Device and method for filtering hydraulic oil of forklift

A hydraulic oil filtration and hydraulic oil technology, which is applied in the direction of fluid pressure actuation device, lifting device, fluid pressure actuation system components, etc., to achieve good effect, easy repair and maintenance, reliable and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] The invention provides a hydraulic oil filtering device, which is mainly used for filtering the hydraulic oil in the hydraulic system of the forklift, so that the hydraulic oil of the forklift can be used repeatedly, which greatly saves the production cost.

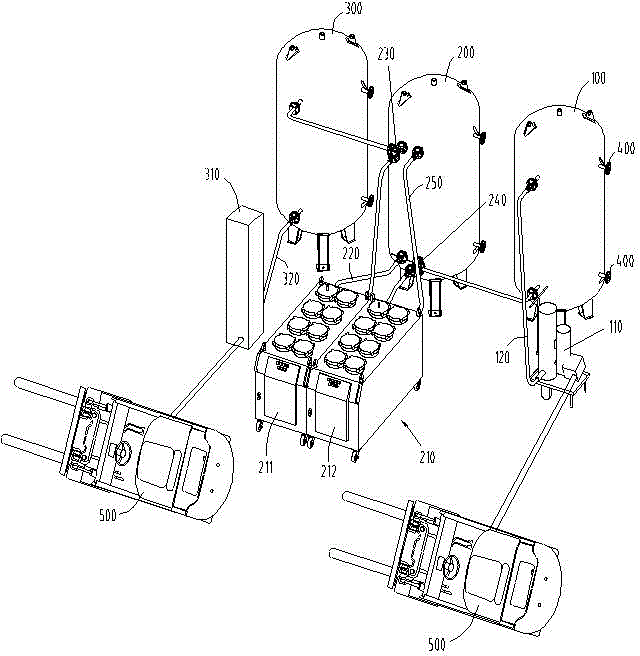

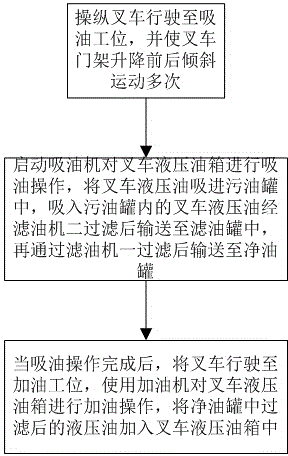

[0031] like figure 1 As shown, the filtering device includes a dirty oil tank 100, an oil filter tank 200 and a clean oil tank 300 which are arranged side by side in sequence, wherein an oil suction machine 110 is arranged on one side of the dirty oil tank 100, here is the oil suction station, and the forklift 500 is driving To the oil suction station, the dirty hydraulic oil in the hydraulic oil tank of the forklift can be sucked out by the oil suction machine and transported to the dirty oil tank. One side of the clean oil tank 300 is provided with a refueling machine 310, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com