Barreled water production line and technological process thereof

A barreled water and production line technology, applied in the direction of water pollutants, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of adverse effects of treatment, poor filtering and impurity removal effects, etc., and achieve the goal of improving the filtering and impurity removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

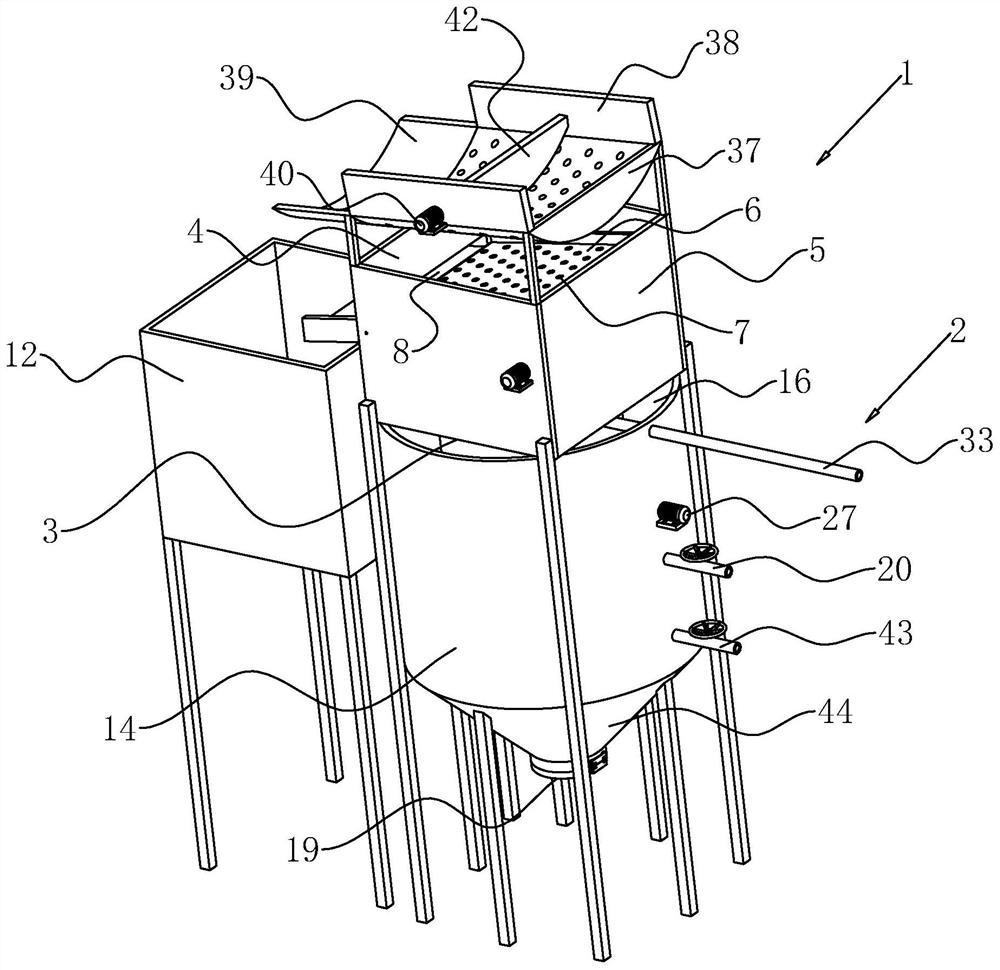

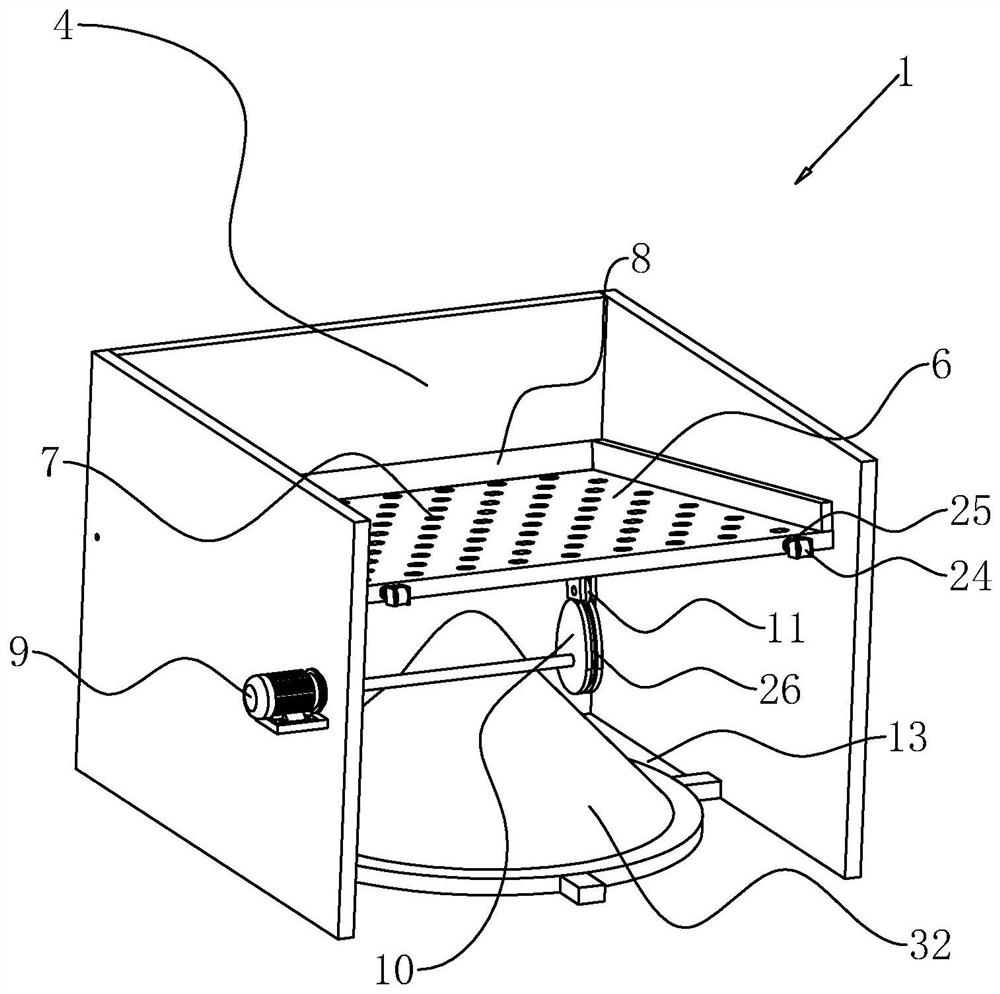

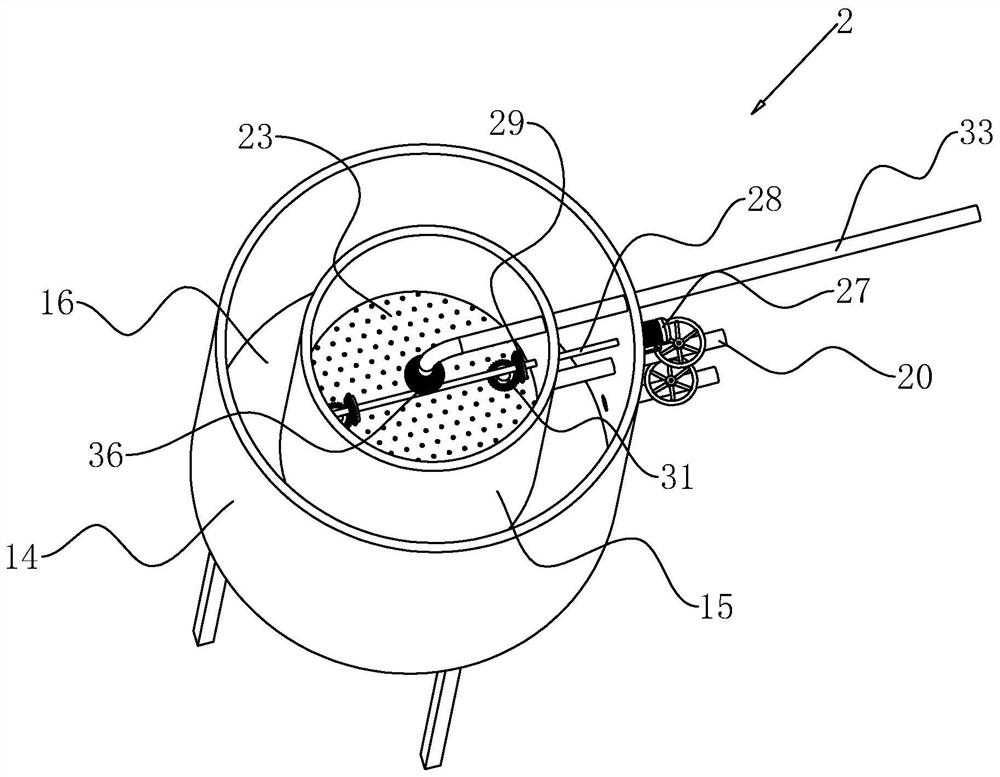

[0046] refer to figure 1 , a barreled water production line, comprising a filter box 1 with an open upper end and a raw water pool filter tank 2 located below the filter box 1, the filter box 1 includes a bottom plate 3, a first side plate 4 and a second side plate 5, the first side There is an inclined vibrating sieve plate 6 between the plate 4 and the second side plate 5, the vibrating sieve plate 6 is provided with a first mesh 7, the first side plate 4 is provided with a discharge port 8, and the vibrating sieve plate 6 is close to the discharge One end of the mouth 8 is hinged with the first side plate 4, and the side of the filter box 1 away from the second side plate 5 is provided with a waste box 12, and the discharge port 8 is located above the waste box 12, and the water just extracted from the ground is relatively turbid, and the Contains more massive solids, impurities of large particle size and small particle size, massive solids are heavy, and when the massive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com