Water-soluble cationic collector and its preparation method and use

A technology of water-soluble cations and collectors, applied in the preparation of mineral processing agents, amine cation collectors and their preparation fields, can solve problems such as hindering the application of cation flotation process, easy to corrode equipment, etc., to achieve easy defoaming, Easy to operate, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

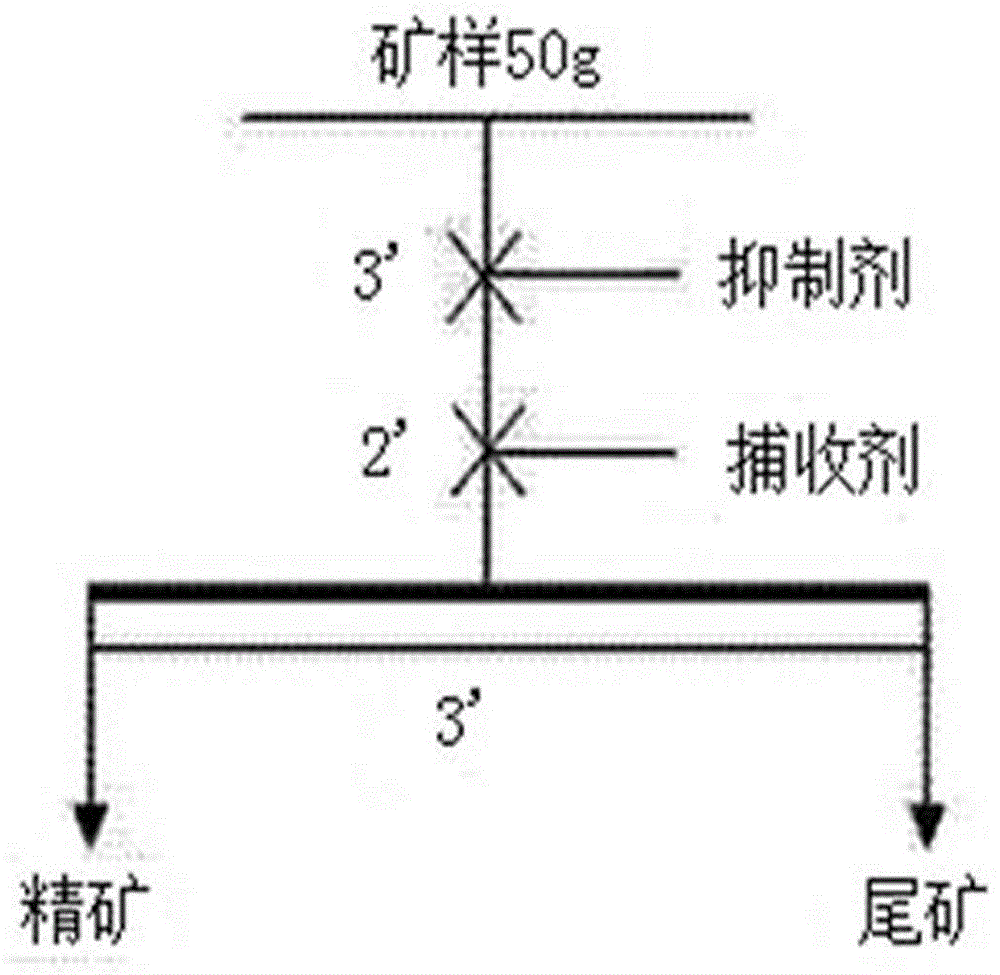

Method used

Image

Examples

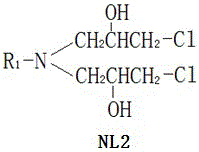

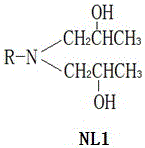

Embodiment 1

[0024] Add 0.10mol decylamine and 100mL absolute ethanol into a 250mL three-necked flask equipped with a thermometer and a reflux condenser, and fix the three-necked flask in a 25°C water bath equipped with a constant temperature magnetic stirrer; heat, stir, and within 3h Slowly add 0.2mol propylene oxide liquid dropwise, and stir continuously for 10 h after the dropwise addition is completed; after the reaction is completed, transfer the reactants in the three-neck flask to a round-bottomed flask of a rotary evaporator for distillation, and evaporate the unreacted epoxy Propane and ethanol; first adjust the temperature of the water bath to be 35 degrees, evaporate the unreacted propylene oxide, then adjust the temperature of the water bath to be 79 degrees, and evaporate the absolute ethanol; stop heating, cool the system, and the The reactant is poured into a beaker, and a transparent high-viscosity liquid can be obtained, which is the new collector N,N-bis(2-hydroxypropyl)d...

Embodiment 2

[0026] Add 0.10mol laurylamine and 100mL absolute ethanol into a 250mL three-necked flask equipped with a thermometer and a reflux condenser, and fix the three-necked flask in a 25°C water bath equipped with a constant temperature magnetic stirrer; heat, stir, and in 3.5h Slowly add 0.25mol propylene oxide liquid dropwise, and continuously stir for 10 h after the dropwise addition is completed; after the reaction is completed, transfer the reactants in the three-neck flask to a round-bottomed flask of a rotary evaporator for distillation, and evaporate the unreacted epoxy Propane and ethanol; first adjust the temperature of the water bath to be 35 degrees, evaporate the unreacted propylene oxide, then adjust the temperature of the water bath to be 79 degrees, and evaporate the absolute ethanol; stop heating, cool the system, and the The reactant is poured into a beaker, and a transparent high-viscosity liquid can be obtained, which is the new collector N,N-bis(2-hydroxypropyl)d...

Embodiment 3

[0028] Add 0.10mol palmitamine and 100mL absolute ethanol into a 250mL three-necked flask equipped with a thermometer and a reflux condenser, and fix the three-necked flask in a 25°C water bath equipped with a constant temperature magnetic stirrer; heat, stir, and in 2.5h Slowly add 0.3mol propylene oxide liquid in the tank, and stir continuously for 10 h after the addition; after the reaction is completed, transfer the reactants in the three-neck flask to a round-bottomed flask of a rotary evaporator for distillation, and evaporate the unreacted rings. Propylene oxide and ethanol; first adjust the temperature of the water bath to 35 degrees, evaporate the unreacted propylene oxide, then adjust the temperature of the water bath to 79 degrees, and evaporate the absolute ethanol; stop heating, cool the system, and put the The reactant is poured into a beaker, and a transparent high-viscosity liquid can be obtained, which is a new collector N,N-bis(2-hydroxypropyl)hexadecylamine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com