Solid oxidant and preparation method and application thereof

An oxidant and solid technology, applied in the field of solid oxidant and its preparation, achieves the effects of simple equipment, convenient use, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

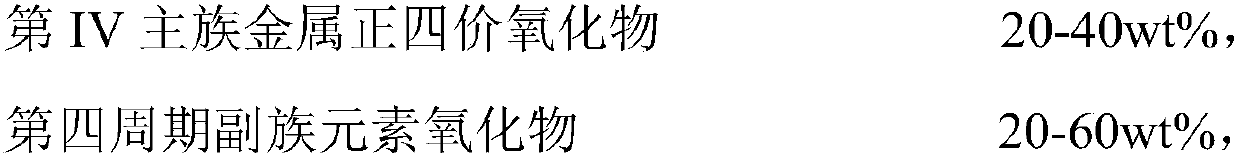

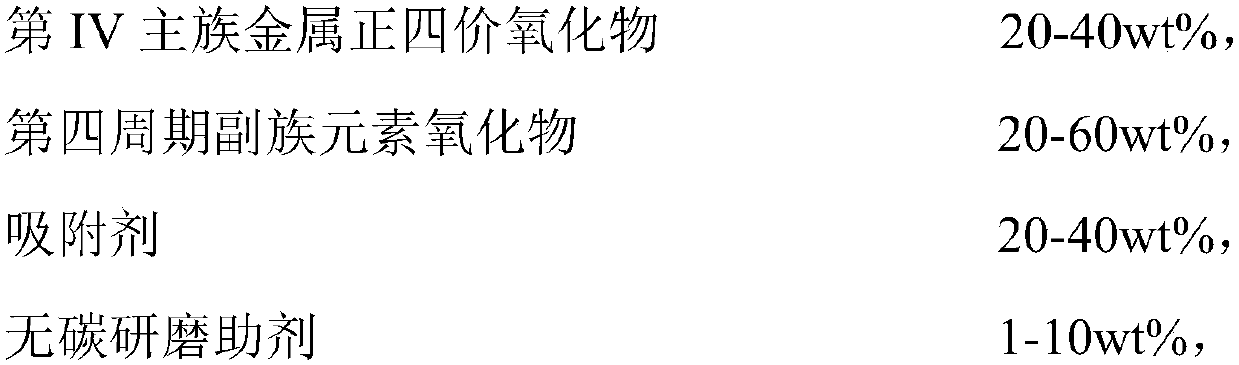

[0035] The second aspect of the present invention provides the preparation method of above-mentioned solid oxidizing agent, and this preparation method comprises:

[0036] (1) dispersing the adsorbent in water to obtain an adsorbent dispersion;

[0037] (2) Mix the adsorbent dispersion with the solution of the soluble salt of the fourth period subgroup element, and disperse evenly to obtain a mixed system;

[0038] (3) adjusting the pH value of the mixed system to be alkaline to obtain a mixed suspension system;

[0039] (4) Evaporating the mixed suspension system to dryness, collecting the remaining solid, and calcining the solid to obtain the treated solid;

[0040] (5) co-grinding the treated solid, the tetravalent oxide of the main group IV metal and a carbon-free grinding aid to obtain the solid oxidant.

[0041] In the process of transforming the soluble salts of the fourth-period subgroup elements into hydroxides of the fourth-period subgroup elements by the action of...

Embodiment 1

[0057] 1) Weigh 10 g of diatomaceous earth and add it into a sufficient amount of deionized water, and ultrasonically treat it to form a dispersion system;

[0058] 2) Weigh 15.7g CuSO 4 ·5H 2 O (analytically pure), add an appropriate amount of deionized water to dissolve, fully mix with the diatomite dispersion system obtained in step 1), keep stirring, and obtain a mixed system;

[0059] 3) Under vigorous stirring, add dropwise the 0.05M NaOH solution prepared in advance with analytically pure NaOH and deionized water to the mixed system obtained in step 2), and monitor the pH value of the system at the same time until the pH value of the system is adjusted to 9-10, to obtain a mixed suspension system;

[0060] 4) Slowly evaporate the mixed suspension system obtained in step 3), collect the remaining solid mixture after evaporation, transfer the solid to a porcelain crucible, and place it in an air atmosphere at 500°C for 4 hours; after cooling, use The solid product was ...

Embodiment 2

[0063] 1) Weigh 10g of active γ-alumina and add it into a sufficient amount of deionized water, and ultrasonically treat it to form a dispersion system;

[0064] 2) Weigh 26g Fe 2 (SO 4 ) 3 ·xH 2 O (analytically pure, Fe content is 21-23wt%), add an appropriate amount of deionized water to dissolve, fully mix with the active γ-alumina dispersion system obtained in step 1), and keep stirring to obtain a mixed system;

[0065] 3) Under vigorous stirring, add dropwise the 0.05M NaOH solution prepared in advance with analytically pure NaOH and deionized water to the mixed system obtained in step 2), and monitor the pH value of the system at the same time until the pH value of the system is adjusted to 8. Obtain a mixed suspension system;

[0066] 4) Slowly evaporate the mixed suspension system obtained in step 3), collect the remaining solid mixture after evaporation, transfer the solid to a porcelain crucible, and place it in an air atmosphere at 500°C for 4 hours; after cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com