Triester-based quaternary ammonium salt positive ion collecting agent and preparation method and application thereof

A cationic collector and ester-based quaternary ammonium salt technology, applied in solid separation, flotation, etc., can solve the problems of water pollution, poor fluidity, difficult defoaming, etc., to save heating costs, simple chemical system, and economical The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

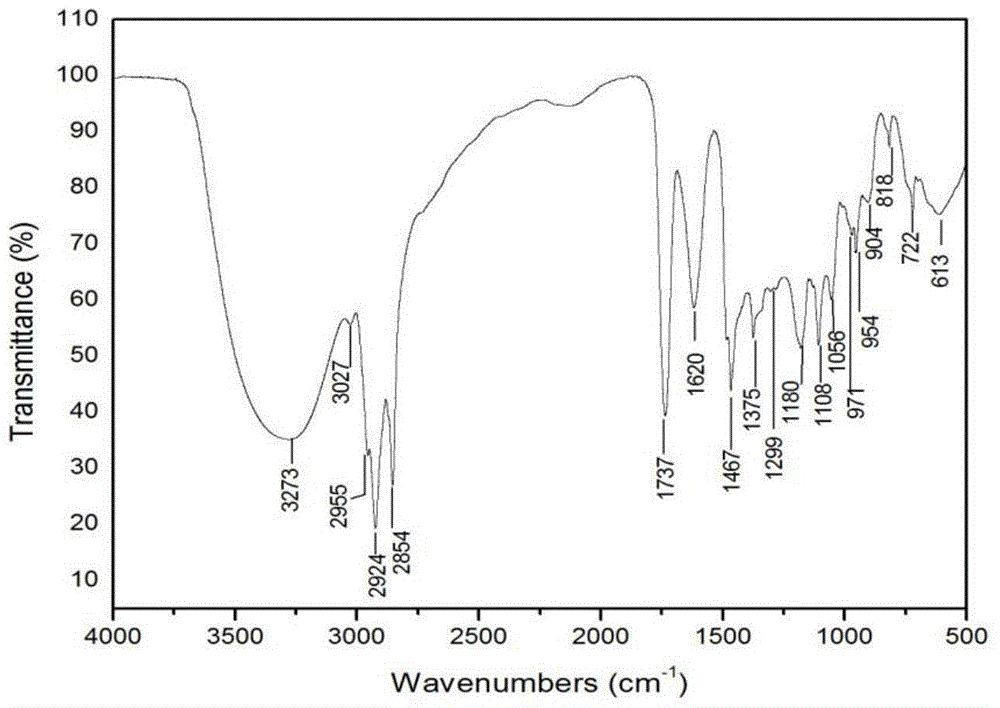

[0044] A kind of triester group quaternary ammonium salt cationic collector, its preparation method comprises the following steps:

[0045] 1) Weigh 0.5mol epichlorohydrin into a three-necked flask equipped with a reflux condenser and a dropping funnel, add 70g of acetone as a reaction solvent, place the three-necked flask in an oil bath and heat it to 60°C, and use the dropping funnel to Slowly add 0.2 mol of dodecyl tertiary amine dropwise, magnetically stir for 12 h, and then spin distill off the solvent acetone to obtain the intermediate product as light yellow liquid.

[0046] 2) Take 0.2 mol of the obtained intermediate product and add it to a three-necked flask, add 0.06 mol (11.52 g) of citric acid, add 70 g of isopropanol as a reaction solvent, and add 2% (0.23 g) of citric acid mass to p-toluenesulfonic acid as a catalyst , heated to 100 ° C and refluxed for 9 h. Then the product is rotated to distill off the solvent to obtain the triester-based quaternary ammonium ...

Embodiment 2

[0049] A kind of triester group quaternary ammonium salt cationic collector, its preparation method comprises the following steps:

[0050] 1) Weigh 0.5mol epibromohydrin into a three-necked flask equipped with a reflux condenser and a dropping funnel, add 70g of acetone as a reaction solvent, place the three-necked flask in an oil bath and heat it to 80°C, and use the dropping funnel to Slowly add 0.25 mol of dodecyl tertiary amine dropwise, stir magnetically for 11 h, and then spin distill off the solvent acetone to obtain an intermediate product in the form of a pale yellow liquid.

[0051] 2) Get 0.25mol of the intermediate product obtained and add in a three-necked flask, add 0.08mol (15.36g) of citric acid, add 76.8g of acetone as a reaction solvent, add p-toluenesulfonic acid of 2.5% (0.384g) of citric acid quality as a catalyst, Heated to 120°C and stirred at reflux for 6h. Then the product is rotatably distilled off the solvent to obtain the triester-based quaternary...

Embodiment 3

[0053] A kind of triester group quaternary ammonium salt cationic collector, its preparation method comprises the following steps:

[0054] Weigh 0.21mol of epichlorohydrin and 0.06mol of citric acid into a three-necked flask equipped with a dropping funnel and a reflux condenser, add 57.5g of isopropanol as a solvent and magnetically stir for 20min, then slowly add twelve Tertiary amine 0.2mol (42.6g), heated to 100 DEG C, condensed and refluxed for 12 hours, and then the solvent isopropanol was distilled off by rotary distillation to obtain a light yellow jelly, which is the triester-based quaternary ammonium salt cationic collector, The cationic degree measured by sodium tetraphenylborate back titration method was 82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com