Mgf2-caf2 Binary System Sintered Body For Radiation Moderator And Method For Producing The Same

A manufacturing method and radiation technology, applied in the directions of X-ray/γ-ray/particle irradiation therapy, radiation/particle treatment, reactor, etc., can solve the problems of not easy foaming control, easy foaming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

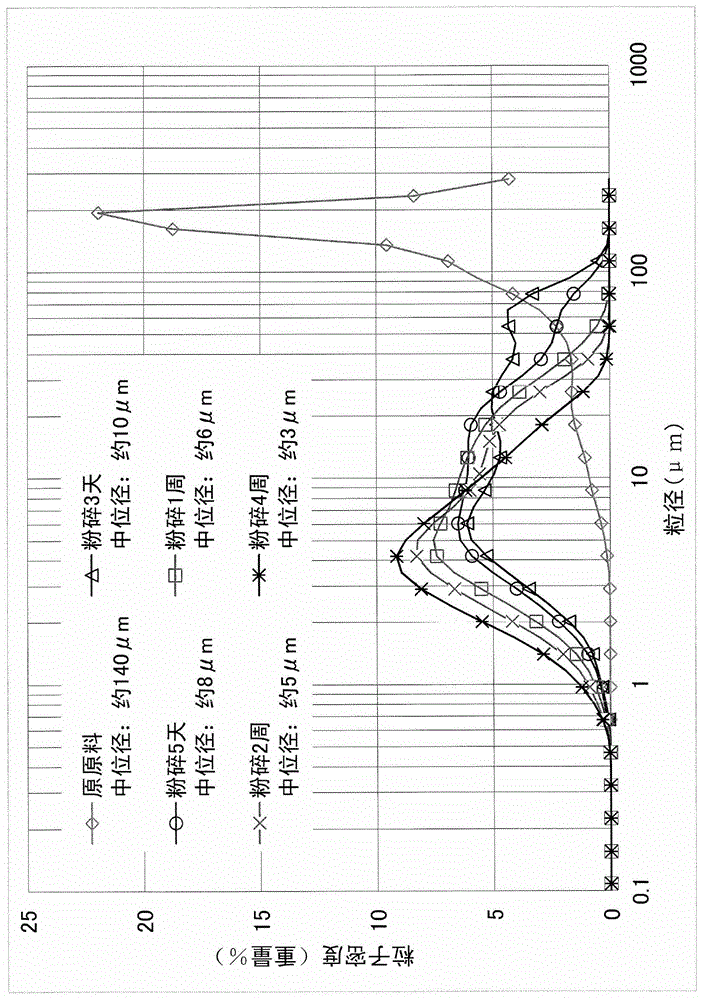

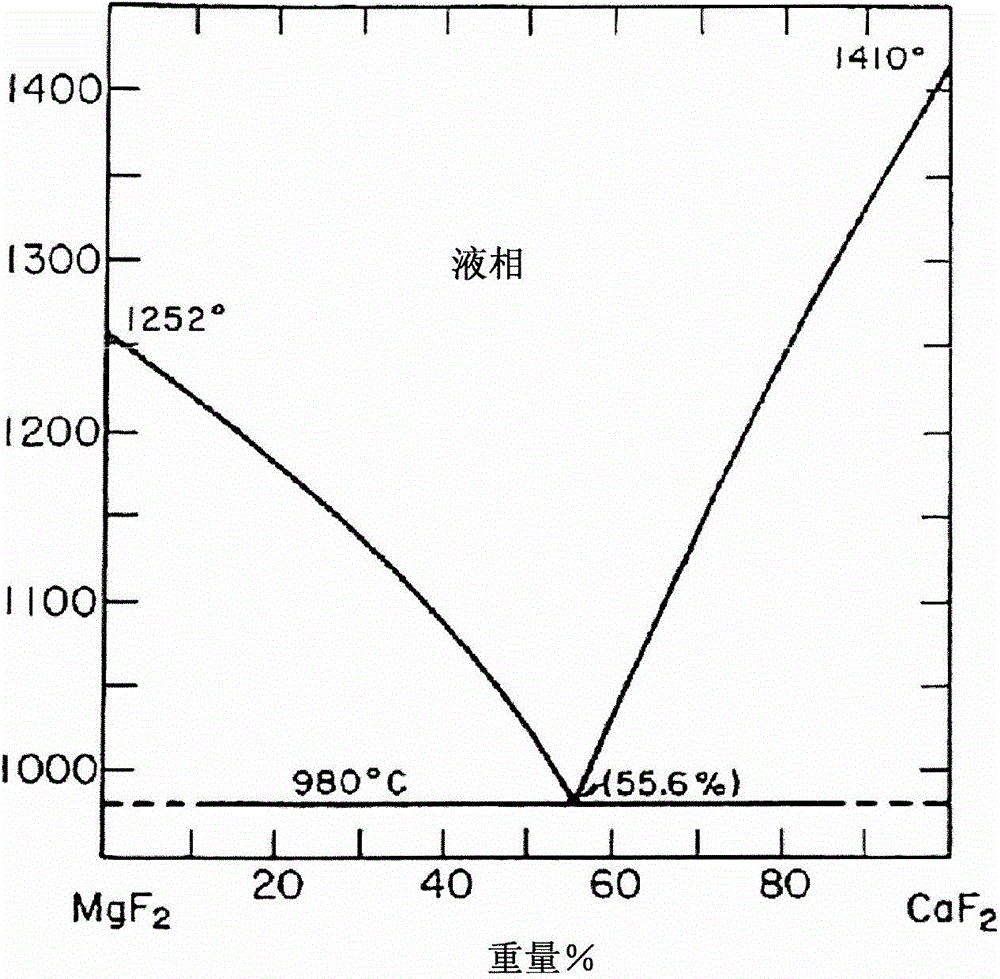

[0261] In high-purity MgF as the main raw material 2 CaF is mixed in a ratio of 1.5% by weight to the powder (average particle size: 4 μm, purity: 99.9% by weight or more) 2 The powder (average particle size 4 μm, purity 99.9% by weight or more) was mixed in a ball mill for 12 hours. Then, relative to the mixture 100, a hydroxymethylcellulose (CMC) solution was added as a sintering aid at a ratio of 0.1% by weight, and the resulting mixture was used as a starting material after mixing in a pot mill for 12 hours.

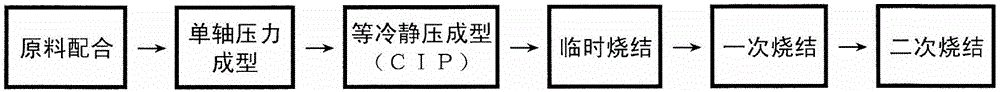

[0262] Fill the starting material into the template of the uniaxial pressure molding machine (the inner size of the template is 220mmx220mmx 150mm in height), and the uniaxial pressure is added to 20MPa for compression and molding. Put the pressure-formed body (about 220mmx220mmxt85mm in size) into a thick plastic bag, degas it, and fill the enclosed molded body into the forming part of the cold isostatic pressing (CIP) machine (internal dimensions: diameter 350mmx ...

Embodiment 2

[0269] In MgF as the main raw material 2 Powder (average particle size 6μm, purity 99.9% by weight) was mixed with CaF at a ratio of 0.2% by weight 2 The powder (average particle size 6 μm, purity 99.9% by weight) was mixed in a ball mill for 12 hours. Then, a CIP molded body was produced under the same molding conditions as in Example 1 above, and the CIP molded body was subjected to a preliminary sintering process at 640° C. for 6 hours in an air atmosphere to obtain a temporary sintered body.

[0270] The temporary sintered body is heated from room temperature to 800°C at a certain speed in a helium atmosphere for 6 hours, and after maintaining the temperature for 5 hours, it is heated to 920°C at a certain speed for 4 hours, and the temperature is maintained 1 hour. Then the furnace is cooled to 100°C of the take-out temperature and taken out. The bulk density of the sintered body is 2.97g / cm 3 (true density 3.15g / cm 3 , relative density 94.3%), somewhat light, but no...

Embodiment 3

[0273] As in the case of Example 1 above, MgF 2 Powder mixed with CaF at a ratio of 2% by weight 2 Powder, mixed in a ball mill for 12 hours. Then 1.0% by weight of calcium stearate (SAC) was added as a sintering aid, and after mixing in a pot mill for 12 hours, the mixture was used as a starting material.

[0274] Using a uniaxial press molding machine, press molding was performed at a pressing pressure of 30 MPa, and then, using a cold isostatic pressing molding machine (CIP), CIP molding was performed at a CIP pressure of 30 MPa. This CIP molded body was subjected to provisional sintering at 700° C. for 6 hours in an air atmosphere to obtain a provisional sintered body.

[0275] The temporary sintered body was heated from room temperature to 840° C. at a constant rate over 6 hours in the air atmosphere, and the temperature was maintained for 8 hours. Then the temperature was raised to 1150° C. at a certain speed in 2 hours, and the temperature was maintained for 0.75 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loose density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com