Self-defoaming water-based polyurethane emulsion

A water-based polyurethane and emulsion technology, applied in the field of polyurethane emulsion, can solve the problems of poor defoaming durability of external defoaming agent, poor compatibility of defoaming agent and polyurethane, and large-scale foam production efficiency, etc., to achieve good hand feeling, Increased glass transition temperature and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

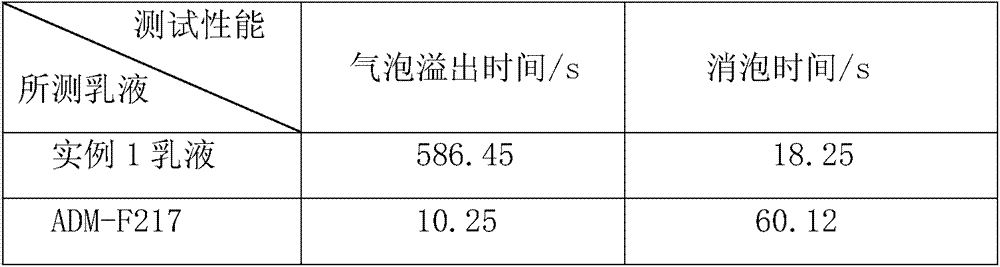

Embodiment 1

[0024] The self-defoaming aqueous polyurethane emulsion of the present embodiment is prepared by the method comprising the following steps:

[0025] (1) Material preparation:

[0026] Prepare raw materials according to the following components and quality: 10.00g isophorone diisocyanate, 10.00g hexamethylene diisocyanate, 30.00g commercially available polybutylene adipate (Mn=3000), 10.00g commercially available hydroxyl Silicone oil (Mn=300, hydroxyl content 9.0%), 5.00g hydrophilic chain extender 2,2-dimethylolbutyric acid, 0.50g chain extender ethylene glycol, 1.00g chain extender diethylenetriamine, 0.50 g crosslinking agent glycerol, 3.00g neutralizing agent N,N-dimethylethanolamine, 30.00g urethane grade acetone (about 38.00ml);

[0027] (2) Preparation of prepolymer:

[0028] Add 30.00g of polybutylene adipate (Mn=3000) into a four-neck flask equipped with a thermometer, condenser and stirrer, vacuumize and heat to 110°C, remove water for 2.0h, and then add 10.00g of ...

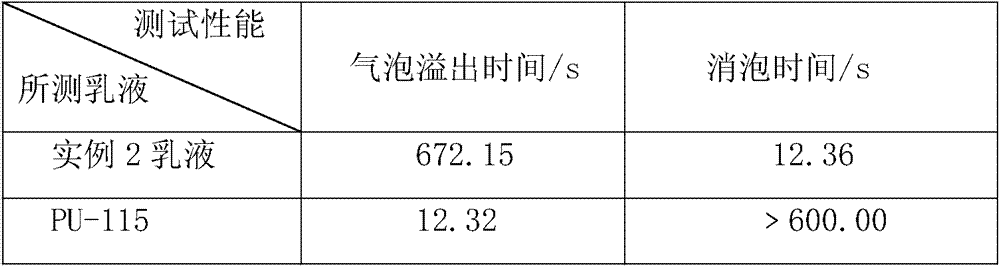

Embodiment 2

[0037] The self-defoaming aqueous polyurethane emulsion of the present embodiment is prepared by the method comprising the following steps:

[0038] (1) Material preparation:

[0039] Prepare raw materials according to the following components and quality: 25.00g hexamethylene diisocyanate, 25.00g commercially available polycarbonate (Mn=2000), 15.00g commercially available hydroxyl silicone oil (Mn=400, hydroxyl content 8.50%), 6.00g Hydrophilic chain extender 2,2-dimethylolbutyric acid, 2.50g chain extender triethylene glycol, 2.00g chain extender triethylenetetramine, 1.00g crosslinking agent trimethylolpropane, 3.50 g neutralizer N,N-dimethylethanolamine, 20.00g acetone (about 25.00ml);

[0040] (2) Preparation of prepolymer:

[0041] Add 25.00g of polycarbonate (Mn=2000) into a four-neck flask equipped with a thermometer, condenser and stirrer, vacuumize and heat to 120°C, remove water for 1.5h, then add 15.00g of hydroxy silicone oil and cool down to 75 Stir at ℃ for ...

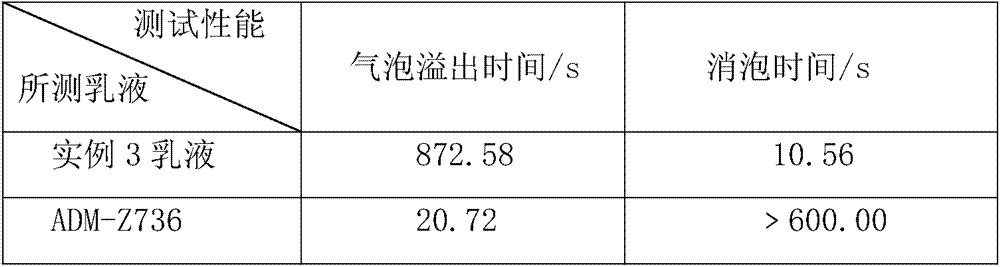

Embodiment 3

[0050] The self-defoaming aqueous polyurethane emulsion of the present embodiment is prepared by the method comprising the following steps:

[0051] (1) Material preparation:

[0052] Prepare raw materials according to the following components and quality: 30.00g hexamethylene diisocyanate, 20.00g commercially available polyneopentyl adipate (Mn=3000), 20.00g commercially available hydroxyl silicone oil (Mn=500, hydroxyl content 8.0%), 7.00g hydrophilic chain extender 2,2-dimethylolbutyric acid, 7.00g chain extender triethylene glycol, 0.50g chain extender triethylenetetramine, 1.50g crosslinking agent triethylene glycol Methylolpropane, 4.00g neutralizer N,N-dimethylethanolamine, 10.00g butanone (about 13.00ml);

[0053] (2) Preparation of prepolymer:

[0054] Add 20.00g of polyneopentyl glycol adipate (Mn=3000) into a four-neck flask equipped with a thermometer, condenser and stirrer, vacuumize and heat to 130°C, remove water for 1.0h, then add 20.00g Hydroxyl silicone oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com