A kind of pretreatment method of coking wastewater

A coking wastewater and pretreatment technology, applied in the field of water treatment, can solve the problems of difficult discharge of pollutants, failure to meet environmental protection requirements, high investment and operating costs of tertiary treatment processes, and achieve efficient oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

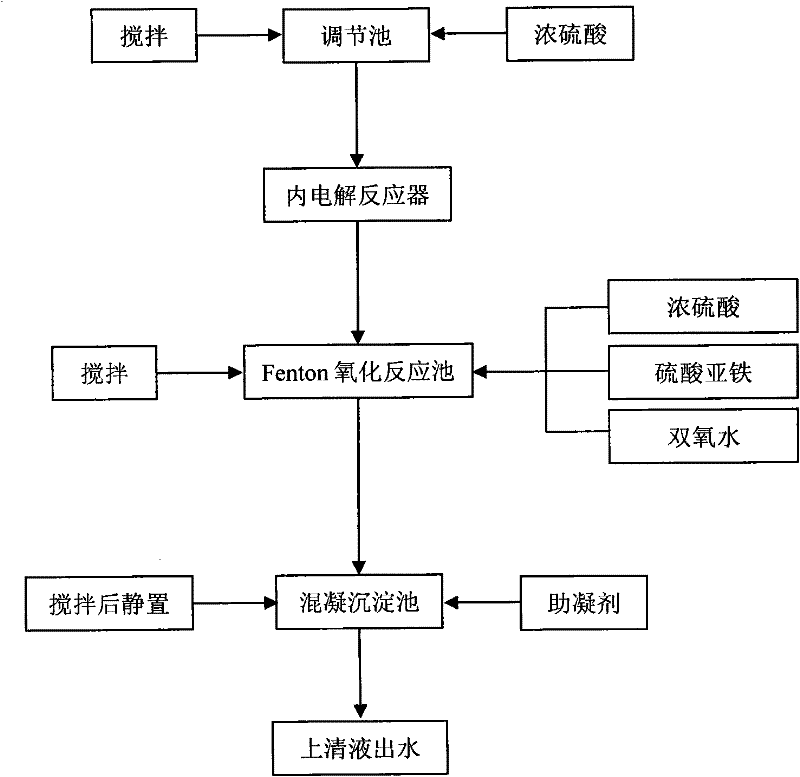

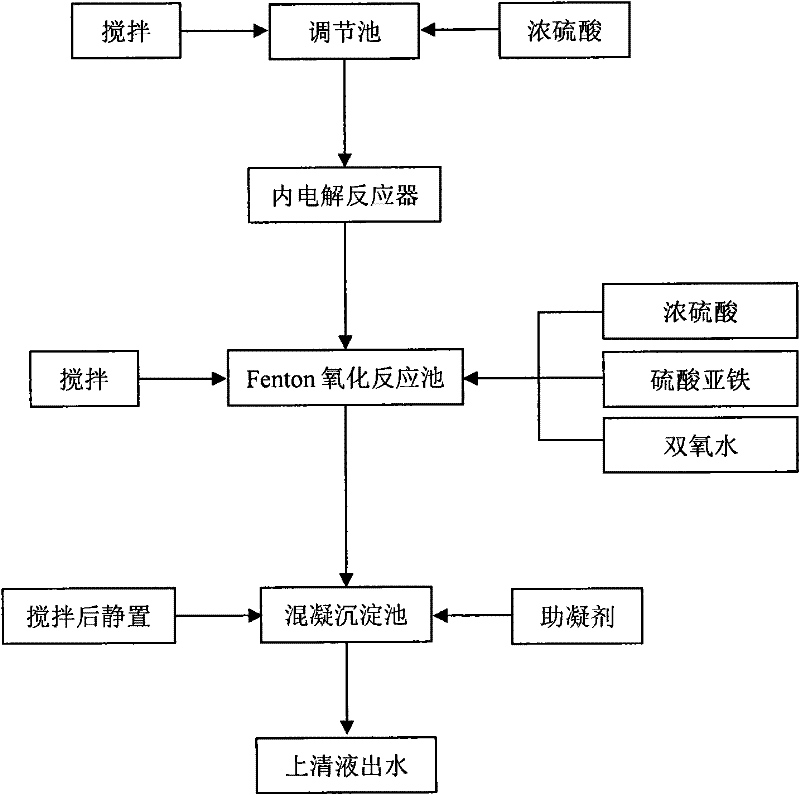

Image

Examples

Embodiment 1

[0016] Slowly add concentrated sulfuric acid to the coking waste water in the adjustment tank while stirring, so that the pH of the waste water is 2.7; then pump it into the upper part of the cylindrical inner electrolysis reactor. The filler of the reactor is composed of cast iron filings and shell activated carbon, and the mass ratio of the two is 8:1. The residence time of the wastewater in the column is 2h, and the effluent flows into the Fenton oxidation pond.

[0017] The Fenton oxidation process adopts intermittent operation. After the wastewater in the pool reaches 3 / 4, it starts to stir and add concentrated sulfuric acid at the same time to make the pH to 3. Add ferrous sulfate solid at one time to make the concentration of ferrous ions reach 700ppm, and then slowly add hydrogen peroxide solution to make the concentration reach 1500ppm. After reacting for 2 hours under stirring, the waste water flows into the coagulation sedimentation tank.

[0018] Add 3ppm coagula...

Embodiment 2

[0020] Slowly add concentrated sulfuric acid to the coking wastewater in the adjustment pool while stirring, so that the pH of the wastewater is 3;

[0021] Then it is pumped into the upper part of the cylindrical inner electrolytic reactor. The filler of the reactor is composed of cast iron filings and shell activated carbon, and the mass ratio of the two is 8:1. The residence time of the wastewater in the column is 2.3h, and the effluent flows into the Fenton oxidation pond.

[0022] The Fenton oxidation process adopts intermittent operation. After the wastewater in the pool reaches 4 / 5, it starts stirring and adds concentrated sulfuric acid at the same time to make its pH 3.3. Add ferrous sulfate solid at one time to make the concentration of ferrous ions reach 800ppm, and then slowly add hydrogen peroxide solution to make the concentration reach 1700ppm. After reacting for 2.5 hours under stirring, the waste water flows into the coagulation sedimentation tank.

[0023] ...

Embodiment 3

[0025] Slowly add concentrated sulfuric acid to the coking wastewater in the adjustment pool while stirring, so that the pH of the wastewater is 3.3;

[0026] Then it is pumped into the upper part of the cylindrical inner electrolytic reactor. The filler of the reactor is composed of cast iron filings and shell activated carbon, and the mass ratio of the two is 8:1. The residence time of the wastewater in the column is 2.5h, and the effluent flows into the Fenton oxidation pond.

[0027] The Fenton oxidation process adopts intermittent operation. After the wastewater in the pool reaches 5 / 6, it starts stirring and adds concentrated sulfuric acid at the same time to make its pH 3.5. Add ferrous sulfate solid at one time to make the concentration of ferrous ions reach 900ppm, and then slowly add hydrogen peroxide solution to make the concentration reach 1900ppm. After reacting for 3 hours under stirring, the waste water flows into the coagulation sedimentation tank.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com