Method for strengthening oxidation of ammonium sulfite

A technology for strengthening ammonium sulfite and ammonium sulfite, which is applied in chemical instruments and methods, separation methods, perfluorocarbon/hydrofluorocarbon capture, etc. Slowness, constraints and other problems, to achieve the effect of good oxidation effect, low equipment investment cost and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

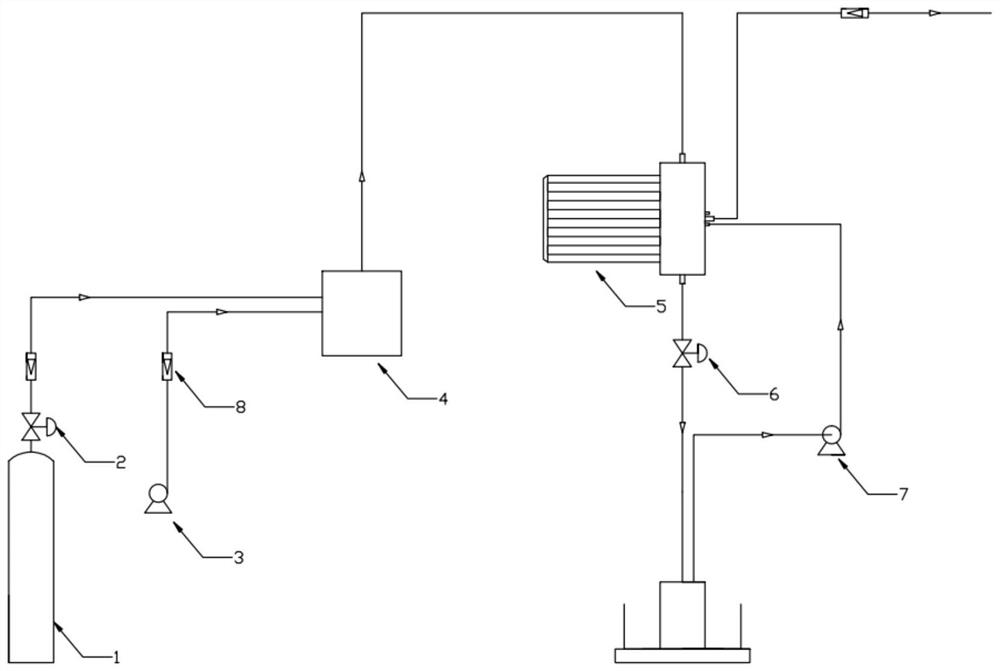

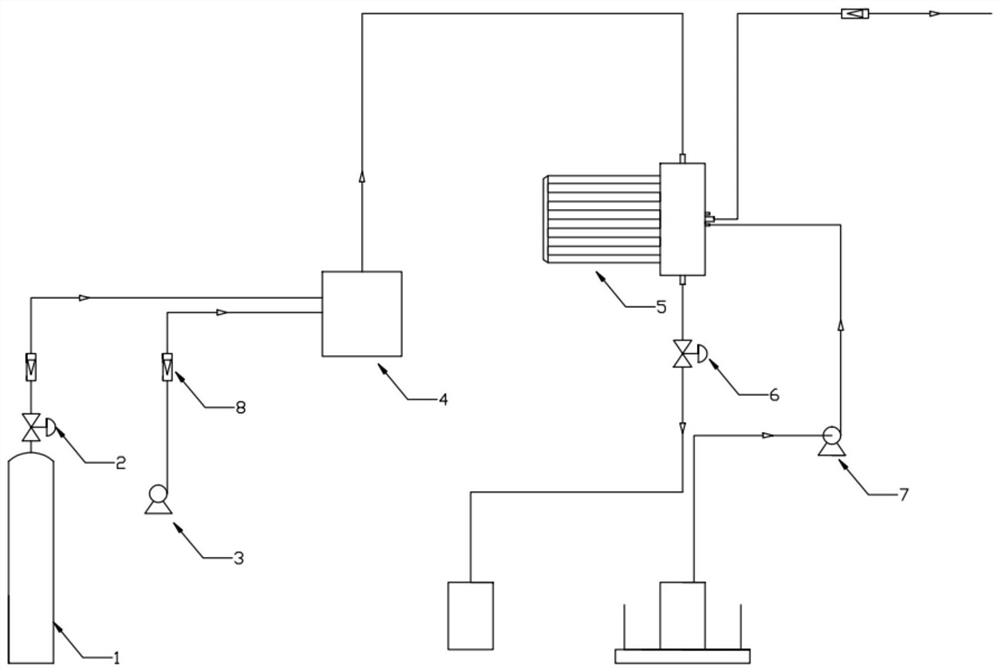

[0033] Use a supergravity machine (developed by Beijing University of Chemical Technology by itself), use wire mesh packing, adjust the speed of the supergravity machine to 1200 rpm, and flow air and ammonium sulfite solution from the gas inlet respectively according to the gas-liquid flow volume ratio of 2:1 and the liquid inlet into the supergravity machine, the temperature of the ammonium sulfite solution is 60°C, the air temperature and pressure are 25°C and 0.1MPa respectively, the concentration of the ammonium sulfite solution is 0.2mol / L, and the pH of the ammonium sulfite solution is 8.14. Under batch operation, after 500ml of ammonium sulfite solution was circulated and oxidized in the supergravity machine for 10 minutes, the oxidation rate of ammonium sulfite was 63.38%.

Embodiment 2

[0035] Using a supergravity machine (self-developed by Beijing University of Chemical Technology), using wire mesh filler, adjusting the speed of the supergravity machine to 1400 rpm, according to the gas-liquid flow volume ratio of 2:1, pure oxygen and ammonium sulfite solution were separated from the gas The inlet and the liquid inlet are sent into the supergravity machine, the temperature of the ammonium sulfite solution is 50°C, the temperature and pressure of pure oxygen are 25°C and 0.1MPa respectively, the concentration of the ammonium sulfite solution is 0.2mol / L, and the pH of the ammonium sulfite solution is The value is 8.14. Under batch operation, after 500ml of ammonium sulfite solution was circulated and oxidized in the supergravity machine for 1min, the oxidation rate of ammonium sulfite was 74.11%.

Embodiment 3

[0037] Using a supergravity machine (developed by Beijing University of Chemical Technology), using wire mesh filler, adjusting the speed of the supergravity machine to 1200 rpm, and mixing air and ammonium sulfite solution with positive twelve according to the gas-liquid flow volume ratio of 2:1 The alkane mixed liquid is sent into the supergravity machine from the gas inlet and the liquid inlet respectively, the volume fraction of n-dodecane is 8%, the temperature of the ammonium sulfite solution is 60°C, the air temperature and pressure are 25°C and 0.1MPa respectively, and the The concentration of the ammonium sulfate solution is 0.2mol / L, and the pH value of the ammonium sulfite solution is 8.14. Under batch operation, after 500ml of ammonium sulfite solution was circulated and oxidized in the supergravity machine for 10 minutes, the oxidation rate of ammonium sulfite was 74.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com