Patents

Literature

56results about How to "Easy to defoam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

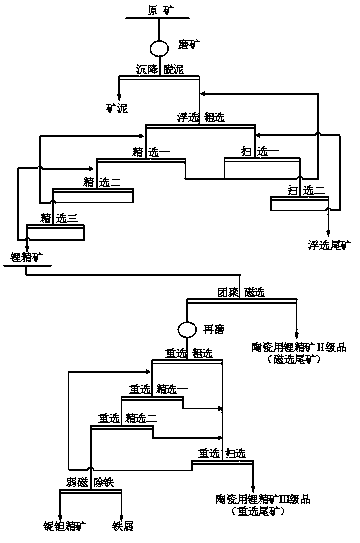

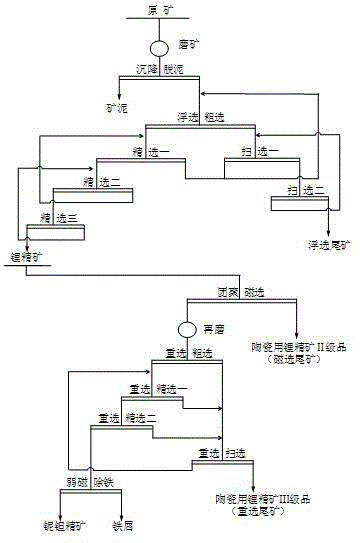

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

InactiveCN103418488ASolve the problems of low recovery rate, single beneficiation products, and poor economic benefitsRaise the gradeFlotationMagnetic separationLithiumNiobium

The invention relates to a comprehensive recovery process for lithium-containing polymetallic ores with associated fine-grained niobium-tantalum. The process comprises the steps of raw ore crude grinding, settlement for desliming, flotation, agglomeration and magnetic separation, gravity separation and the like. The process provided by the invention is particularly applicable to the comprehensive recovery of lithium-containing polymetallic ores which contain a great amount of slime, are located in mining areas at low temperature all through the year, are low in grade of associated niobium-tantalum minerals and are fine in disseminated grain size, the process is advanced, reliable, simple, reasonable and highly targeted, the requirement on raw ore grinding fineness is not high, the regrinding amount is small, the operation cost is low, the comprehensive recovery rate is higher and the industrialization prospect is good.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Ink composition and method of ink-jet recording

InactiveUS20050081745A1Excellent toneImprove the immunityMeasurement apparatus componentsInksWeather resistanceImaging quality

An ink composition comprising: at least one dye having an oxidation potential of more positive than 1.0 V dissolved or dispersed in an aqueous medium; and a surface active agent in an amount of from 0.05 to 50 g / l. The ink composition having the aforesaid constitution exhibits a high ejection stability and can provide an image having assured hue and an excellent weathering resistance and being free of defects in water resistance and image quality.

Owner:FUJIFILM HLDG CORP +1

Solid detergents

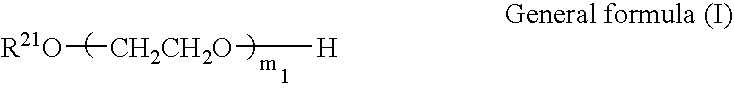

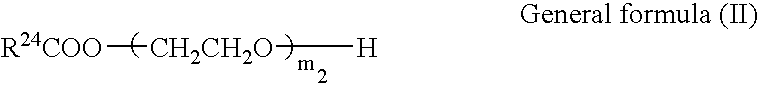

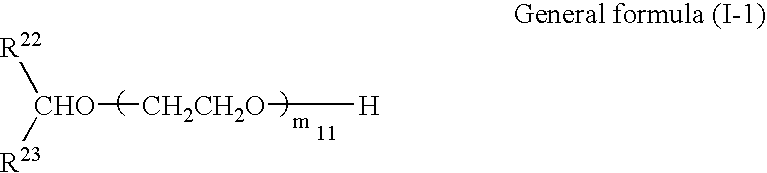

InactiveUS20030022809A1Improve solubilityDefoamed more readilySurface-active detergent compositionsDetergent powders/flakes/sheetsEtherNon ionic

Owner:COGNIS DEUT GMBH & CO KG COGNIS

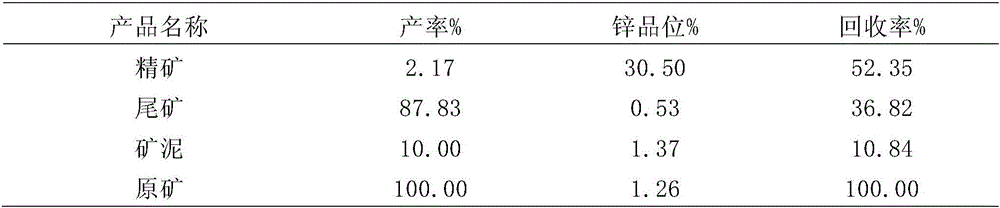

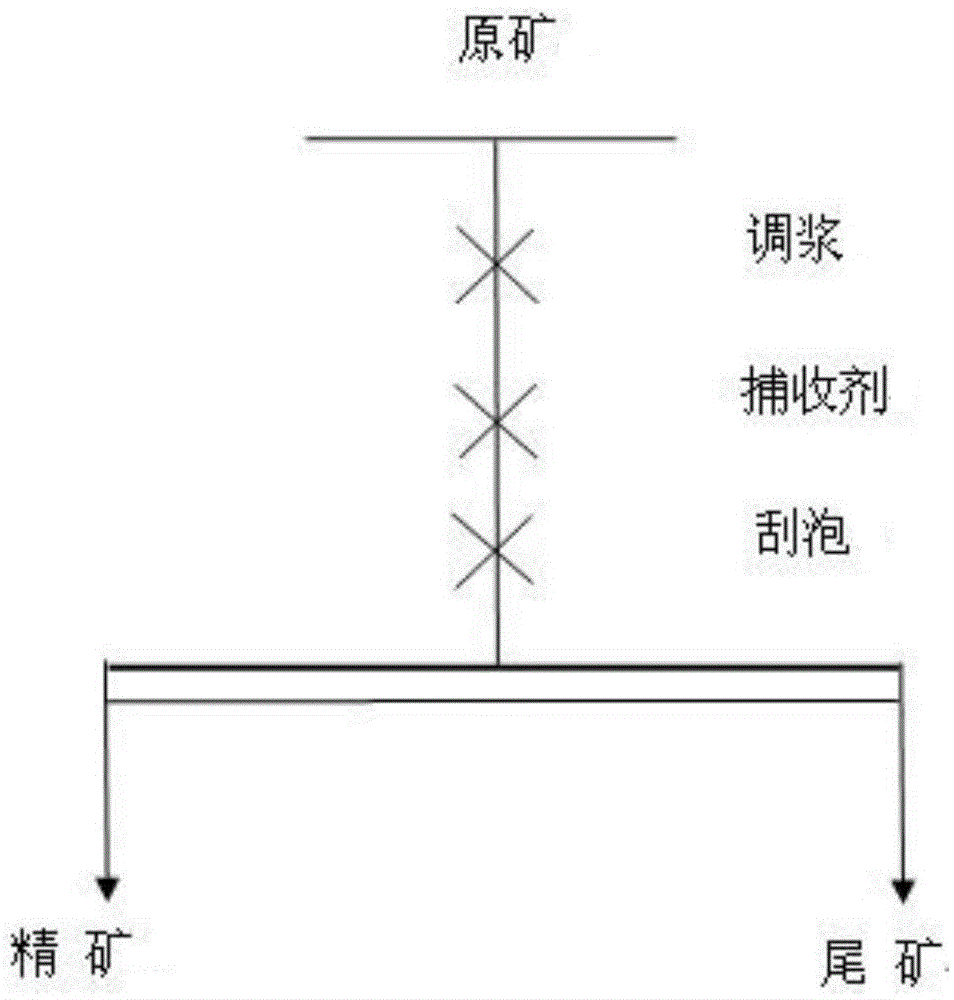

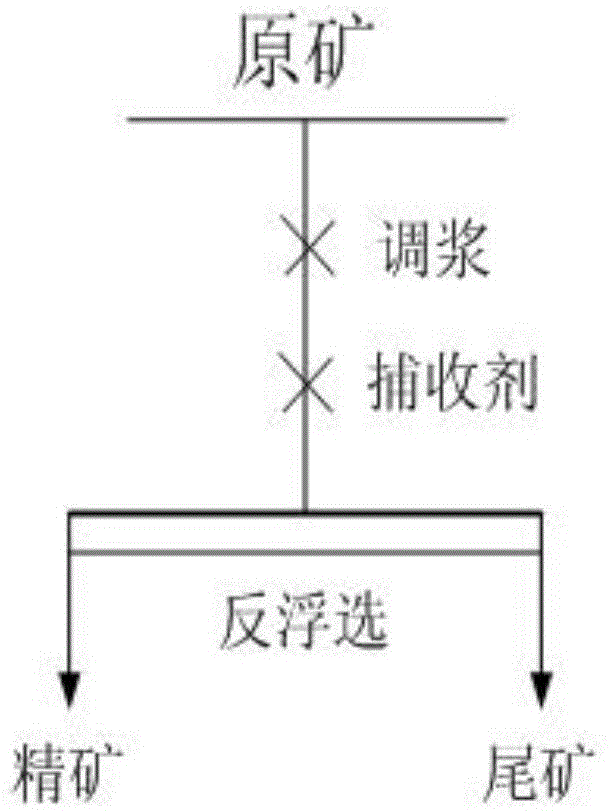

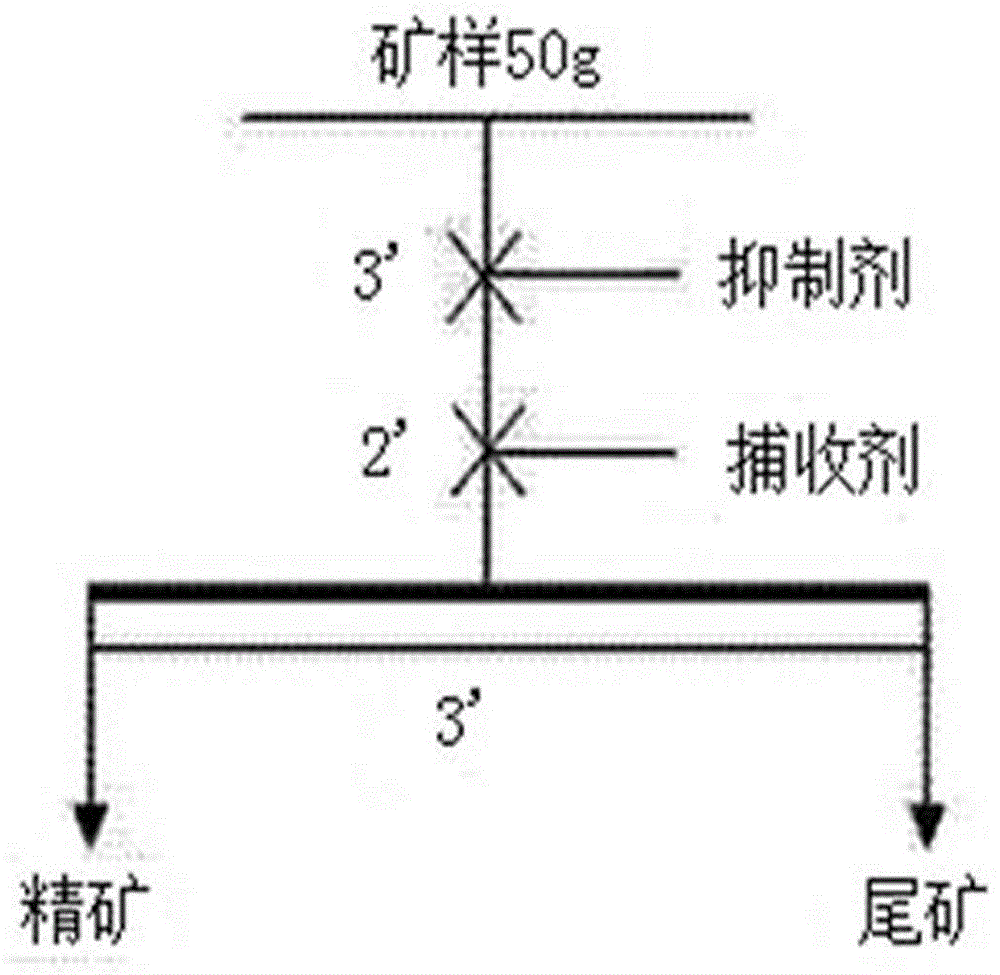

Beneficiation method for recovering low-grade zinc oxide ore from lead-zinc ore flotation tailings

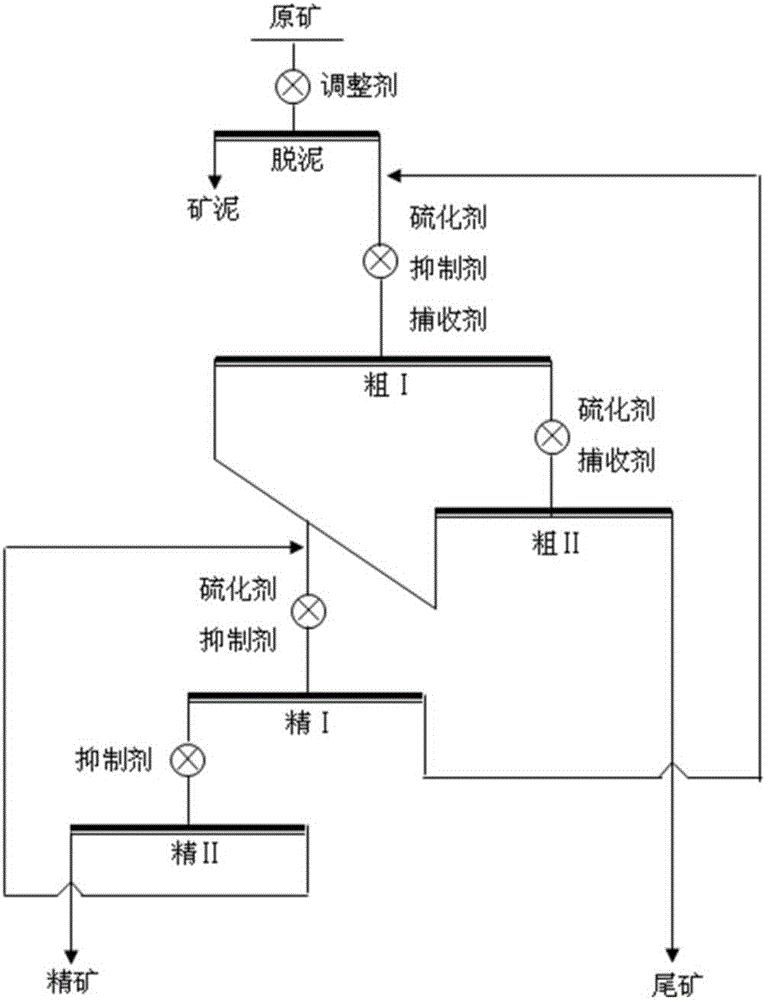

The invention discloses a beneficiation method for recovering low-grade zinc oxide ore from lead-zinc ore flotation tailings and belongs to beneficiation methods for zinc oxide ore. The method includes the steps that the lead-zinc ore flotation tailings are used as raw ore, and desliming is carried out after a regulator is added and stirred for pulp conditioning; and a vulcanizing agent, an inhibitor and a collecting agent are added into ore pulp obtained after desliming and stirred for pulp conditioning, the zinc oxide ore is recovered through a flotation column, and after two times of closed roughing flotation and two times of closed cleaner flotation, zinc oxide concentrate is obtained. According to the method, the agent selectivity is improved firstly, so that the problems that bubbles are sticky and hard to remove are solved; then the sorting effect of equipment on micro-fine particles is improved, so that the concentrate grade and the recovery rate are increased; and finally the technological process is simplified, production cost is lowered, and enterprise benefits and the resource utilization rate are guaranteed. The method has the advantages that the sorting effect is good, the technological process is short, production cost is low, and the method is friendly to environment; efficient sorting of the low-grade zinc oxide ore in the lead-zinc ore flotation tailings is achieved, the comprehensive utilization rate of mineral resources is increased, and high economic and social benefits are achieved.

Owner:CHINA UNIV OF MINING & TECH

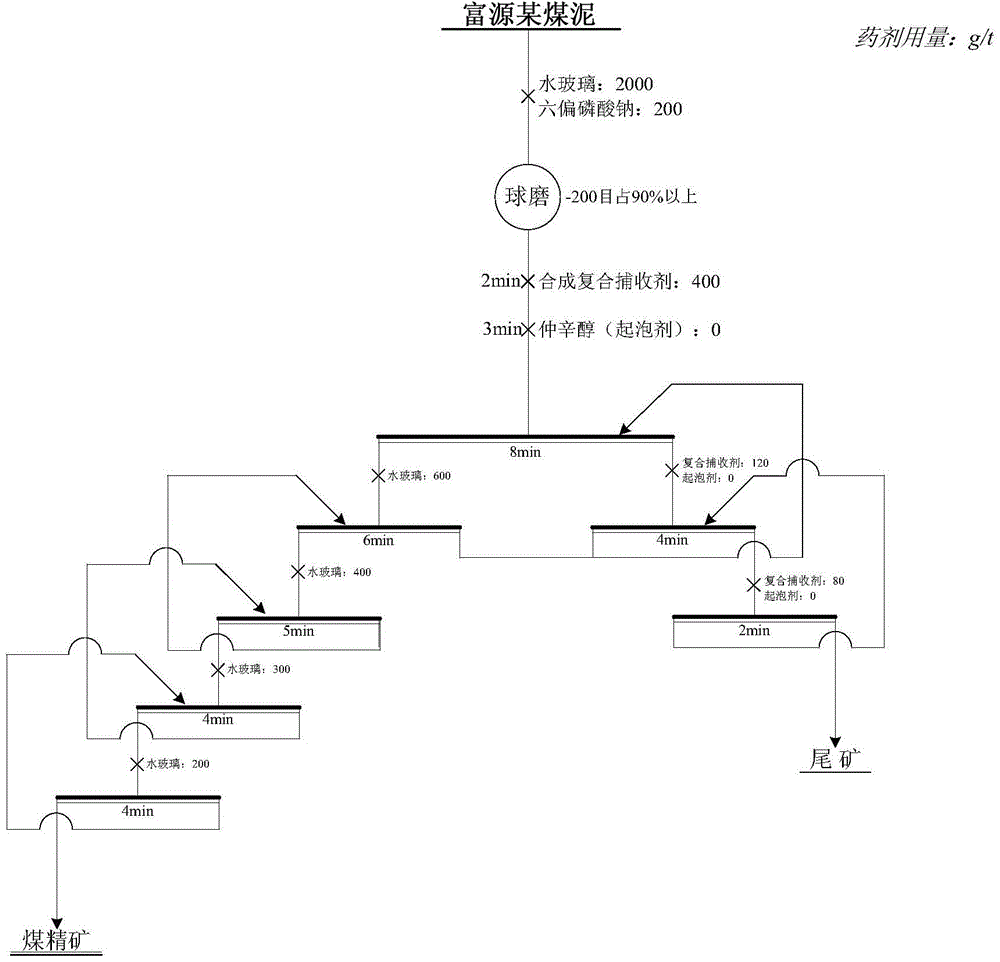

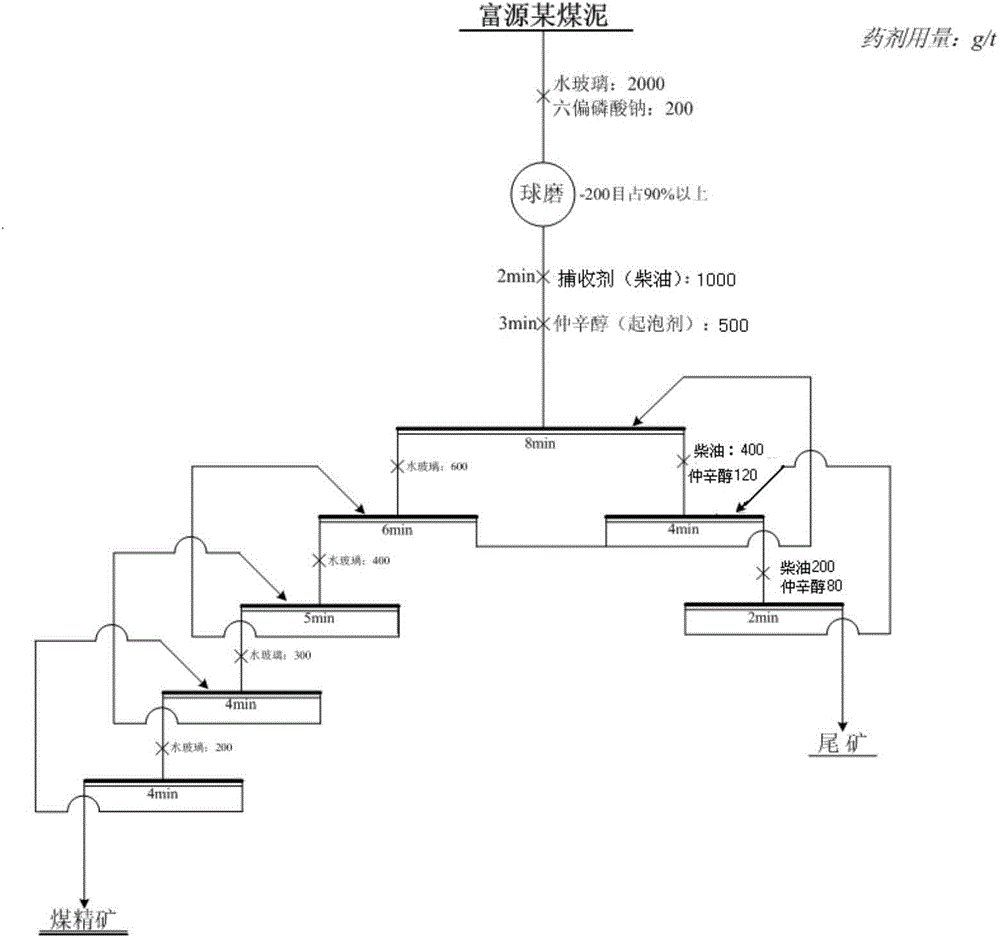

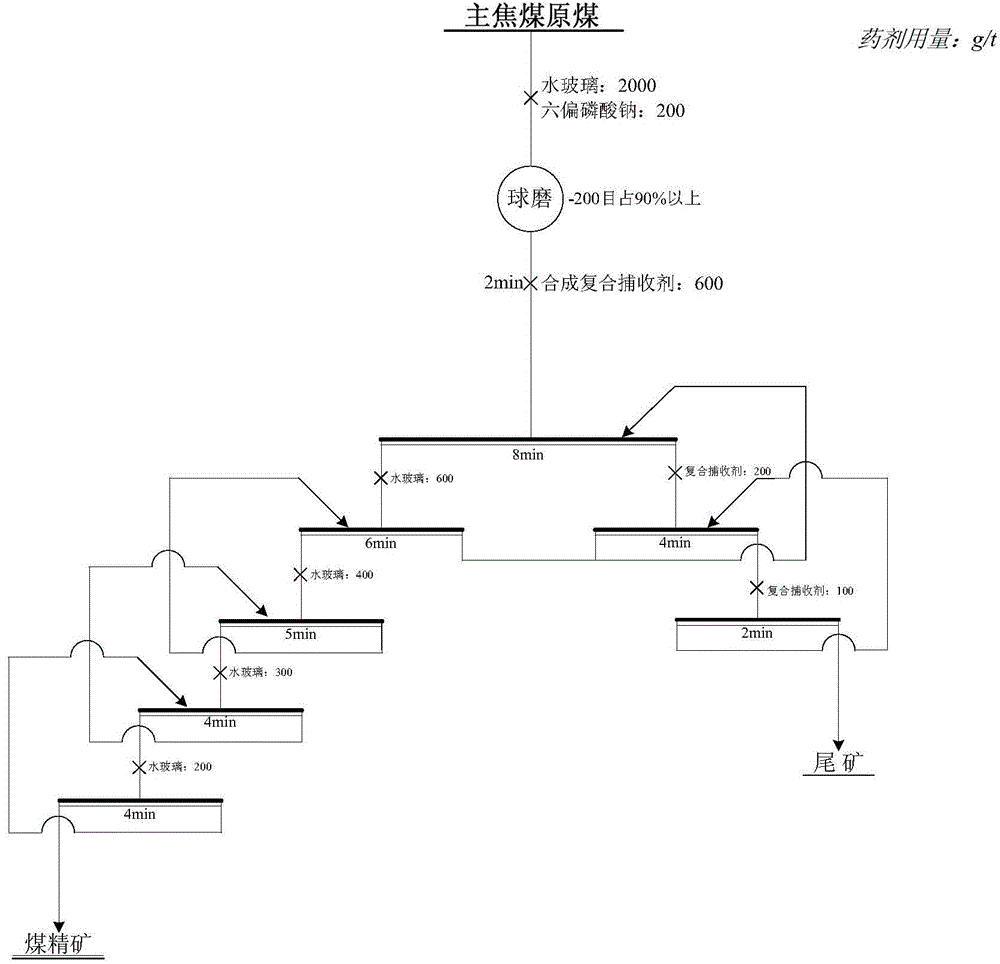

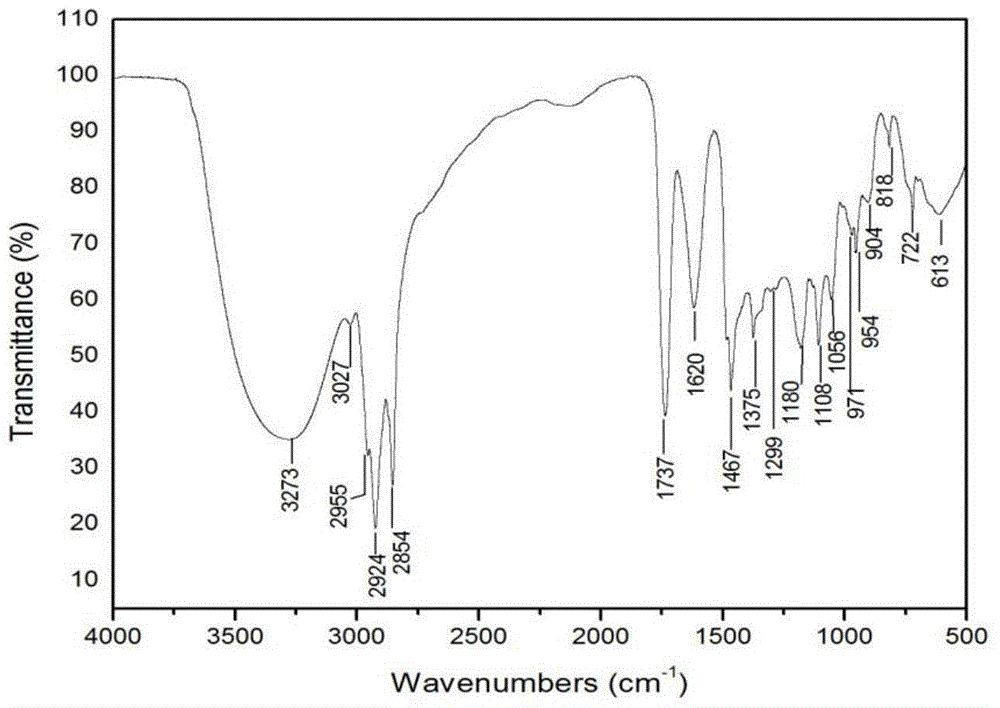

Coal dressing collecting agent and preparing method thereof

The invention relates to a coal dressing collecting agent and a preparing method of the coal dressing collecting agent, in particular to a coal collecting agent with butyl-octyl alcohol residual liquid in petrochemical enterprises as raw materials and a preparing method of the coal collecting agent and belongs to the technical field of preparing of coal slime flotation collecting agents. According to the coal dressing collecting agent, the butyl-octyl alcohol residual liquid in the petrochemical enterprises and phthalic anhydride serve as raw materials, under the action of catalysts, firstly, the temperature is raised to 70-150 DEG C, and a backflow reaction is performed for 1-5 hours; then, the temperature is raised to 120-300 DEG C, water phases and organic phases are separated after the backflow reaction is performed for 1-5 hours, drying and dewatering are performed on the organic phases, and the coal dressing collecting agent can be obtained. According to the coal dressing collecting agent and the preparing method of the coal dressing collecting agent, the preparing process is simple, the obtained product is good in flotation capacity, and industrialized production and industrialized application are facilitated. Meanwhile, the problem that the butyl-octyl alcohol residual liquid cannot be easily processed with high efficiency and high yield is well solved.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

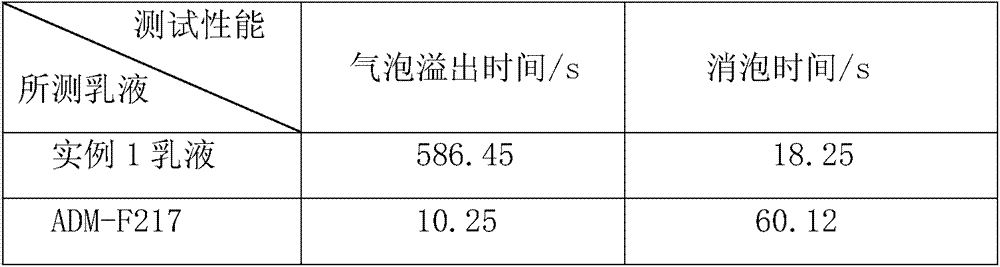

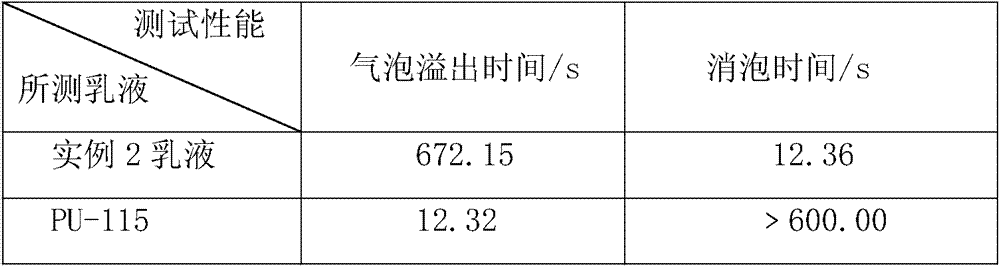

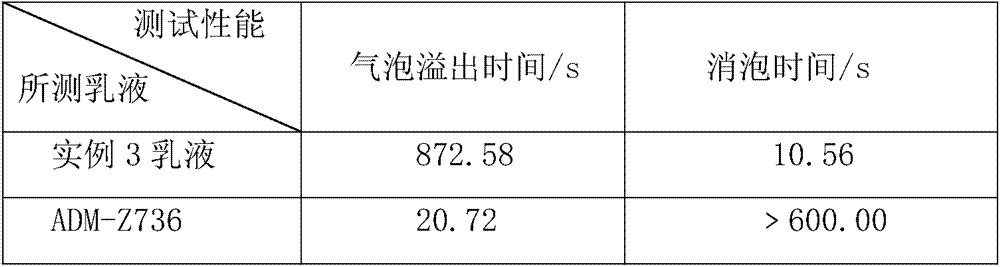

Self-defoaming water-based polyurethane emulsion

InactiveCN103539916AHigh molecular weightImprove temperature resistancePolyurea/polyurethane coatingsChemical structureWater based

The invention relates to a self-defoaming water-based polyurethane emulsion which is prepared by the following steps: vacuum-heating macromolecular polyhydric alcohol to 110-140 DEG C, and dewatering for 0.5-2.0 hours; adding hydroxyl silicone oil and reducing the temperature to 60-75 DEG C, and stirring for 0.5-1.0 hour; adding isocyanate and stirring for reaction at 70-85 DEG C for 1.5-3.0 hours; adding a hydrophilic chain extender and a crosslinking agent, and stirring for reaction for 1.0-2.0 hours to obtain a prepolymer; reducing the temperature of the prepolymer to 40-50 DEG C; adding a solvent, dropwise adding a neutralizer and stirring for 15-45 minutes; and after the chain extender is dissolved in water, dropwise adding into the neutralized prepolymer, and stirring at a stirring rate of 1,000-3,000rpm for 20-40 minutes to obtain the emulsion. According to the self-defoaming water-based polyurethane emulsion provided by the invention, the chemical structure of the molecular chain segment of polyurethane is changed from a synthesis source of polyurethane, and the silicon with low surface energy is introduced so that the emulsion has excellent defoaming ability; and after film formation, the emulsion has good water resistance and solvent resistance.

Owner:SHANGHAI CHENGYING NEW MATERIALS

Insulative potting composite material with high thermal conductivity and preparation method thereof

The invention discloses an insulative potting composite material with high thermal conductivity and a preparation method thereof. The insulative potting composite material is prepared by mixing a component A with a component B at a weight ratio of 1:1 and solidifying at the temperature of 50-150 DEG C for 20-50 minutes. The insulative potting composite material has the advantages that the thermalconductivity reaches 3.5 W / m.K (ASTM D5470, HotDish method) and the electrical insulation property and mechanical properties are excellent. According to the invention, the insulative potting composite material with high thermal conductivity is prepared by using vinyl silicone oil as a base adhesive and hydrogen-containing silicone oil as a solidifying agent, using spherical, flaky, acicular and prismatical heat-conducting fillers to fill, and forming plenty of heat conducting channels by virtue of the reasonable combination of the heat-conducting fillers of different shapes; and the solidified insulative potting composite material has excellent electrical properties and mechanical properties.

Owner:HEFEI BOFA NEW MATERIAL TECH

Preparation method of silicon dioxide for low-specific-surface-area high-density thickening type toothpaste

ActiveCN111484025AAddress manufacturing costsReduce contentCosmetic preparationsToilet preparationsToothpasteSodium silicate

The invention belongs to the technical field of silicon dioxide, and particularly relates to a preparation method of silicon dioxide for low-specific-surface-area high-density thickening type toothpaste. The silicon dioxide for the low-specific-surface-area high-density thickening type toothpaste is prepared by the following steps: taking a sodium sulfate solution with the mass concentration of 10-12% as a mother solution, dripping a sodium silicate solution with the molar concentration of 1.25-1.5 mol / L and a sulfuric acid solution with the molar concentration of 6-7mol / L at the same time, and carrying out a reaction at a segmented temperature and a segmented pH value. When the silicon dioxide for the thickening type toothpaste prepared by the preparation method provided by the inventionis applied to the preparation process of the toothpaste, the time can be shortened, the dust can be reduced, the cost can be saved in the transportation process, and the cleaning effect of the toothpaste cannot be reduced when the silicon dioxide is compounded with the friction type silicon dioxide in the toothpaste body.

Owner:GUANGZHOU FEIXUE MATERIAL TECH +1

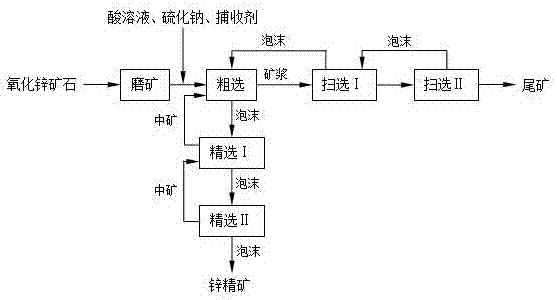

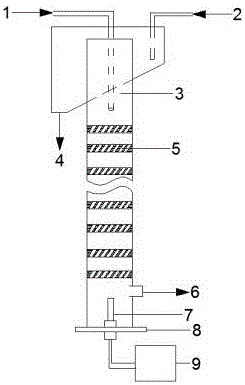

Strengthened floatation method of zinc oxide ore

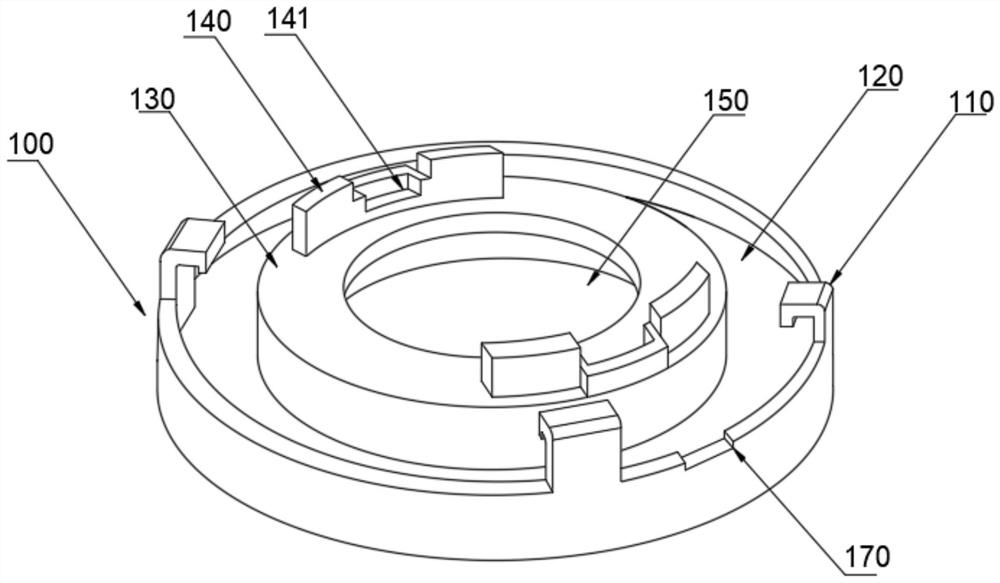

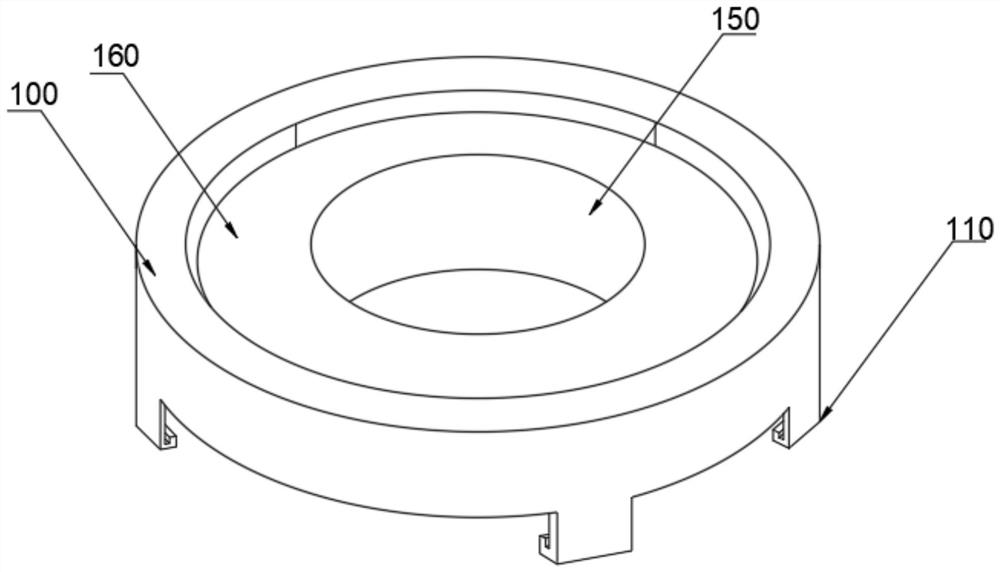

InactiveCN107051749AEasy to defoamOvercome or significantly lessen the impactFlotationZincMaterials science

The invention relates to a strengthened floatation method of zinc oxide ore. The strengthened floatation method of zinc oxide ore comprises the following steps: performing fine grinding on zinc oxide ore, sequentially adding an acid solution, sodium sulfide and a compound collector for reaction, performing roughing flotation once, performing roughing flotation on roughing flotation froth for twice, and performing scavenging on ore pulp in a roughing cell for twice. According to the strengthened floatation method of zinc oxide ore, the problems in the prior art that the conventional zinc oxide ore sulfuration-amine flotation recovery rate is low and froth is difficult to control are solved, and the flotation recovery rate can reach 60-85%.

Owner:KUNMING UNIV OF SCI & TECH

Ultra-low-hardness polyurethane rubber material for printing rubber roller and preparation method thereof

The invention discloses an ultra-low-hardness polyurethane rubber material for a printing rubber roller and a preparation method, and belongs to the field of rubber. Hydroxyl-terminated polybutadiene(HTPB) macromolecular polyol of about 4,000 in molecular weight is taken as a primary material in the polyurethane rubber material, isophorone diisocyanate (IPDI) is taken as a crosslinking agent in the polyurethane rubber material, HTPB of about 2,000 in molecular weight and dimethyl thio-toluene diamine (DMTDA) are taken as chain extenders in the polyurethane rubber material. The ultra-low-hardness polyurethane rubber material for printing rubber rollers of different performances is made by a prepolymer method, and has ultralow shore A hardness and high elasticity.

Owner:TIANJIN RUBBER IND RES INST

Double-layer steamed milk prepared from Chuzhou chrysanthemums and making method of double-layer steamed milk

InactiveCN105660863APromote absorptionImprove absorption rateMilk preparationIcing sugarRoom temperature

The invention discloses double-layer steamed milk prepared from Chuzhou chrysanthemums and a making method of the double-layer steamed milk. According to a formula, the double-layer steamed milk is prepared from following components: 15-25 g of whole milk powder, 3-7 g of powdered sugar, 20-30 g of an egg white and 160-200 ml of a Chuzhou chrysanthemum extract liquid. The making method comprises the following steps: (1) the Chuzhou chrysanthemum extract liquid is prepared; (2) the whole milk powder is brewed completely with the Chuzhou chrysanthemum extract liquid and then heated and boiled slightly, and then the mixture is poured into a first bowl and cooled until a film is formed completely on the surface; (3) an opening is formed along the wall of the first bowl though cutting with a knife, and Chuzhou chrysanthemum milk without skin is poured into a second bowl through the opening; (4) the egg white is prepared; (5) the egg white and the powdered sugar are poured into the second bowl, the materials are stirred uniformly and sieved by a 60-mesh sieve, a product is placed in a vacuum defoaming device for degassing, and a Chuzhou chrysanthemum milk and egg white mixed solution is obtained; (6) the Chuzhou chrysanthemum milk and egg white mixed solution is subjected to back filling; (7) a big fire is adopted for steaming, and the double-layer steamed milk prepared from the Chuzhou chrysanthemums is obtained after room-temperature cooling is performed until solidification forming is realized. The double-layer steamed milk prepared from the Chuzhou chrysanthemums has high nutritional value, excellent taste, fragrance of eggs and milk as well as unique flavor of the Chuzhou chrysanthemums and can meet demands of groups including children, adolescents, young and middle-aged groups and the like.

Owner:ANHUI SCI & TECH UNIV

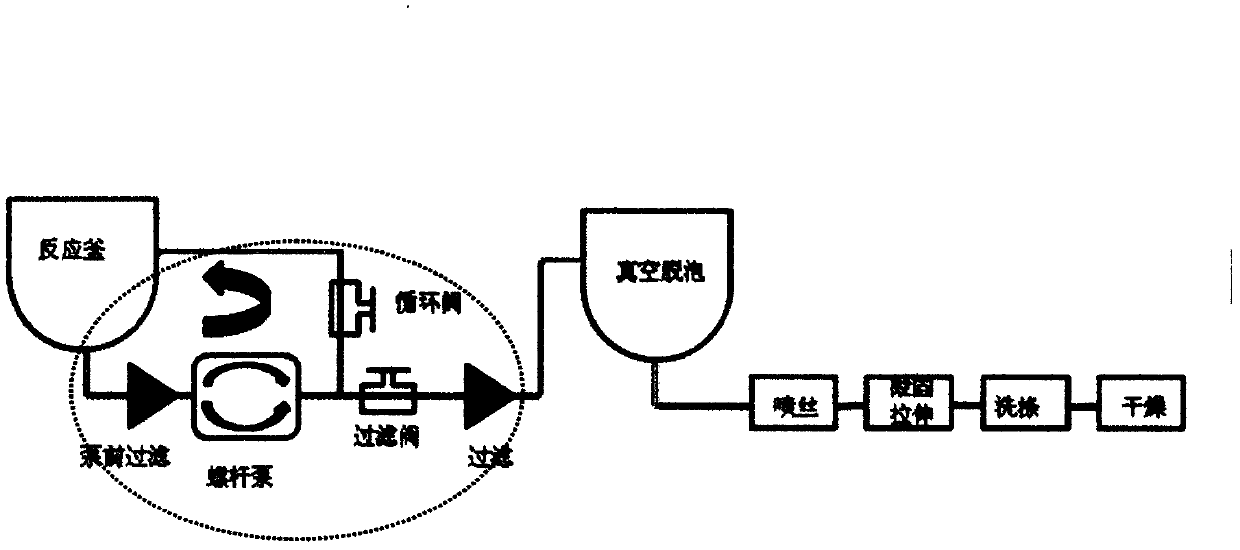

Preparation method of producing high-strength chitosan fiber by use of double-screw pump

ActiveCN102851790AShort dissolution timeShort filter timeFibre chemical featuresSpinning solutions preparationYarnAcetic acid

The invention relates to a preparation method of chitosan fibers, overcomes the shortcomings, such as low solution concentration, long dissolving time, difficult filtering, long defoaming time, instable product quality and low fiber strength, of the chitosan fiber preparation process at present, and adopts 2-5% glacial acetic acid as solvent, where a chitosan tablet raw material is added at a room temperature and stirred for 15-30 min. A double-screw pump is adopted for cyclic delivery for 1 hr, to fully dissolve the preparation, and also used to press-filter the solution and feed it into a vacuum tank for deforming for 2-4 hr to obtain 0.5-30% homogenous-phase transparent chitosan spinning fluid. A spinning machine is adopted for spinning, the yarn extruded by a metering pump enters a condensation bath, and high-strength chitosan fibers are obtained by drawing, water washing, alcohol washing and drying.

Owner:TIANJIN ZHONGSHENG BIO ENG CO LTD

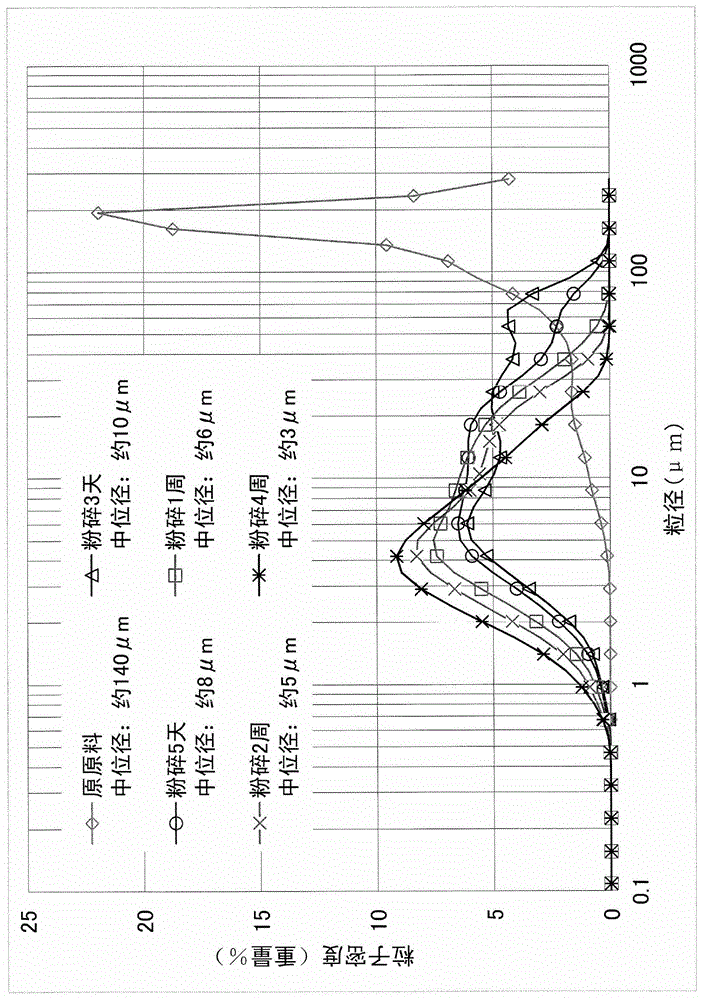

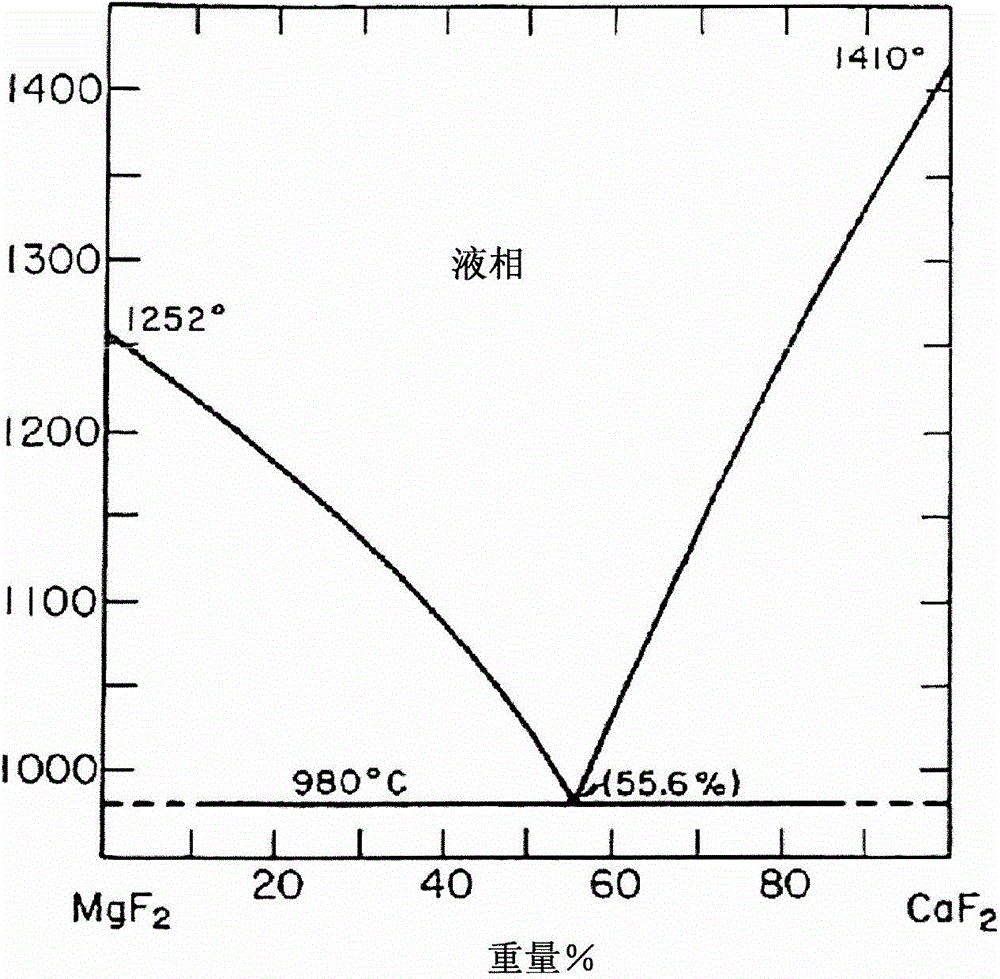

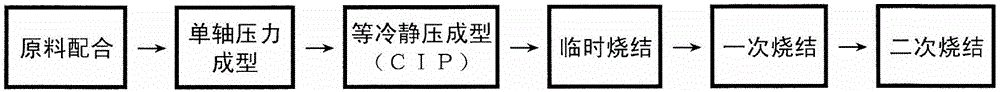

Mgf2-caf2 Binary System Sintered Body For Radiation Moderator And Method For Producing The Same

ActiveCN106145950AEasy to increase relative densityEasy to defoamRadiation/particle handlingShieldingFlexural strengthUltimate tensile strength

A MgF2-CaF2 binary system sintered body for a radiation moderator having a compact polycrystalline structure excellent in radiation moderation performance, especially neutron moderation performance, comprises MgF2 containing CaF2 from 0.2% by weight to 90% by weight inclusive, having a bulk density of 2.96 g / cm3 or more, and a bending strength of 15 MPa or more and a vickers hardness of 90 or more as regards mechanical strengths.

Owner:UNIV OF TSUKUBA +2

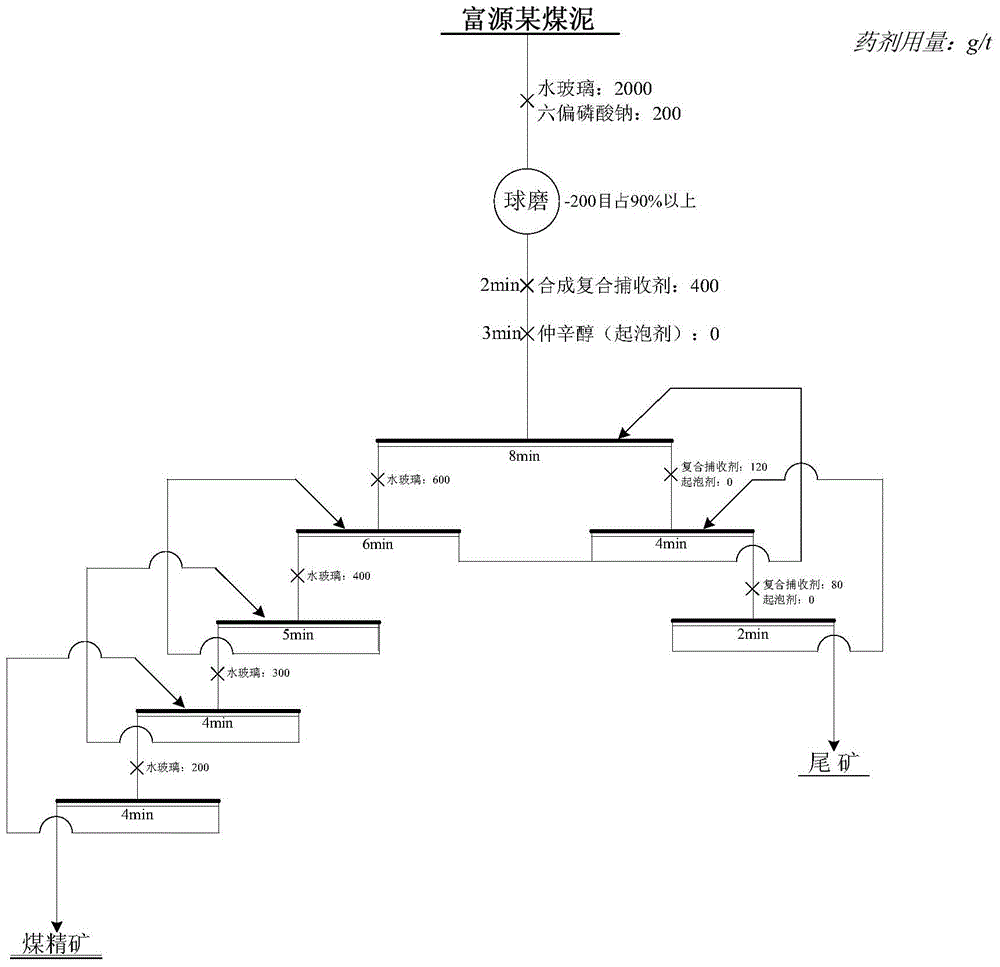

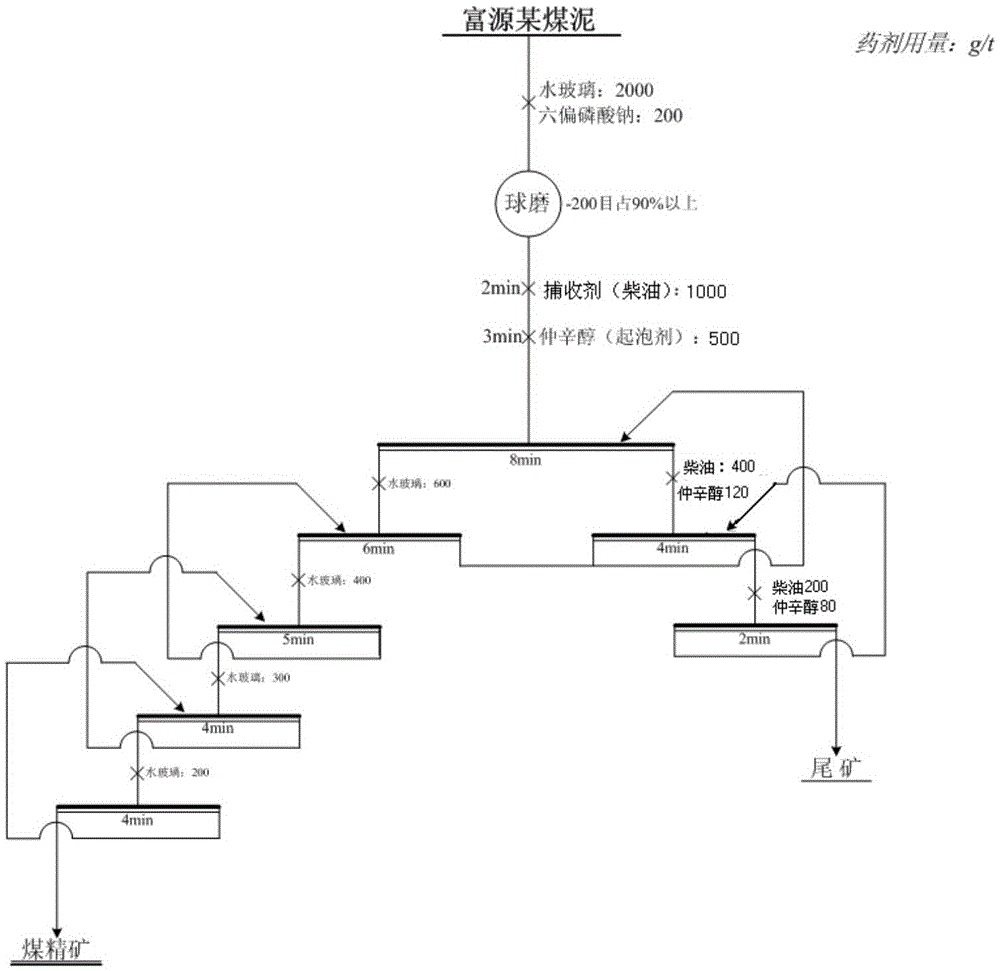

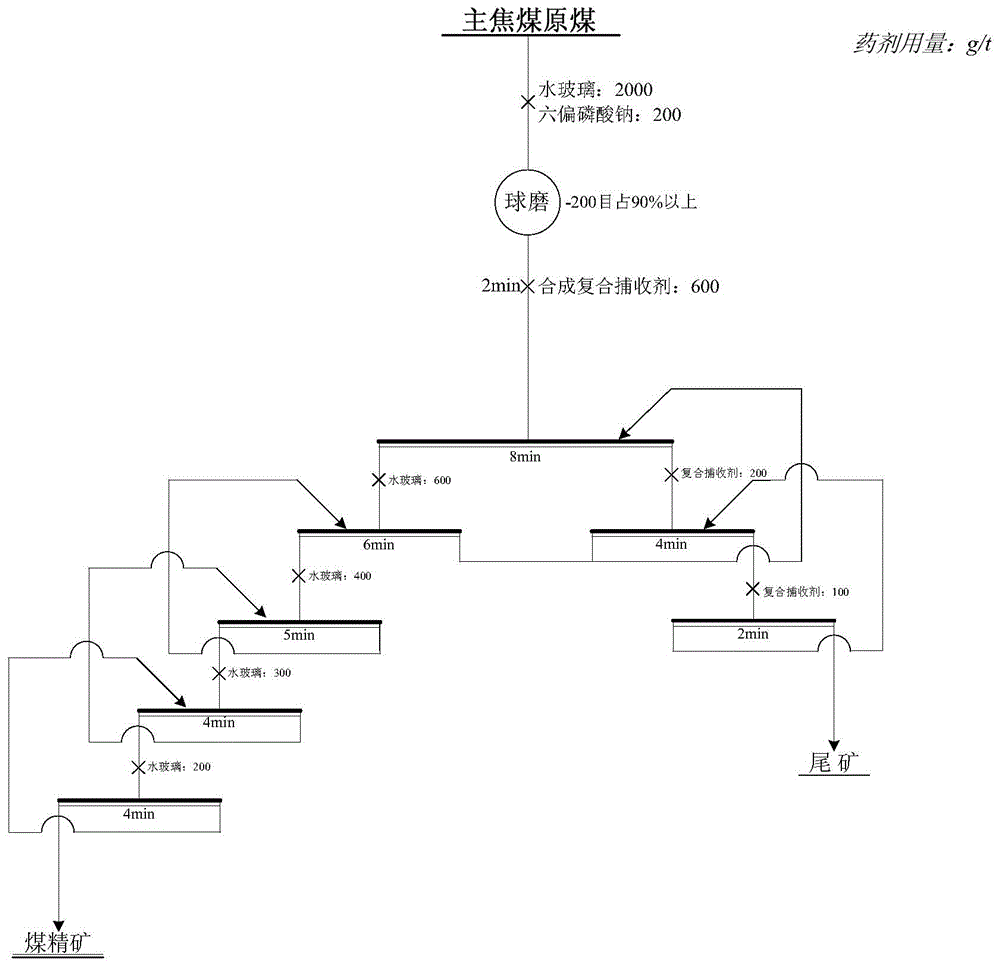

A kind of coal preparation collector and preparation method thereof

ActiveCN104525385BSolve the problem of comprehensive utilizationEfficient use ofFlotationAlcoholPetrochemical

The invention relates to a coal dressing collecting agent and a preparing method of the coal dressing collecting agent, in particular to a coal collecting agent with butyl-octyl alcohol residual liquid in petrochemical enterprises as raw materials and a preparing method of the coal collecting agent and belongs to the technical field of preparing of coal slime flotation collecting agents. According to the coal dressing collecting agent, the butyl-octyl alcohol residual liquid in the petrochemical enterprises and phthalic anhydride serve as raw materials, under the action of catalysts, firstly, the temperature is raised to 70-150 DEG C, and a backflow reaction is performed for 1-5 hours; then, the temperature is raised to 120-300 DEG C, water phases and organic phases are separated after the backflow reaction is performed for 1-5 hours, drying and dewatering are performed on the organic phases, and the coal dressing collecting agent can be obtained. According to the coal dressing collecting agent and the preparing method of the coal dressing collecting agent, the preparing process is simple, the obtained product is good in flotation capacity, and industrialized production and industrialized application are facilitated. Meanwhile, the problem that the butyl-octyl alcohol residual liquid cannot be easily processed with high efficiency and high yield is well solved.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

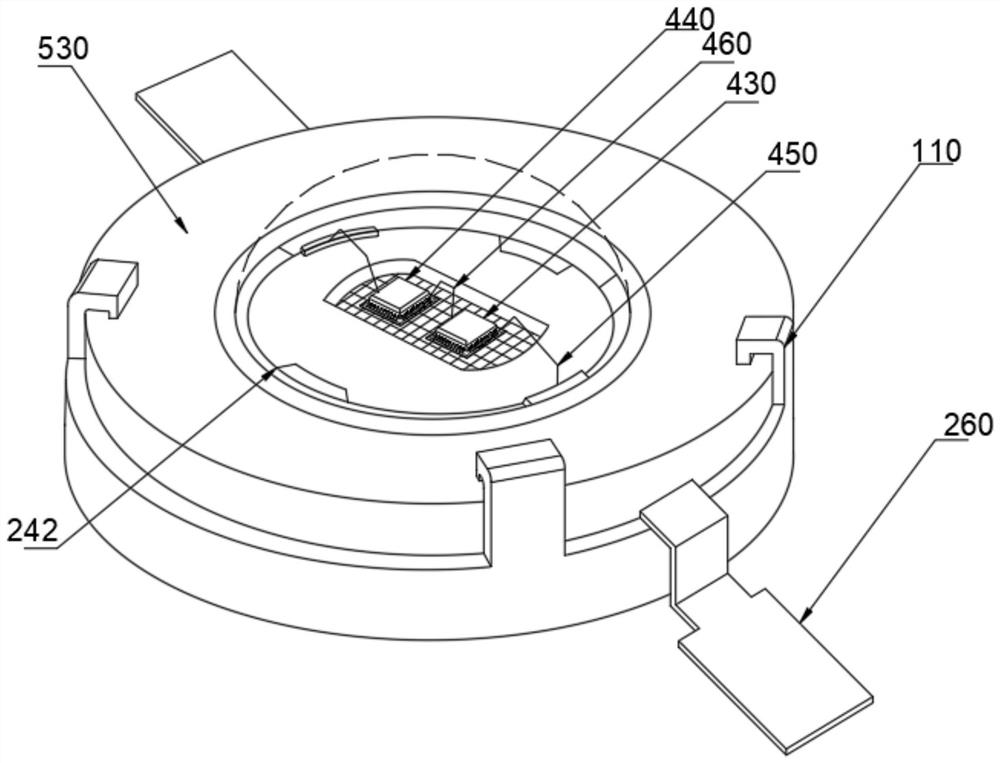

Low-power LED lamp bead low-thermal-resistance packaging structure and packaging process

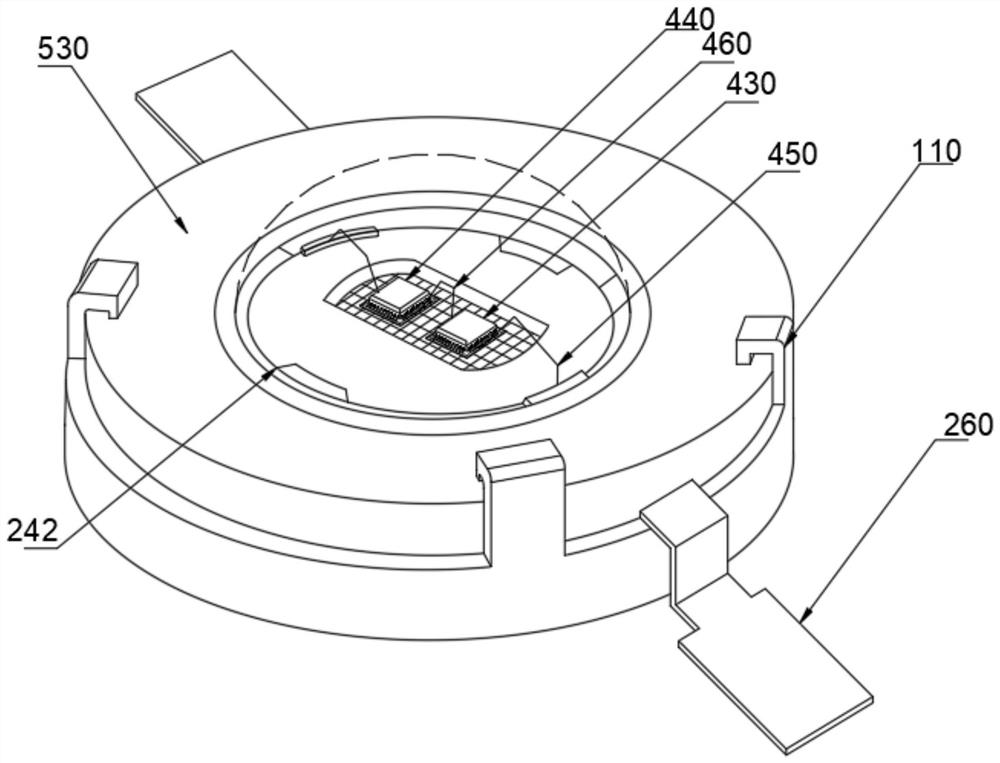

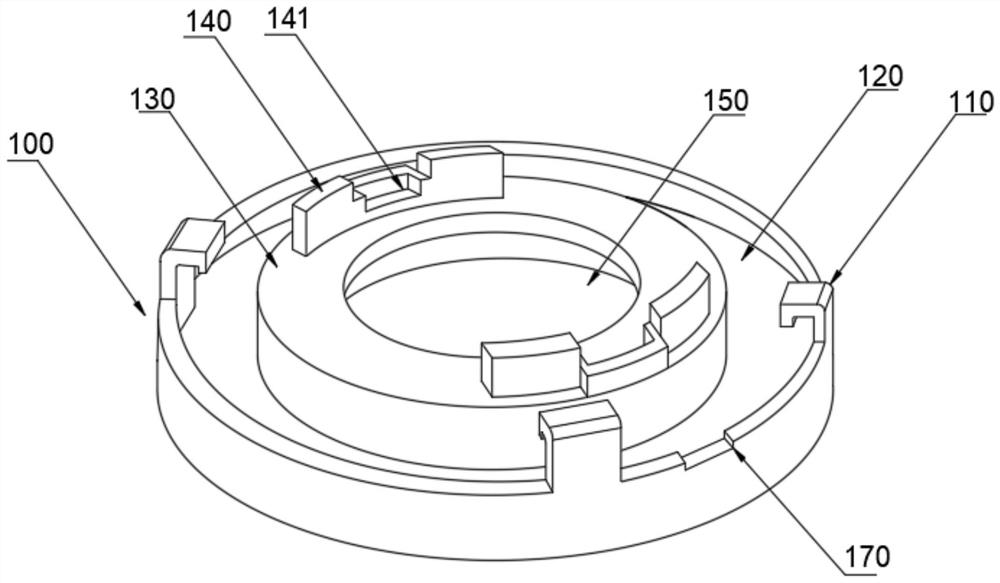

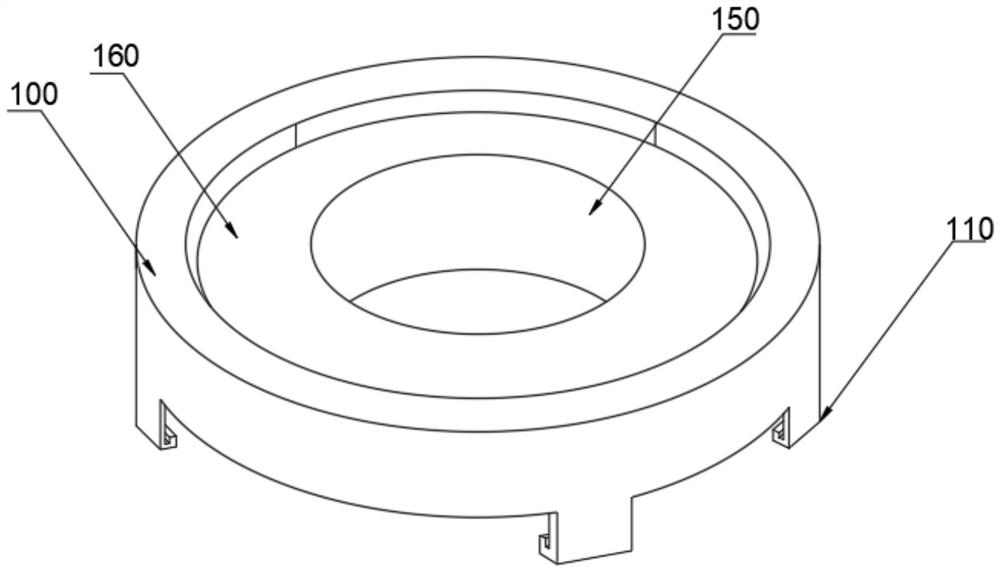

ActiveCN112259672AIncrease the heat exchange areaHave releasedSolid-state devicesSemiconductor devicesEngineeringSilica gel

The invention discloses a low-power LED lamp bead low-thermal-resistance packaging structure and a packaging process. The structure comprises a base, a supporting base, a heat conduction device, a light-emitting assembly, an insulating sleeve and a protection assembly, wherein a first mounting groove is formed in the top of the base, the supporting base is arranged on the inner wall of the first mounting groove, and the supporting base comprises a base plate; a second boss is fixedly installed at the top of the base plate, a bonding pad base is fixedly installed at the top of the second boss,a tangent plane is arranged at the top of the bonding pad base, first inserting grooves are formed in the two sides of the bonding pad base, electrode pins are inserted into the inner walls of the first inserting grooves, and one ends of the electrode pins are fixedly installed on the inner wall of the tangent plane. The invention has the beneficial effects that the fourth installation groove is formed in the bottom of the copper column, a heat conduction pipe is fixedly installed on the inner wall of the fourth installation groove, a fifth installation groove is formed in the inner wall of the heat conduction pipe, a heat conduction column is fixedly installed on the inner wall of the fifth installation groove, first ribs are evenly installed on the outer wall of the heat conduction pipeand the outer wall of the heat conduction column, and gaps between the first ribs are filled with heat dissipation silica gel, so the effect of releasing heat energy is achieved.

Owner:SHENZHEN YULIANG OPTOELECTRONICS TECH

White LED (Light-Emitting Diode) nano-phosphor powder

InactiveCN105932142AIncrease luminous fluxIncreased durabilitySemiconductor devicesCompression moldingFluorescence

This invention discloses a white LED nano-phosphor powder. The nano-phosphor powder comprises nano-amorphous silicon nitride powder body and phosphor powder; the weight of the nano-amorphous silicon nitride powder body is 25 to 35 percentage of the weight of the phosphor powder. The nano-phosphor powder is prepared by the following steps: stirring and prilling the nano-amorphous silicon nitride powder body and the phosphor powder; after obtaining compound phosphor powder, preparing phosphor glue; covering the phosphor glue on a LED chip; and adhering the compound phosphor power on the surface of the LED chip by the gravity. Thus, the white LED nano-phosphor powder has high refractive index and high light transmittance, can protect the LED chip and increase the luminous flux of the LED, has small viscosity, is easy to defoam, is suitable for filling and compression molding, and makes the LED get better durability and reliability.

Owner:安徽众博新材料有限公司

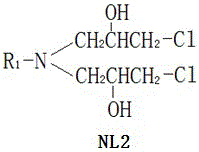

Triester-based quaternary ammonium salt positive ion collecting agent and preparation method and application thereof

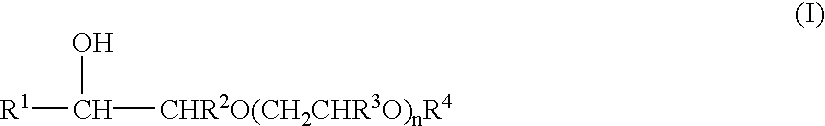

The invention discloses a triester-based quaternary ammonium salt positive ion collecting agent. The general formula I of the collecting agent is as follows, FORMULA, wherein n is any integer from 1 to 3, R is selected from straight chain or branched chain alkyl groups of C12-C21, and X is selected from a helium atom or a bromine atom. A molecule of the triester-based quaternary ammonium salt positive ion collecting agent contains a hydrophilic group hydroxyl which is easy to dissolve; when being applied to mineral flotation, the collecting agent is high in collecting performance and selectivity; formed foams are fine, fragile and easy to eliminate; when the collecting agent is used, no acid is needed to be added for dissolving, so that equipment cannot be corroded; meanwhile, the collecting agent is good in flotation effect under a low-temperature condition; the preparation technology is simple and easy to operate; the triester-based quaternary ammonium salt positive ion collecting agent is environment-friendly.

Owner:WUHAN UNIV OF TECH

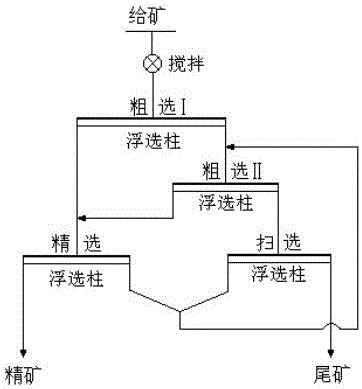

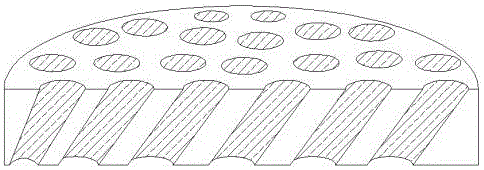

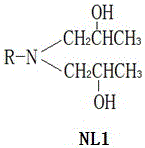

Column type positive ion reversed flotation technology of micro-fine particle hematite

The invention discloses a column type positive ion reversed flotation technology of micro-fine particle hematite; the applied flotation device is a filling type micro-bubble reverse flow contact type flotation pillar. The micro-fine particle hematite enters a stirring bucket firstly and mixes with medicament, and then pumps to a rough selection flotation pillar to perform the rough selection; a foam product of the primary rough selection flotation pillar enters a secondary rough flotation pillar to perform the secondary rough selection; the bottom flows of the primary rough selection flotation pillar and the secondary rough selection flotation pillar are combined and then enter a fine selection flotation pillar to carry out fine selection; the bottom flow of the fine selection flotation pillar is concentrate; the foam product of the secondary rough selection flotation pillar enters a sweeping flotation pillar, and the bottom flow of the sweeping flotation pillar and the foam product of the fine selection flotation pillar are combined and returned to the secondary selection rough flotation pillar by the pump; the foam product of the sweeping flotation pillar is tailings. The technology simplifies the flotation flow and drug preparation of hematite, realizes the constant temperature flotation and reduces the flotation cost.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing paste resin with medium viscosity

The invention discloses a method for preparing paste resin with medium viscosity. The method comprises the following steps: producing the paste resin by using an emulsion polymerization method; adding a monomer and aids into a polymerizing kettle according to a formula proportion; performing vacuumizing and deoxidation, raising the temperature to 50-63 DEG C under a stirring state, performing polymerization reaction at the temperature of 50-63 DEG C, starting to reduce the pressure of 0.83MPa, and ending the reaction when the pressure is reduced to 0.4MPa. The method is characterized in that 1, the tensile strength of leather working gloves produced by using the paste resin with the medium viscosity is higher than that of common leather working gloves; 2, the glossiness of the leather working gloves produced by using the paste resin with the medium viscosity is higher than that of the common leather working gloves; 3, compared with other processes, a process of producing the leather working gloves produced by using the paste resin with the medium viscosity has the advantages of moderate viscosity and simplicity in de-foaming.

Owner:TIANJIN BOTIAN CHEMICAL

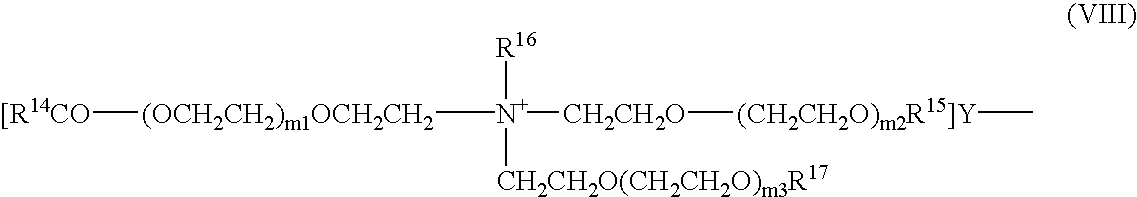

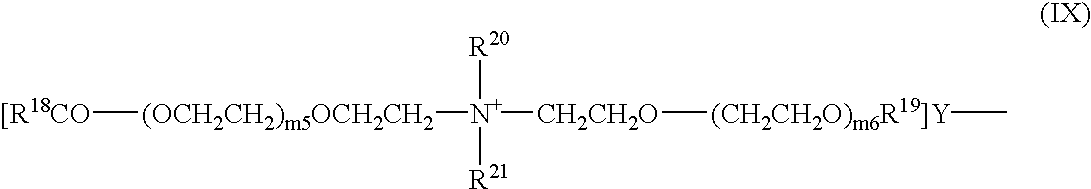

Water-soluble cationic collector and its preparation method and use

Owner:NORTHEASTERN UNIV LIAONING

Novel UV cross-linked cured multi-layer optical adhesive film and application thereof

InactiveCN110684475ANot easy to spill glueAvoid glue overflowFilm/foil adhesivesPolyureas/polyurethane adhesivesUV curingAcrylate ester

The invention relates to a novel UV cross-linked cured multi-layer optical adhesive film. The novel UV cross-linked cured multi-layer optical adhesive film sequentially comprises a first release layer, a first viscous layer, a non-viscous layer, a second viscous layer and a second release layer, wherein the first viscous layer and the second viscous layer each are an acrylate adhesive layer, the non-viscous layer is an ethylene vinyl acetate copolymer layer, and the adhesive film is subjected to UV curing. The invention further provides application of the novel UV cross-linked cured multi-layer optical adhesive film. By adopting the novel UV cross-linked cured multi-layer optical adhesive film and the application thereof, after UV curing, the adhesive layer is not prone to fracturing if being bent, good spatial malleability is achieved, and the phenomena of adhesive overflowing and difficult defoaming in the LOCA optical adhesive fitting process are avoided; in the mold cutting process, wiredrawing does not exist, and adaptability to sizes of fit screens is wide; and the production cost is low, processing is easy, the solid content is 100%, energy conservation and environmental protection are achieved, in the processing and use processes, defoaming is easy, adhesive overflowing is avoided, adaptability is wide, and the fitting good product rate is increased.

Owner:SHANGHAI HIUV NEW MATERIALS +1

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

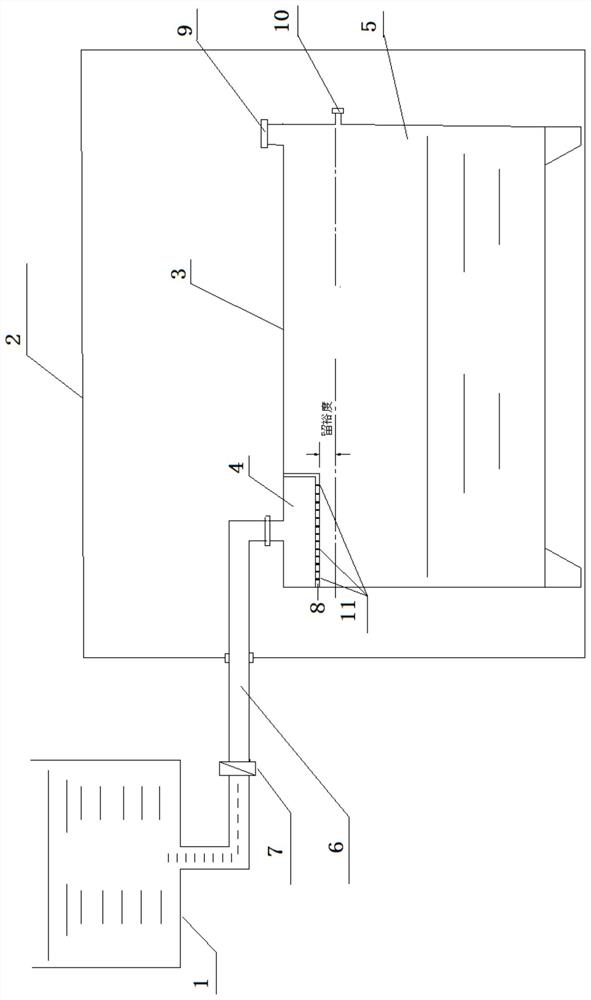

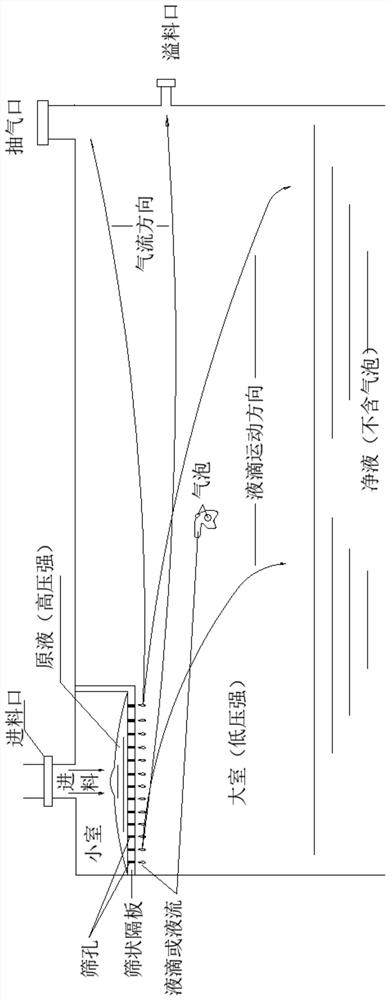

Method for carrying out vacuum defoaming on high-viscosity liquid by utilizing pressure difference and aerodynamic force generated by gas contained in liquid

ActiveCN112973196AIncreases the chance of exposure to liquid surfacesEfficient defoamingFlash degasificationEngineeringControl valves

The invention discloses a method for carrying out vacuum defoaming on high-viscosity liquid by utilizing pressure difference and aerodynamic force generated by gas contained in the liquid. A system is designed and comprises a hopper arranged outside a vacuum box and a defoaming container arranged in the vacuum box; the hopper is in closed connection with a feeding hole in one side of the top of a degassing container in the vacuum box and a small cutting chamber through a bottom control valve and a conveying pipe, the small chamber is communicated with a large defoaming chamber of the container through a sieve-shaped partition plate, and the large chamber is communicated with the vacuum box only through an extraction opening in the top of the other side of the container and an overflow opening in the middle of the side surface; and the overflow port is lower than the sieve-shaped partition plate. During working, the vacuum box is vacuumized, the valve is opened, the stock solution in the hopper flows through the small chamber and the large chamber under the action of pressure, and defoaming is completed under the action of aerodynamic force. An additional power device is not needed, and the whole device is simple and effective. The actual operation of defoaming the liquid with the viscosity of 50,000-120,000 cps proves that the method is effective.

Owner:悉瑞绿色电气(苏州)有限公司

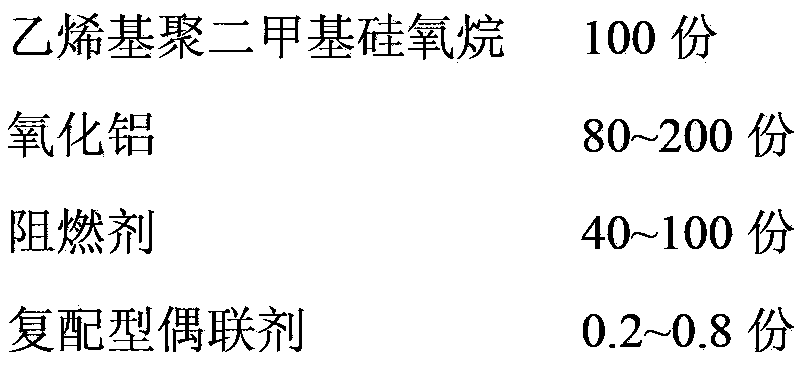

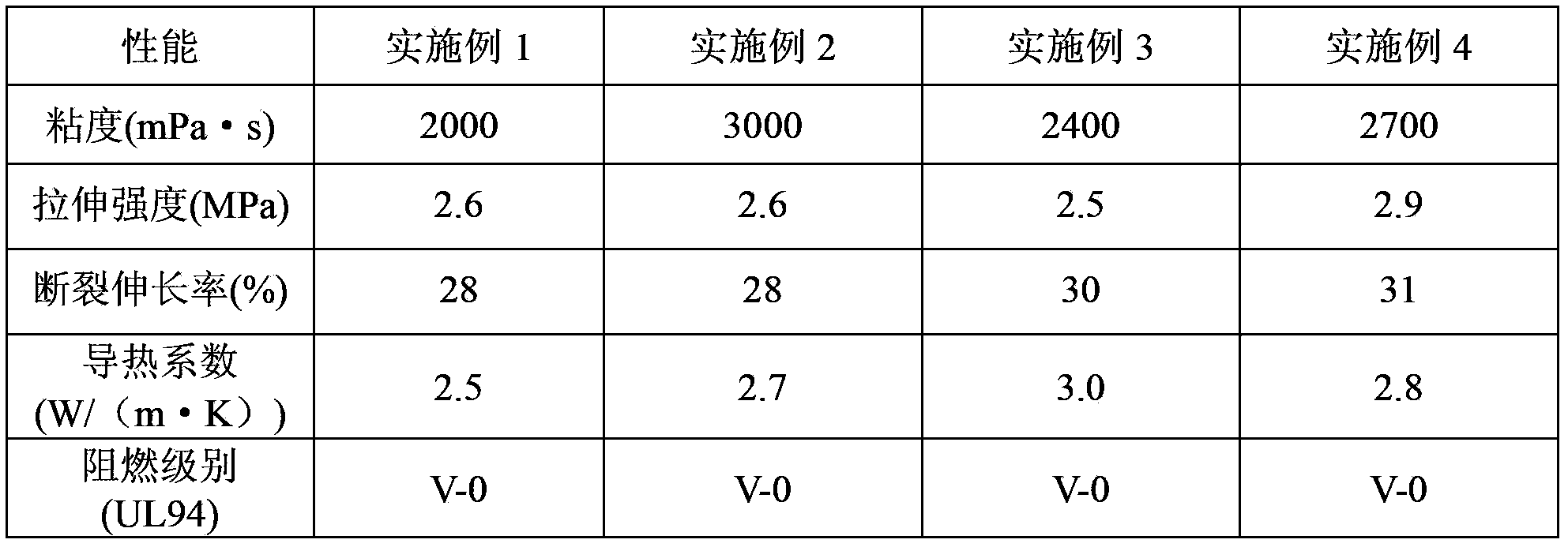

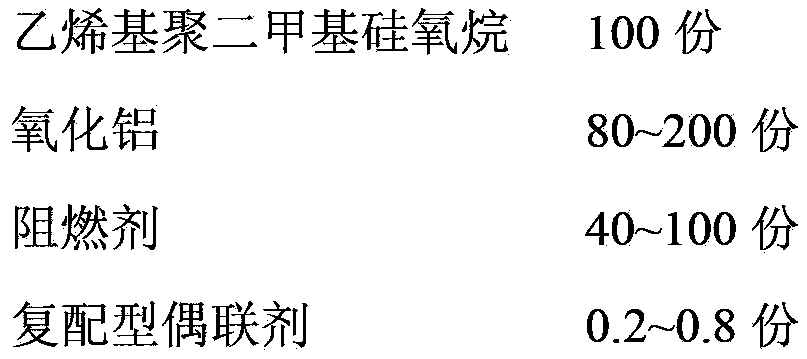

Low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and preparation method thereof

ActiveCN103146340BGood compatibilityLower surface energyNon-macromolecular adhesive additivesOther chemical processesSealantDimethyl siloxane

The invention provides low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and a preparation method thereof. The method comprises the following steps of: mixing high viscosity and low viscosity of vinyl polydimethylsiloxane; adding aluminum oxide with particle size of 1-5 microns as heat conduction filler; further adding a compound coupling agent formed by combining aluminic acid ester, KH570 (gamma-methylacryloyloxypropyl trimethoxysilane) and KH550 (gamma-aminopropyl triethoxysilane) and a compound flame retardant formed by combining melamine cyanurate and aluminum hydroxide into a base material system; and preparing the electronic pouring sealant according to a proper proportion. The prepared pouring sealant has high heat conductivity up to 2.5-3.0W.m<-1>.K<-1>, low viscosity of 2000-3000mPa.s, perfect fluidity and good flame retardance effect; and the production cost is low.

Owner:GUANGZHOU GLORYSTAR CHEM

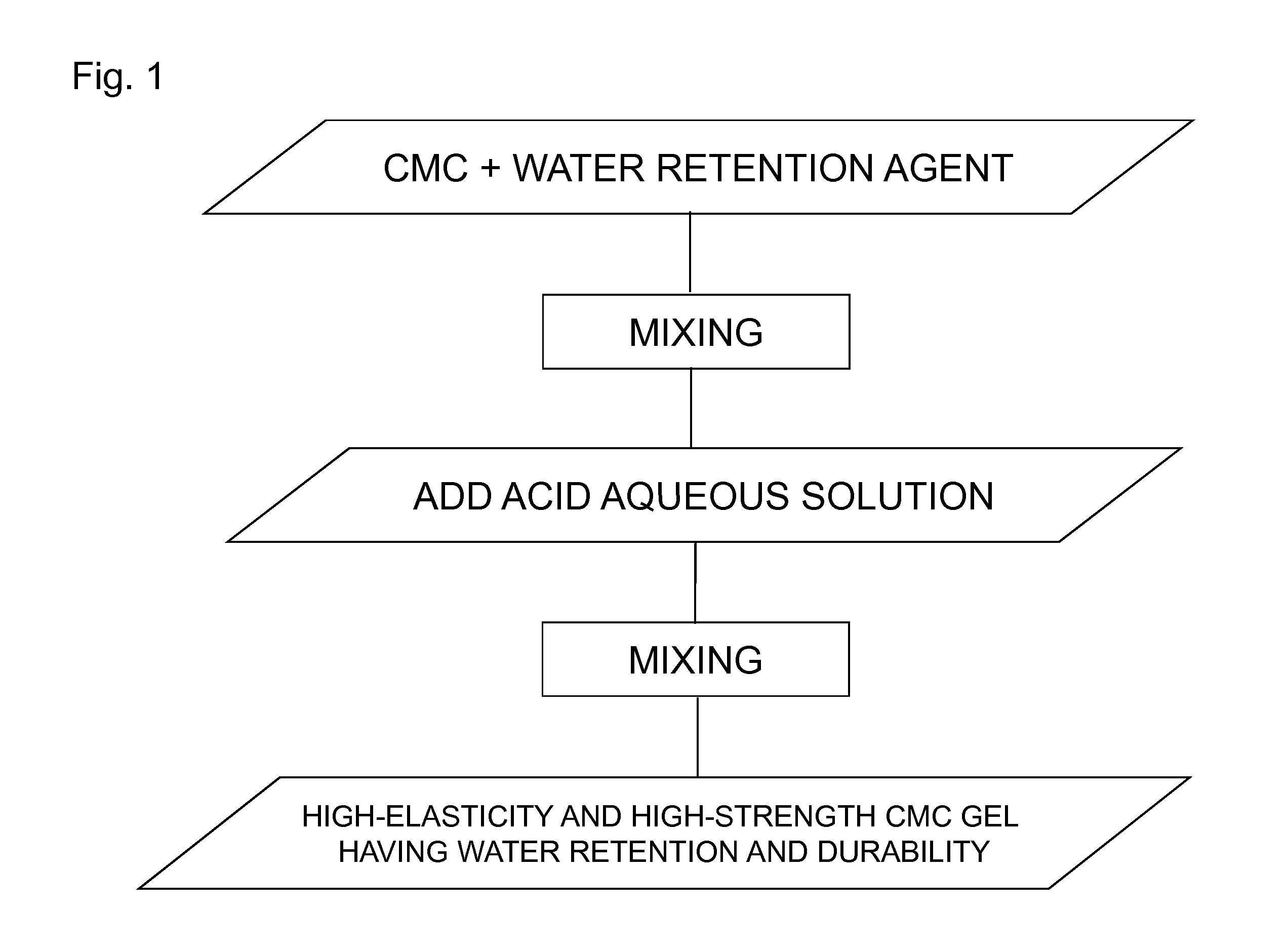

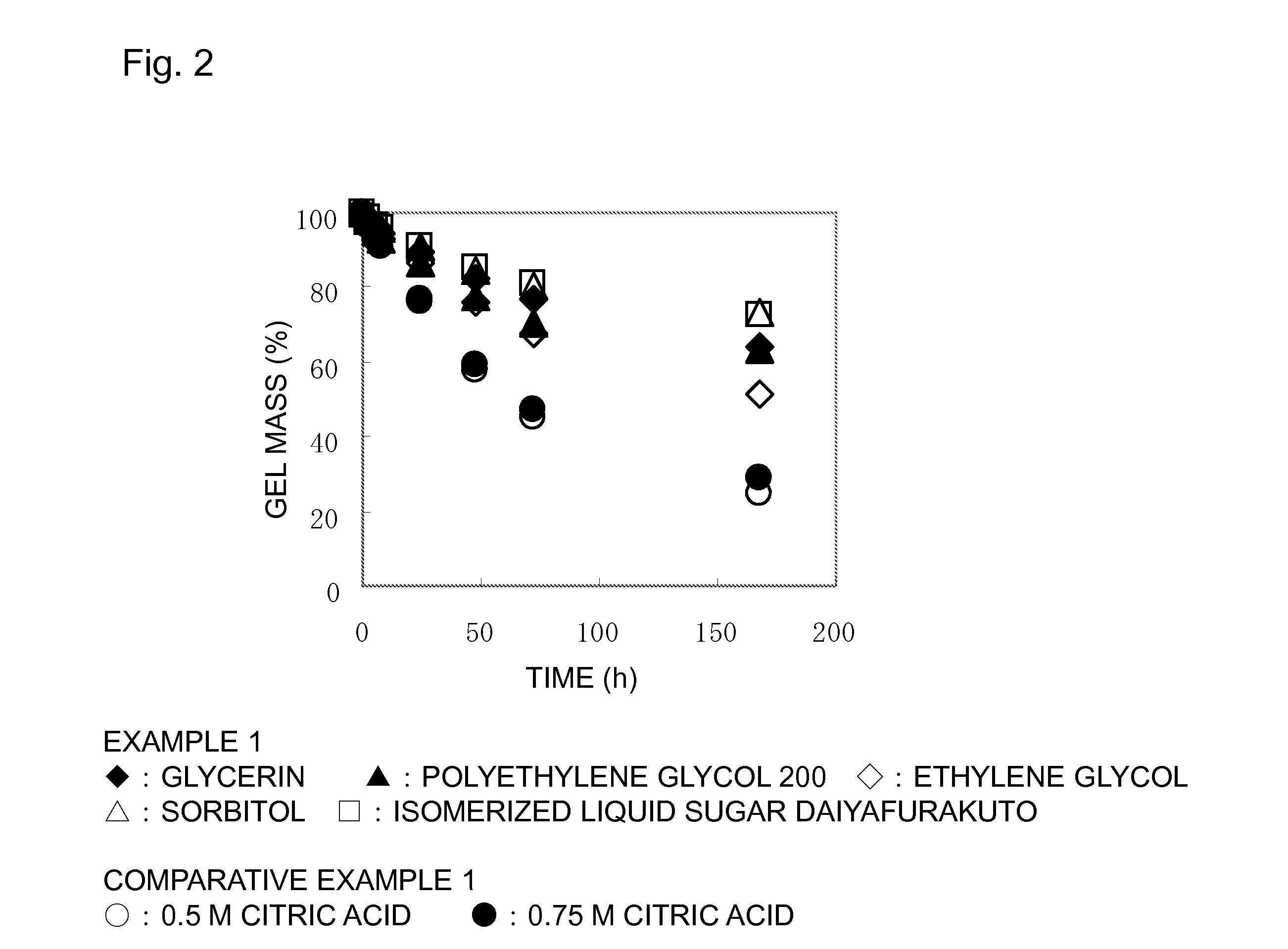

Process for producing gel of carboxymethyl cellulose alkali metal salt

InactiveUS20120071569A1Increase elasticityHigh strengthCosmetic preparationsToilet preparationsCarboxymethyl celluloseAqueous solution

To provide a method for producing a gel of a carboxymethyl cellulose alkali metal salt, in which a gel having high elasticity and strength and also having excellent water retention and durability can be obtained inexpensively and simply.The method for producing a gel of a carboxymethyl cellulose alkali metal salt of the present invention includes previously mixing a mixture containing a carboxymethyl cellulose alkali metal salt and a water retention agent and subsequently mixing the resulting mixture with an acid aqueous solution to obtain a gel.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP +1

A polyurethane template for modeling concrete and its preparation process

The invention provides a polyurethane template for modeling concrete and a preparation method thereof. The polyurethane template raw materials include hydroxyl-terminated silicone polyether polyol, isocyanate, chain extender, filler, plasticizer, anti-aging agent, color paste, anti-settling agent, defoamer, catalyst, water remover, sepiolite powder, boron nitride nanotubes, cross-linked polytetrafluoroethylene powder, alkali-resistant glass fiber; preparation method: polyol polyether polyether with hydroxyl-terminated silicone, chain extension agent, filler, plasticizer, and anti-aging agent to obtain mixture A; mix sepiolite powder, boron nitride nanotubes, and cross-linked polytetrafluoroethylene powder to obtain mixture B; mix alkali-resistant glass fiber with color paste Obtain mixture C; mix mixture A, B, C, anti-sedimentation agent, defoamer, catalyst, water remover and isocyanate, and then perform stirring, defoaming, mold casting and curing in sequence to obtain a polyurethane template. The polyurethane template of the present invention has excellent performance, and the material body has low viscosity during the preparation process, is easy to defoam and is easy to operate.

Owner:重庆千美集科技有限公司

Visible light-cured adhesive and application thereof

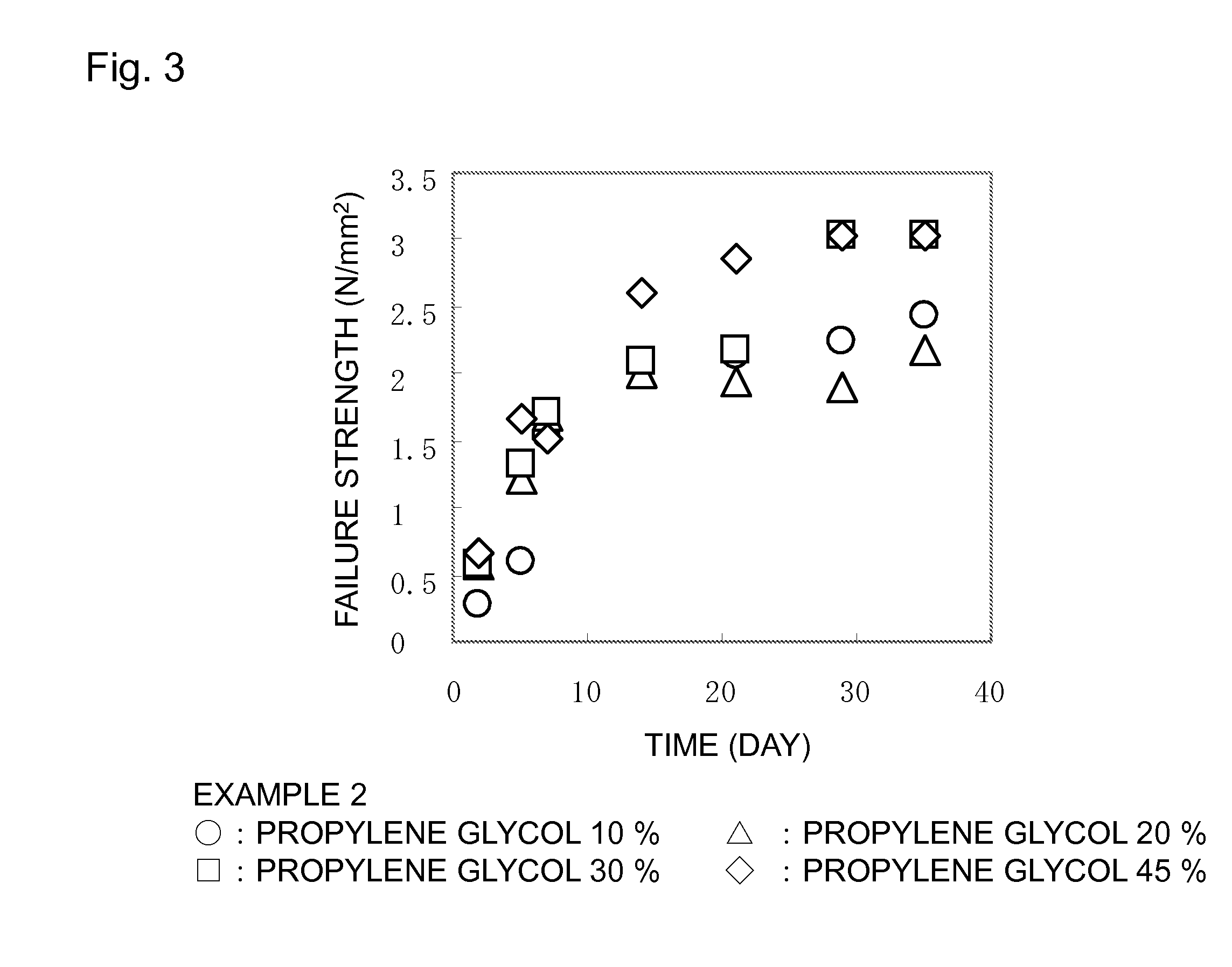

InactiveCN110128995AGood self-levelingEasy to defoamNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesLeveling effectGlass cover

The invention discloses a visible light-cured adhesive, which comprises the following ingredients (by weight): 20-65 parts of polyurethane acrylate, 15-70 parts of a light-cured monomer, 1-8 parts ofa photoinitiator, 0.2-8 parts of a leveling agent, 0.1-5 parts of an antifoaming agent and 0.2-4 parts of a coupling agent. The photoinitiator is an organic phosphine photoinitiator. The visible light-cured adhesive can be cured under visible light, and the curing process is very convenient. When being applied between a display screen and a glass cover plate, the visible light-cured adhesive has agood self-leveling effect, is easy to discharge foams, has an adhesion effect, and makes the glass cover plate and the display screen to be tightly combined and improves wear resistance. In addition,the visible light-cured adhesive has low application cost. In comparison with the application cost of a traditional UV photocureable adhesive, the application cost of the visible light-cured adhesiveis greatly reduced.

Owner:GUANGDONG INST OF SCI & TECH

Insulative potting composite material with high thermal conductivity and preparation method thereof

The invention discloses an insulative potting composite material with high thermal conductivity and a preparation method thereof. The insulative potting composite material is prepared by mixing a component A with a component B at a weight ratio of 1:1 and solidifying at the temperature of 50-150 DEG C for 20-50 minutes. The insulative potting composite material has the advantages that the thermalconductivity reaches 3.5 W / m.K (ASTM D5470, HotDish method) and the electrical insulation property and mechanical properties are excellent. According to the invention, the insulative potting composite material with high thermal conductivity is prepared by using vinyl silicone oil as a base adhesive and hydrogen-containing silicone oil as a solidifying agent, using spherical, flaky, acicular and prismatical heat-conducting fillers to fill, and forming plenty of heat conducting channels by virtue of the reasonable combination of the heat-conducting fillers of different shapes; and the solidified insulative potting composite material has excellent electrical properties and mechanical properties.

Owner:HEFEI BOFA NEW MATERIAL TECH

Wet spinning method of cellulose carbamate

InactiveCN107523889AGuaranteed temperatureStable temperatureArtificial filaments from cellulose derivativesWet spinning methodsFiberCellulose

The invention relates to a wet spinning method of cellulose carbamate. The wet spinning method comprises steps as follows: 1) filtration: all pipelines, middle barrel and filters used in the filtration process are in jacket type, and the temperature of a circulation liquid in the jackets is controlled at 8-15 DEG C; 2) temperature adjustment: the temperature of a plate type heat exchanger is controlled at 12-30 DEG C before defoaming; 3) defoaming: the absolute vacuum degree of a continuous vacuum defoamer (basket type or overflow type) is controlled between 97 mpa.s and 99.9 mpa.s; 4) acid bath forming: colloid directly enters an acid bath of a spinning machine for spinning and acid-bath forming after being defoamed and filtered, and fiber tows are regenerated; 5) secondary bath drafting forming: the fiber tows formed in the acid bath are subjected to drafting forming through a draw-off godet and moves to a secondary bath provided with a first-stage drafting machine, wherein the secondary batch contains 0-5% of sulfuric acid and has the temperature of 25-70 DEG C; 6) refining: all that is required is that the fiber tows are washed, blanched (or not blanched), oiled, opened and dried in a drying machine for packaging in the refining process.

Owner:孙飞勇

A low-power LED lamp bead low thermal resistance packaging structure and packaging process

ActiveCN112259672BIncrease the heat exchange areaHave releasedSolid-state devicesSemiconductor devicesHeat resistanceEngineering

The invention discloses a low-power LED lamp bead low-thermal-resistance packaging structure and packaging technology. The technical solution is: including a base, a support seat, a heat conduction device, a light-emitting component, an insulating sleeve and a protection component, and an installation groove is opened on the top of the base. 1. The inner wall of the installation groove 1 is provided with a support seat, the support seat includes a chassis, the top of the chassis is fixedly installed with the boss 2, the top of the boss 2 is fixedly installed with a pad seat, and the top of the pad seat A cut surface is provided, a slot 1 is opened on both sides of the pad seat, an electrode pin is plugged into the inner wall of the slot 1, and one end of the electrode pin is fixedly installed on the inner wall of the cut surface. The beneficial effects of the present invention are: the copper column The bottom is provided with installation groove 4, and the inner wall of installation groove 4 is fixedly installed with a heat conduction pipe. The gap of the sheet is filled with heat dissipation silica gel, which has the effect of releasing heat energy.

Owner:SHENZHEN YULIANG OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com