Electric chemical device and method for generating hydrogen peroxide from cathode and treating organic wastewater with anode

A technology of hydrogen peroxide and organic wastewater, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Simple structure, favorable for transfer and enrichment, and short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

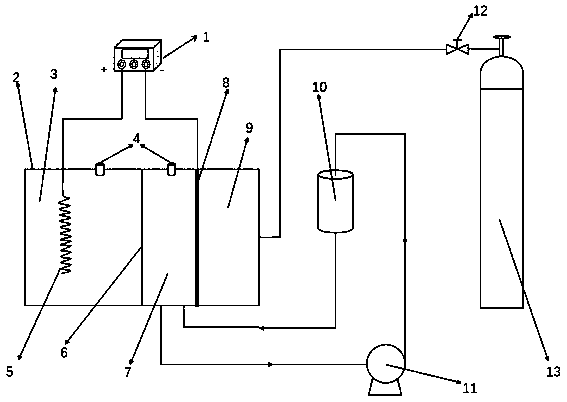

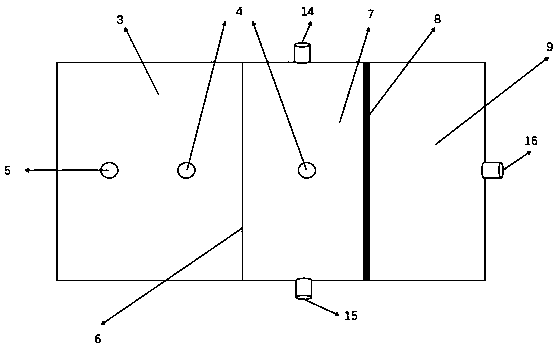

Method used

Image

Examples

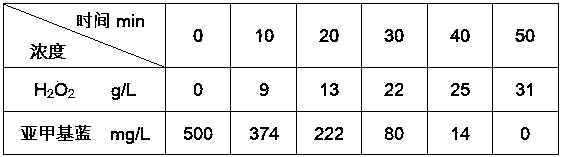

Embodiment 1

[0043] The present embodiment provides a kind of electrochemical method that adopts above-mentioned device to carry out cathode to produce hydrogen peroxide while anode treats organic waste water, and it adds the Na of 0.5mol / L to cathode chamber 2 SO 4 solution with a mass fraction of 98% H 2 SO 4 Adjust the pH to 0.5, as the catholyte, the catholyte volume is 20ml; add 500mg / L methylene blue solution and 0.5mol / L Na 2 SO 4 solution and adjust the pH to 0.5, as the anolyte, the volume of the anolyte is 20ml; the reaction is carried out under the conditions of current 1.05A, oxygen flow rate 20ml / min, and circulation pump flow rate 20ml / min; oxygen diffuses to the cathode through the gas diffusion cathode On the surface, an oxygen reduction reaction occurs, and hydrogen peroxide is prepared in situ; an oxygen evolution reaction occurs at the anode, and the organic matter in the organic wastewater is directly oxidized by using the anodic oxidation environment; due to the exi...

Embodiment 2

[0048] The present embodiment provides a kind of electrochemical method that adopts above-mentioned device to carry out cathode to produce hydrogen peroxide while anode treats organic waste water, and it adds the Na of 0.5mol / L to cathode chamber 2 SO 4 solution with a mass fraction of 98% H 2 SO 4 Adjust the pH to 0.5, as the catholyte, the catholyte volume is 20ml; add 500mg / L rhodamine B solution and 0.5mol / L Na 2 SO 4 solution and adjust the pH to 0.5, as the anolyte, the volume of the anolyte is 20ml; the reaction is carried out under the conditions of current 1.05A, oxygen flow rate 20ml / min, and circulation pump flow rate 20ml / min; oxygen diffuses to the cathode through the gas diffusion cathode On the surface, an oxygen reduction reaction occurs, and hydrogen peroxide is prepared in situ; an oxygen evolution reaction occurs at the anode, and the organic matter in the organic wastewater is directly oxidized by using the anodic oxidation environment; due to the existe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com