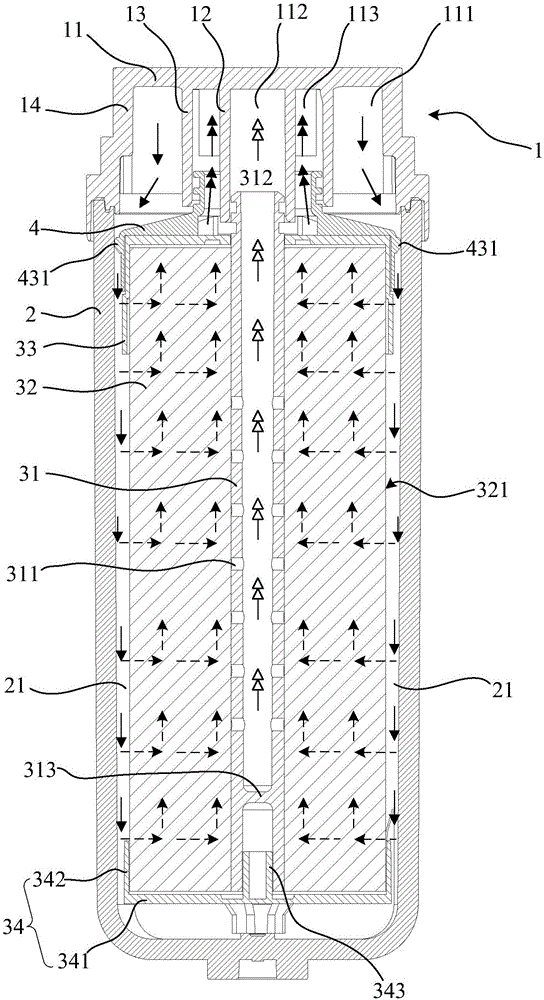

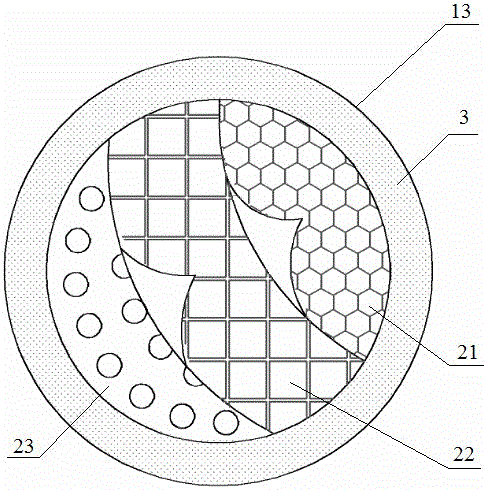

Reverse osmosis membrane assembly, filter element and water purifier

InactiveCN106139904AImprove filtration efficiencyHigh recovery rateMembranesWater/sewage treatment bu osmosis/dialysisWastewaterReverse osmosis

The invention discloses a reverse osmosis membrane assembly, a filter element and a water purifier. The reverse osmosis membrane assembly comprises a central pipe, a reverse osmosis membrane, an upper end cover and a lower end cover, wherein a plurality of water collection holes which are used for clean water to flow in are formed in the central pipe, a pipe orifice which is used for the clean water to flow out is formed in the upper end of the central pipe, and the lower end of the central pipe is closed; the reverse osmosis membrane sleeves the periphery of the central pipe, and the peripheral surface of the reverse osmosis membrane is a raw material infiltration surface which is used for infiltrating raw material; the upper end cover sleeves the upper end of the reverse osmosis membrane, the lower end cover is buckled at the lower end of the reverse osmosis membrane, and both the upper end cover and the lower end cover are matched with the peripheral surface of the reverse osmosis membrane in a sealing manner; and the upper end cover is provided with a through hole matched with the central pipe and a through groove which is disposed on the periphery of the central pipe and used for waste water to flow out. The reverse osmosis membrane is relatively high in filter efficiency and recovery rate.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG

Production method for extracting tryptophan from fermentation liquor by one-step refining

ActiveCN101863822ANot prone to membrane foulingShort filter timeOrganic chemistryFood processingUltrafiltrationSolvent

The invention discloses a production method for extracting tryptophan from fermentation liquor by one-step refining, which comprises the pretreatment of the fermentation liquor. In the method, mycoprotein is filtered off by using a ceramic microfiltration membrane, is decolorized by using an ultrafiltration membrane and is desalted and concentrated by using a nanofiltration membrane; the nanofiltration membrane concentrated liquor is directly decolorized by using activated carbon, the decolorized liquor is subjected to isoelectric point crystallization at a low temperature, and a qualified competitive product is obtained by rinsing with ice water during centrifugal separation; the crystallization mother liquor returns to the nanofiltration membrane for circulation; protein feed with high additional value is prepared by mixing, drying and crushing the ultrafiltration strong liquor and mycoprotein; and nanofiltration strong brine can be used as a culture medium for later use or sold serving as a base fertilizer. The method has the advantages of avoiding adding an organic solvent and an inorganic solvent in the preparation process of a crude product and a fine product, saving the solvent recovery cost, solving the problems of sewage treatment and environmental pollution, along with high utilization rate of the mother liquor, high product quality, and more contribution to industrial production, wherein the total extraction yield of L-tryptophan is 83.5 percent in a 500-ton production line.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

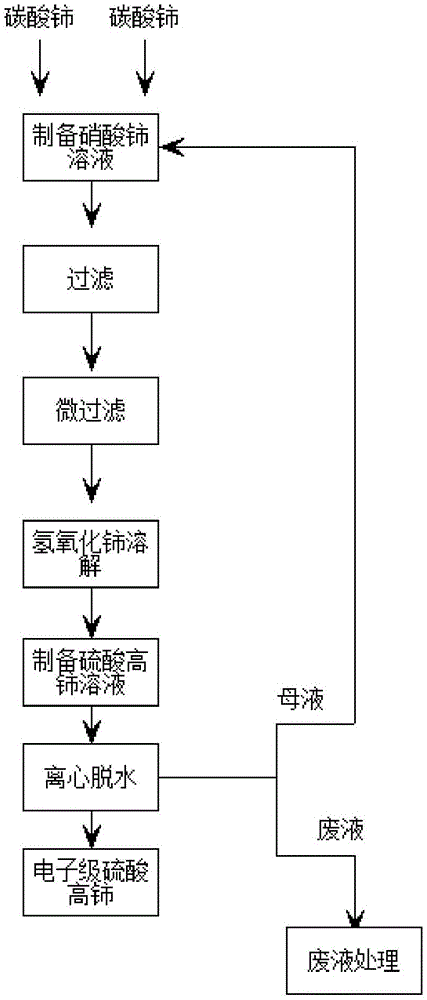

Preparation method of electronic grade ceric sulfate

ActiveCN105016371AProduct oxidation rate is highHigh product purityRare earth metal compoundsMicropore FilterSal ammoniac

The invention relates to a preparation method of electronic grade ceric sulfate, which comprises the following steps: 1)adding a dilute nitric acid solution in cerous carbonate to obtain a cerium nitrate solution; 2)dropping an ammonium carbonate aqueous solution in the solution, heating until the mass concentration of the cerium nitrate solution is 220-240g / L; 3)filtering; 4)adding a filtrate in a micropore filter for filtering; 5)adding hydrogen peroxide with volume concentration being 30% in the filtrate, dropping aqueous ammonia in the filtrate, controlling the reaction temperature being 30-35 DEG C; 6)performing plate filtration to obtain the sediment; 7)adding a cerium hydroxide filter cake in excessive concentrated sulfuric acid; 8)adding concentrated sulfuric acid in the solution, concentrating for reacting for 5 hours, filtering to obtain the ceric sulfate crystal; and 9)dehydrating the ceric sulfate crystal to obtain the electronic grade ceric sulfate. The preparation method has the following beneficial effect that 1)filtering time is short, yield is high; 2)product oxidation rate is high; 3)products purity is high; 4)products fineness is high; and 5)products non rare earth metal impurity is low.

Owner:乐山沃耐稀电子材料有限公司

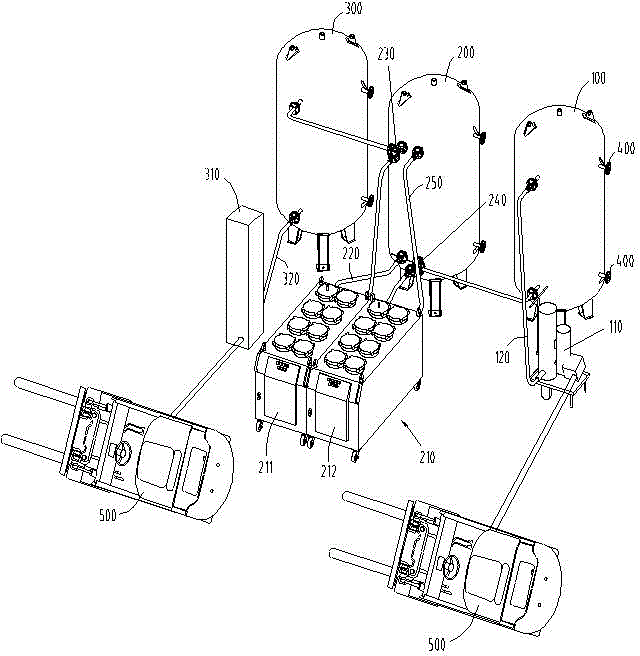

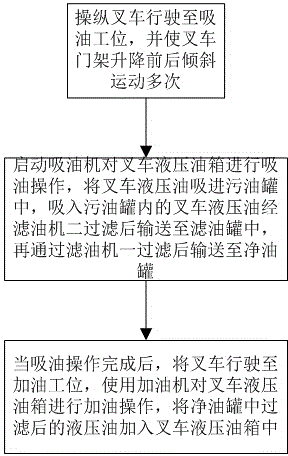

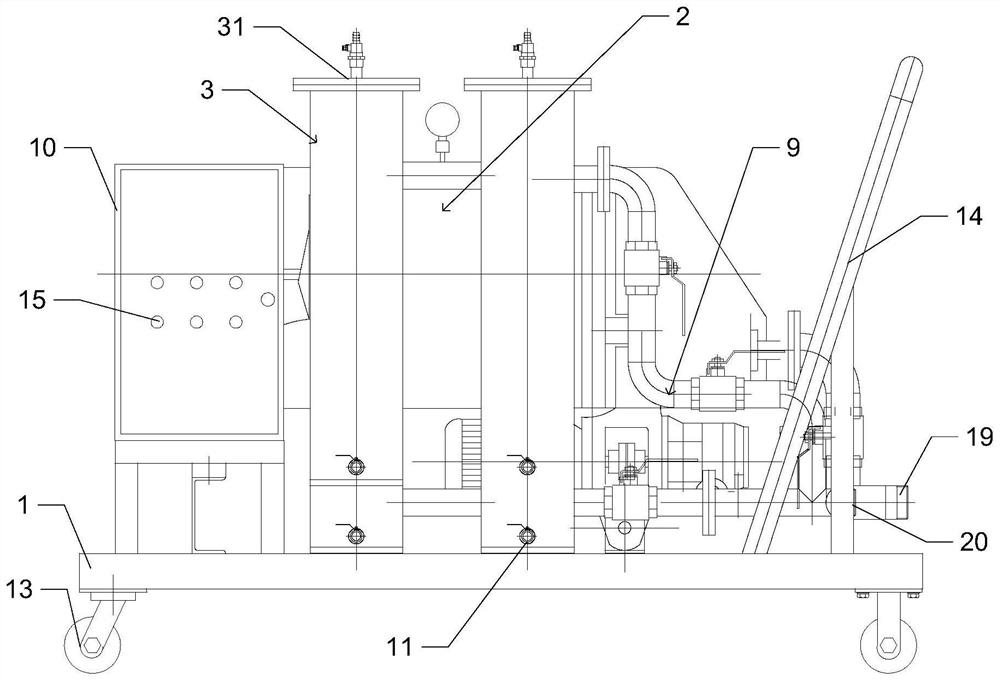

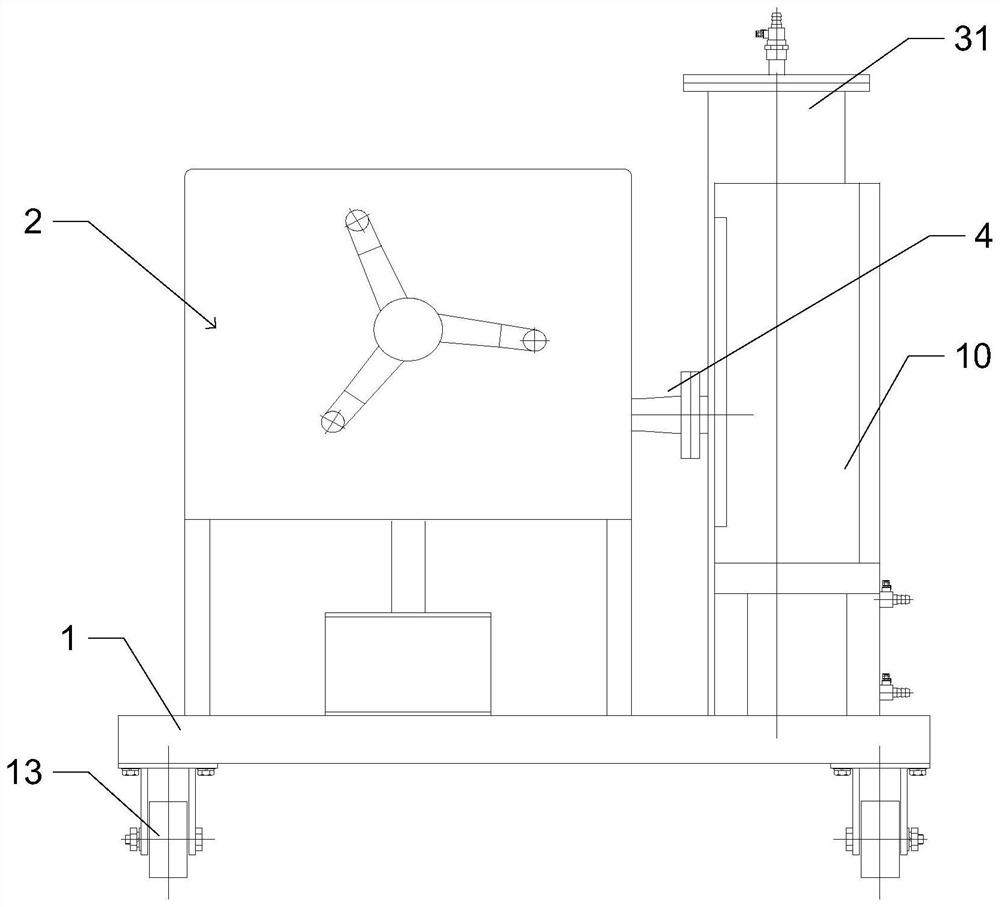

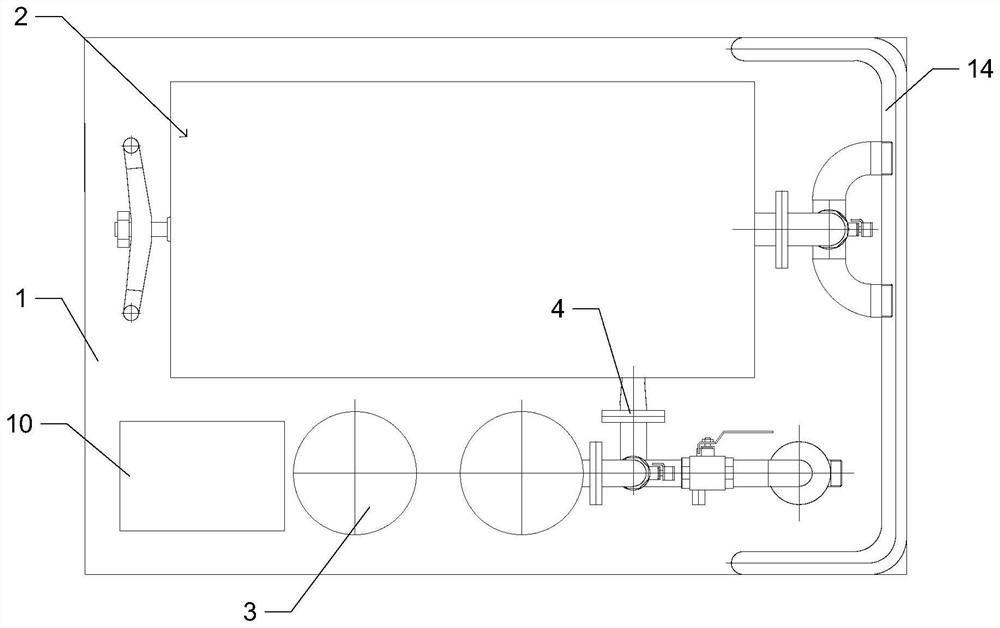

Device and method for filtering hydraulic oil of forklift

InactiveCN104100604AShort filter timeGood effectLifting devicesFluid-pressure actuator componentsProcess engineeringOil filter

The invention provides a device for filtering hydraulic oil of a forklift. The device comprises a slop oil tank, an oil filtering tank, an oil purifying tank, an oil sucking machine, an oil feeding machine and an oil filtering machine unit. The invention also provides a method for filtering the hydraulic oil of the forklift by using the device. The method comprises the following steps of controlling the forklift to run to an oil sucking workstation; enabling a portal of the forklift to ascend, descend and obliquely move in the front-back direction repeatedly; starting the oil sucking machine to suck oil of a hydraulic oil tank of the forklift; sucking the hydraulic oil of the forklift in the slop oil tank; filtering the hydraulic oil of the forklift in the slop oil tank by using a second oil filtering machine and conveying the filtered hydraulic oil to the oil filtering tank; filtering the oil by using a first oil filtering machine and then conveying the oil to the oil purifying tank; running the forklift to an oil feeding workstation after oil suction operation is finished; feeding oil in the hydraulic oil tank of the forklift by using the oil feeding machine; and feeding the filtered hydraulic oil in the oil purifying tank in the hydraulic oil tank of the forklift. The device has the advantages that the filtering time is short, the filtering effect is high, oil suction operation and oil feeding operation can be simultaneously performed on two forklifts, filtering operation can be continuously performed without waiting when the filtering amount is large, and the efficiency is high.

Owner:ANHUI HAOYUN MACHINERY

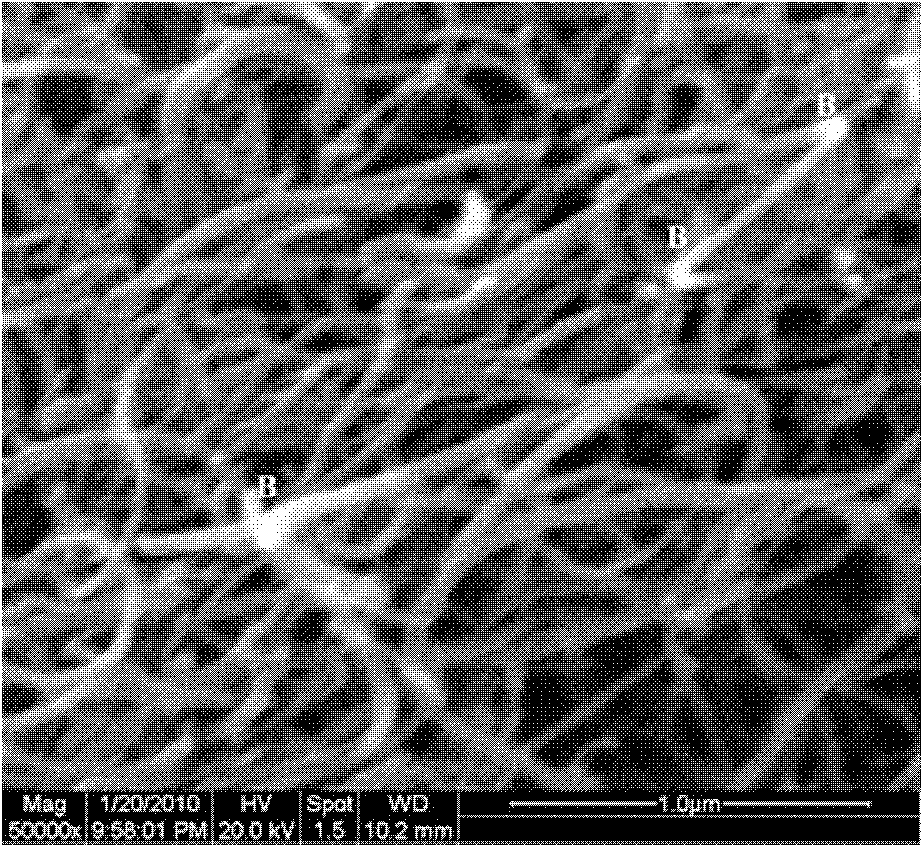

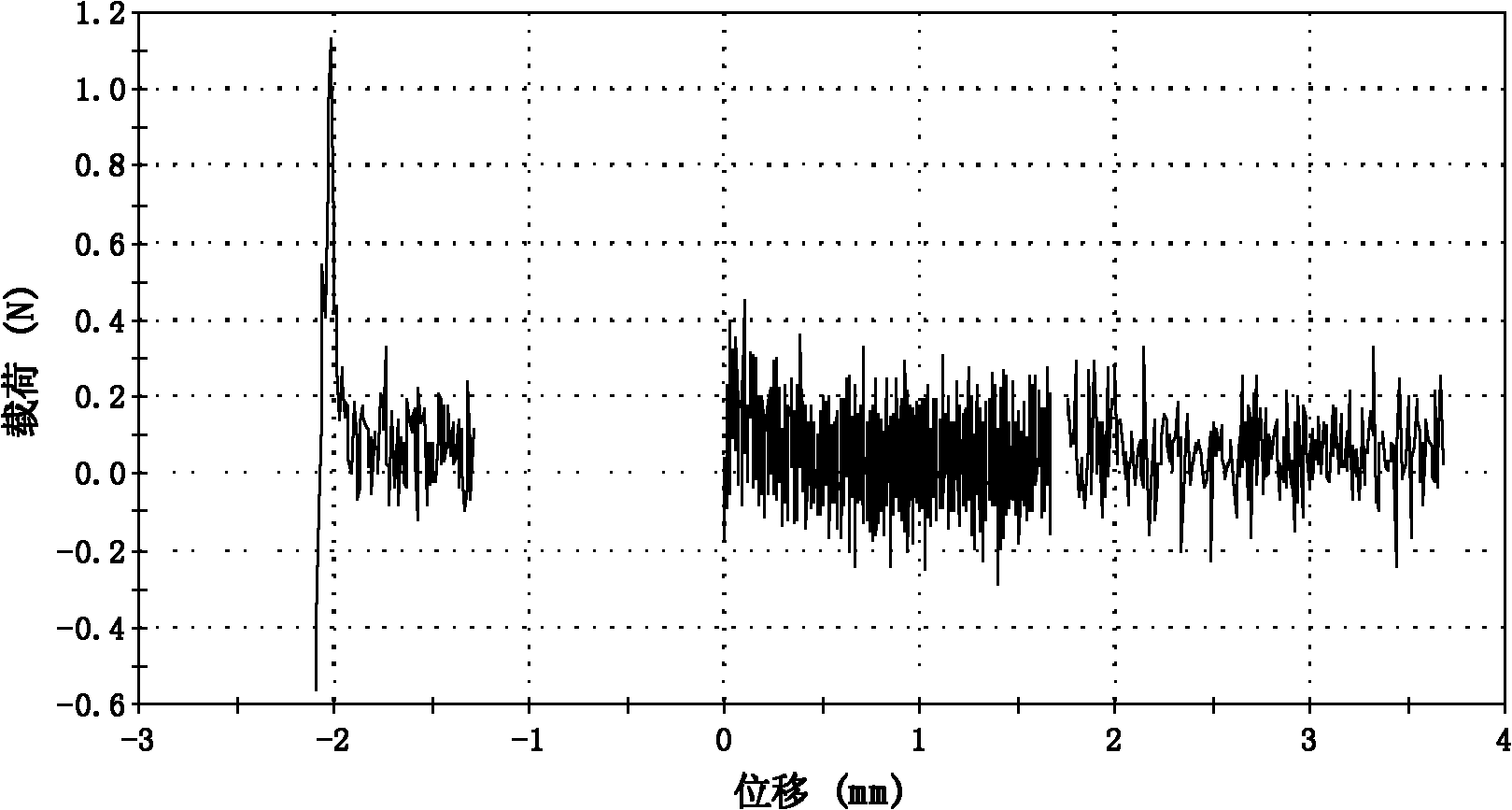

Method for preparing three-dimensional macro carbon nanometer pipe network

InactiveCN101837970AImprove mechanical propertiesImprove electrical performanceNanostructure manufactureFiltrationCarbon nanotube

The invention provides a method for preparing a three-dimensional macro carbon nanometer pipe network. The method comprises the following steps of: preparing a precursor of the carbon nanometer pipe network by purification and filtration treatments; loading a catalyst used for connection; making external carbon atoms form a chemical bond connection on contact points among carbon nanometer pipes at the high temperature and under an inducing action of the catalyst so as to realize the connection among the carbon nanometer pipes in a mode of chemical bonds; and finally obtaining the three-dimensional macro carbon nanometer pipe network with the chemical bond connection. The carbon nanometer pipes of the three-dimensional macro carbon nanometer pipe network are connected by chemical bonds, so that the whole carbon nanometer pipe network has high conductive property and mechanical property.

Owner:SOUTHWEST JIAOTONG UNIV

Press ink recovery device

ActiveCN109677116AImprove filtration efficiencyShort filter timePrinting press partsStationary filtering element filtersFiltrationEngineering

The invention discloses a press ink recovery device comprising a shell. A strainer is fixedly connected to the inner wall of the shell. A support block is fixedly connected to the left side of the topof the shell. A first oil outlet pipe is arranged on the left side of the support block. The right end of the first oil outlet pipe penetrates through the support block and extends to the right sideof the support block. The surface of the first oil outlet pipe is fixedly connected to the inner wall of the support block. The right end of the first oil outlet pipe is sleeved with a telescopic pipe. The right end of the telescopic pipe is connected with a second oil outlet pipe in a sleeving mode. Through mutual matching of a slider, a sliding block, a buffer spring, a rotary motor, a rotary shaft, a reel, a fixed rope, an electric push rod, a brush, a second through groove and a waste box, the effect of high filtration efficiency is achieved, the problem of low filtration efficiency of a press ink recovery device is solved, thus filtration time is short, the filtration effect is good, work efficiency is improved greatly, progress delay of subsequent work is avoided, and great convenience is brought to a user.

Owner:山东诚丰包装股份有限公司

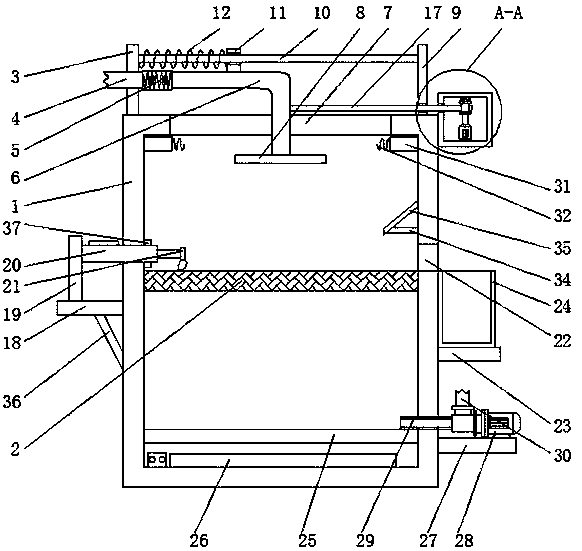

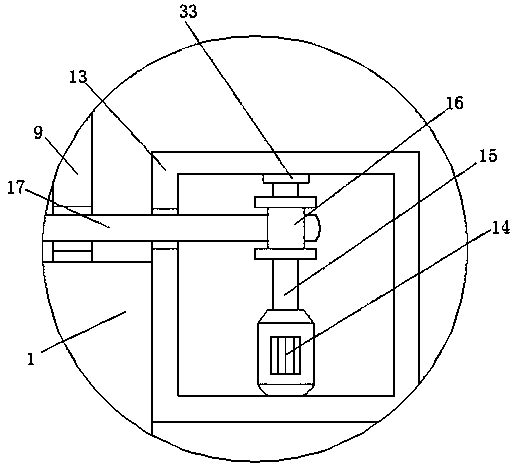

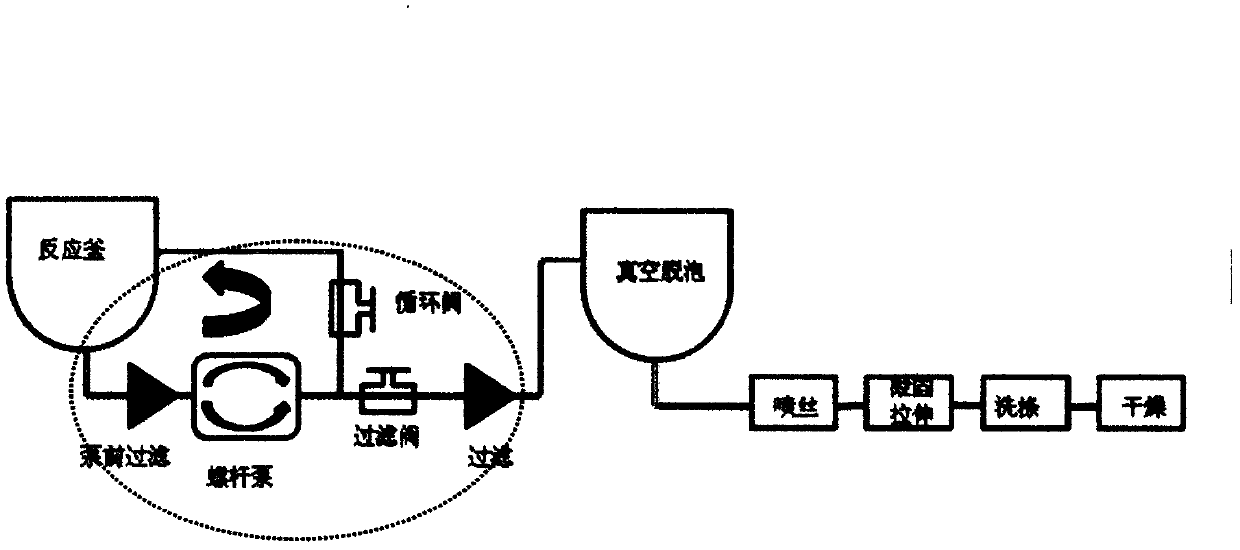

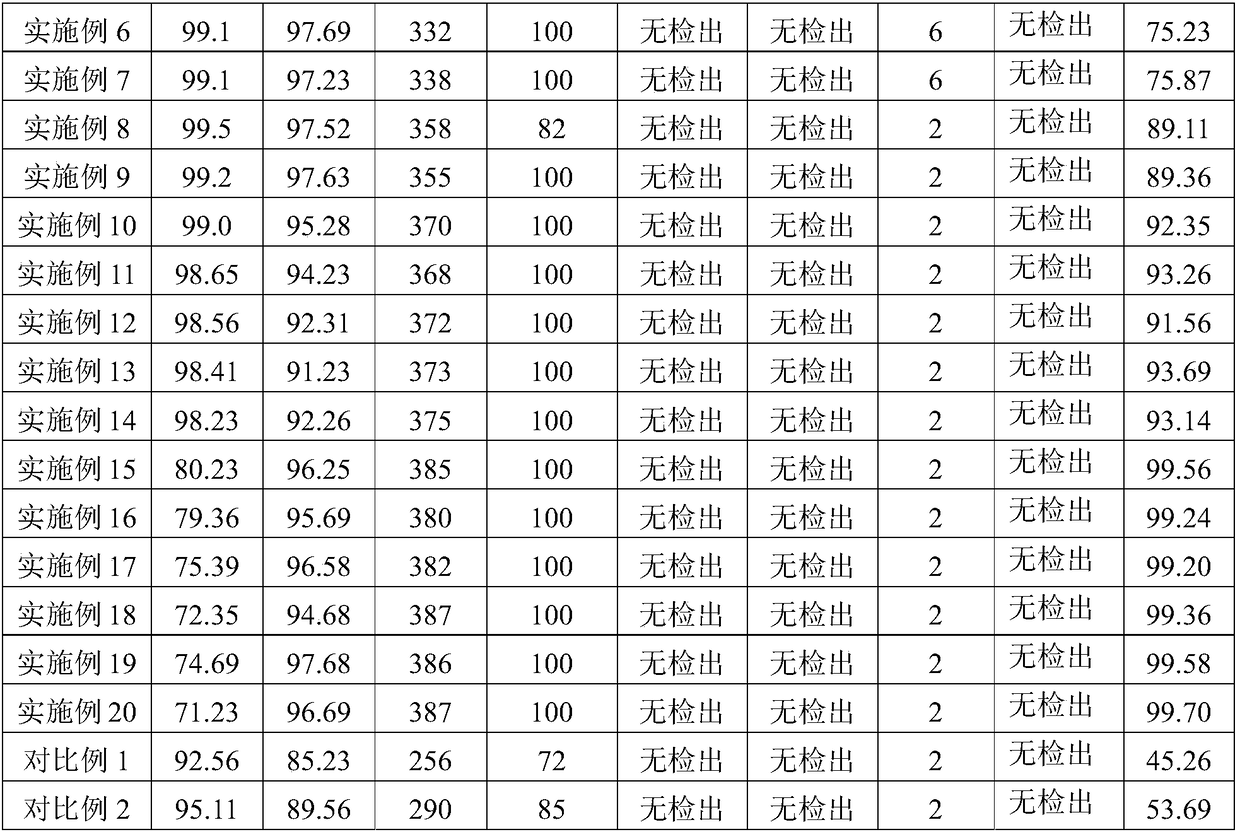

Preparation method of producing high-strength chitosan fiber by use of double-screw pump

ActiveCN102851790AShort dissolution timeShort filter timeFibre chemical featuresSpinning solutions preparationYarnAcetic acid

The invention relates to a preparation method of chitosan fibers, overcomes the shortcomings, such as low solution concentration, long dissolving time, difficult filtering, long defoaming time, instable product quality and low fiber strength, of the chitosan fiber preparation process at present, and adopts 2-5% glacial acetic acid as solvent, where a chitosan tablet raw material is added at a room temperature and stirred for 15-30 min. A double-screw pump is adopted for cyclic delivery for 1 hr, to fully dissolve the preparation, and also used to press-filter the solution and feed it into a vacuum tank for deforming for 2-4 hr to obtain 0.5-30% homogenous-phase transparent chitosan spinning fluid. A spinning machine is adopted for spinning, the yarn extruded by a metering pump enters a condensation bath, and high-strength chitosan fibers are obtained by drawing, water washing, alcohol washing and drying.

Owner:TIANJIN ZHONGSHENG BIO ENG CO LTD

Ceramic filter element, preparation method and application thereof

ActiveCN108947508AHigh hardnessHigh strengthFiltration separationWater qualityUltimate tensile strength

The invention discloses a ceramic filter element, a preparation method and an application thereof. The preparation method comprises the following step: sintering a filter element blank, wherein in thesintering process, the sintering temperature is divided into 3-6 sections. The ceramic filter element has the advantages of high mechanical strength, good filter effect, free of heavy metal pollution, high yield, low cost and short process consumed time, 20-30% of time is shortened compared with that of a conventional process, and the ceramic filter element is suitable for water quality treatment.

Owner:BEYCLEAN ENVIRONMENTAL PROTECTION TECH

Removal method for titanate from esterified product

InactiveCN1283614CPromote hydrolysisPromote complexationOrganic compound preparationCarboxylic acid esters preparationSodium bicarbonateFiltration

The invention provides a method for removing the titanate catalyst in the esterification product, by adding sodium percarbonate or a mixture of sodium carbonate and hydrogen peroxide or a mixture of sodium bicarbonate and hydrogen peroxide to accelerate the hydrolysis of titanate, Complexation, the formed flocculent precipitate can be removed by normal pressure filtration, the filtration time is short, and the final esterification product obtained has no mechanical impurities. The problem that the titanate catalyst remains in the esterification product and the separation is difficult is solved, and the method improves the production process of the titanate catalyzed esterification, and can shorten the production cycle.

Owner:PETROCHINA CO LTD

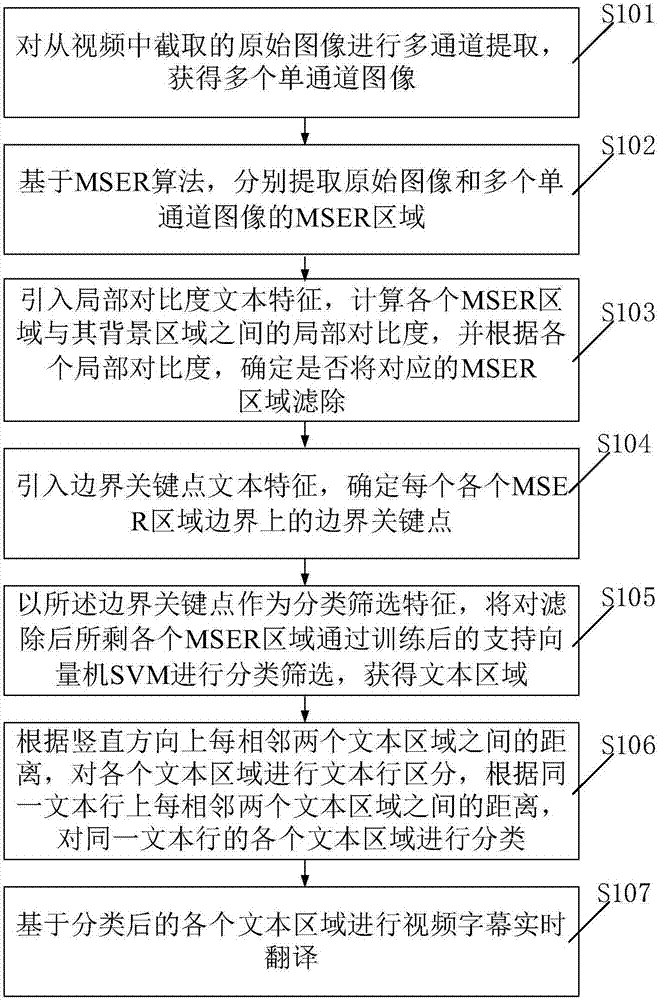

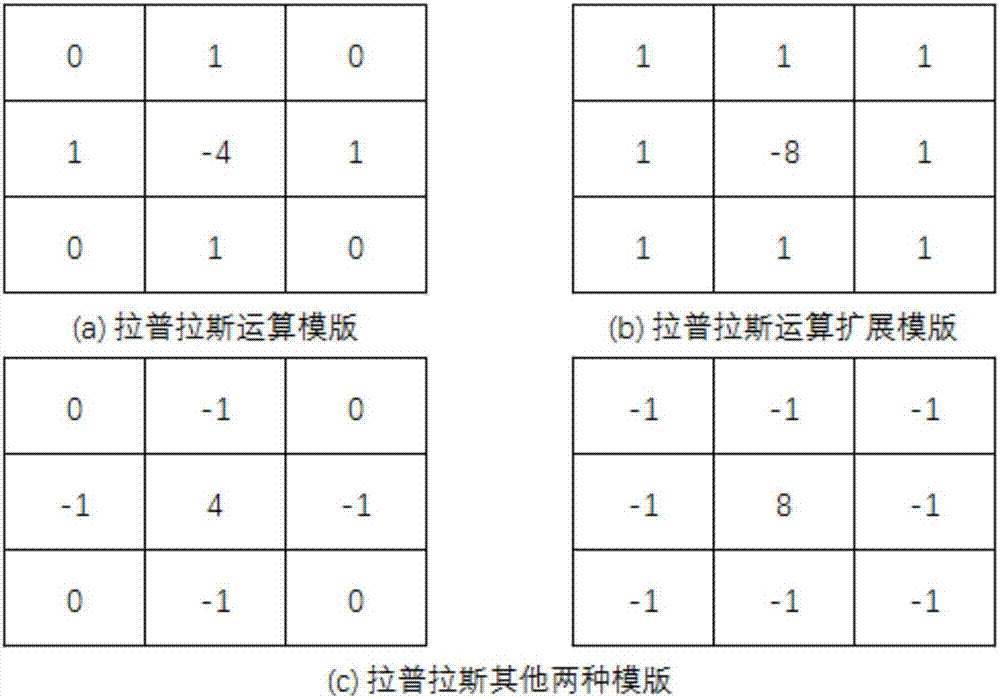

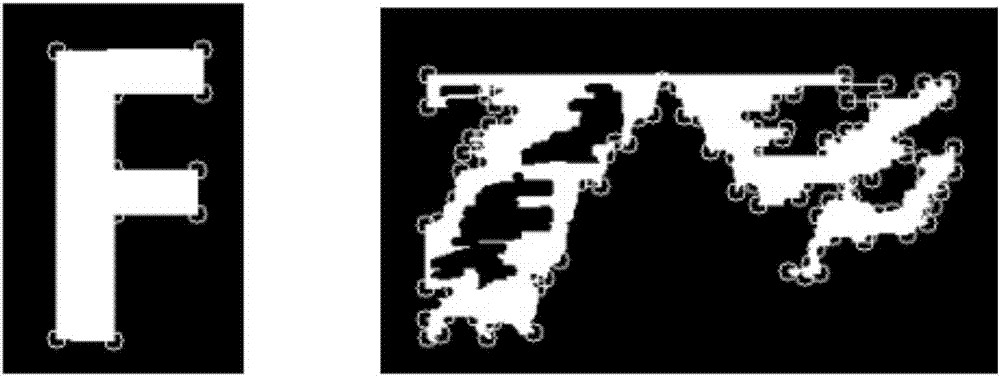

Real-time translation method of video captions

InactiveCN107145888AImprove accuracyIncreased complexityNatural language translationSpecial data processing applicationsPattern recognitionImage capture

The present invention provides a real-time translation method of video captions. The method comprises: performing multi-channel extraction of original images captured in video, and obtaining a plurality of single-channel images; based on the MSER algorithm, extracting MSER areas of the original images and the single-channel images; calculating the local contrast between each MSER area and a background area, determining whether the corresponding MSER areas are filtered or not according to each local contrast; determining the boundary key points of each MSER area; taking the boundary key points as classification screening characteristics, performing classification screening of the each residual MSER area after filtering through a trained SVM, and obtaining a test area; according to a distance between each two adjacent test areas on the vertical direction, performing test distinguishing of each test area, and according to a distance between each two adjacent test areas on the same test line, performing classification of each test area of the same test line; and performing real-time translation of video captions based on each test area after classification.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

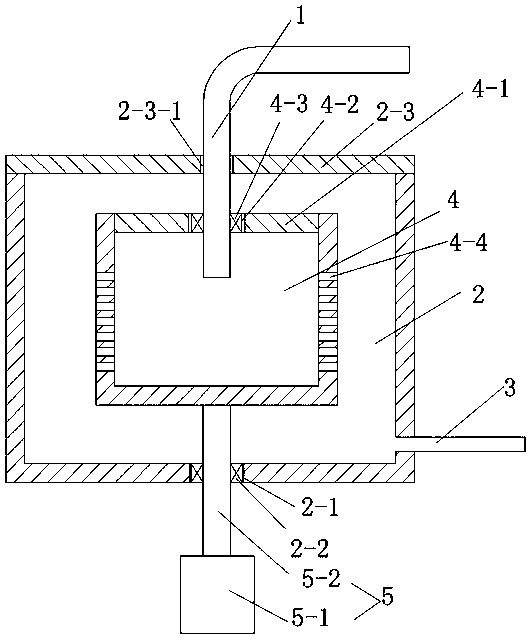

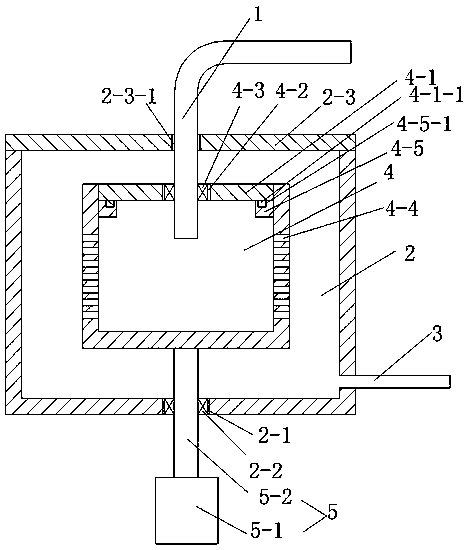

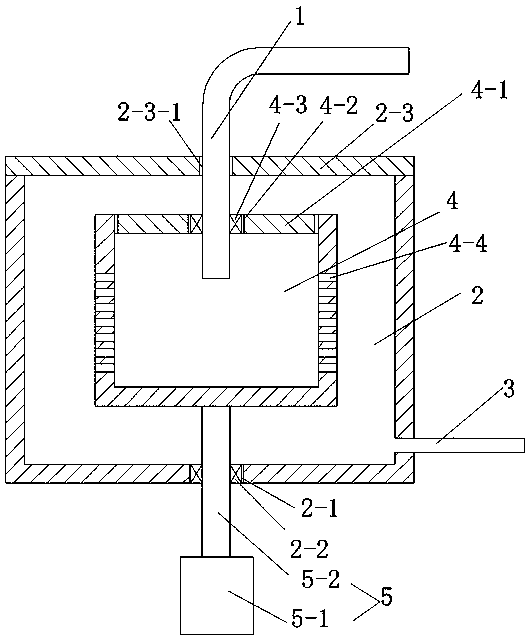

Wastewater centrifugal filtering device for water jet loom

The invention relates to a wastewater centrifugal filtering device for a water jet loom. The wastewater centrifugal filtering device comprises a water intake pipe, a filtering box and a water drain pipe, wherein the water drain pipe is connected with the filtering box; a filtering cylinder and a driving device are arranged in the filtering box, and the driving device is used for driving the filtering cylinder to rotate; the filtering cylinder is of a cylindrical structure of which the upper end is provided with an opening; a cover plate is arranged at the opening; the cover plate is provided with a water inlet and a bearing block, and the bearing block is connected with the water inlet; the water intake pipe penetrates through the bearing block and enters the filtering cylinder; a circularhole is formed in the side wall of the filtering cylinder, and is used for allowing a water body to penetrate through. The wastewater centrifugal filtering device has the advantages that by arrangingthe filtering cylinder with the circular hole and the driving device for driving the filtering cylinder to rotate, the wastewater of the water jet loom is sent into the filtering cylinder, and is directly subjected to centrifugal filtering; compared with other filtering devices for treating the wastewater by multiple filtering layers, the filtering time is shorter, the working efficiency is higher, the arrangement of multiple filtering materials is not needed, and the production cost is lower.

Owner:陈启发

A methylotrophic bacillus wettable powder and its preparation method and application

ActiveCN104222076BGuaranteed control effectQuality improvementBiocideFungicidesPesticide residueRoot rot

The invention discloses a methylotrophic bacillus wettable powder, which comprises 100 parts by mass of the original drug of the methylotrophic bacillus, 4-10 parts by mass of a wetting agent and 4-10 parts by mass of a dispersant; The preparation method of methylotrophic bacillus is as follows: take the original drug of methylotrophic bacillus, wetting agent and dispersant in proportion, mix uniformly; bacillus wettable powder. The wettable powder has stable quality, is convenient for long-term storage and use, has a strong control effect on cucumber gray mold and apple rot, overcomes the environmental side effects and pesticide residue problems caused by chemical agents, and is highly efficient and non-toxic. , safety and residue-free characteristics, is a safe, effective, low-residue environment-friendly green microbial pesticide, and has broad application prospects in the field of microbial control.

Owner:NORTH CHINA PHARMA GROUP AINO

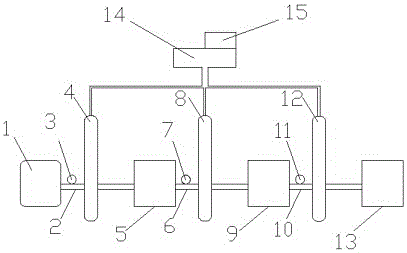

Multilayer membrane filtration system of fruit vinegar

InactiveCN106422786AShorten the production cycleShort filter timeSemi-permeable membranesMicroorganismFiber

The invention discloses a multilayer membrane filtration system of fruit vinegar. The multilayer membrane filtration system comprises a fruit vinegar storage tank used for storing unfiltered fruit vinegar, wherein the fruit vinegar in the fruit vinegar storage tank is transported by a No. 1 pipeline to No. 1 membrane filtration equipment for filtration under the action of a No. 1 pressure pump, the filtered fruit vinegar is transported to a No. 1 filtration tank, the fruit vinegar in the No. 1 filtration tank is transported by a No. 2 pipeline to No. 2 membrane filtration equipment for filtration under the action of a No. 2 pressure pump, the filtered fruit vinegar is transported to a No. 2 filtration tank, the fruit vinegar in the No. 2 filtration tank is transported by a No. 3 pipeline to No. 3 membrane filtration equipment for filtration under the action of a No. 3 pressure pump, the filtered fruit vinegar is transported to a No. 3 filtration tank, the No. 1 pressure pump, the No. 2 pressure pump and the No. 3 pressure pump are connected with a controller, and the controller is connected with a washing device in a control manner. The multilayer membrane filtration system of the fruit vinegar disclosed by the invention removes macromolecular proteins, colloids, fibers, microorganisms and the like in the fruit vinegar at one time, and the technical requirements can be achieved by one-time filtration, thereby shortening the production cycle.

Owner:HEFEI XINDA MEMBRANE TECH

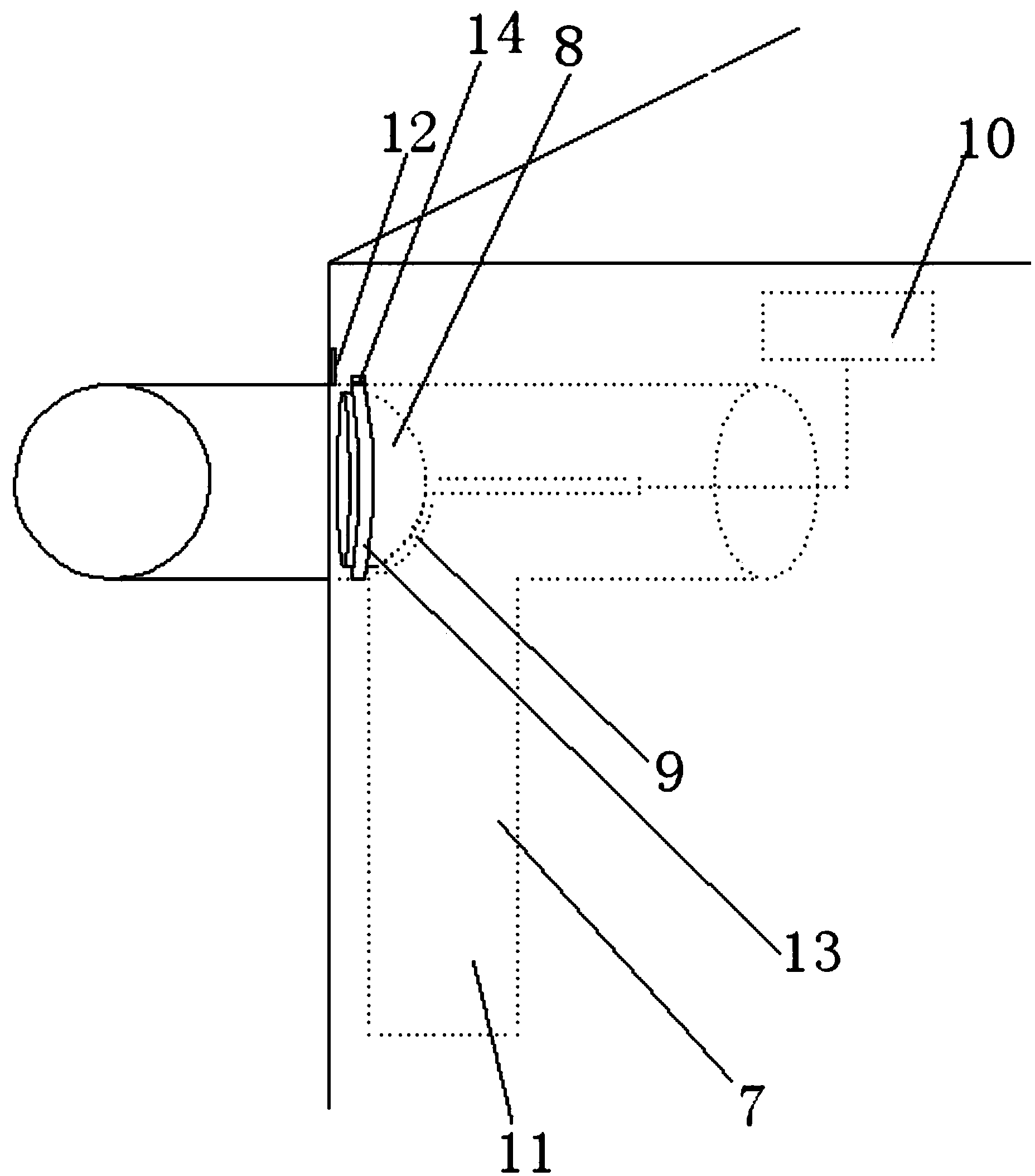

Magnetic filter device for crab shell enzymolytic tank

InactiveCN103931734ARealize self-cleaning functionImprove filtering effectShellfish processingStationary filtering element filtersMagnetic tension forceFilter effect

The invention discloses a magnetic filter device for a crab shell enzymolytic tank. The filter device (7) is characterized by comprising a filter screen (8), a scraper (9), a motor (10), an impurity screen (11), a baffle (12), a magnetic ring (13) and a magnetic rotor (14), wherein the baffle (12) is arranged in front of the filter screen (8) and fixedly connected with the outer wall of a water outlet pipe (6); the magnetic ring (13) externally sleeves the end opening of the filter screen, and is movably connected with the inner wall of the water outlet pipe (6); the magnetic rotor (14) is arranged on the outer wall of the water outlet pipe (6). The magnetic force action of a magnetic material is adopted for the magnetic filter device for a crab shell enzymolytic tank to start a self-cleaning device, and the self-cleaning device has a self-cleaning function, is convenient to operate and good in filter effect; and the filter screen need not to be changed.

Owner:DONGXING XINYU IND

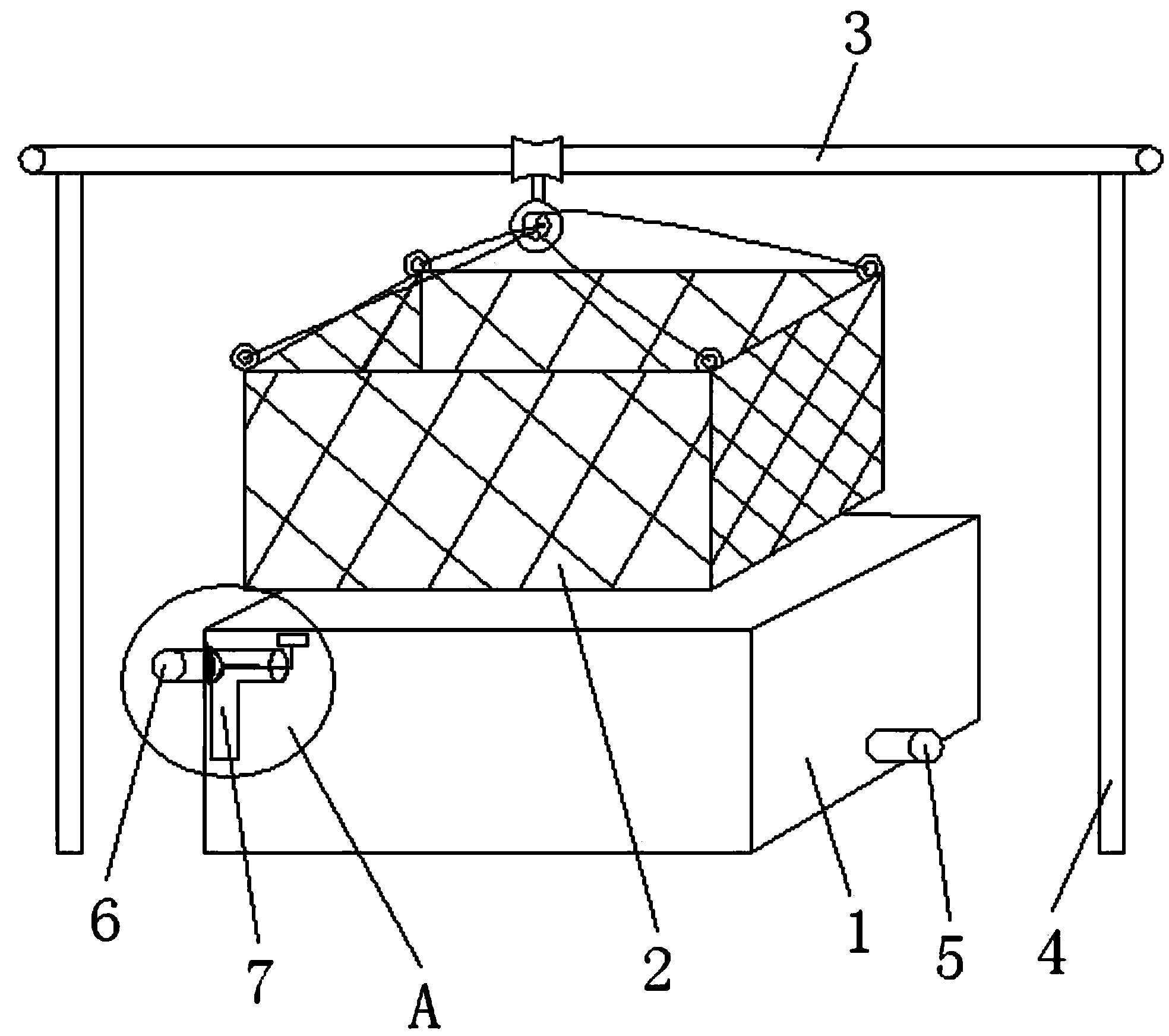

Automatic nano material filtering machine and use method thereof

InactiveCN103272419AImplement automatic filteringReduce labor intensityStationary filtering element filtersAutomatic controlFiltration

The invention particularly discloses an automatic nano material filtering machine and a use method thereof. The automatic nano material filtering machine comprises a funnel, wherein two sides of the funnel are connected with symmetric lifting devices through funnel support shafts, an ultrasonic cleaning machine is arranged below the funnel, and the bottom of the funnel is connected with a vacuum pump. The automatic nano material filtering machine also comprises a cleaning solution pump, wherein the cleaning solution pump is connected with a cleaning solution barrel through a flexible pipe, the cleaning solution barrel is connected with a nozzle device, and the ultrasonic cleaning machine, the cleaning solution pump and the vacuum pump are connected with a control host through a control circuit board. According to the automatic nano material filtering device, the automatic control of the whole filtering process can be realized, and thus errors possibly caused by the manual operation are greatly reduced, and the production safety is improved; according to the automatic nano material filtering device, the large-capacity material filtration can be realized, the filtering time is short and the production efficiency is high; and by adopting the cleaning solution flow control and the rapid nozzle movement, a filter net can be efficiently cleaned, the consumption of the cleaning solution can be reduced, and the production cost is saved.

Owner:SHANDONG UNIV

New filter, filter unit, treatment apparatus, method and use

PendingUS20220298712A1Improve filtration efficiencyShort filter timeOther washing machinesSeparation devicesFiberMechanical engineering

Owner:XEROS LTD

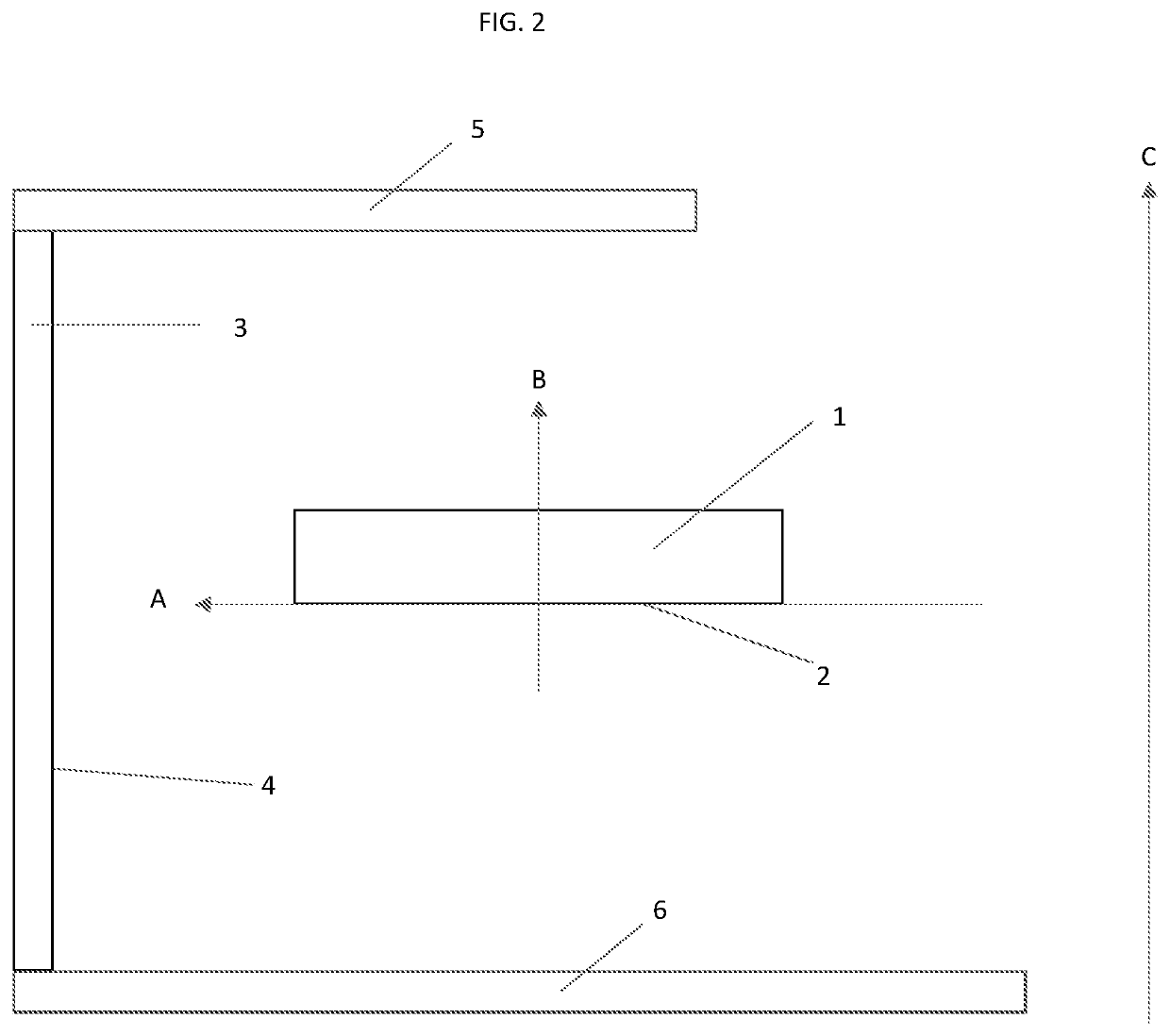

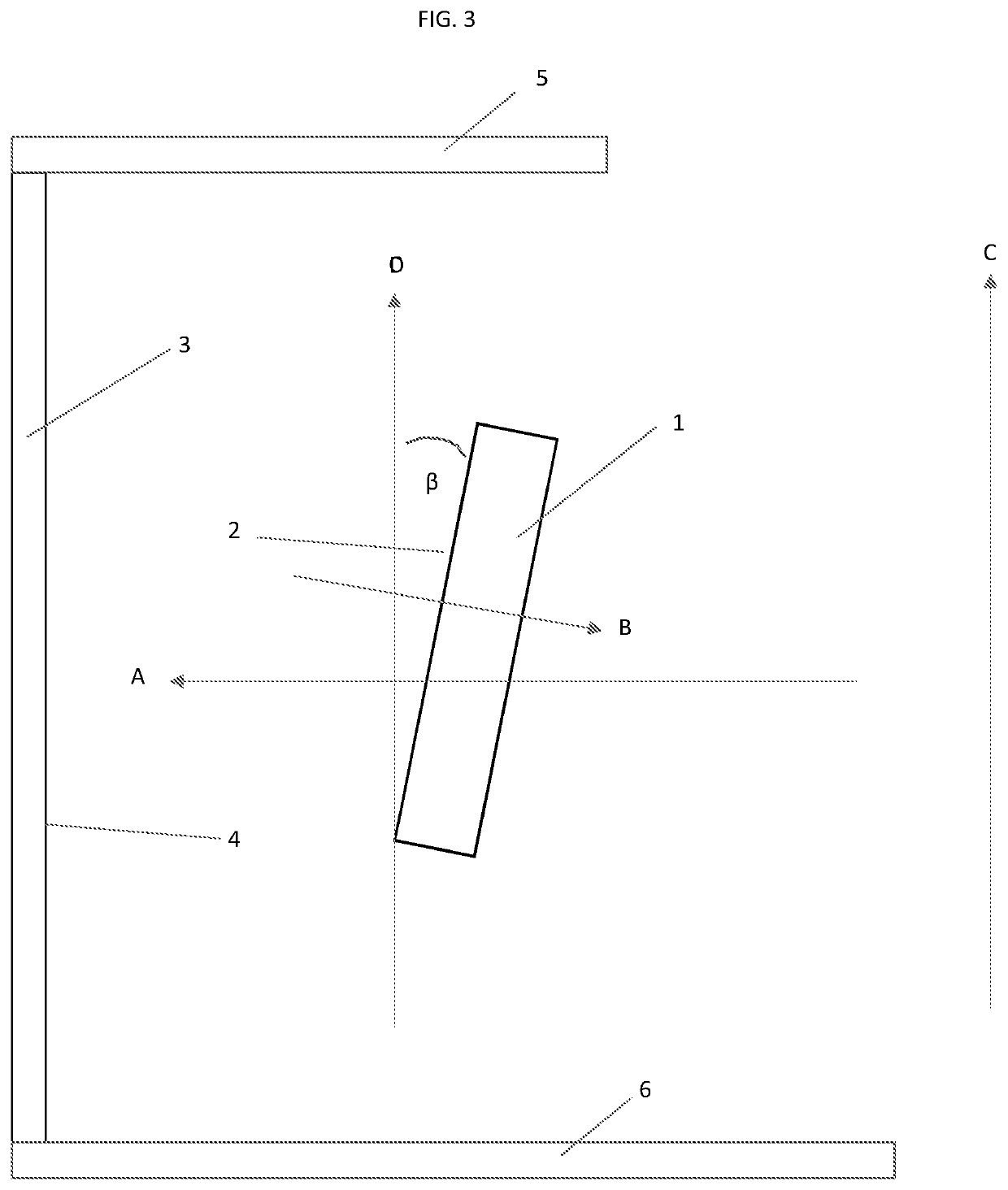

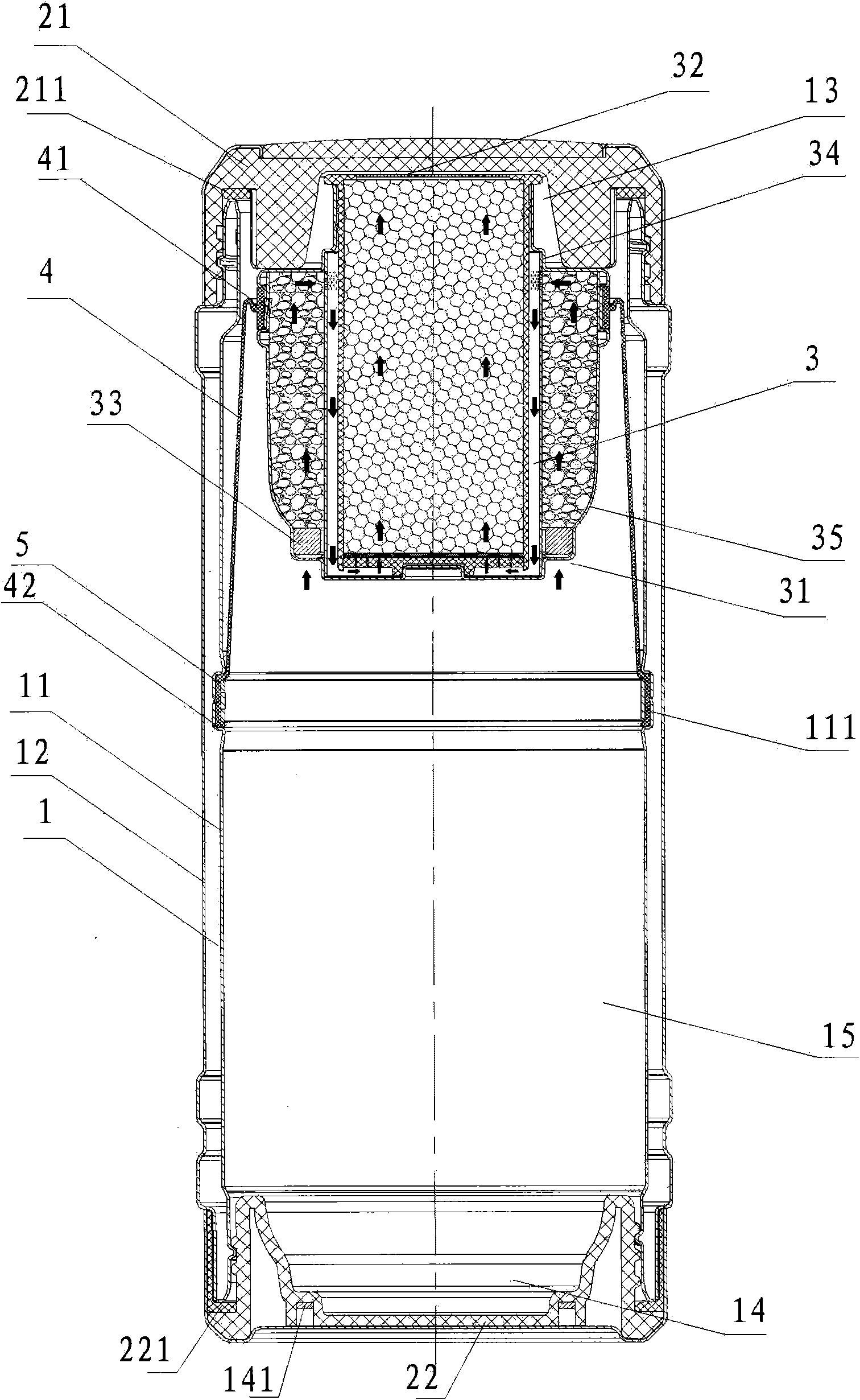

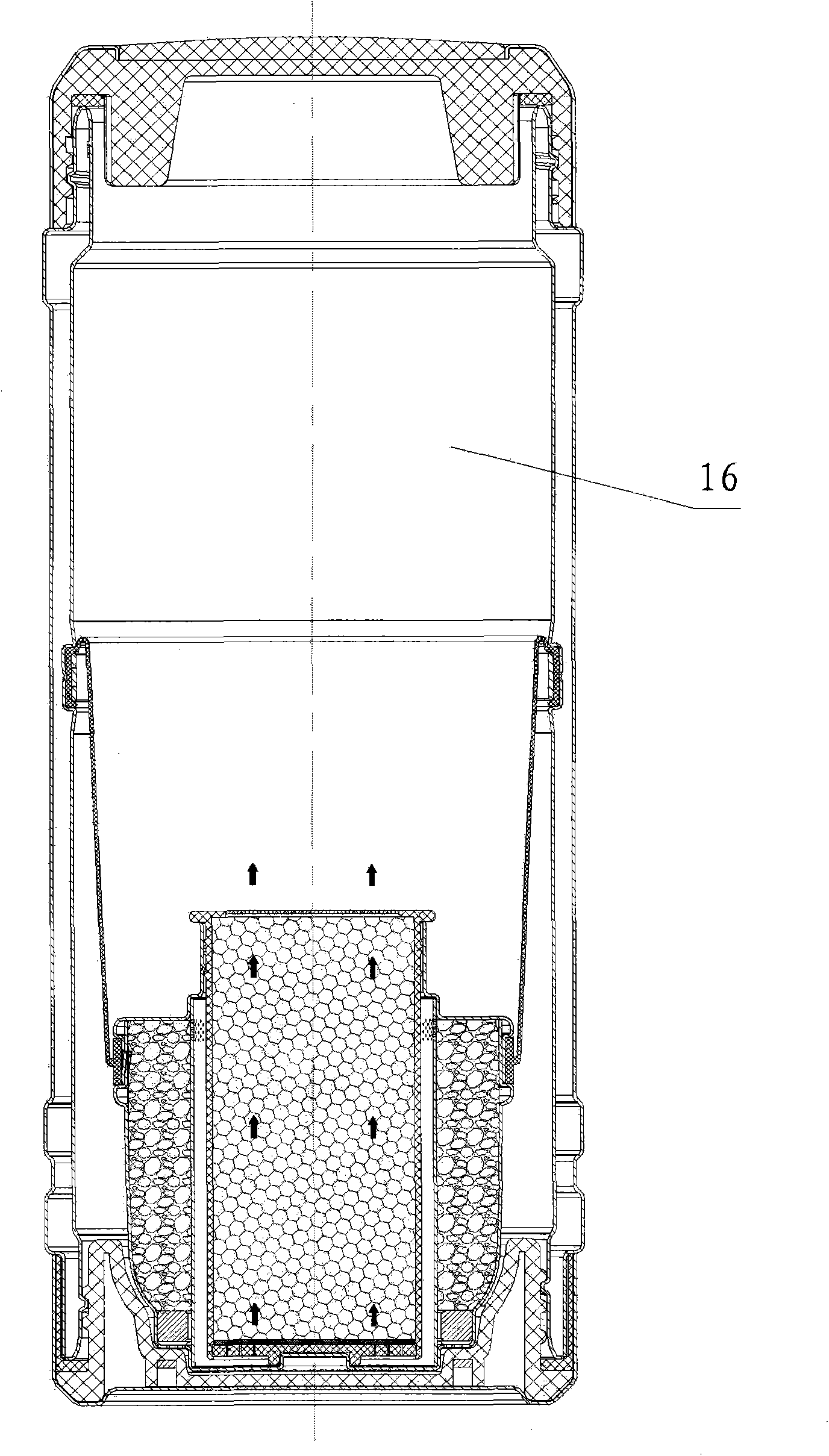

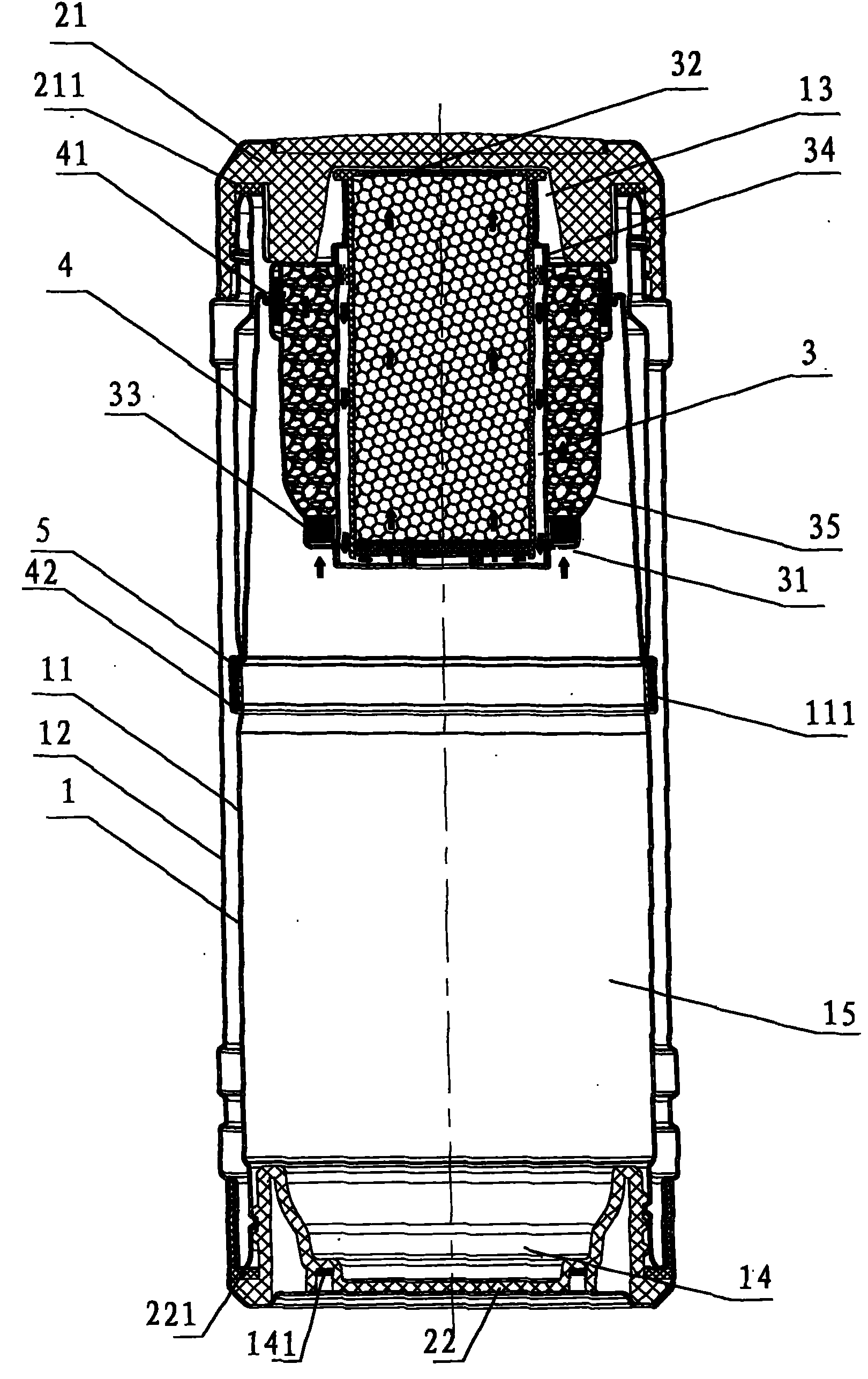

Inherent filtering water glass

InactiveCN101912223AEasy to disassemble and washImplement deep filteringDrinking vesselsWater filterFiltration

The invention relates to an inherent filtering water glass and mainly relates to water filtering equipment applying external force, in particular to a filtering water glass. The filtering water glass comprises a glass body (1), a glass body inner wall (11) and a glass body outer wall (12), wherein the glass body (1) is provided with two glass rims (13) and (14); the two glass rims (13) and (14) are provided with an sealing upper cover (21) and a sealing lower cover (22) respectively; a filter (3) is arranged in the glass body (1); a seal cup (4) is arranged in the glass body (1); the head end (41) of the seal cup (4) is fixedly connected with the filter (3) in a sealing way, so the water inlet (3) and the water outlet (32) of the filter (3) are divided into two areas; and the tail end (42) of the seal cup (4) is fixedly connected with the middle part of the glass body inner wall (11) in a sealing way. The filtering water glass with the structure realizes water filtration by using the weight of the filter, can perform deep filtration by using various filtering materials, and shortens the filtration time of water.

Owner:孙银焕

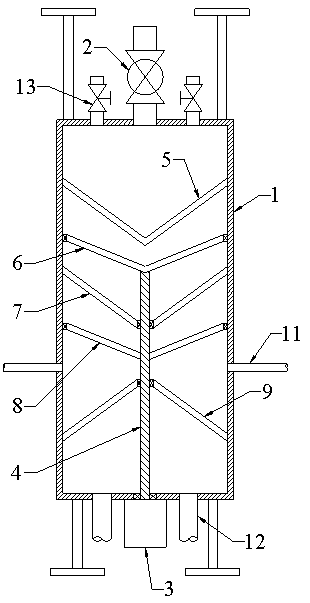

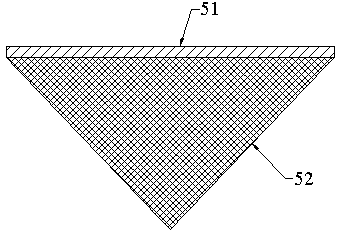

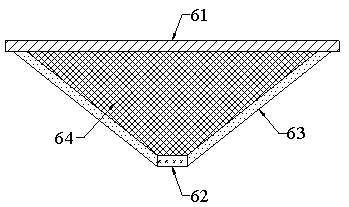

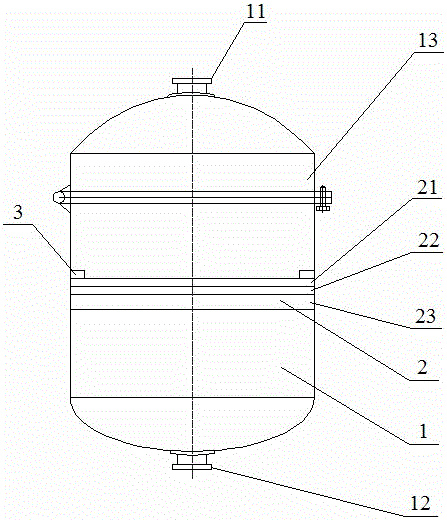

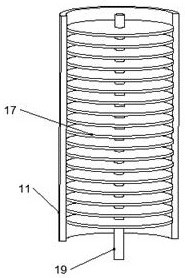

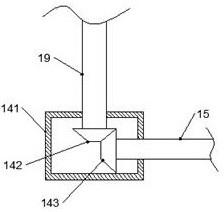

Transformer oil-immersing and filtering device

ActiveCN108114525AShort filter timeImprove filtration efficiencyFiltration circuitsTransformer oilCompressed air

The invention relates to a transformer oil-immersing and filtering device. The transformer oil-immersing and filtering device comprises a vertical cylinder, a boosting pump, a motor and a rotating shaft; an inverted-cone first filter, an inverted-cone second filter, an inverted-cone third filter, an inverted-cone fourth filter and an inverted-cone fifth filter are arranged in the vertical cylindersequentially from top to bottom; a compressed air inlet pipe communicated with a gas inlet is arranged on the outer side of the vertical cylinder; a plurality of discharging ports are formed at the bottom of the vertical cylinder; and discharging pipes communicated with the discharging ports are arranged below the vertical cylinder. The transformer oil-immersing and filtering device is short in filtering time, high in filtering efficiency, good in filtering effect and convenient in washing and cleaning operation, does not need to change the first filter, the second filter, the third filter, the fourth filter and the fifth filter frequently, and has good implementation effect.

Owner:TONGLING RIKE ELECTRONICS

Novel technique for extracting L-tryptophan from fermentation broth

ActiveCN101812009BSolving Recycling ProblemsHigh extraction yieldOrganic chemistryAnimal feeding stuffMycoproteinUltrafiltration

The invention discloses a novel technique for extracting L-tryptophan from fermentation broth, which includes the following steps that: fermentation broth is pretreated, and the treated liquid is pumped into a ceramic microfiltration membrane filter, so that tryptophan microfiltrate without mycelium and mycoprotein are obtained; the tryptophan microfiltrate is pumped into an ultrafiltration membrane filter, so that tryptophan ultrafiltrate and concentrated liquid containing pigment and protein are obtained; the tryptophan ultrafiltrate is pumped into a nanofiltration membrane filter, so that concentrated tryptophan liquid and permeate containing salt are obtained; waste filtrate is comprehensively utilized to produce protein feed; industrial ethylic acid is used for promoting low-temperature crystallization, crystallization mother liquid is treated by the ion exchange method and used, and after crystals are centrifugally dehydrated and dried, the L-tryptophan product is obtained. The invention solves the problem on how to recover industrial ethylic acid, and greatly increases the extraction rate of L-tryptophan; and since the filtrate and the mycoprotein are comprehensively utilized, the product profit is maximized. The total extraction rate of L-tryptophan is 85.2 percent, and the refined product meets the standards of Chinese Pharmacopoeia edition 2005.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

Production method for extracting tryptophan from fermentation liquor by one-step refining

ActiveCN101863822BNot easy to cause pollutionPromote crystallizationOrganic chemistryFood processingIce waterMycoprotein

The invention discloses a production method for extracting tryptophan from fermentation liquor by one-step refining, which comprises the pretreatment of the fermentation liquor. In the method, mycoprotein is filtered off by using a ceramic microfiltration membrane, is decolorized by using an ultrafiltration membrane and is desalted and concentrated by using a nanofiltration membrane; the nanofiltration membrane concentrated liquor is directly decolorized by using activated carbon, the decolorized liquor is subjected to isoelectric point crystallization at a low temperature, and a qualified competitive product is obtained by rinsing with ice water during centrifugal separation; the crystallization mother liquor returns to the nanofiltration membrane for circulation; protein feed with high additional value is prepared by mixing, drying and crushing the ultrafiltration strong liquor and mycoprotein; and nanofiltration strong brine can be used as a culture medium for later use or sold serving as a base fertilizer. The method has the advantages of avoiding adding an organic solvent and an inorganic solvent in the preparation process of a crude product and a fine product, saving the solvent recovery cost, solving the problems of sewage treatment and environmental pollution, along with high utilization rate of the mother liquor, high product quality, and more contribution to industrial production, wherein the total extraction yield of L-tryptophan is 83.5 percent in a 500-ton production line.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

Method for directly preparing anhydrous calcium dodecyl benzene sulfonate, and product

PendingCN113480456AEasy to produceLess filter residueOrganic compound preparationSulfonic acids salts preparationPhysical chemistryBenzenesulfonic acid

The invention relates to a method for directly preparing anhydrous calcium dodecyl benzene sulfonate with simple steps, and a product. The method comprises the following steps: step 1, reacting dodecylbenzene sulfonic acid with calcium in a solvent at a preset temperature; step 2, adjusting the pH value to 4-7; step 3, raising the temperature, and removing water; and step 4, filtering to obtain the product. The reacted mother liquor is subjected to vacuum filtration to obtain the clear and transparent product, and the method is simple and convenient in production, less in filter residue, less in pollution, economical and environment-friendly.

Owner:无锡颐景丰科技有限公司

Precise plate type oil filter

The invention is applicable to the technical field of oil filtering equipment, and provides a precise plate type oil filter which is used for filtering oil in an oil tank, and an oil inlet pipe and anoil outlet pipe are arranged on the oil tank. The precise plate type oil filter comprises a rack; a plate frame oil filtering device, wherein an oil inlet in the plate frame oil filtering device is communicated with the oil inlet pipe; a plurality of filters which are communicated with the plate frame oil filtering device through a first pipeline, wherein oil outlets are formed in the tail ends of the plurality of filters, and the oil outlets are communicated with the oil outlet pipe; a protection device which is arranged on the oil outlets of the plurality of filters; a control electric boxwhich is electrically connected with the plate frame oil filtering device, the plurality of filters and the protection device; by filtering oil in the oil tank layer by layer, the plate frame oil filtering device has the advantages of simple structure, convenience and quickness in filter element replacement, simplicity in operation, low running cost, convenience in maintenance, stable and reliableperformance, short filtering time, high precision, capability of meeting proper filtering precision requirements by selecting filter paper with different qualities and filter elements, and the like.

Owner:THE FIRST NORTHEAST ELECTRIC POWER ENG CO LTD

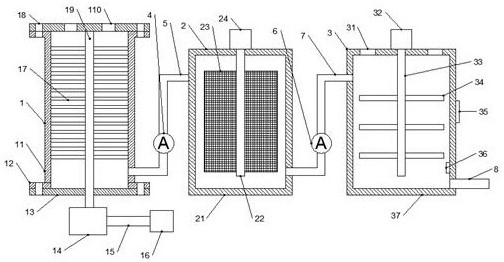

Vacuum filter used for removing impurities in process of producing ethylene glycol antimony

InactiveCN106731003AIncreased average whitenessGood filter and impurity removal effectSolid sorbent liquid separationHydroxy compound separation/purificationFiberCarbon fibers

The invention discloses a vacuum filter used for removing impurities in a process of producing ethylene glycol antimony. The vacuum filter is composed of a vacuum filter barrel and a filter layer, wherein the vacuum filter barrel consists of an upper charge hole, a lower discharge hole and a barrel body; the filter layer consists of a carbon fiber felt, a stainless steel screen and a punching plate from top to bottom in sequence; the punching plate is fixedly arranged on the middle part of the vacuum filter barrel; and the periphery of the carbon fiber felt and the stainless steel screen is clamped onto the punching plate through an environment-friendly sealing ring. The whiteness average value of a product obtained by removing the impurities through the filter is increased to 93%, the b*average value of the product is reduced to 1.1 and the black point average value of the product is increased to 100%, so that the filtration and impurity-removal effect is good. The filter only needs 10-20 minutes for filtering 1m<3> of filtrate. The vacuum filter is reasonable in structure, is simple and convenient to operate, and does not easily generate leakage filtration or penetration filtration; and the filter layer can be repeatedly used, so that the whole filter process is environmentally friendly.

Owner:锡矿山闪星锑业有限责任公司

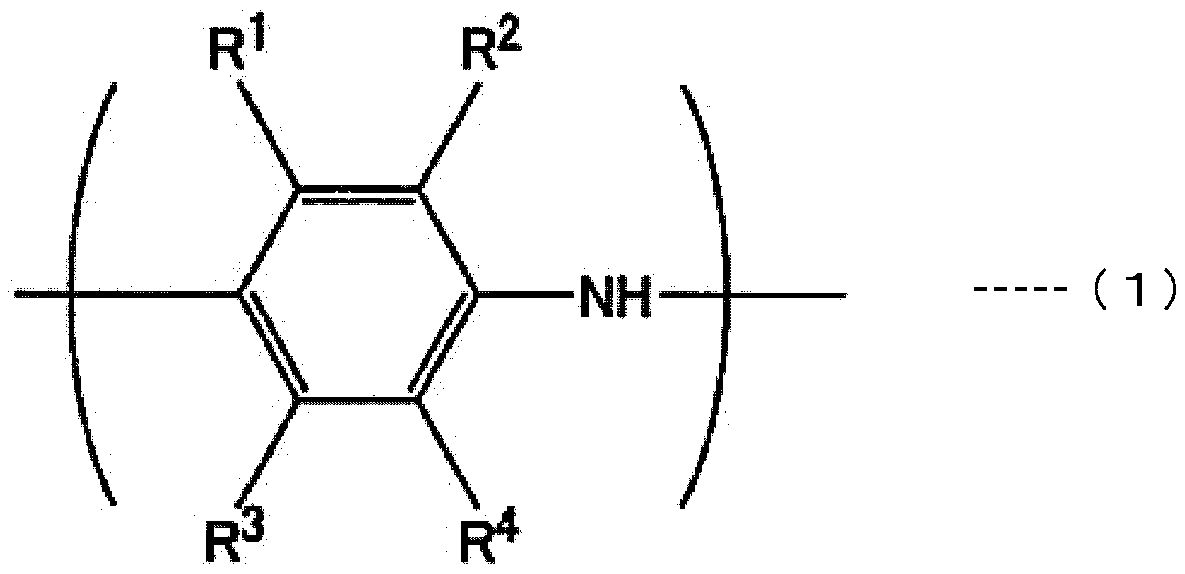

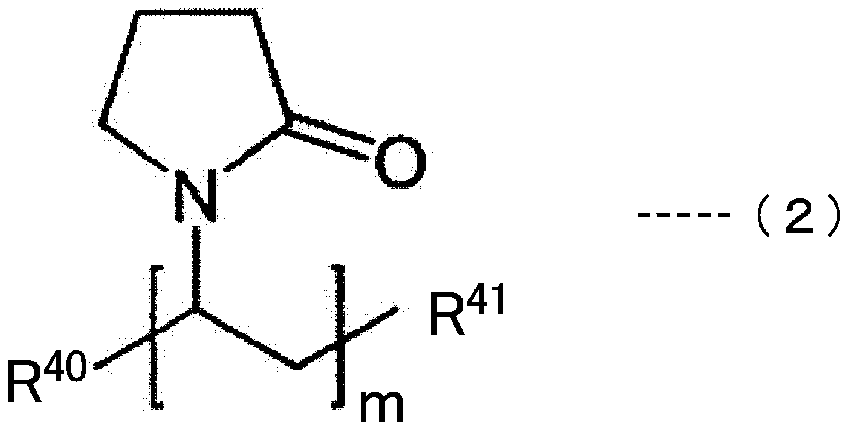

Conductive composition, method for producing conductive composition, and method for producing conductor

ActiveCN110249006AShort filter timeConductive layers on insulating-supportsConductive materialIon currentFluid phase

This conductive composition contains a conductive polymer (A), a water-soluble polymer other than the conductive polymer (A), and a solvent. When a test solution obtained by extracting the water-soluble polymer (B) from the conductive composition using n-butanol is measured using a high performance liquid chromatograph mass spectrometer, the area ratio calculated by equation (I) below is no greater than 0.44. (I) Area ratio=Y / (X+Y) (In equation (I), X is the sum of peak area values when an extracted ion chromatogram is prepared from the total ion current chromatogram using ions derived from a compound having a molecular weight (M) of at least 600, and Y is the sum of peak area values when an extracted ion chromatogram is prepared from the total ion current chromatogram using ions derived from a compound having a molecular weight (M) of less than 600.)

Owner:MITSUBISHI CHEM CORP

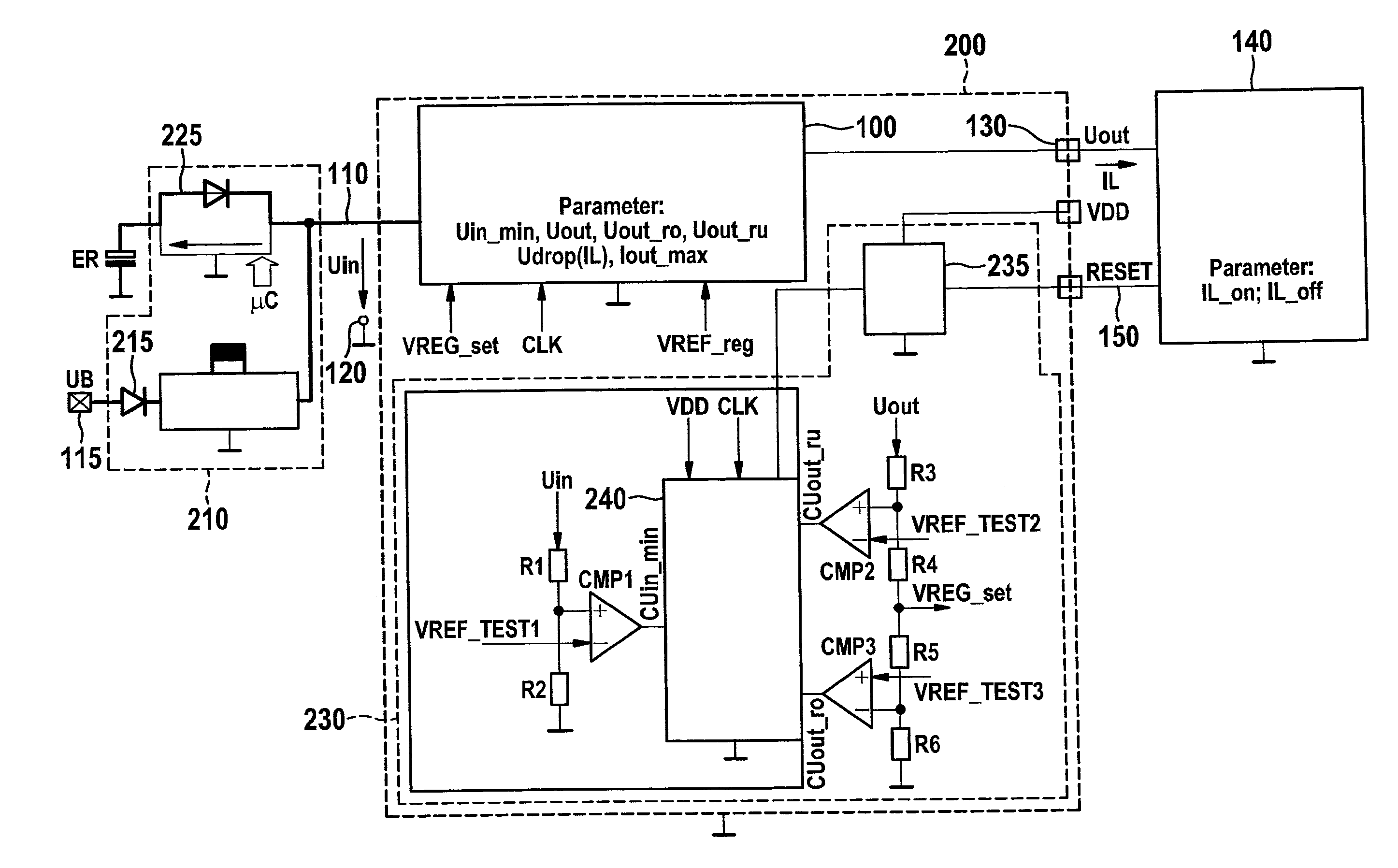

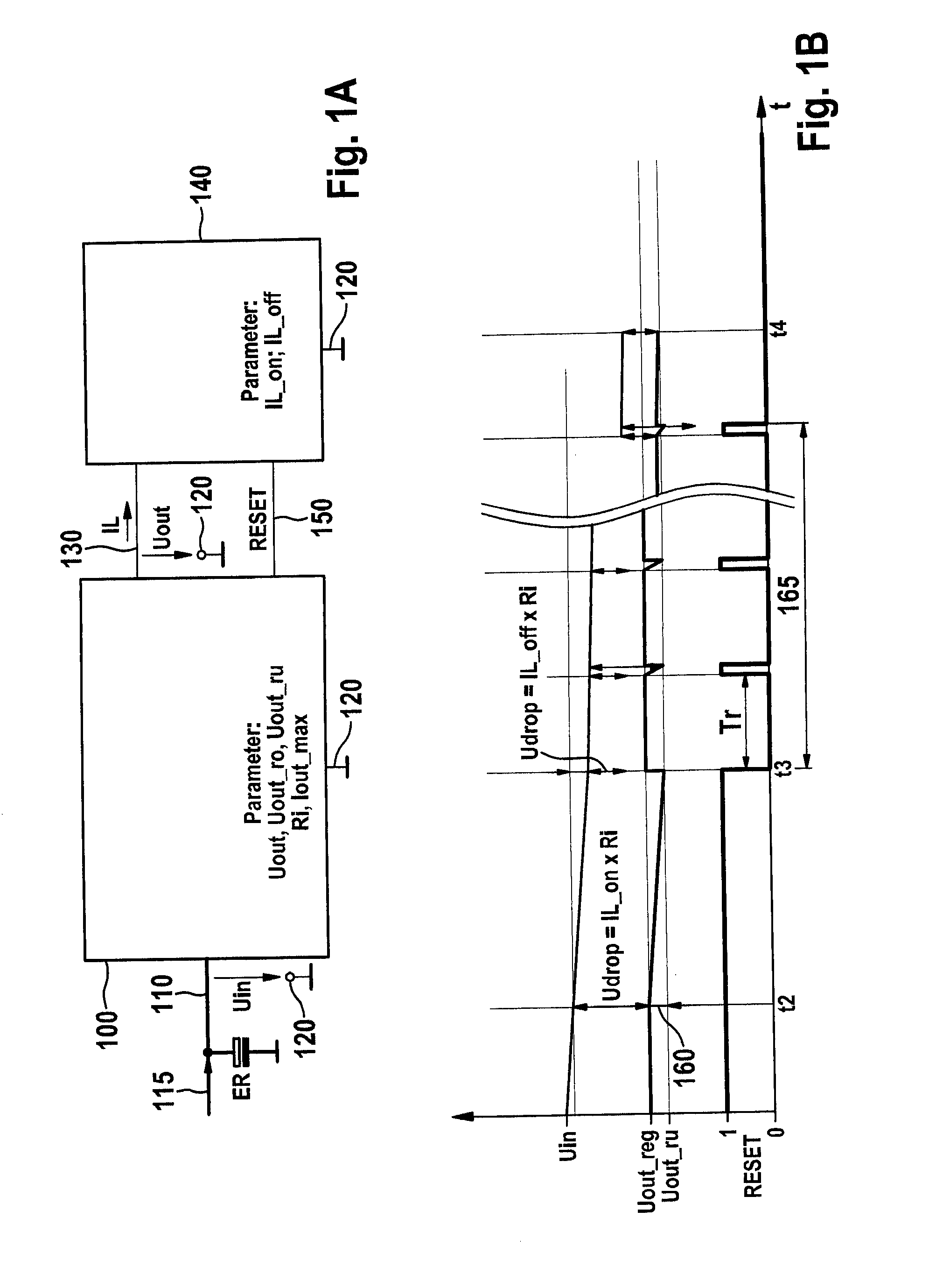

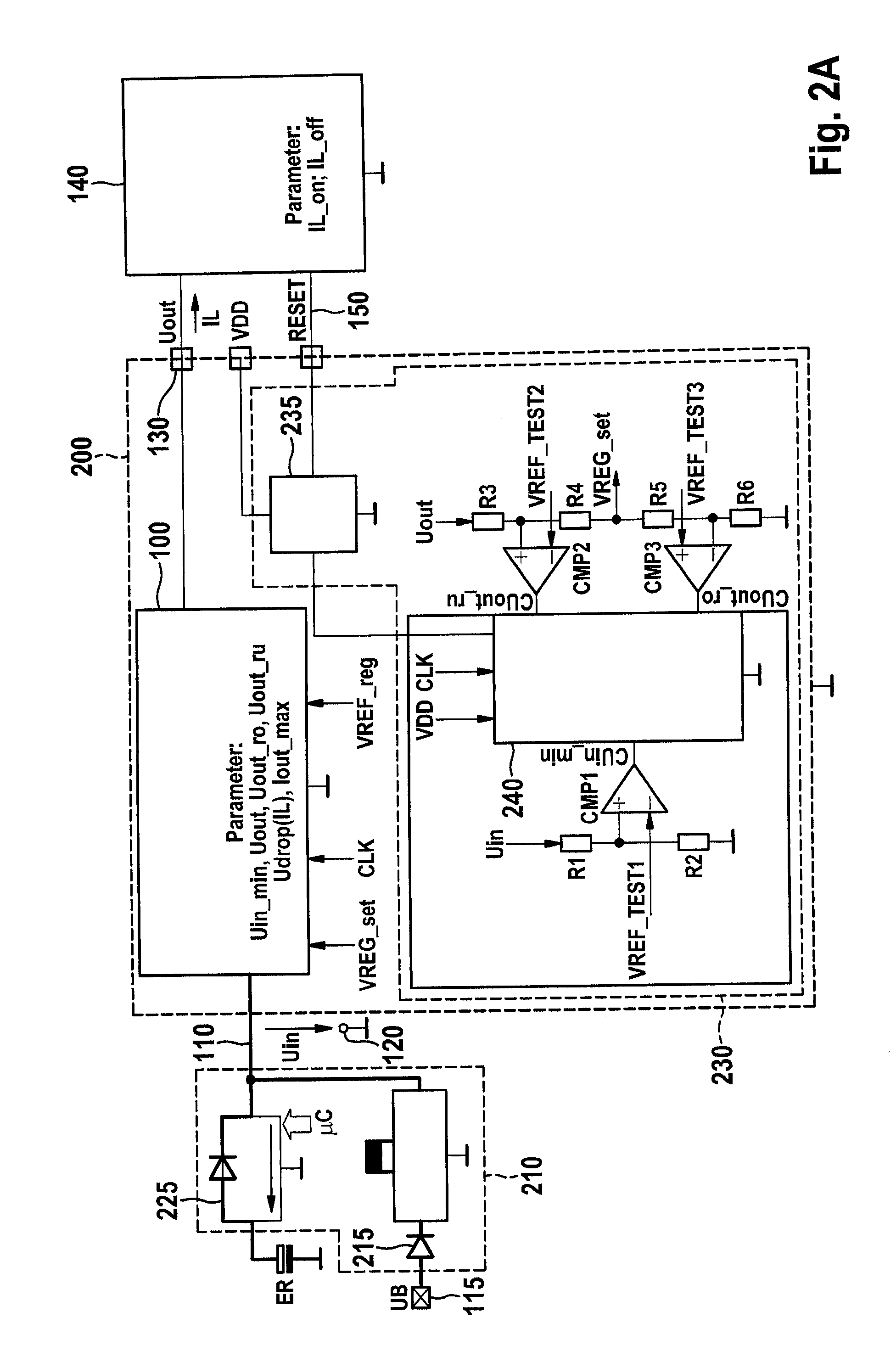

Energy supply unit and method for operating an energy supply unit for autonomously supplying a consumer

ActiveUS20150343978A1Stable and reliableTechnically simpleElectric signal transmission systemsBatteries circuit arrangementsEnergy supplyBiological activation

An energy supply unit for supplying a consumer, includes an energy store to supply electric when the consumer is decoupled from an energy supply network. The energy supply unit includes an energy supply controller having an input coupled to the energy store, via a diode, for receiving electric energy and an output for delivering electric energy, and a monitoring unit for outputting a monitoring signal, configured to set the monitoring signal to an active state when an output voltage between the output and a reference potential is lower / greater than a predefined activation threshold value, the monitoring unit configured, when an excessively low input voltage is identified between the input and reference potential of the controller, especially paired with an excessively low output voltage, the monitoring signal is switched to the inactive state when the input voltage is above a reset threshold and the output voltage is within the monitoring band.

Owner:ROBERT BOSCH GMBH

Chemical waste liquid treatment system based on ultrafiltration rotary ceramic membrane and treatment method thereof

InactiveCN111892193AExtended service lifeShort filter timeSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisActivated carbonElectric machine

The invention discloses a chemical waste liquid treatment system based on an ultrafiltration rotary ceramic membrane and a treatment method thereof. The system comprises a filtering unit, an adsorption unit and a pH adjusting unit, wherein the filtering unit comprises an outer cylinder; a first rotating shaft is arranged in the outer cylinder; a ceramic membrane is arranged on the first rotating shaft; a first water pipe is connected to the right of the outer cylinder; the adsorption unit comprises an adsorption box; a second motor is arranged at the top of the adsorption box and connected with a second rotating shaft; an activated carbon net is arranged on the second rotating shaft; the adsorption box is connected with a second water pipe; the pH adjusting unit comprises an adjusting box;a third motor is arranged at the top of the adjusting box and connected with a third rotating shaft; and a stirring rod is arranged on the third rotating shaft. By arranging the shaft disc type ceramic membrane for filtration, wastewater with high viscosity can be treated, operation cost is low, the service life of the ceramic membrane is long, and filtration time is short; and a high shear rateis generated on the surface of the ceramic membrane along with high-speed rotation of the ceramic membrane, so rotational-flow sweeping flow is formed, a filter cake layer on the surface of the ceramic membrane is very thin, and blockage can be avoided.

Owner:南京浩普环境科技有限公司

A ceramic filter element, its preparation method and application

The invention discloses a ceramic filter element, its preparation method and application. The preparation method includes sintering the filter element green body. During the sintering process, the sintering temperature is divided into 3-6 sections. The ceramic filter element prepared by the invention has mechanical High strength, good filtering effect, no heavy metal pollution, high yield, low cost, and short process time, 20%-30% less time than traditional process, suitable for water quality treatment.

Owner:BEYCLEAN ENVIRONMENTAL PROTECTION TECH

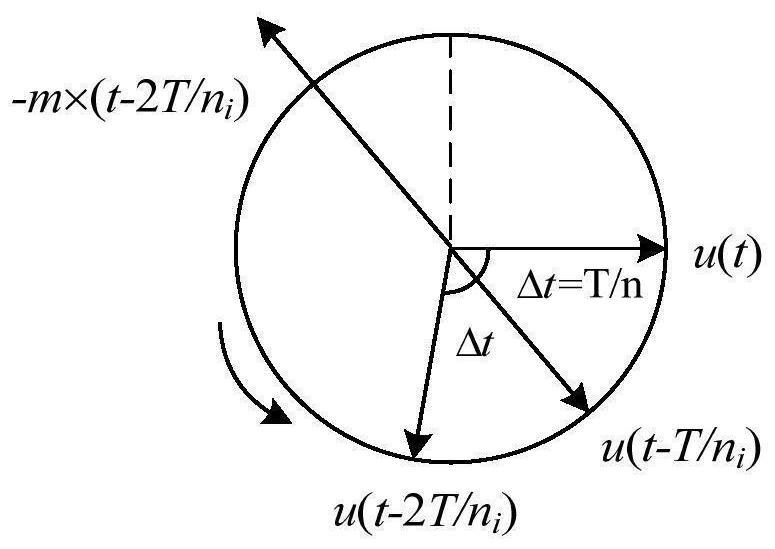

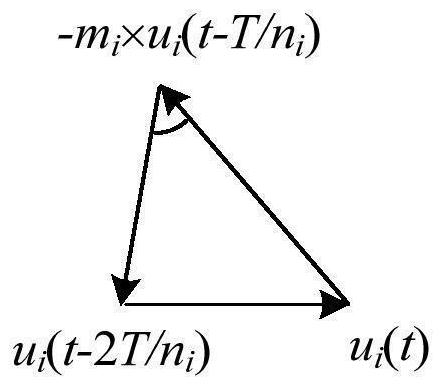

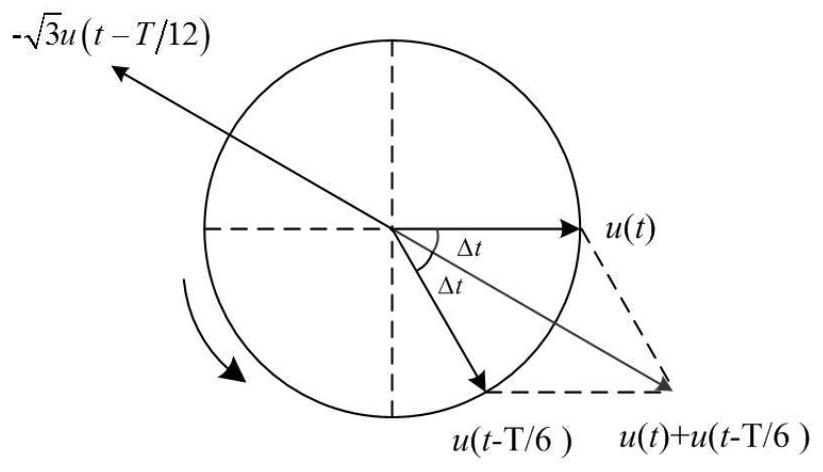

A Fast Delayed Signal Destruction Filtering Method

ActiveCN112929024BEliminate target harmonicsShort filter timePulse automatic controlHarmonic reduction arrangementSignal cancellationElectric network

The invention discloses a fast time-delayed signal destructive filtering method, which divides the target harmonic into sub-harmonics with a certain frequency variation law; Triangulation eliminates this sub-harmonic; cascading different delay operators suppresses all target harmonics. The method can quickly eliminate target harmonics and accurately extract fundamental wave voltage components in the case of severe grid voltage distortion. Compared with the traditional delay cancellation method, this method has a shorter filtering time and has a stronger ability to filter out harmonics.

Owner:SHANDONG INST OF BUSINESS & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com