A method for removing irritating odor with electronic grade phosphoric acid

An electronic-grade phosphoric acid and pungent odor technology, which is applied in the field of phosphorus chemical industry, can solve problems such as product quality fluctuations, and achieve the effects of stabilizing product quality, removing pungent odors, and removing irritating odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

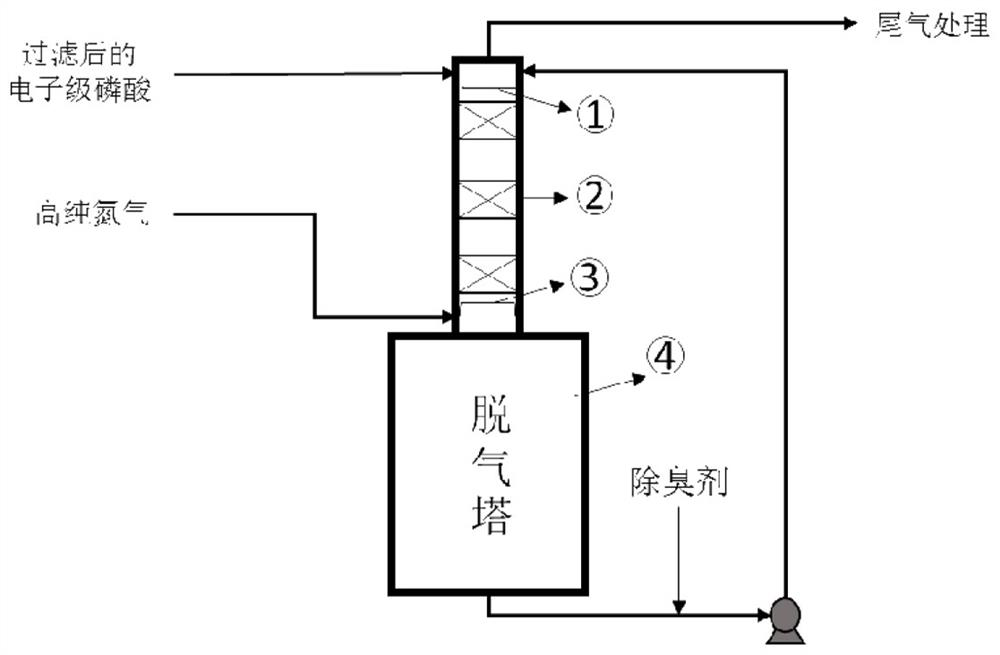

Image

Examples

Embodiment 1

[0039] The filtered electronic-grade phosphoric acid enters the degassing tower, accounting for about 1 / 2 of the volume of the degassing tower. Keep the temperature of phosphoric acid in the degassing tower at 70°C, and continuously feed high-purity nitrogen (purity 99.99%) into the degassing tower for 3 hours. Gas volume is controlled at 300~700m 3 / h, and then continue to put 400mL of deodorant with the formula of 35% (mass fraction) hydrogen peroxide, 8% inorganic acid, and 57% water from the inlet of the circulating acid pump, and ventilate for 1 hour to obtain electronic-grade phosphoric acid and pure water In contrast, there is no odor, and the concentration of easy oxides is less than or equal to 2ppm, and the concentration of sulfate ions is less than or equal to 2ppm. The gas from the top of the degassing tower is sent to the tail gas system.

Embodiment 2

[0041] The filtered electronic-grade phosphoric acid enters the degassing tower, accounting for about 3 / 5 of the volume of the degassing tower. Keep the temperature of phosphoric acid in the degassing tower at 70°C, and continuously feed high-purity nitrogen (purity 99.99%) into the degassing tower for 4 hours. Gas volume is controlled at 300~700m 3 / h, then continuously put 650mL of deodorant with the formula of 55% (mass fraction) hydrogen peroxide, 15% inorganic acid, and 30% water from the inlet of the circulating acid pump, and ventilate for 2 hours to obtain electronic-grade phosphoric acid and pure water In contrast, there is no odor, and the concentration of easy oxides is ≤2ppm, and the concentration of sulfate ions is ≤2ppm. The gas from the top of the degassing tower is sent to the tail gas system.

Embodiment 3

[0043] The filtered electronic-grade phosphoric acid enters the degassing tower, accounting for about 2 / 3 of the volume of the degassing tower. Keep the temperature of phosphoric acid in the degassing tower at 70°C, and continuously feed high-purity nitrogen (purity 99.99%) into the degassing tower for 5.5 hours , the gas volume is controlled at 300-700m 3 / h, and then continuously put 730mL of deodorant with the formula of 40% (mass fraction) hydrogen peroxide, 25% inorganic acid and 35% water from the inlet of the circulating acid pump, and ventilate for 2 hours to obtain electronic grade phosphoric acid and pure water In contrast, there is no odor, and the concentration of easy oxides is ≤2ppm, and the concentration of sulfate ions is ≤2ppm. The gas from the top of the degassing tower is sent to the tail gas system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com