Wastewater centrifugal filtering device for water jet loom

A technology of centrifugal filtration and water jet loom, which is applied in the direction of looms, filtration separation, auxiliary weaving equipment, etc. It can solve the problems of large volume of filtration devices, reduce work efficiency, occupy factory space, etc., and achieve short filtration time and high working efficiency. The effect of high efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

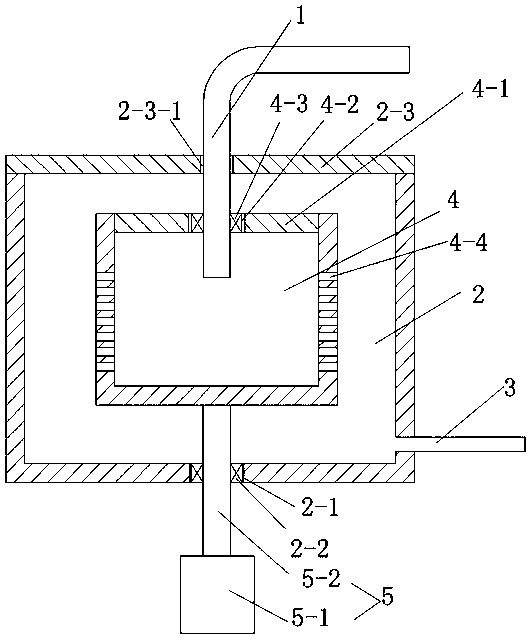

[0026] Such as figure 2As shown, the driving device 5 includes a motor 5-1 arranged on the outside of the filter box 2 and a rotating shaft 5-2 for connecting the filter cartridge 4 and the motor 5-1, and the bottom of the filter box 2 is provided with a rotating hole 2-1 , and a rotating bearing seat 2-2 is set in the rotating hole 2-1, and the rotating shaft 5-2 passes through the rotating bearing seat 2-2 and is connected with the filter cartridge 4. At the same time, it should be ensured that the rotating bearing seat 2-2 is an oil seal to prevent water from flowing out of the bearing seat. The distance between the bottom of the filter cartridge 4 and the bottom of the filter box 2 is 25 cm. The central axis of the rotating shaft 5 - 2 coincides with the central axis of the filter cartridge 4 . The motor 5-1 that drives the filter cartridge 4 to rotate is arranged outside the filter box 2, without using a waterproof motor, which can reduce the manufacturing cost of the ...

Embodiment 2

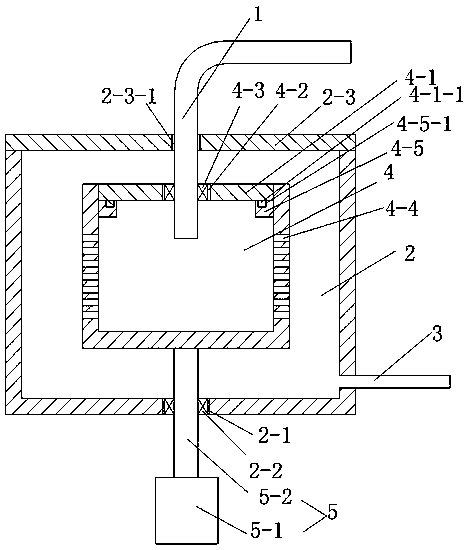

[0028] Such as image 3 As shown, on the basis of the arrangement of the driving device 5 in Embodiment 1, the cover plate 4-1 is movably connected with the filter cartridge 4, the inner wall of the filter cartridge 4 is provided with internal threads, and the outer wall of the cover plate 4-1 is provided with the inner thread. External thread for thread fit. The cover plate 4-1 is movably connected with the filter cartridge 4, and the filter material in the filter cartridge 4 can be replaced by opening the cover plate 4-1, thereby improving the filtering effect. At the same time, the external thread on the cover plate 4-1 cooperates with the internal thread on the inner wall of the filter cartridge 4 to fix the relative position of the cover plate 4-1 and the filter cartridge 4, which can ensure the connection strength of the two, and at the same time make the entire cover The installation and removal of the board 4-1 is more convenient.

Embodiment 3

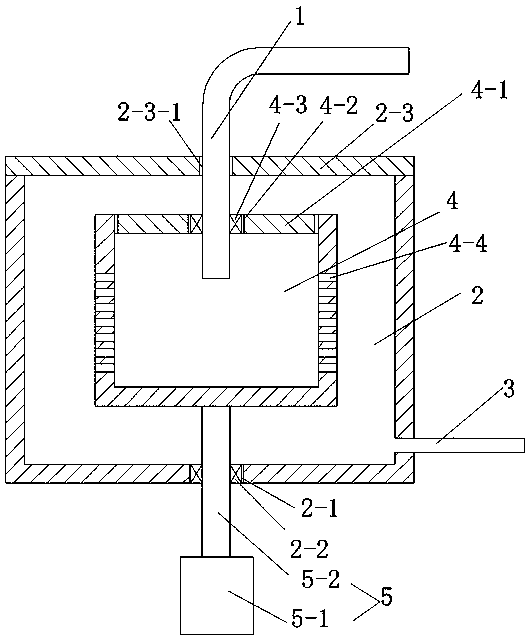

[0030] Such as Figure 4 As shown, on the basis of the arrangement of the driving device 5 in the first embodiment, the cover plate 4-1 is fixedly connected with the filter cartridge 4, specifically by welding. Fixing by welding can not only ensure the connection strength between the cover plate and the filter cartridge, but also ensure the sealing of the cover plate, preventing waste water from flowing out from the gap between the cover plate and the filter cartridge and affecting the entire filtering effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com