Vacuum filter used for removing impurities in process of producing ethylene glycol antimony

A production process, ethylene glycol antimony technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, separation methods, etc., can solve the problem that the adsorption and decolorization layer is prone to filtration or leakage, frequent replacement of filter layers, and filtration. Slow speed and other problems, to achieve the effect of good impurity removal, easy operation and short filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

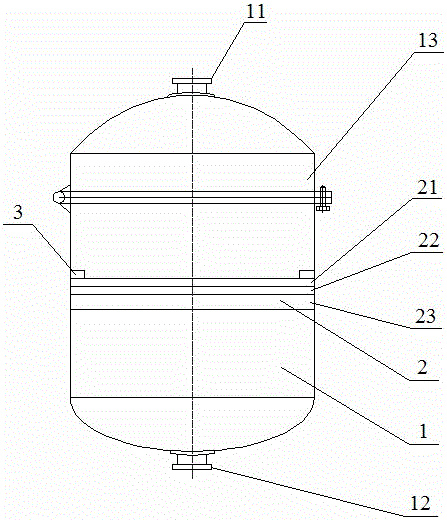

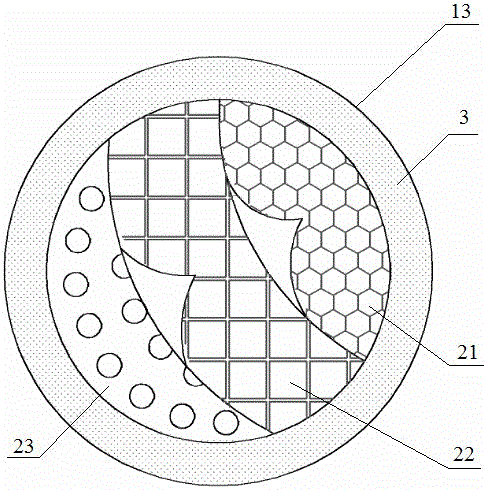

[0025] like figure 1 , 2 As shown, a vacuum filter used for removing impurities in the production process of ethylene glycol antimony is composed of a cylindrical vacuum filter cartridge 1 and a filter layer 2 made of stainless steel. The interface radius of the vacuum filter is 0.20m, and the vacuum negative pressure 60kPa; wherein, the vacuum filter cartridge 1 is composed of an upper feed port 11, a lower discharge port 12 and a cylinder body 13; the filter layer 2 is sequentially composed of two layers of pitch-based carbon felt 21, 50 mesh stainless steel screen mesh 22 and a perforated plate 23 with a filter hole diameter of 9mm and a porosity of 10%; The pitch-based carbon felt 21 and the stainless steel screen 22 are clamped tightly on the punching plate 23; each layer of the pitch-based carbon felt 21 is 4mm thick and has a specific surface area of 1800m 2 / g.

[0026] The working process of the present embodiment vacuum filter is: the 1m 3 The mixed solution af...

Embodiment 2

[0029] like figure 1 , 2 As shown, a vacuum filter used for removing impurities in the production process of ethylene glycol antimony is composed of a stainless steel cylindrical vacuum filter cartridge 1 and a filter layer 2. The interface radius of the vacuum filter is 0.22m, and the vacuum negative pressure It is 50kPa; Wherein, described vacuum filter cartridge 1 is made up of three parts of upper part feed port 11, lower part discharge port 12 and cylinder body 13; Described filter layer 2 is successively made of 4 layers of phenolic base carbon felt 21, 150-mesh stainless steel screen 22 and a perforated plate 23 with a filter hole of 8mm and an opening rate of 25%; The surroundings of base carbon felt 21 and stainless steel mesh 22 are fastened on punching plate 23; each layer of described phenolic base carbon felt 21 is 3mm thick, and specific surface area is 1200m 2 / g.

[0030] The working process of the present embodiment vacuum filter is: the 1m 3 The mixed sol...

Embodiment 3

[0033] like figure 1 , 2 As shown, a vacuum filter used for removing impurities in the production process of ethylene glycol antimony is composed of a stainless steel cylindrical vacuum filter cartridge 1 and a filter layer 2. The interface radius of the vacuum filter is 0.28m, and the vacuum negative pressure It is 70kPa; Wherein, described vacuum filter cartridge 1 is made up of three parts of upper part feed port 11, lower part discharge port 12 and cylinder body 13; Described filter layer 2 is successively made up of 6 layers of phenolic base carbon felt 21, The 350-mesh stainless steel screen 22 and the perforated plate 23 with a filter hole of 6mm and an opening rate of 40% are composed of the perforated plate 23; The surroundings of base carbon felt 21 and stainless steel screen mesh 22 are fastened on punching plate 23; each layer of described phenolic base carbon felt 21 is thick 2mm, and specific surface area is 2500m 2 / g.

[0034] The working process of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com