Low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and preparation method thereof

A silicone, high thermal conductivity technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem that the heat of electronic equipment cannot be dissipated in time, affects the reliability and life of electronic components, and uses a large amount of thermally conductive fillers, etc. problem, to achieve the effect of small distance, good mechanical properties and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

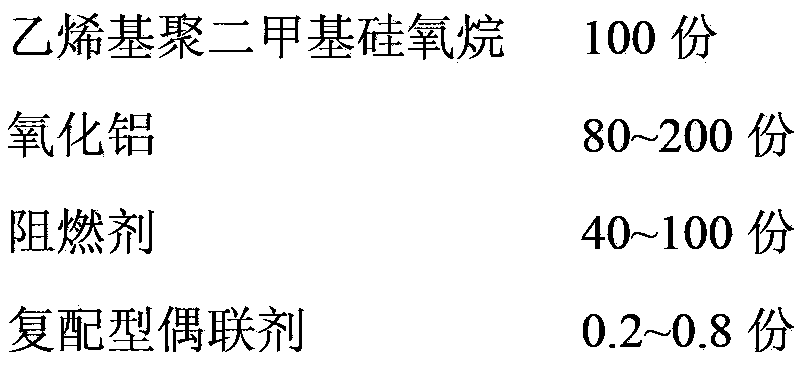

Method used

Image

Examples

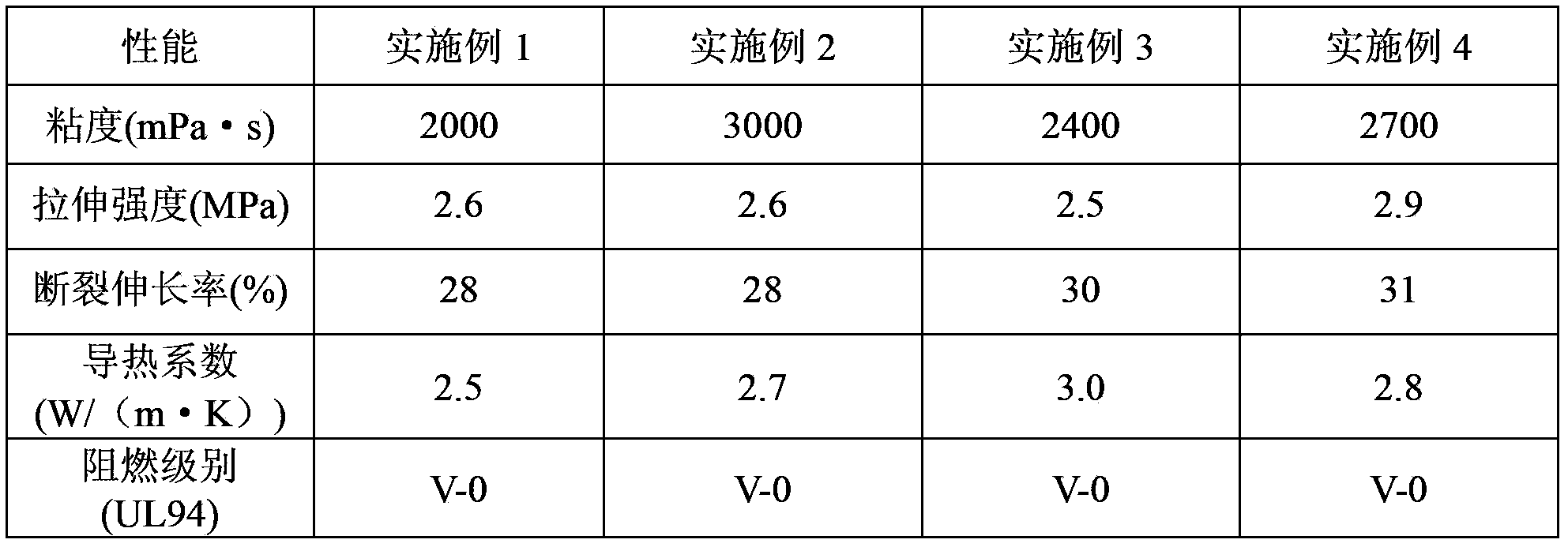

Embodiment 1

[0030] 1) Preparation of base material: 100 parts by weight of branched vinyl polydimethylsiloxane, 80 parts by weight of spherical alumina with a particle size of 1.6 μm, and 40 parts by weight of flame retardant were added to vacuum kneading In the machine, under the conditions of 110°C and vacuum degree of 0.06-0.1MPa, add 0.2 parts by weight of the complex coupling agent diluted with ethanol alcohol solution with water to it dropwise while stirring, then dehydrate and blend for 2 hours, and cool Finally, grind 3 times with a three-roll machine to obtain the base material;

[0031] Wherein, the branched-chain vinyl polydimethylsiloxane is a branched-chain type with viscosities of 1000mPa·s (vinyl content 0.5wt%) and 200mPa·s (vinyl content 0.1wt%) A combination of vinyl polydimethylsiloxane in a mass ratio of 3:2; the flame retardant is a combination of melamine cyanurate and aluminum hydroxide in a mass ratio of 1:2; the compound type The coupling agent is a combination o...

Embodiment 2

[0036]1) Preparation of base material: Add 100 parts by weight of linear vinyl polydimethylsiloxane, 200 parts by weight of spherical alumina with a particle size of 5 μm, and 100 parts by weight of flame retardant into a vacuum kneader At 130°C and a vacuum of 0.06 to 0.1 MPa, 0.8 parts by weight of a complex coupling agent diluted with ethanol alcohol solution in water was added dropwise while stirring, and then dehydrated and blended for 5 hours. After cooling, Obtain the base material by grinding 4 times with a three-roll machine;

[0037] Wherein, the linear vinyl polydimethylsiloxane is a linear polydimethylsiloxane with a viscosity of 1000mPa·s (vinyl content is 1.0wt%) and 500mPa·s (vinyl content is 0.5wt%) A combination of vinyl polydimethylsiloxane in a mass ratio of 3:5; the flame retardant is a combination of melamine cyanurate and aluminum hydroxide in a mass ratio of 1:5; the compound type The coupling agent is a combination of aluminate, KH570 and KH550 with a ...

Embodiment 3

[0042] 1) Preparation of base material: Add 100 parts by weight of linear vinyl polydimethylsiloxane, 160 parts of spherical alumina with a particle size of 3 μm, and 70 parts by weight of flame retardant into a vacuum kneader , under the conditions of 120°C and vacuum degree of 0.06-0.1MPa, 0.5 parts by weight of compound coupling agent diluted with ethanol alcohol solution of water was added dropwise to it while stirring, and then dehydrated and blended for 4 hours, cooled and used The three-roll machine grinds 3 times to obtain the base material;

[0043] Wherein, the linear vinyl polydimethylsiloxane is linear vinyl polydimethylsiloxane with viscosities of 1000mPa·s (vinyl content 0.8%) and 400mPa·s (vinyl content 0.3%) respectively. A combination of polydimethylsiloxane in a mass ratio of 3:4; the flame retardant is a combination of melamine cyanurate and aluminum hydroxide in a mass ratio of 1:3; the complex coupling The agent is a combination of aluminate, KH570 and KH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com