Bacillus methylotrophicus wettable powder and preparation method and application thereof

A methylotrophic, wettable powder technology, applied in the direction of botany equipment and methods, applications, fungicides, etc., can solve problems such as poor control effects, overcome environmental toxic side effects and pesticide residue problems, and reduce production costs , the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

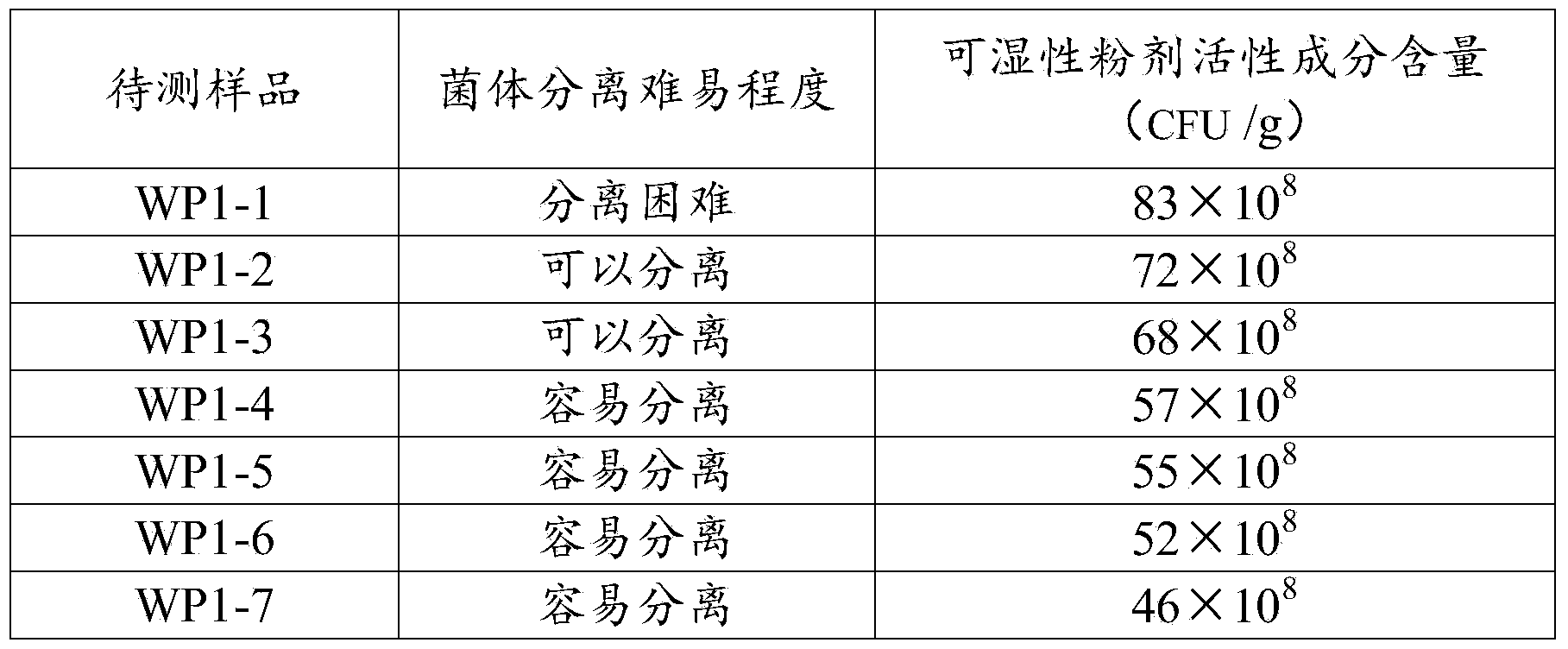

[0048] (1) Preparation of methylotrophic bacillus wettable powder WP1-1

[0049] Add 1.0% diatomaceous earth to 1 part of the fermentation broth containing methylotrophic bacillus, collect the bacteria through the solid-liquid separation step, and dry to moisture at 60°C-70°C and vacuum degree of 0.07Mpa-0.09Mpa ≤5.0%, that is, the original drug of methylotrophic bacillus.

[0050] Add 6 parts by mass of GSWP compound additives and 6 parts by mass of dispersant MF to 100 parts by mass of the original drug of methylotrophic bacillus, mix evenly, and then perform jet milling. The crushing fineness is 45 μm. %, to obtain methylotrophic bacillus wettable powder WP1-1.

[0051] (2) Preparation of methylotrophic bacillus wettable powder WP1-2~WP1-8

[0052] The preparation process is basically the same as the preparation of methylotrophic bacillus wettable powder WP1-1, the difference is: firstly add flocculant polyacrylamide to the fermentation liquid containing methylotrophic ba...

Embodiment 2

[0064] (1) Preparation of methylotrophic bacillus wettable powder WP2-1

[0065] Add 300ppm polyacrylamide to 1 part of the fermentation broth containing methylotrophic bacillus. After the cells are coagulated for 30 minutes, carry out solid-liquid separation and collect the cells without adding diatomaceous earth. °C and vacuum degree of 0.07Mpa to 0.09Mpa and dried until the water content is ≤5.0%, the original drug of methylotrophic bacillus can be obtained.

[0066]Add 6 parts by mass of GSWP compound additives and 6 parts by mass of dispersant MF to 100 parts by mass of the original drug of methylotrophic bacillus, mix evenly, and then perform jet milling. The crushing fineness is 45 μm. %, to obtain methylotrophic bacillus wettable powder WP2-1.

[0067] (2) Preparation of methylotrophic bacillus wettable powder WP2-2~WP2-8

[0068] The preparation process is basically the same as that of the methylotrophic bacillus wettable powder WP2-1, the difference is that after t...

Embodiment 3

[0077] (1) Preparation of methylotrophic bacillus wettable powder WP3-1

[0078] Add 300ppm polyacrylamide to 1 part of the fermentation broth containing methylotrophic bacillus, add 1.0% diatomaceous earth after the cells are coagulated for 30 minutes, collect the cells through the solid-liquid separation step, and store them at room temperature under a vacuum of 0.07 Dry under the condition of MPa~0.09Mpa for 6 hours to obtain the original drug of methylotrophic bacillus.

[0079] Add 6 parts by mass of GSWP compound additives and 6 parts by mass of dispersant MF to 100 parts by mass of the original drug of methylotrophic bacillus, mix evenly, and then perform jet milling. The crushing fineness is 45 μm. %, to obtain methylotrophic bacillus wettable powder WP3-1.

[0080] (2) Preparation of methylotrophic bacillus wettable powder WP3-2~WP3-7

[0081] The preparation process is basically the same as the preparation of the methylotrophic bacillus wettable powder WP3-1, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com