Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

A polymetallic ore, niobium and tantalum technology, applied in the field of mineral processing technology, can solve the problems of narrow application range, lithium loss, long process, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

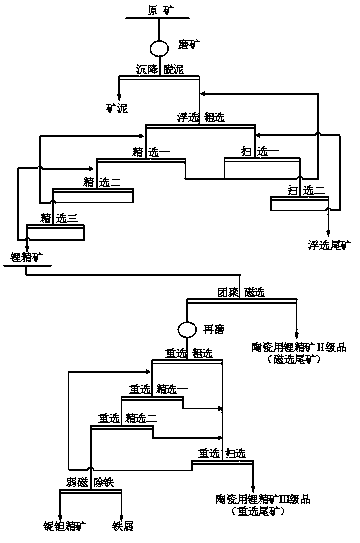

Method used

Image

Examples

Embodiment 1

[0034] Introduction to ore properties: A super-large lithium polymetallic deposit in China, raw ore Li 2 O grade 1.48%, Nb 2 o 5 Grade 0.0115%, Ta 2 o 5 The grade is 0.0041%, and the Sn grade is lower than the industrial grade, which is 0.026%. The useful minerals mainly include spodumene, lepidolite and niobium-tantalite, and the main gangue minerals are feldspar and mica. The ore is open-pit mining, with a high degree of surface weathering and a large amount of mud. It is located in an alpine and high-altitude area, and the associated niobium and tantalum minerals have a finer particle size, with a particle size of less than 0.045mm accounting for 74.01%, which is comparable to the spodumene mineral particle size in the ore (Particle size greater than 0.074mm accounts for 92%). The difference is large, and the comprehensive recovery is difficult. The lithium concentrate obtained by the traditional "gravity separation-magnetic separation-gravity separation tailings float...

Embodiment 2

[0043] Introduction to ore properties: a lithium polymetallic deposit in Rangtang, Sichuan, raw ore Li 2 O grade 1.21%, Nb 2 o 5 Grade 0.0095%, Ta 2 o 5 The grade is 0.0054%, and the Sn grade is lower than the industrial grade, which is 0.034%. The ores are mainly spodumene, feldspar and quartz; a small amount of minerals include tantalum niobite and so on. The ore has a large amount of mud, and the associated niobium and tantalum minerals have a fine particle size, with a particle size of less than 0.1mm accounting for 70.09%, which is quite different from the spodumene mineral particle size in the ore (a particle size greater than 0.1mm accounts for 98.85%), and comprehensive recovery is difficult. big. The lithium concentrate obtained by the traditional "gravity separation-magnetic separation-gravity separation tailings floating lithium" process contains Li 2 O5.75%, recovery rate 63.68%; grade of tantalum and niobium concentrate: Nb 2 o 5 31.01%, Ta 2 o 5 14.85...

Embodiment 3

[0052] Introduction to ore properties: a lithium polymetallic deposit in Dilaqiu, Sichuan, raw ore Li 2 O grade 1.09%, Nb 2 o 5 Grade 0.011%, Ta 2 o 5 The grade is 0.0051%, and the Sn grade is less than 0.1%. The main useful minerals are spodumene and niobium-tantalite, and the main gangue minerals are quartz, feldspar, mica and so on. The ore contains a large amount of fine mud, and the associated niobium and tantalum minerals have a finer particle size, with a particle size of less than 0.045mm accounting for 78.12%, which is quite different from the lithium mineral particle size in the ore (a particle size greater than 0.074mm accounts for 89.01%), making comprehensive recovery difficult. The lithium concentrate obtained by the traditional "gravity separation-magnetic separation-gravity separation tailings floating lithium" process contains Li 2 O5.48%, recovery rate 60.76%; grade of tantalum and niobium concentrate: Nb 2 o 5 30.12%, Ta 2 o 5 12.21%, recovery rate:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com