Preparation method of producing high-strength chitosan fiber by use of double-screw pump

A chitosan fiber, twin-screw pump technology, applied in fiber processing, spinning solution preparation, fiber chemical characteristics, etc., can solve the problems of no mention of dissolution time, no clear proposal, and difficulty in defoaming, and achieve easy deaeration. foam, save energy, reduce the effect of dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

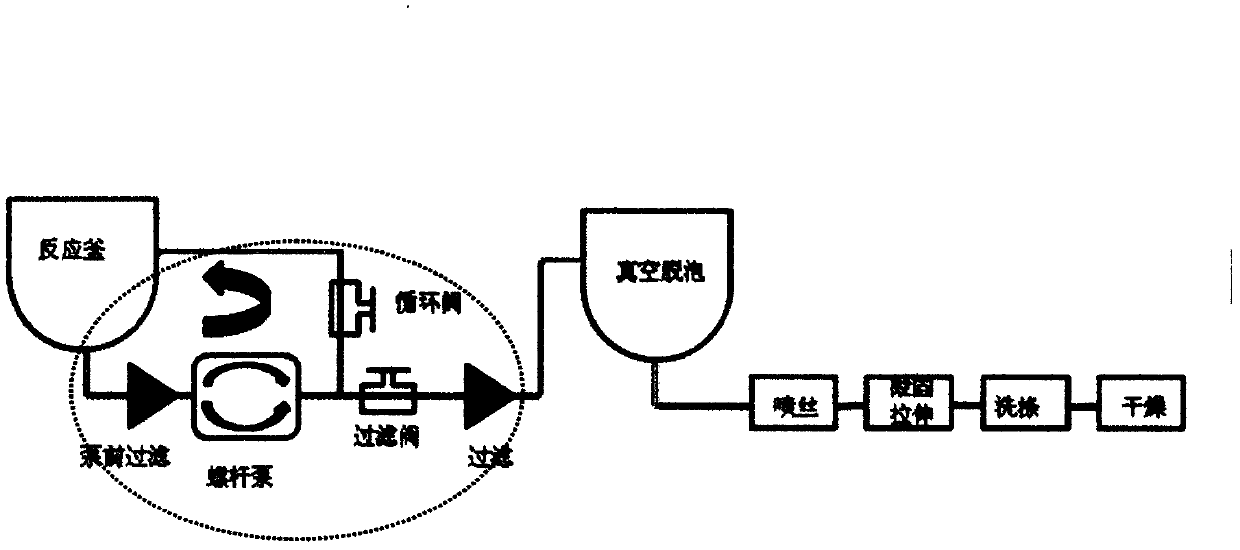

Method used

Image

Examples

Embodiment 1

[0020] Take 600KG deionized water into the reaction kettle, start stirring, put in 20KG chitosan raw material, 12KG glacial acetic acid, 7KG urea, 5KG glycerin, 7KG defoamer in turn, stir at 20°C for 15 minutes, close the filter valve, and open the circulation valve , start the screw pump and run it for 1 hour to obtain evenly dissolved chitosan spinning solution; open the filter valve, close the circulation valve, use the screw pump to pressurize and filter, the filtrate directly enters the vacuum degassing tank, and the pump outlet pressure is controlled at 5MPa Below, the filter is made of stainless steel 600 mesh, the vacuum degree of the vacuum tank is 95%, and the static defoaming time is 2 hours; An aqueous solution of sodium hydroxide and ethanol, the content of sodium hydroxide is 4%, the content of ethanol is 5%, the temperature of the coagulation bath is 20°C, the stretching ratio of the fiber is 1.5, after stretching, deionization is carried out at room temperature ...

Embodiment 2

[0022] Take 300KG deionized water into the reactor, start stirring, put in 20KG chitosan raw material, 12KG glacial acetic acid, 7KG urea, 2KG ethanol, 7KG defoamer in turn, stir at 10°C for 15 minutes, close the filter valve, open the circulation valve, start The screw pump runs for 0.5 hours to obtain evenly dissolved chitosan spinning solution; open the filter valve, close the circulation valve, and use the screw pump to pressurize and filter, the filtrate directly enters the vacuum degassing tank, and the pump outlet pressure is controlled below 5MPa. The filter is made of stainless steel 800 mesh, the vacuum degree of the vacuum tank is 95%, and the static defoaming time is 1 hour; the degassed slurry is pumped to the spinneret with metering pump, the spinneret aperture is 0.04mm, 4000 holes, and the coagulation bath is hydrogen oxidation An aqueous solution of sodium and ethanol, the content of sodium hydroxide is 5%, the content of ethanol is 5%, the temperature of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com