Preparation method of solar cell silicon oxide layer and solar cell

A technology for solar cells and silicon oxide layers, applied in the field of solar cells, can solve the problems of small thickness of silicon oxide layers, low content of high-valence silicon, difficult to control thickness, etc., and achieves shortened time, low preparation temperature, and avoids problems that are difficult to control in quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

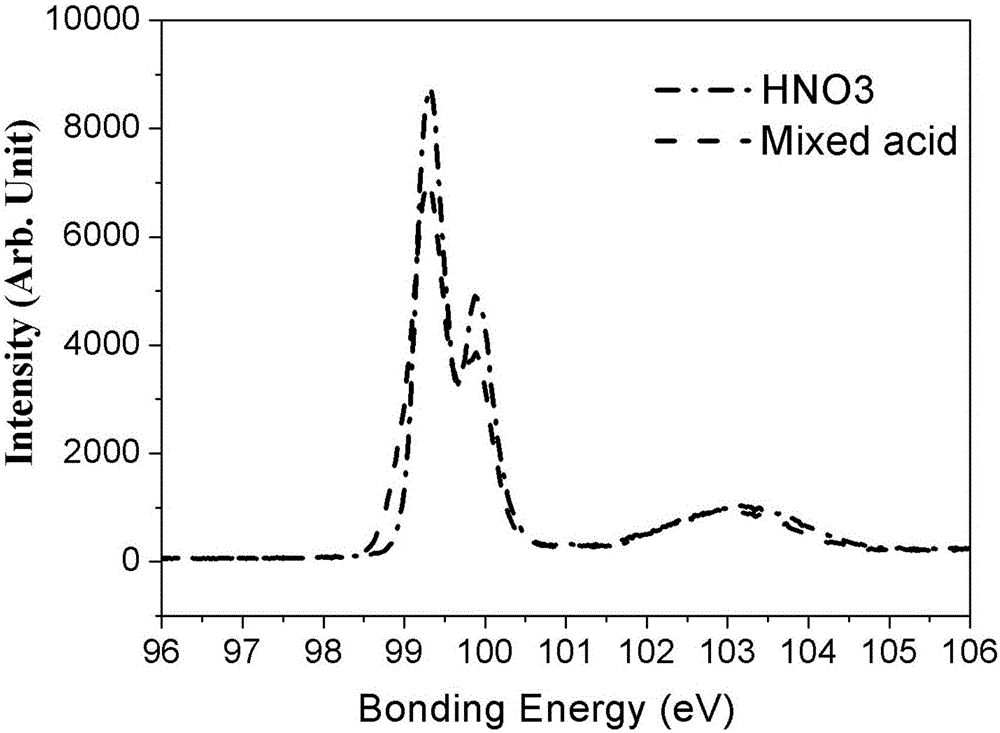

[0055] The oriented n-type silicon wafer is pretreated, that is, the silicon wafer is first cleaned by RCA standard cleaning method, and then the native oxide layer on the surface of the silicon wafer is removed by HF; the pretreated silicon wafer is placed in a temperature of 20°C Oxidation treatment for 2 minutes in the mixed acid solution, wherein the mixed acid solution is formed by mixing nitric acid (68%) and sulfuric acid (98%) at a volume ratio of 3:1.

[0056] The thickness of the silicon oxide layer was measured to be 1.2 nm by spectroscopic ellipsometry.

Embodiment 2

[0058] The oriented n-type silicon wafer is pretreated, that is, the silicon wafer is first cleaned by RCA standard cleaning method, and then the original oxide layer on the surface of the silicon wafer is removed by HF; the pretreated silicon wafer is placed in a temperature of 120 ° C Oxidation treatment in the mixed acid solution for 10 minutes, wherein the mixed acid solution is formed by mixing nitric acid (68%) and sulfuric acid (98%) at a volume ratio of 9:1.

[0059] The thickness of the silicon oxide layer was measured by spectroscopic ellipsometry to be 2.3 nm.

Embodiment 3

[0061] Pretreat the oriented n-type silicon wafer, that is, the silicon wafer is first cleaned by RCA standard cleaning method, and then the native oxide layer on the surface of the silicon wafer is removed by HF; the pretreated silicon wafer is placed in a temperature of 90 ° C Oxidation treatment in the mixed acid solution for 10 minutes, wherein the mixed acid solution is formed by mixing nitric acid (68%) and sulfuric acid (98%) at a volume ratio of 1:1.

[0062] The thickness of the silicon oxide layer was measured to be 2.0 nm by spectroscopic ellipsometry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com