Patents

Literature

131results about "Soldering bits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

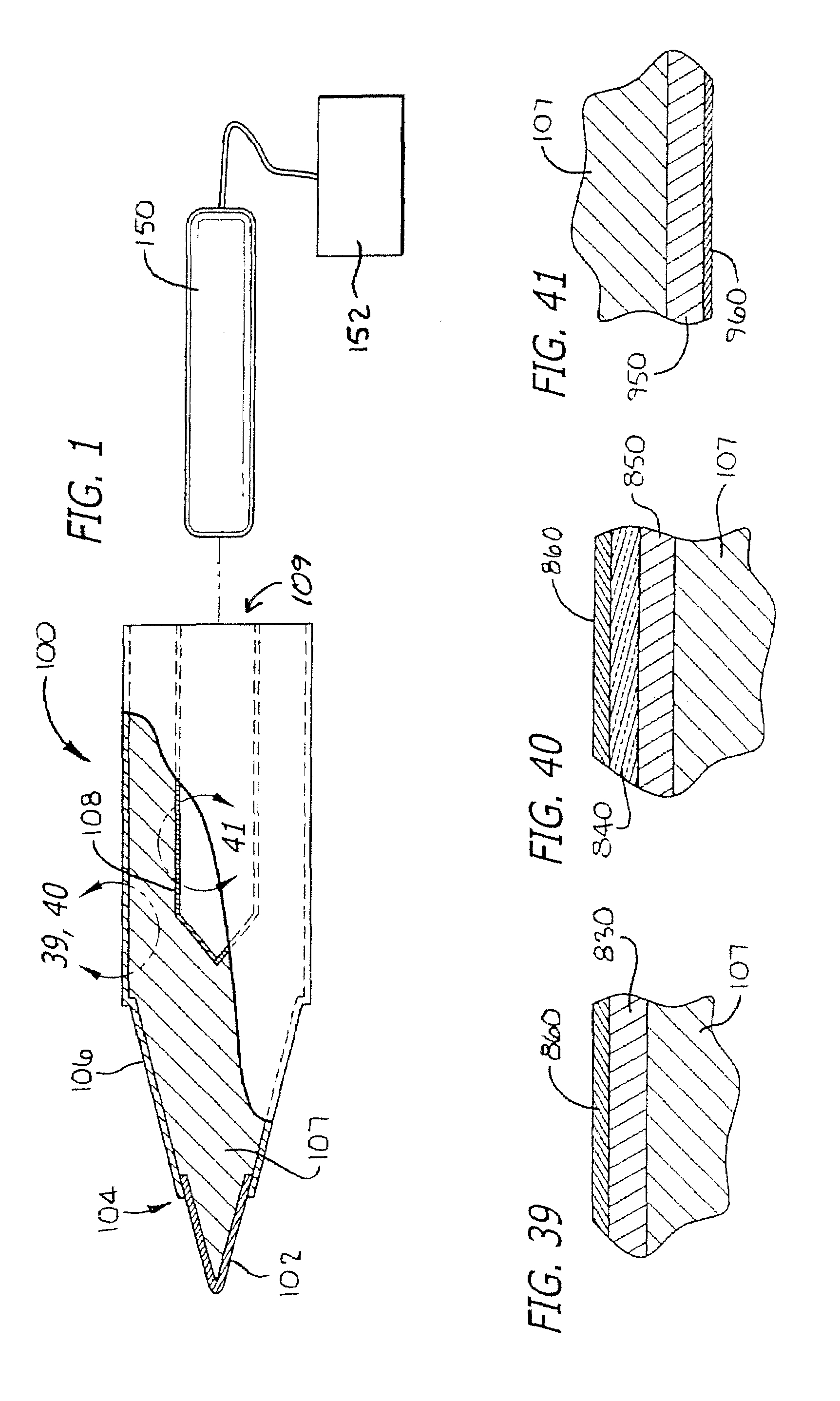

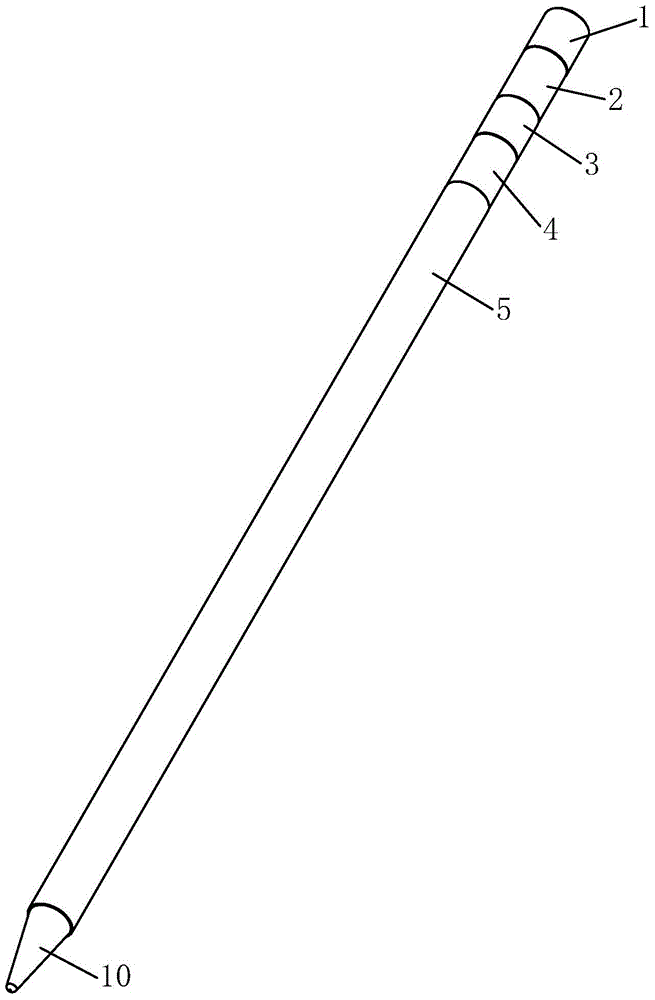

Soldering iron tip with metal particle sintered member connected to heat conducting core

ActiveUS7030339B2Increase plate thicknessExtended processing timeHeating element shapesSoldering bitsCeramic coatingHeat conducting

A soldering iron tip having a copper or copper alloy core and a metal particle sintered member connected to the core to transfer heat therefrom to form a working soldering tip. The sintered member can be manufactured by powder metallurgy from a base material (iron, nickel and / or cobalt particles) and an additive (silicon, copper, silver, tin, boron and / or carbon particles) where needed. The sintered member can be formed as a cap which is fitted onto the working tip with a silver paste sandwiched therebetween, a brazing filler metal ring is positioned between an abutment shoulder and the cap, flux applied to the joint and the cap brazed into place. A metal, cermet or ceramic coating sprayed on the outer surface of the core, except for the (masked) working tip end, is not wettable by solder. An Ag—Al—Cu alloy coating layer in the rearwardly-disposed cavity improves heat conduction from the heater therein.

Owner:HAKKO CO LTD

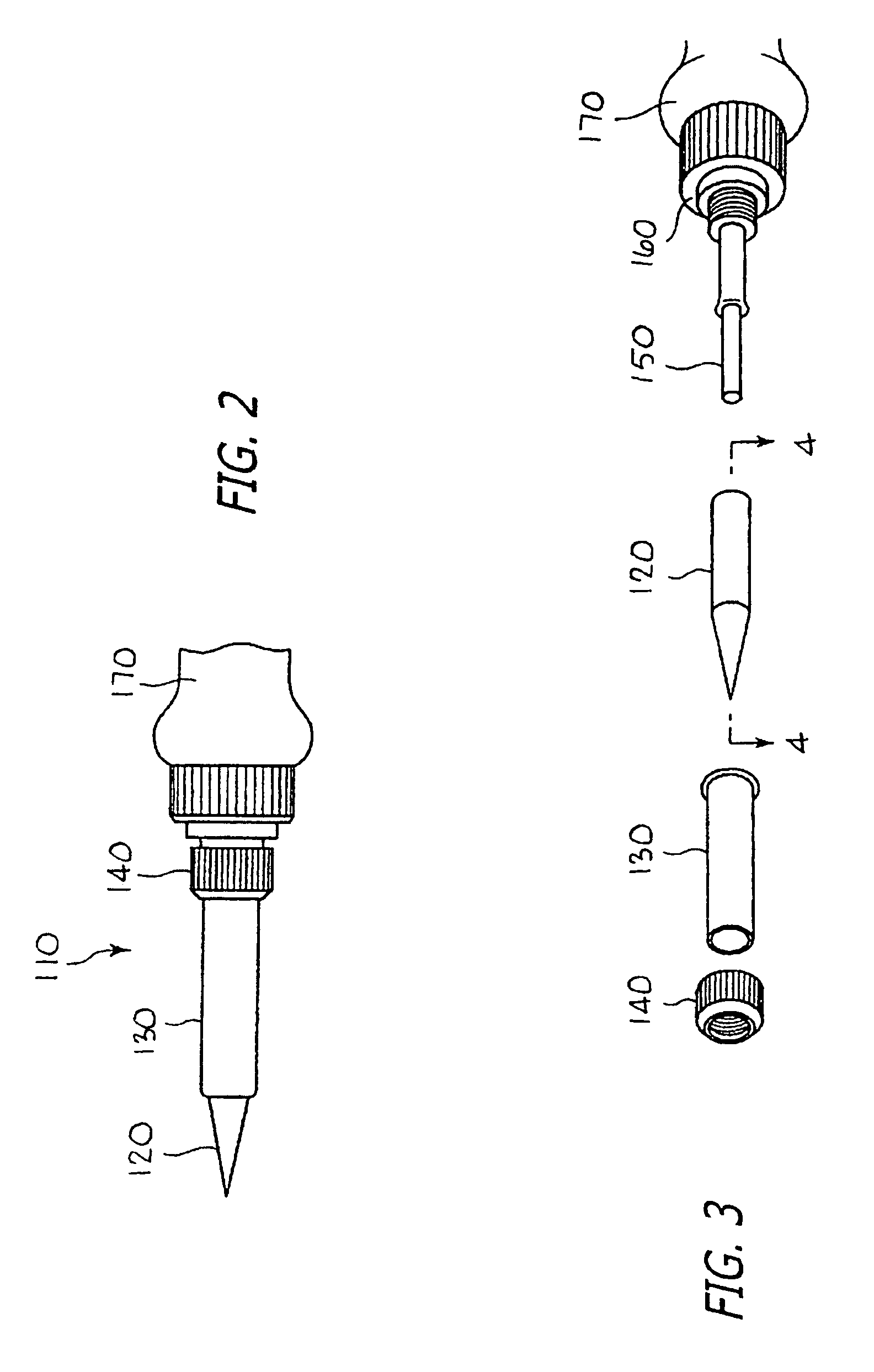

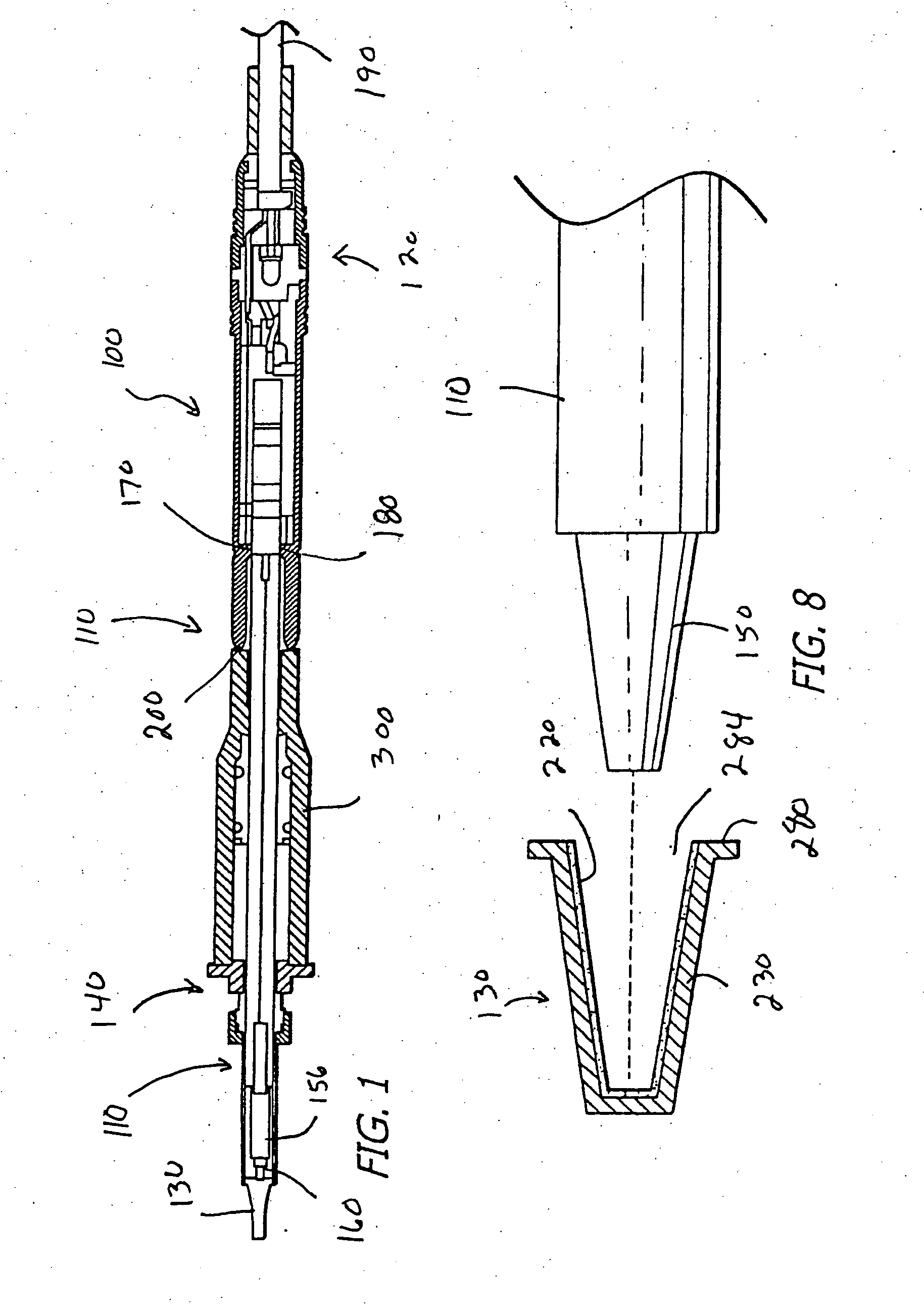

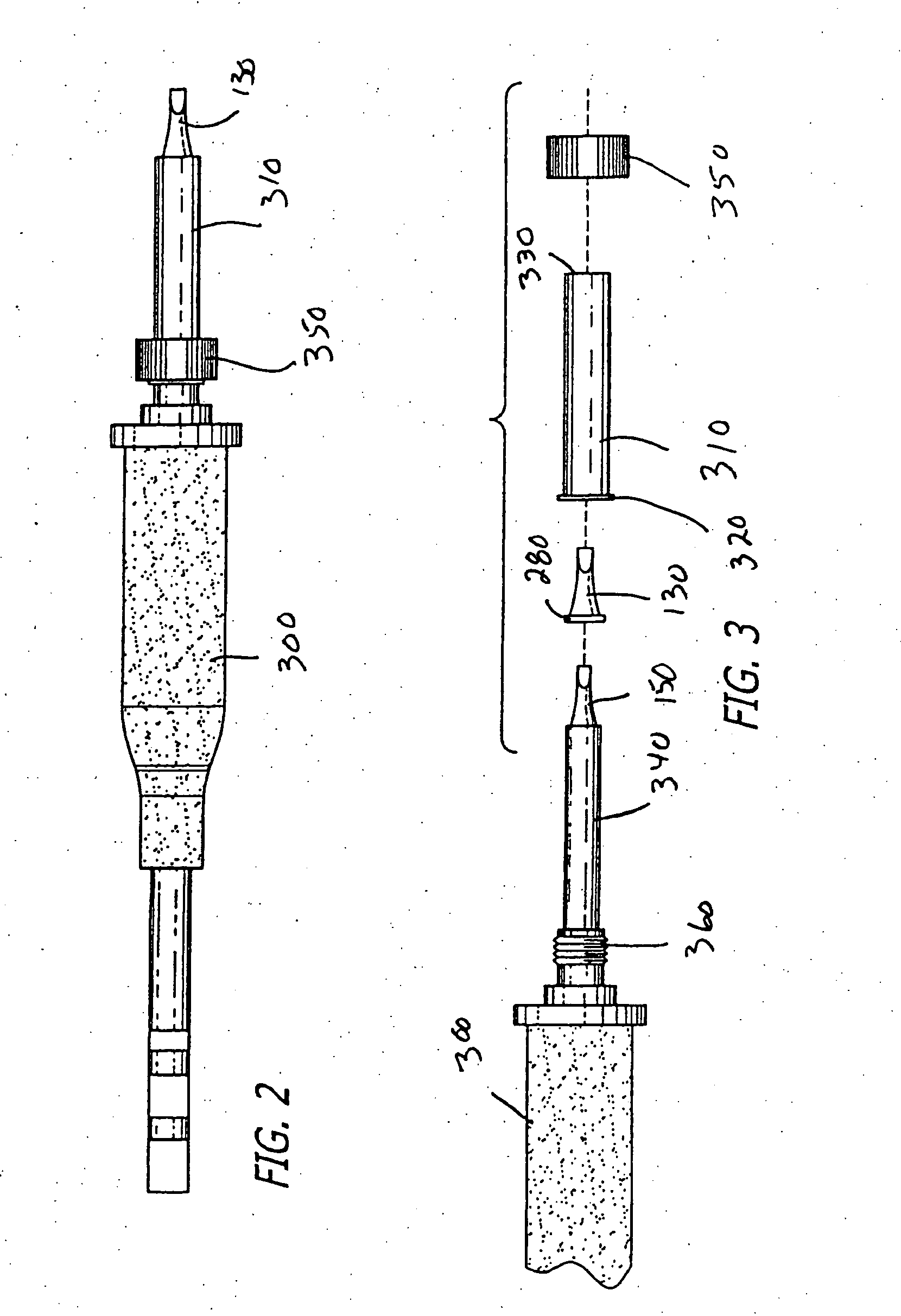

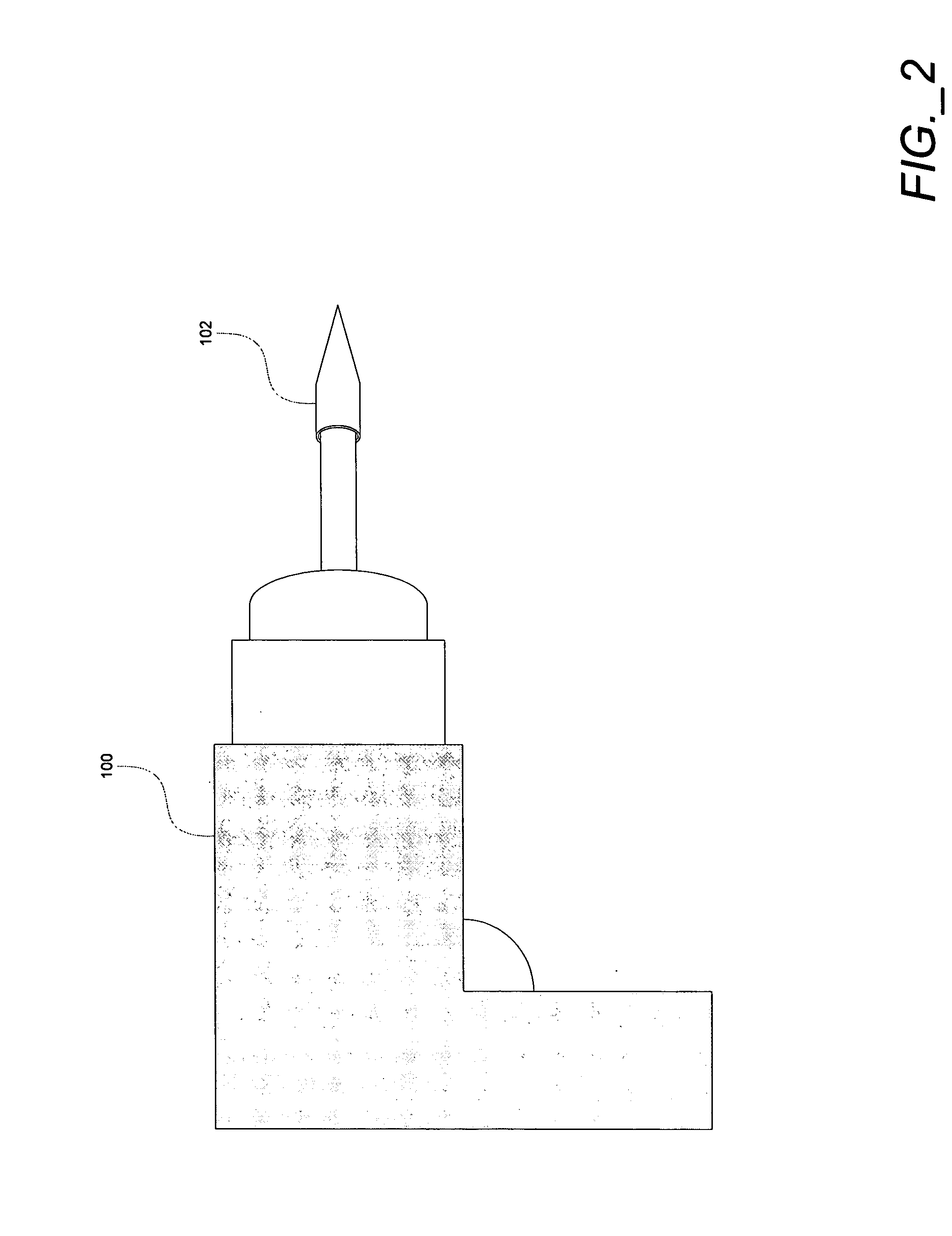

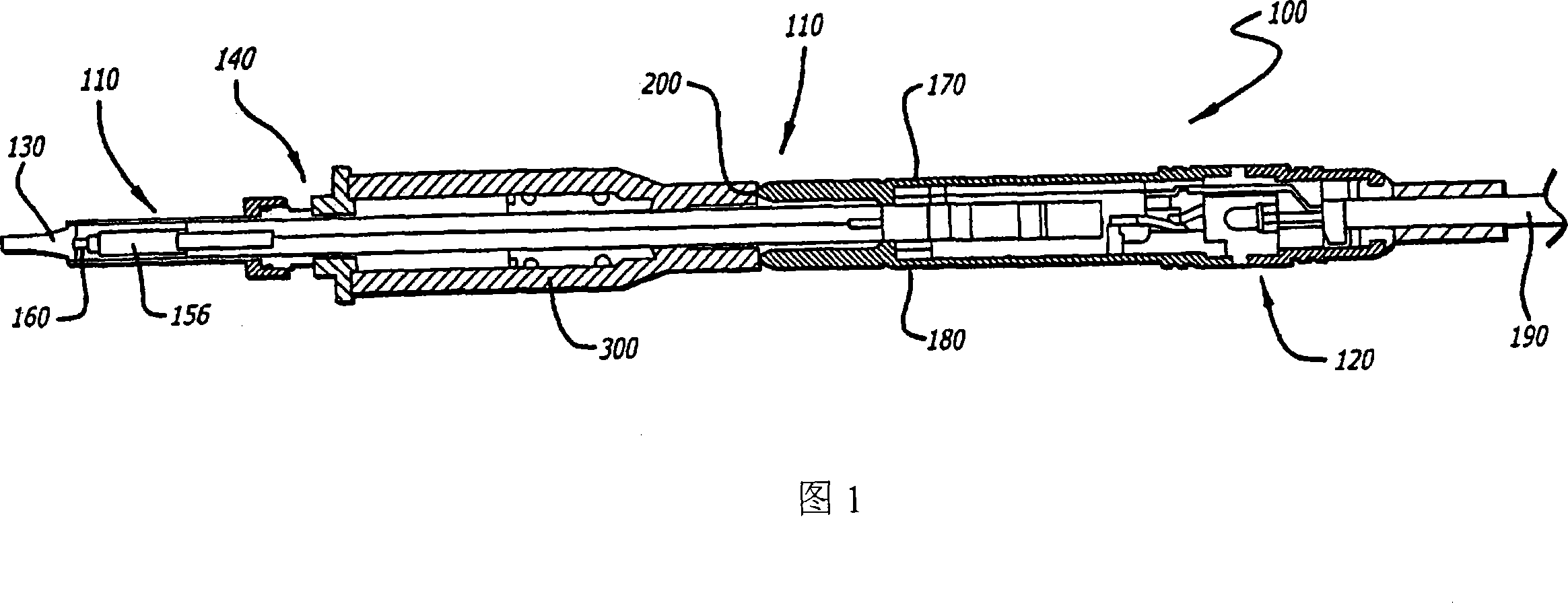

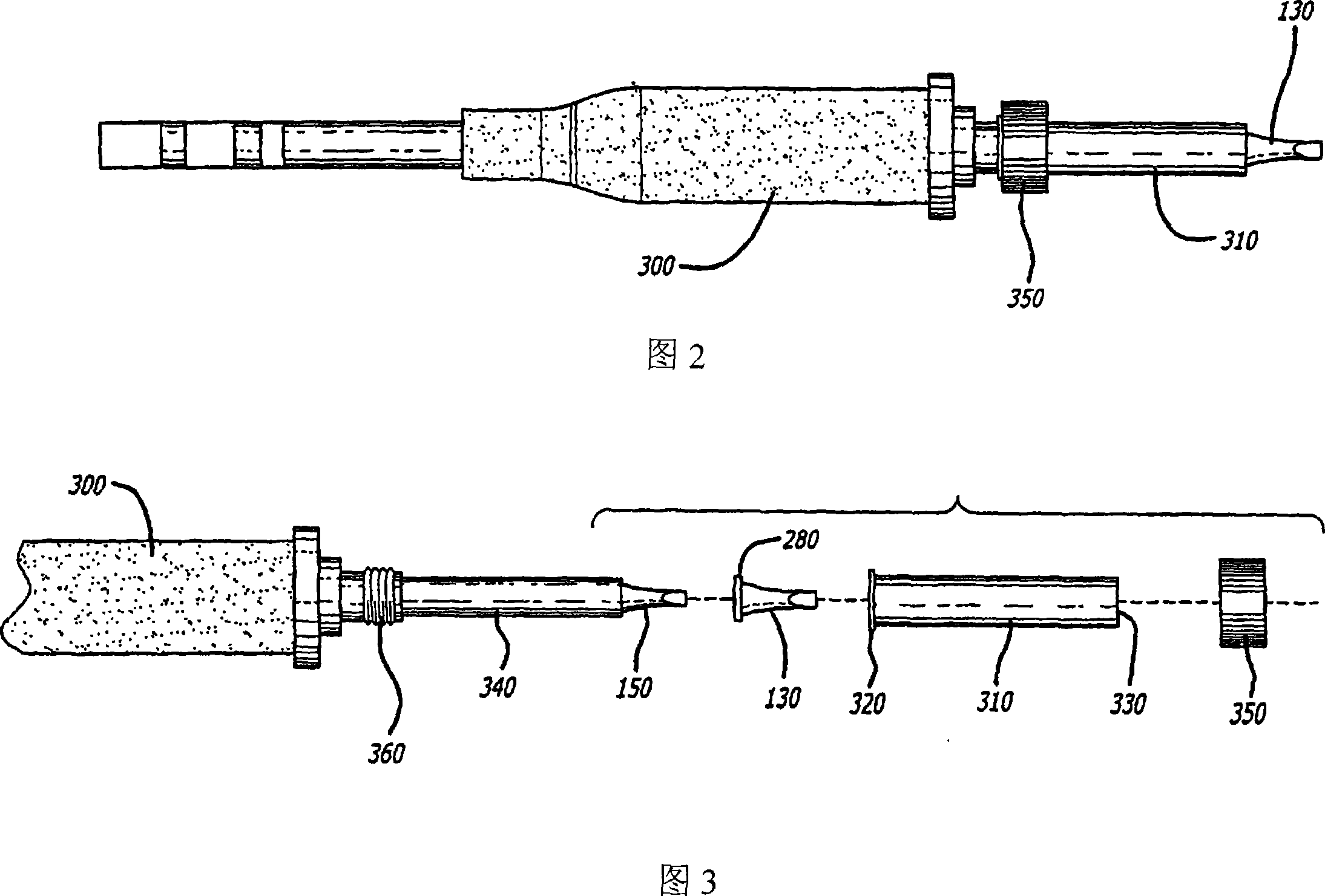

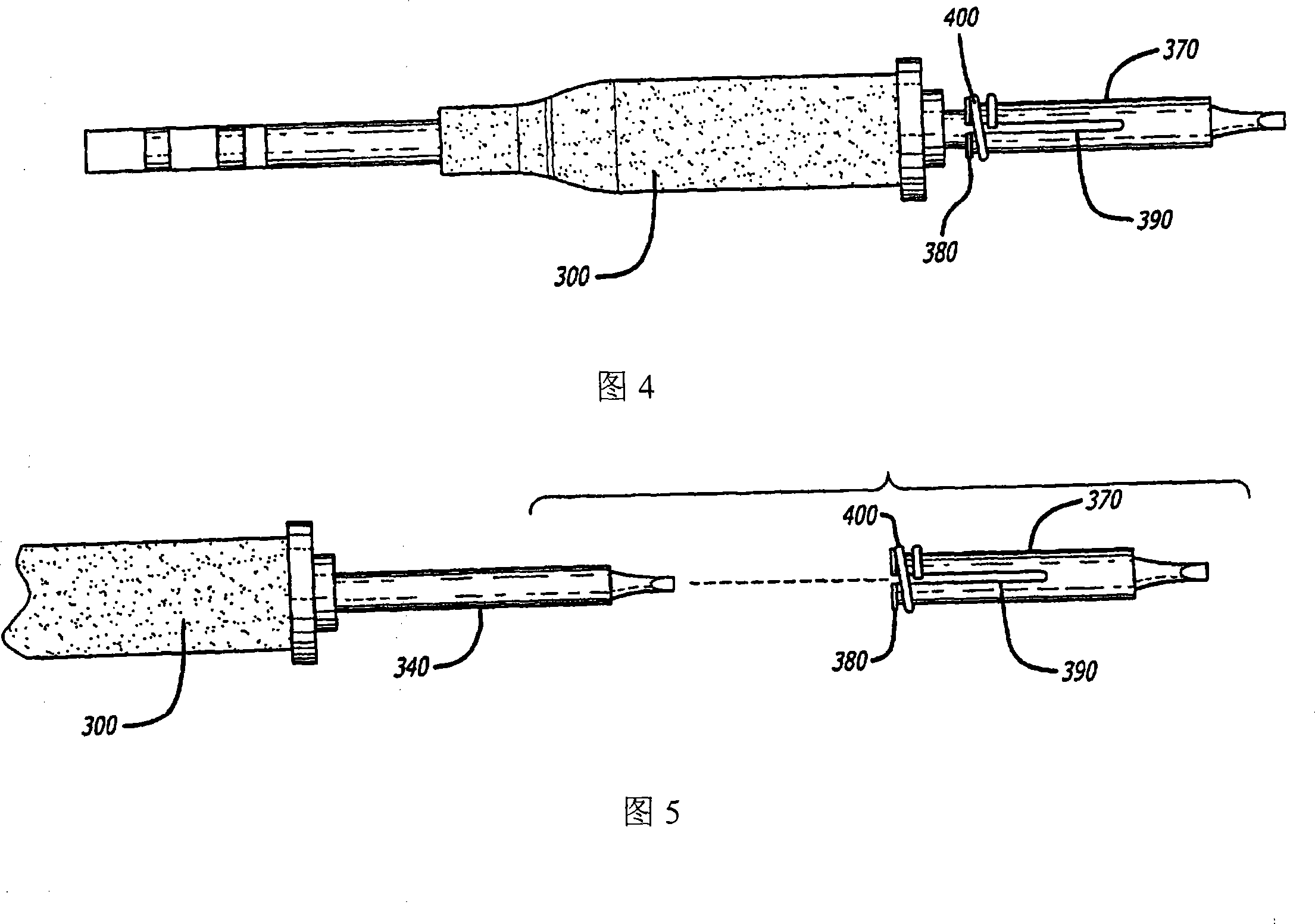

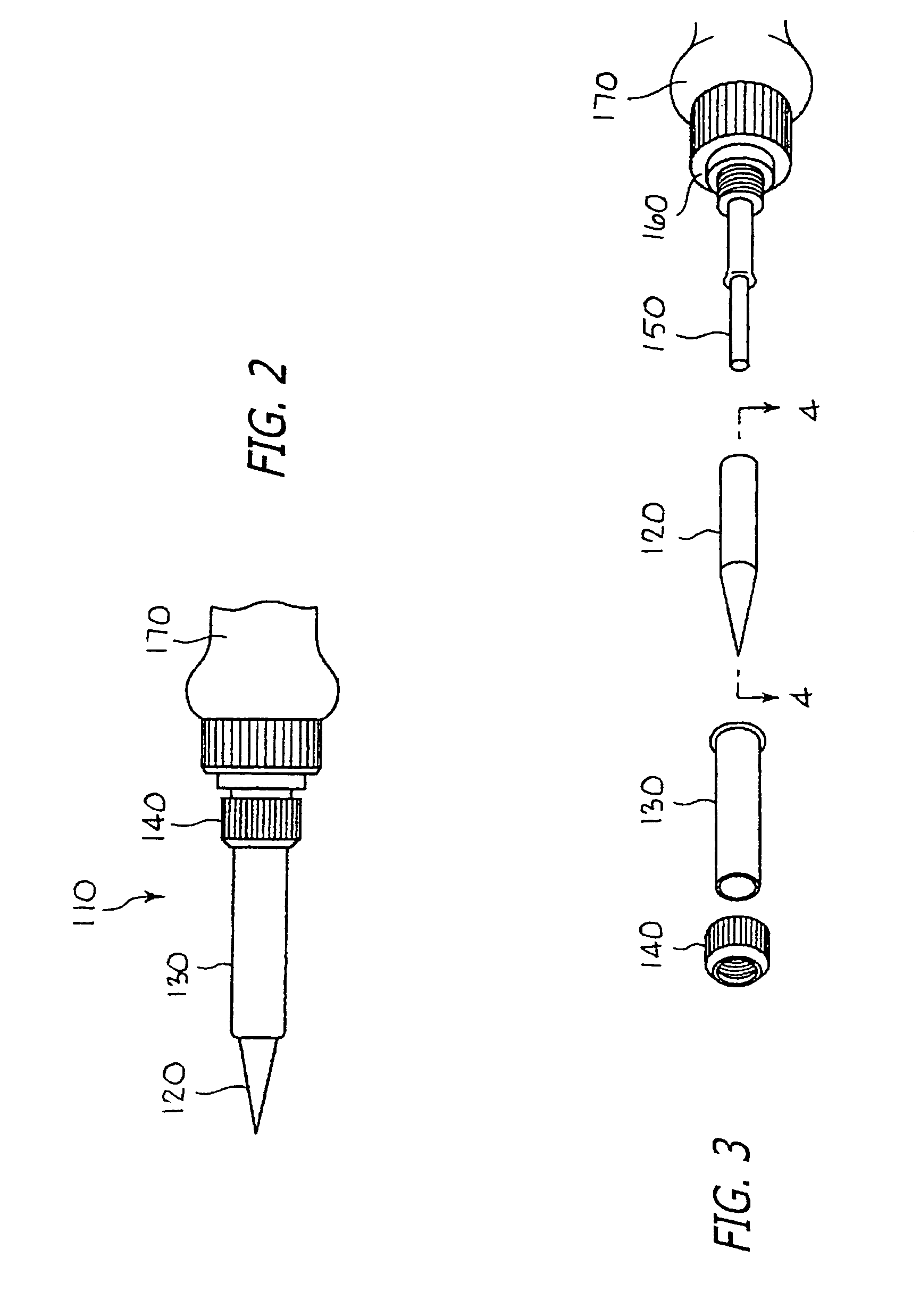

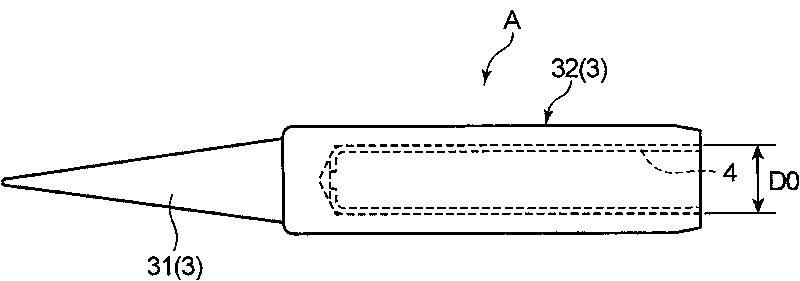

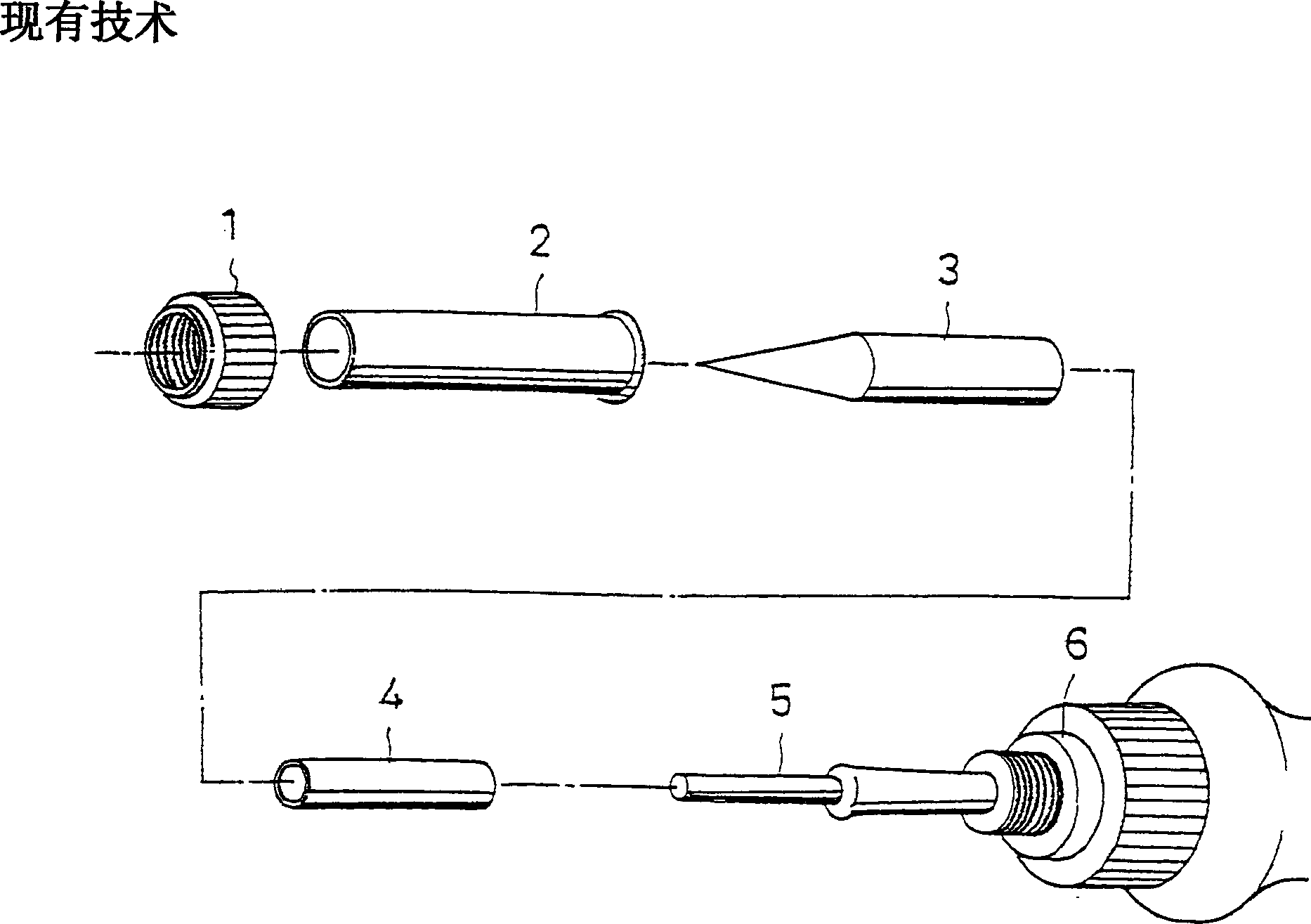

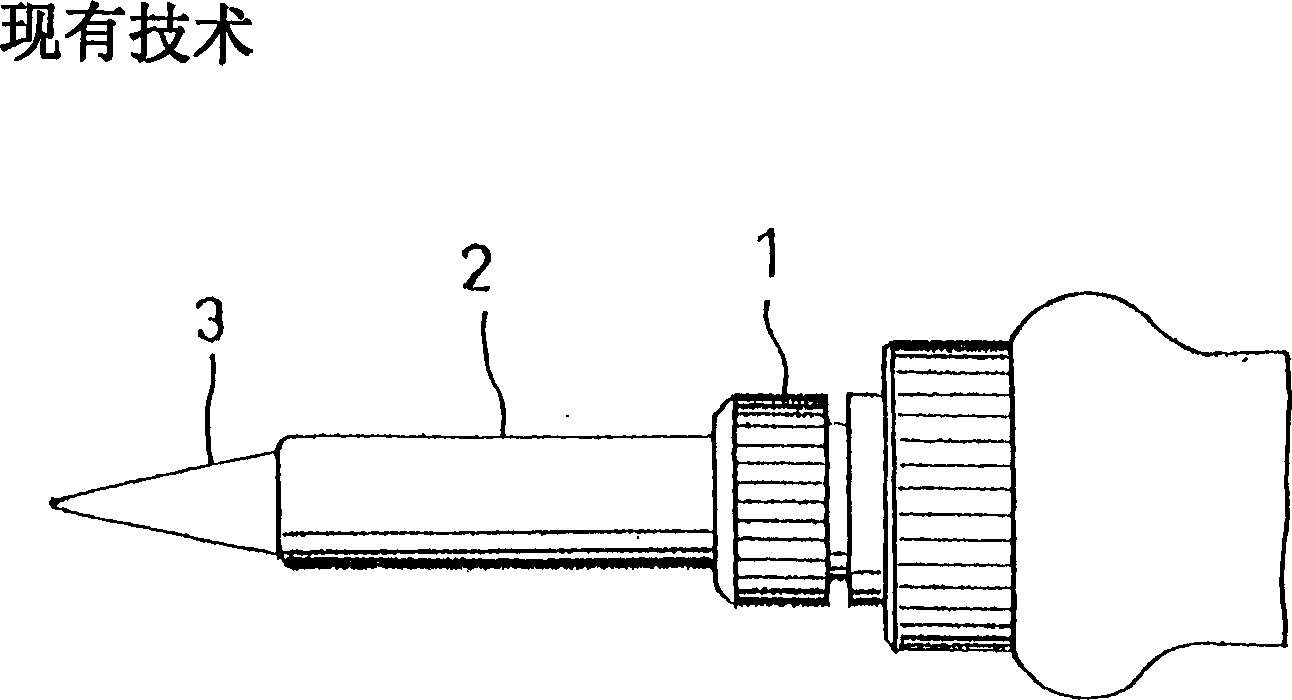

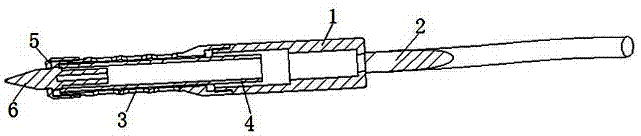

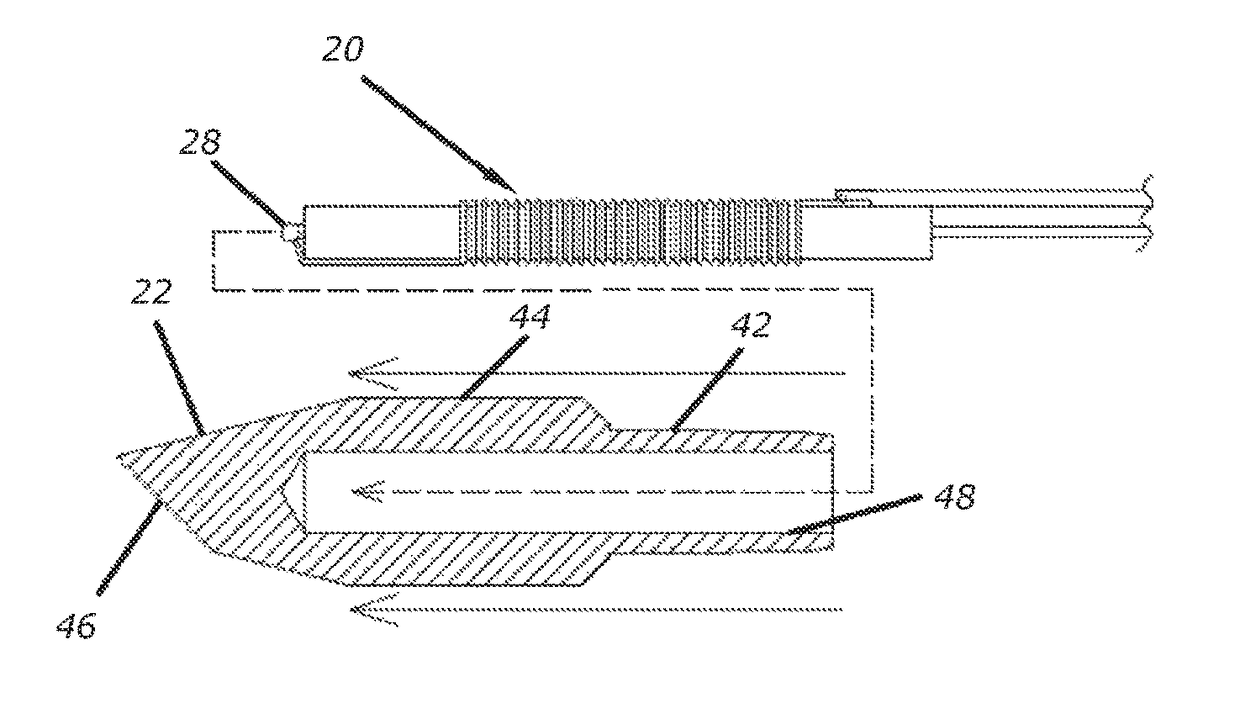

Soldering iron with replaceable tip cap

InactiveUS20050011876A1Improve thermal conductivityImprove the immunityHeating element shapesSoldering bitsConductive pasteHeat conducting

A soldering iron (and a desoldering iron) with a replaceable tip cap are herein disclosed. The replaceable tip cap is fitted on the forward heat-conducting core end of a soldering (or desoldering) iron heat assembly. Conductive paste, powder or a low melting temperature material such as solder, can be sandwiched between the tip cap and the forward end to improve heat conductivity therebetween. An assembly which allows for the easy removal and application of a replacement tip cap can include a sleeve with tightening bolt, a coil spring sleeve, or a slotted compressible sleeve. The tip cap can thus be replaced after it has worn out, and the heat assembly unit need not be replaced until it has burnt out.

Owner:HAKKO CO LTD

Desoldering sheath

A desoldering sheath that comprises at least one hollow metal wire molded to conform to the tip of a desoldering tool. In one implementation, the desoldering sheath is formed using a hollow metal wire that is coiled around a male cone-shaped mold. The coiled, hollow metal wire is then compressed between the male cone-shaped mold and a female cone-shaped mold to cause the hollow wire to retain the coiled shape. In use, the desoldering sheath is placed on the tip of a desoldering gun or iron and then heated. The heated desoldering sheath, while still on the tip of the desoldering gun or iron, is then placed into contact with solder. This causes the solder to melt and the desoldering sheath captures the molten solder by using capillary action to draw the molten solder into the hollow metal wire.

Owner:CHOI MOON GUL +1

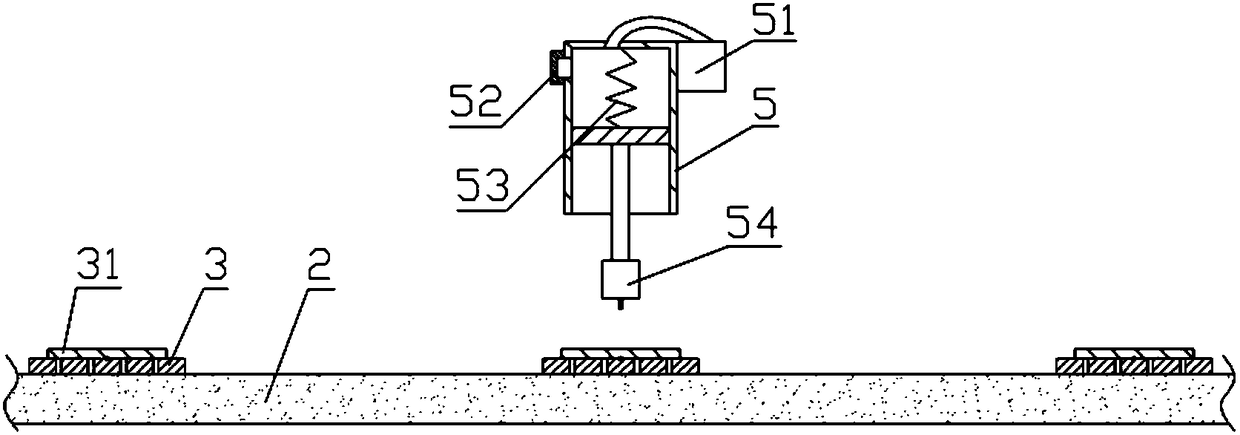

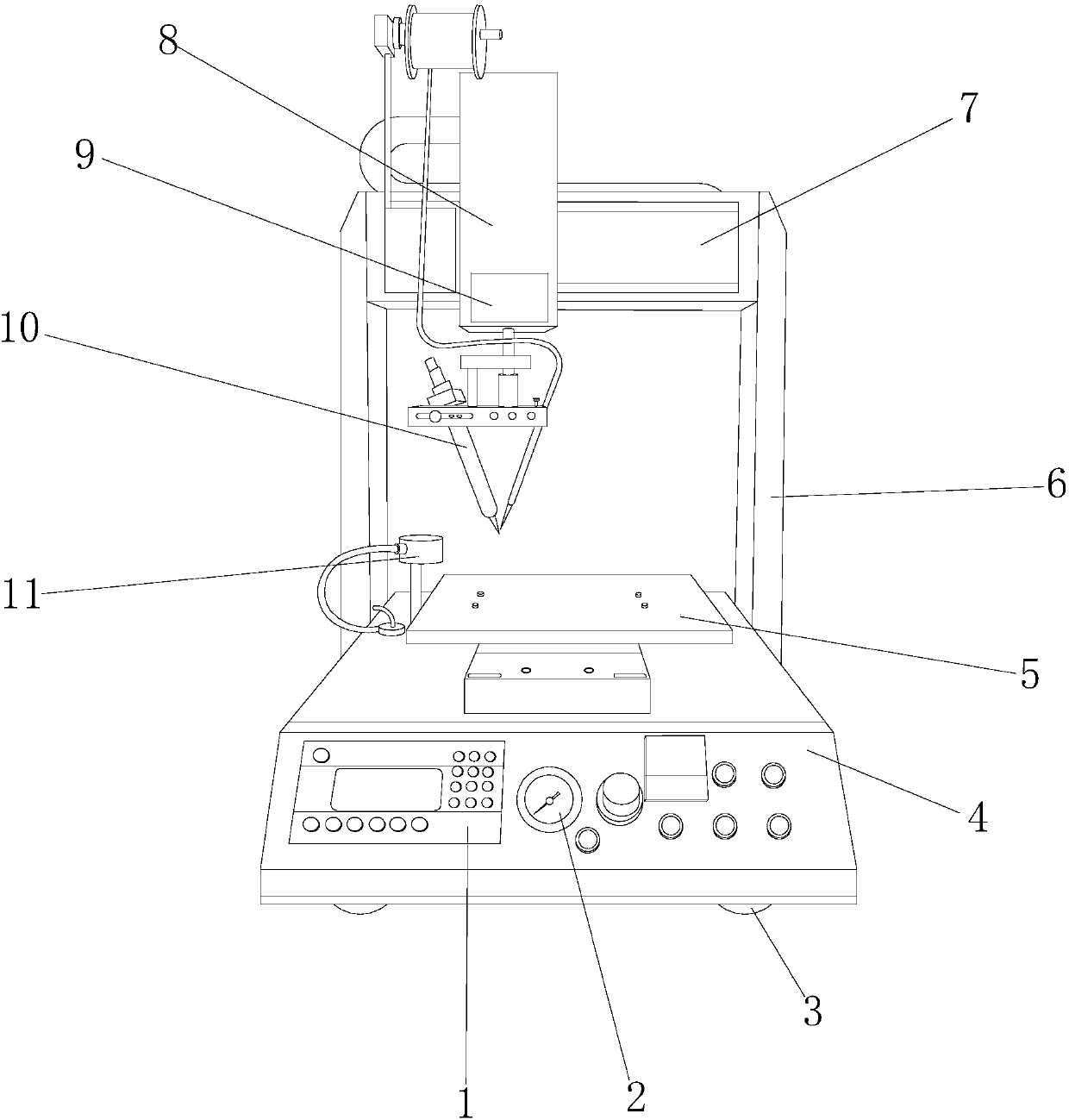

Flexible circuit board welding device

InactiveCN108115242ANo manual operation requiredReduce workloadWelding/cutting auxillary devicesAuxillary welding devicesFlexible circuitsEngineering

The invention relates to the field of circuit board production, and particularly discloses a flexible circuit board welding device comprising a machine frame, a cooling fan, a conveyor belt, a weldingmechanism and a control mechanism, wherein a supporting plate is fixed on the conveyor belt; the welding mechanism comprises an electric soldering iron, a cylinder and a welding fan; the cylinder isprovided with an exhaust port, and a returning spring is arranged in the cylinder; the control mechanism includes a stopping mechanism and a cooling mechanism, and the stopping mechanism and the cooling mechanism each include a cooling fan and an air bag, the air bag and the cooling fan are located on both sides of the conveyor belt respectively, the cooling fan is fixed on the machine frame, andthe air bag can slide relative to the machine frame. A first heated expansive substance is stored in the air bag of the stopping mechanism, a second heated expansive substance is stored in the air bagof the cooling mechanism, a closing switch is fixed on the machine frame, and the closing switch can shut down the conveyor belt and the welding fan, and the machine frame is provided with a compression spring. According to the scheme, the supporting plate can be cooled while a circuit board is welded.

Owner:宁波隆锐机械制造有限公司

Novel automatic spraying robot for ship

InactiveCN107931770AReduce wear and tearDeformation then lowSoldering bitsSoldering ironElectricityContact type

The invention discloses a novel automatic spraying robot for a ship. The novel automatic spraying robot for the ship structurally comprises a system operation panel, a pressure meter, bottom feet, a machine base, a workbench, a stand column, a cross beam, a tin feeding mechanism, a model mark, an electric soldering iron and a tin blowing mechanism; the cross section of the system operation panel is of a rectangular structure and is horizontally and closely attached to the front end of the machine base and mechanical connection is adopted; and the pressure meter is horizontally fixed to the right end of the system operation panel and is electrically connected with the machine base. The machine base achieves that in the tin welding operation process, no electrodes need to be used, the worryof electrode pollution or damage is avoided, because the novel automatic spraying robot for the ship does not belong to the contact type automatic tin welding machine process, the loss and the deformation of the machine can both be reduced to be lowest, it is guaranteed that a laser beam can be focused in a very small area, the automatic tin welding machine is made to be minimum, and for parts small in interval, a high-speed automatic tin welding machine can be easily aligned with a weldment automatically and accurately.

Owner:郁海金

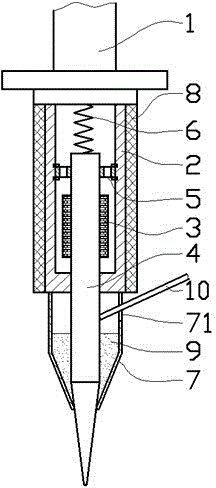

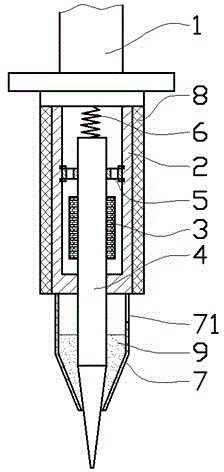

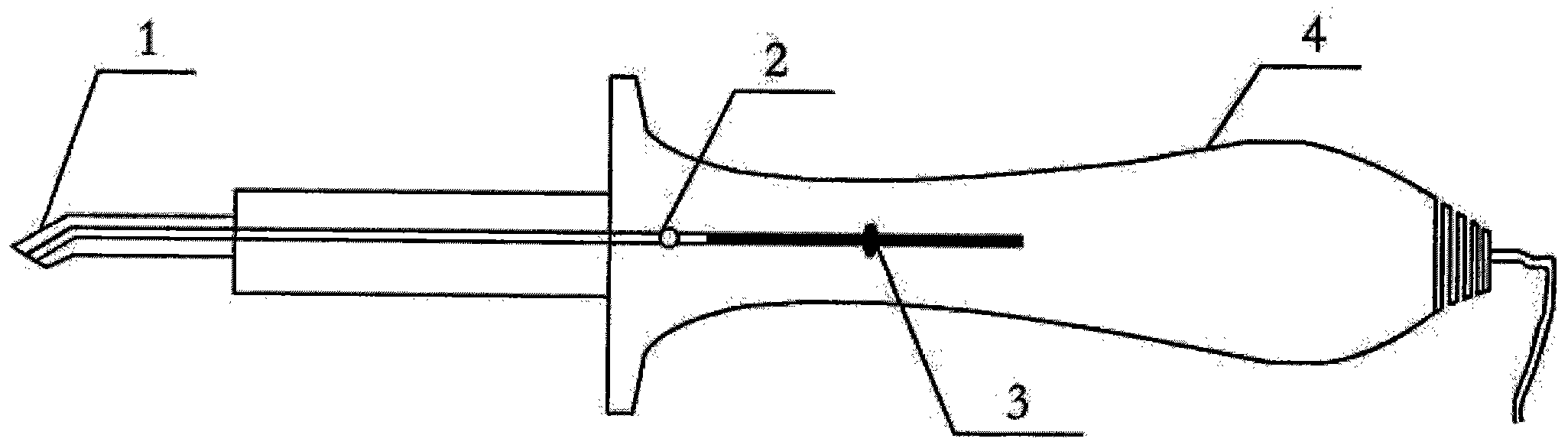

Press-welding type electric soldering iron

InactiveCN104014895ARealize strip edge weldingSoldering bitsSoldering ironEngineeringMaterial storage

The invention provides a press-welding type electric soldering iron. The press-welding type electric soldering iron comprises a handle, a shell, a soldering iron core and a soldering iron head, wherein a guide ring is assembled in the shell; the soldering iron is capable of sliding and penetrating through the guide ring and the lower part of the shell; the external part of the soldering iron head is fixedly covered with the soldering iron core; the soldering iron core is arranged between the guide ring and a bottom plate at the lower part of the shell; the upper part of the soldering iron head is connected to the upper part of the inner wall of the shell through a spring; a material storage hopper in a shape of a conical funnel is fixed on the lower part of the shell; a conical surface of the lower part of the soldering iron head is tightly pressed on a conical outlet of the material storage hopper; a feeding opening is formed in the upper part of the side of the material storage hopper. The electric soldering iron can be operated by one hand; the use amount of soldering tin is easy to control; a soldering tin solution linearly flows to a soldering part, thus soldering bar-shaped sides.

Owner:胡振强

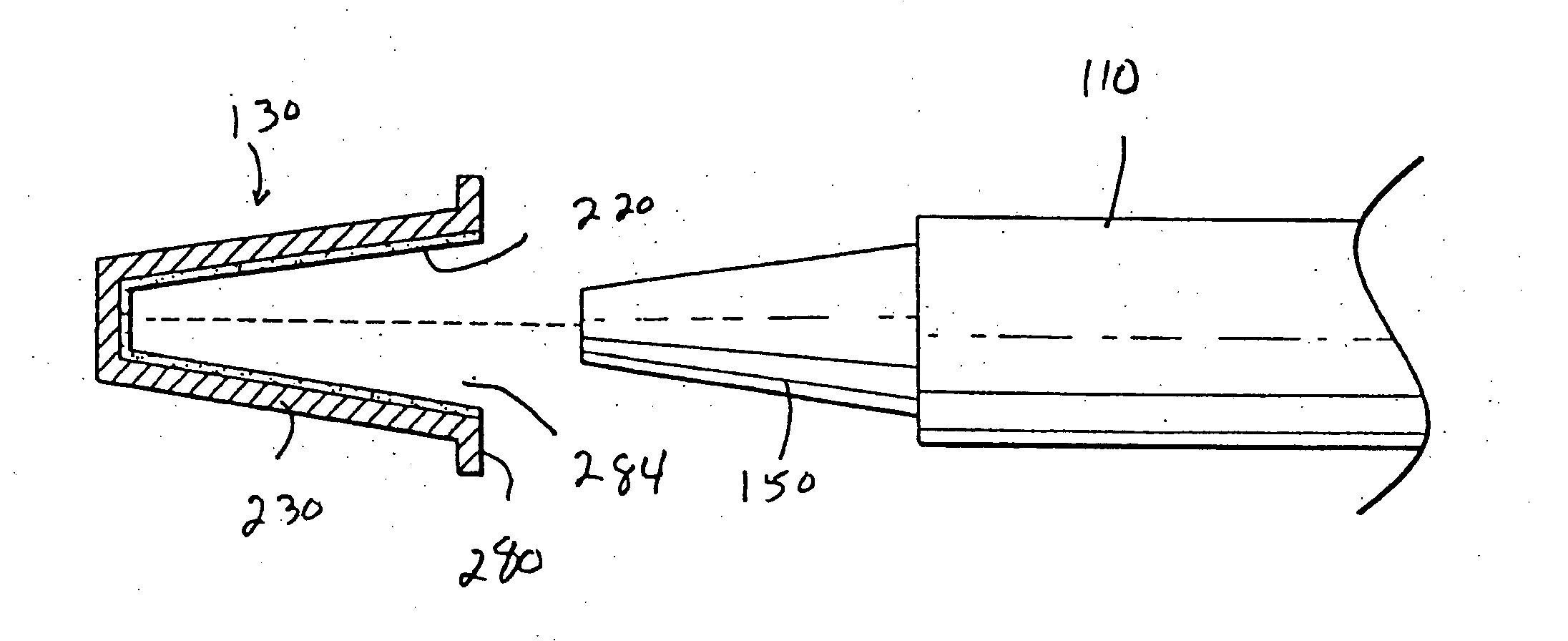

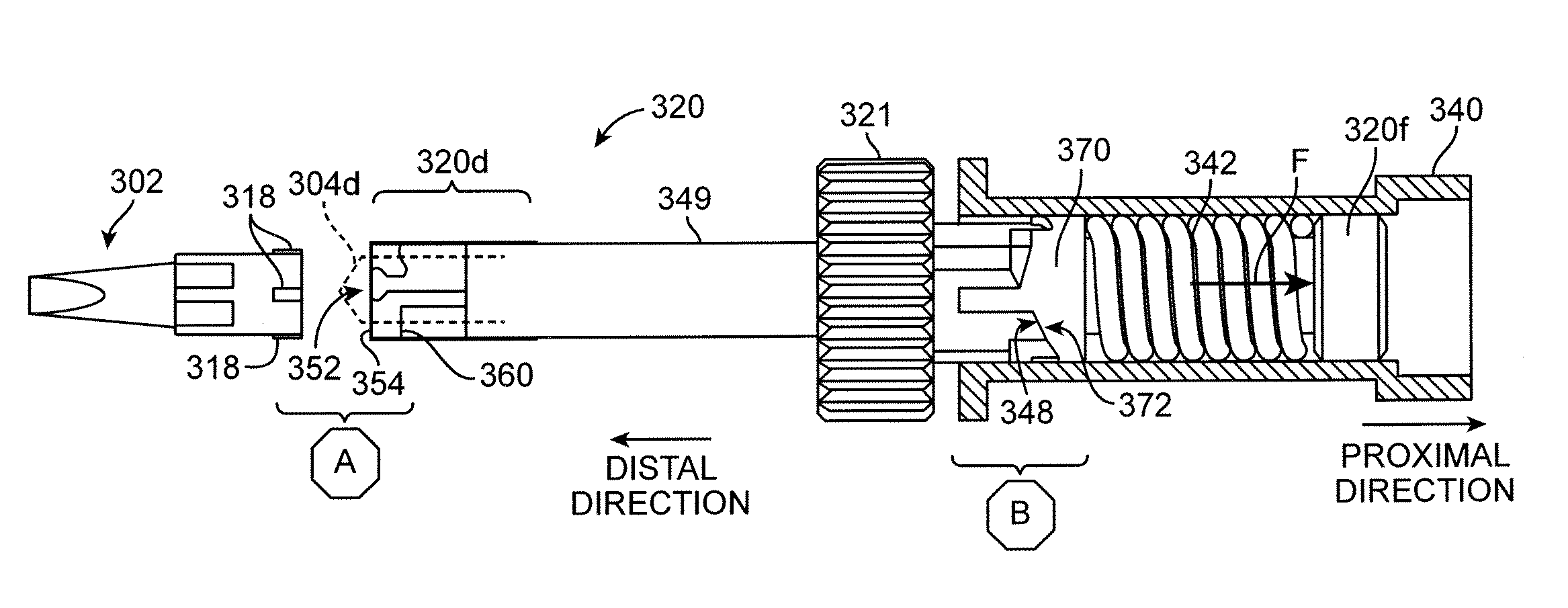

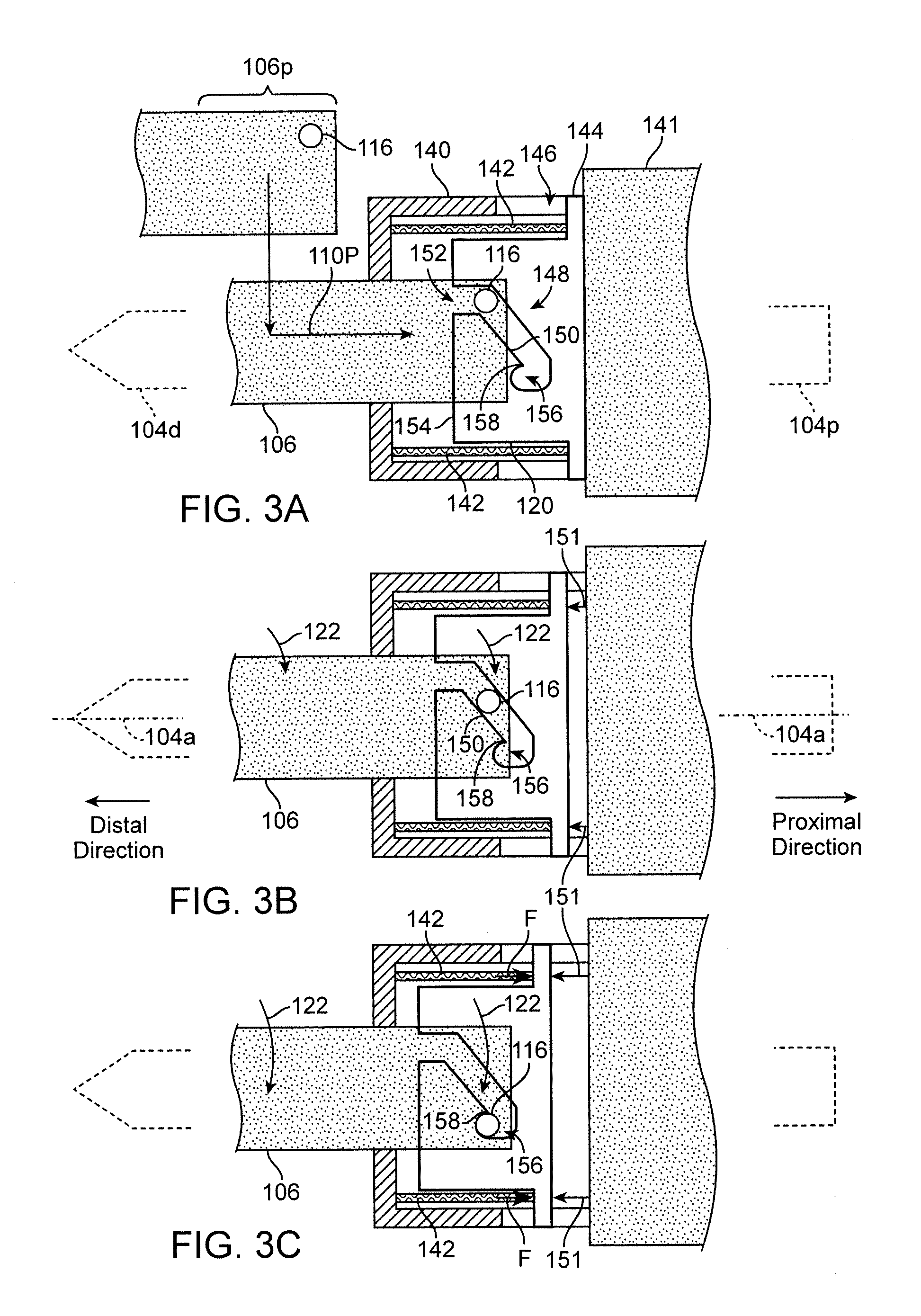

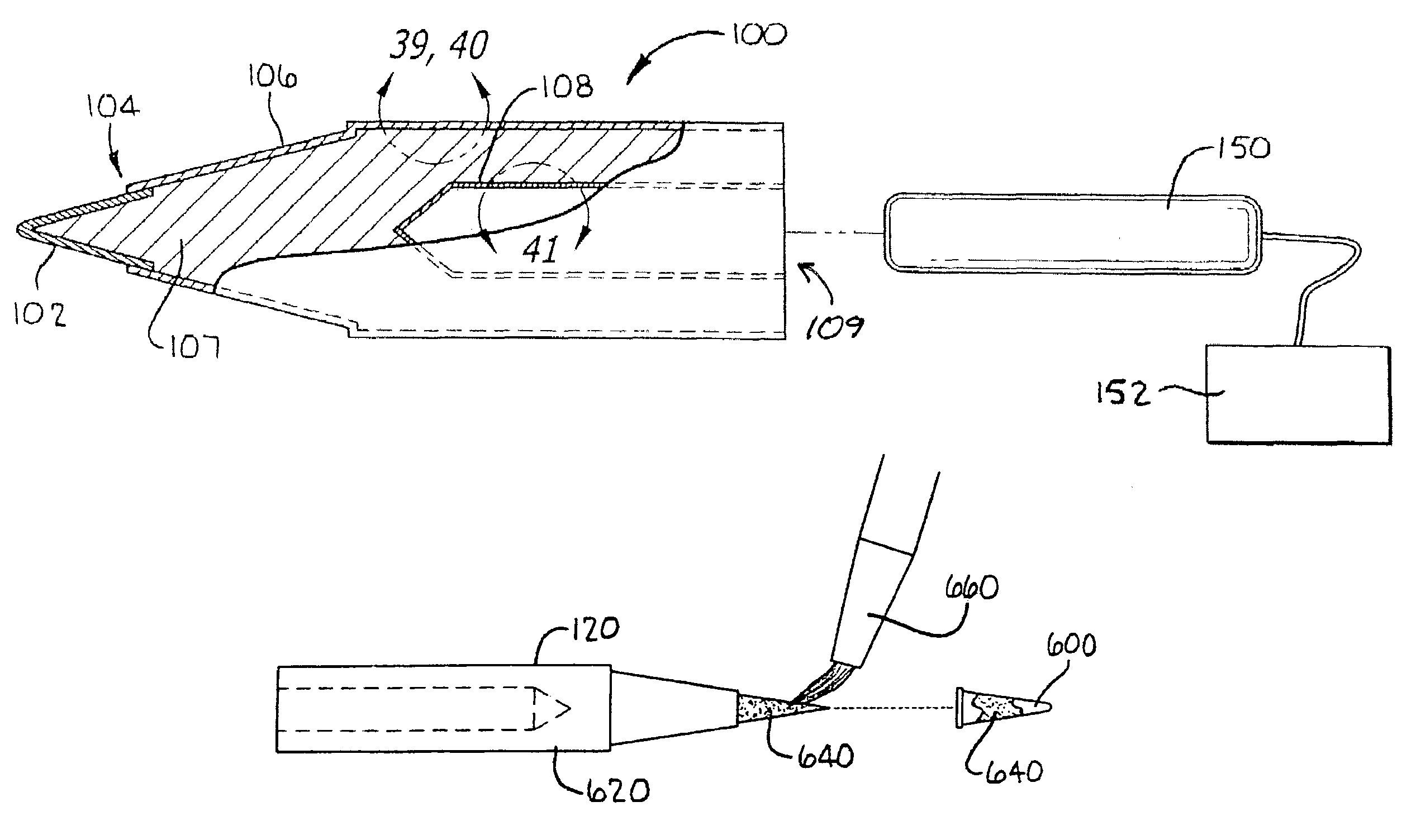

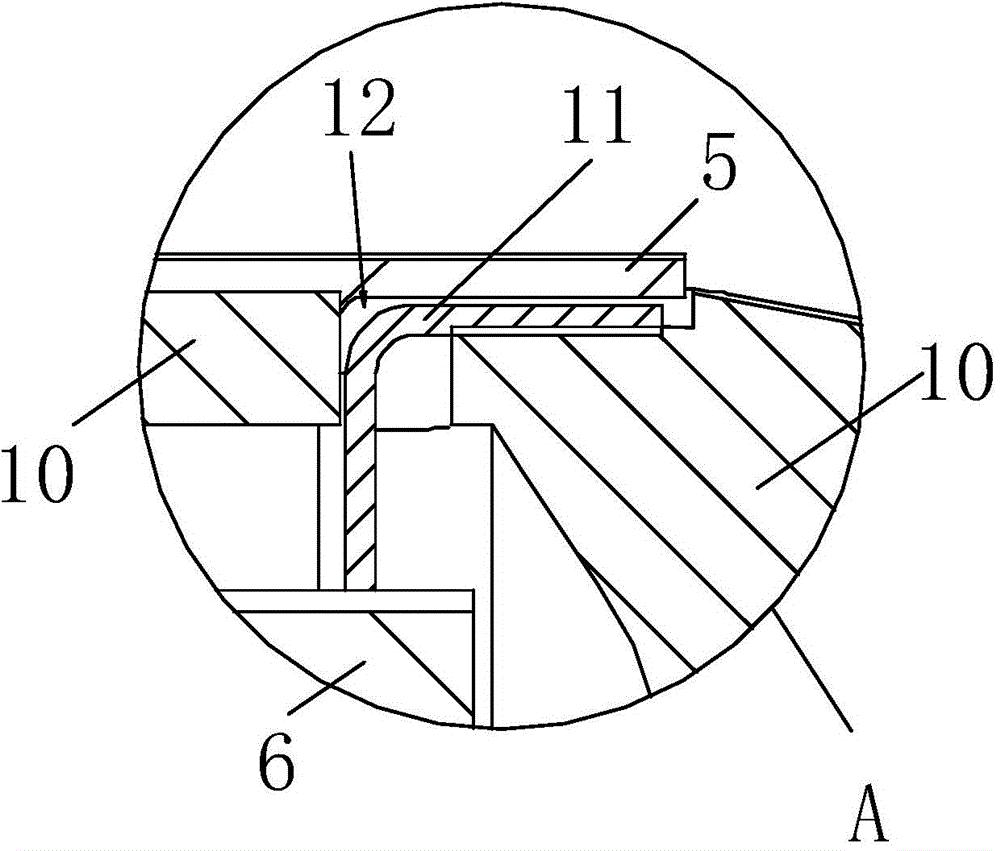

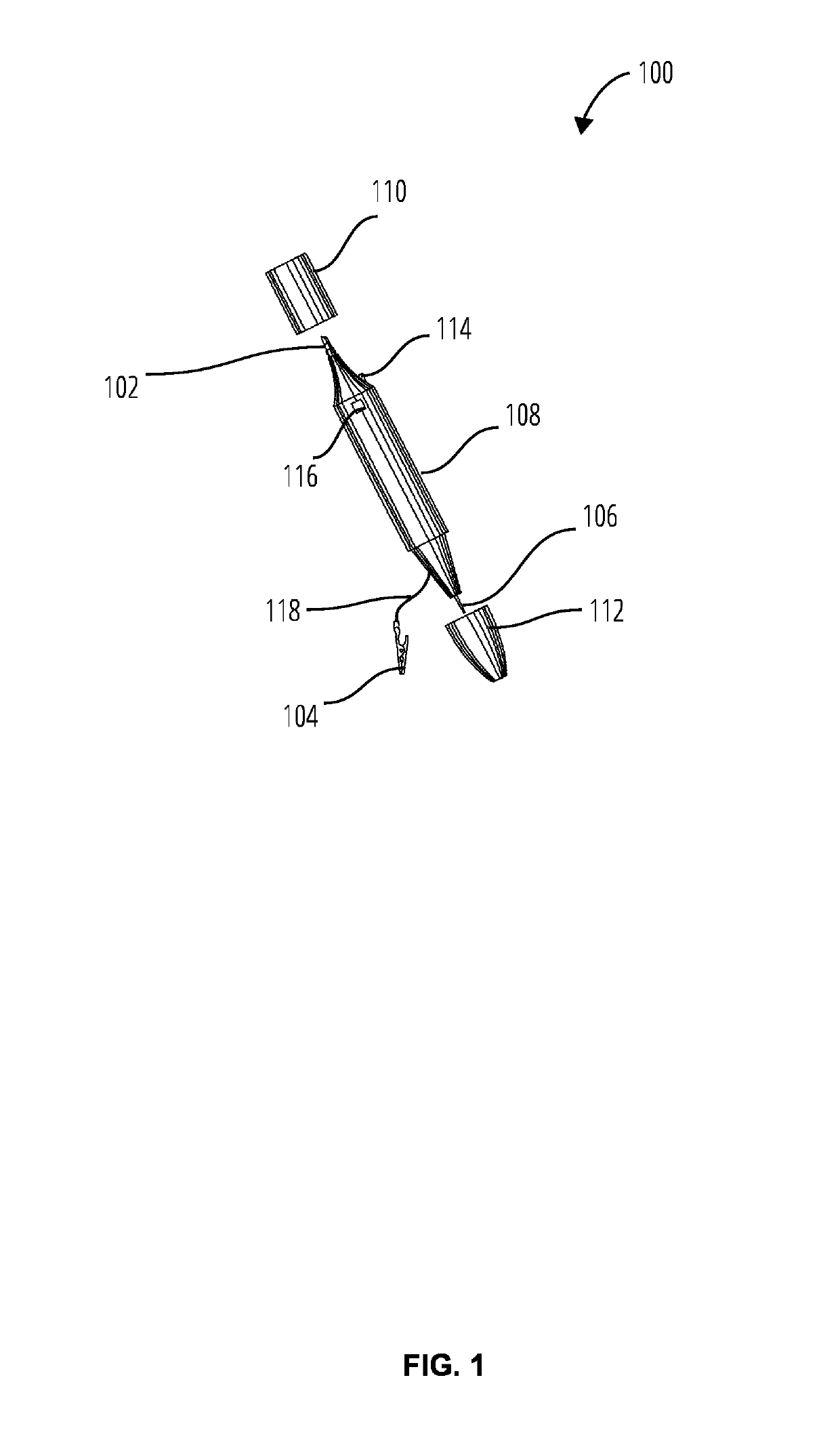

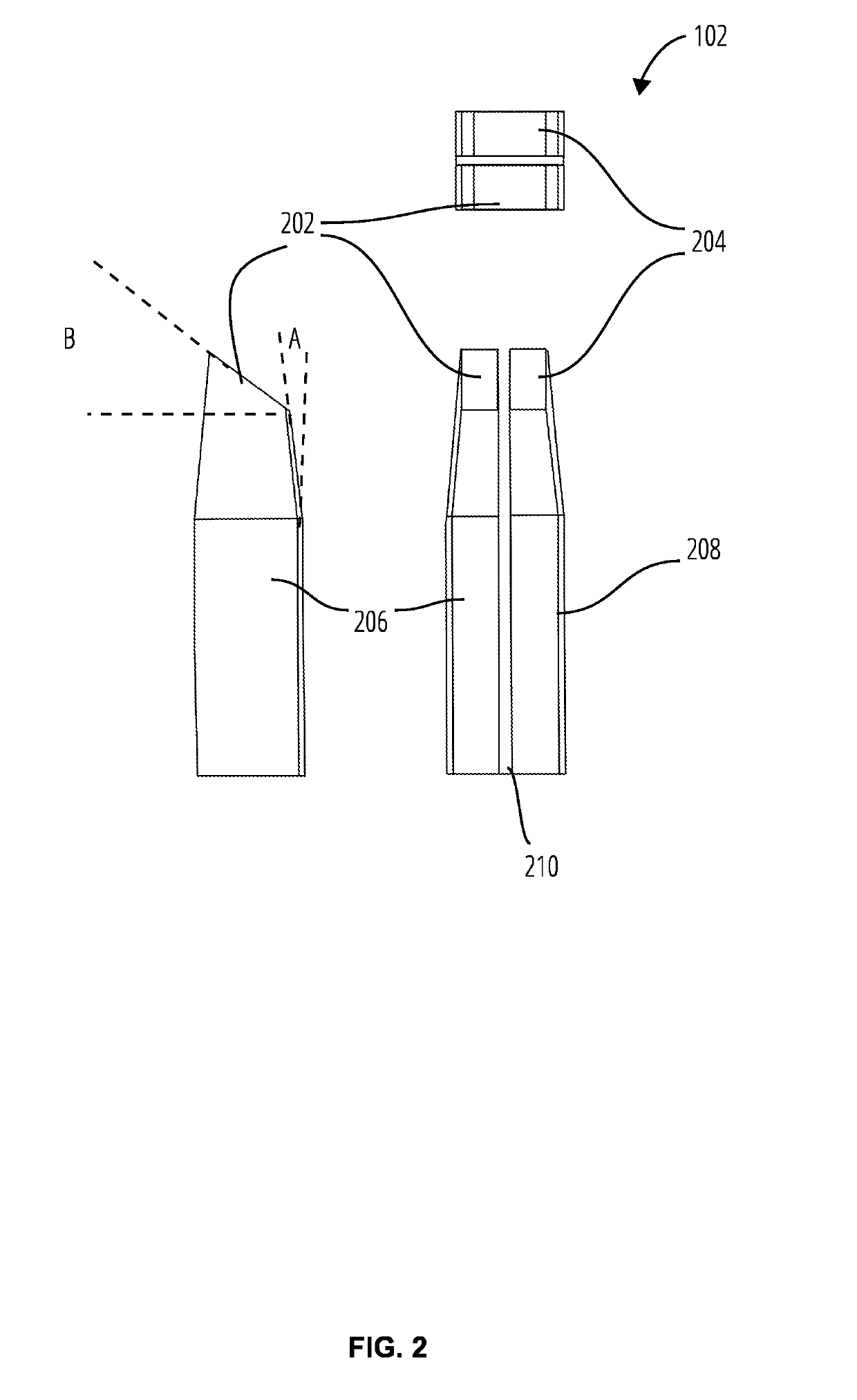

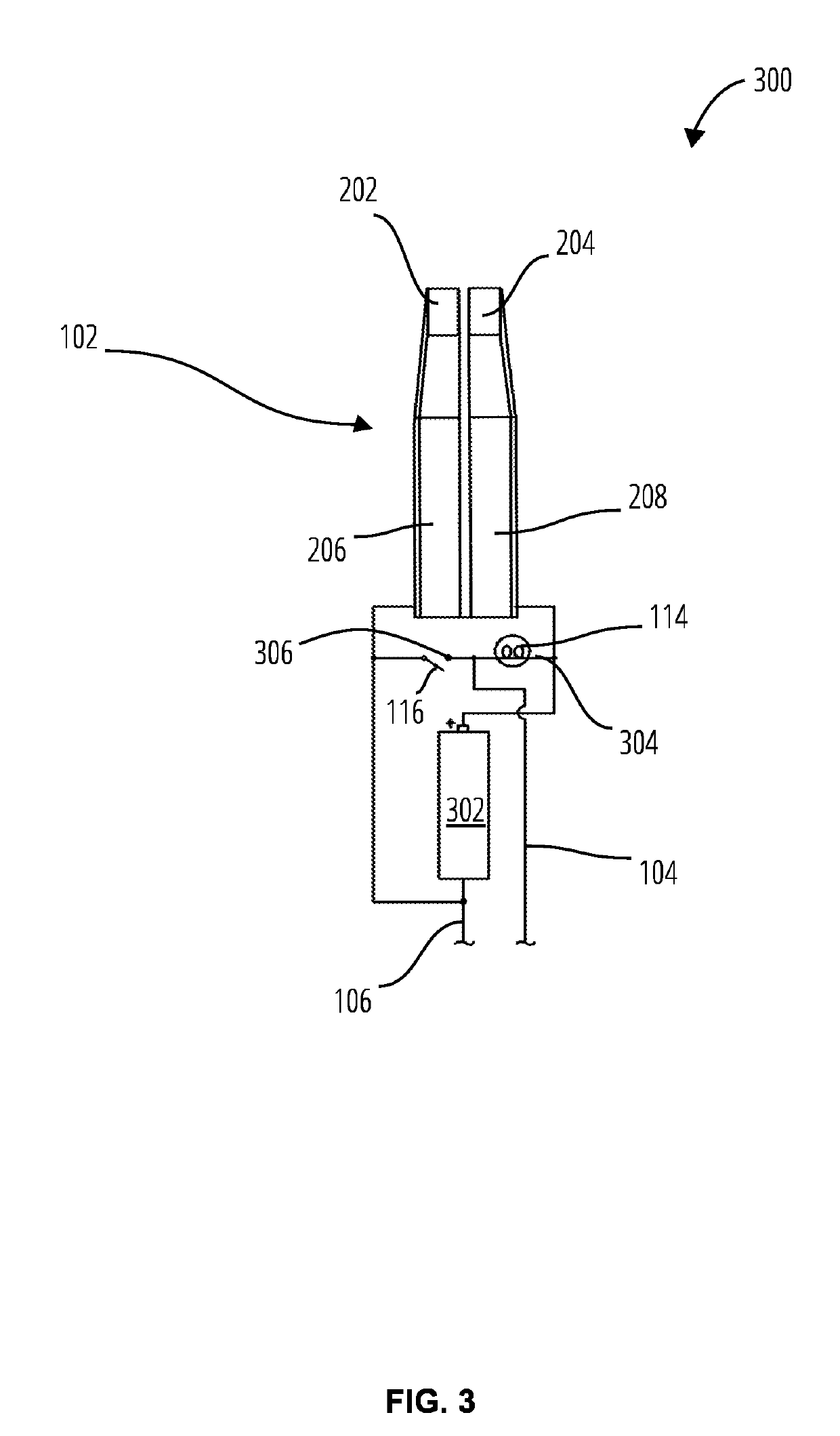

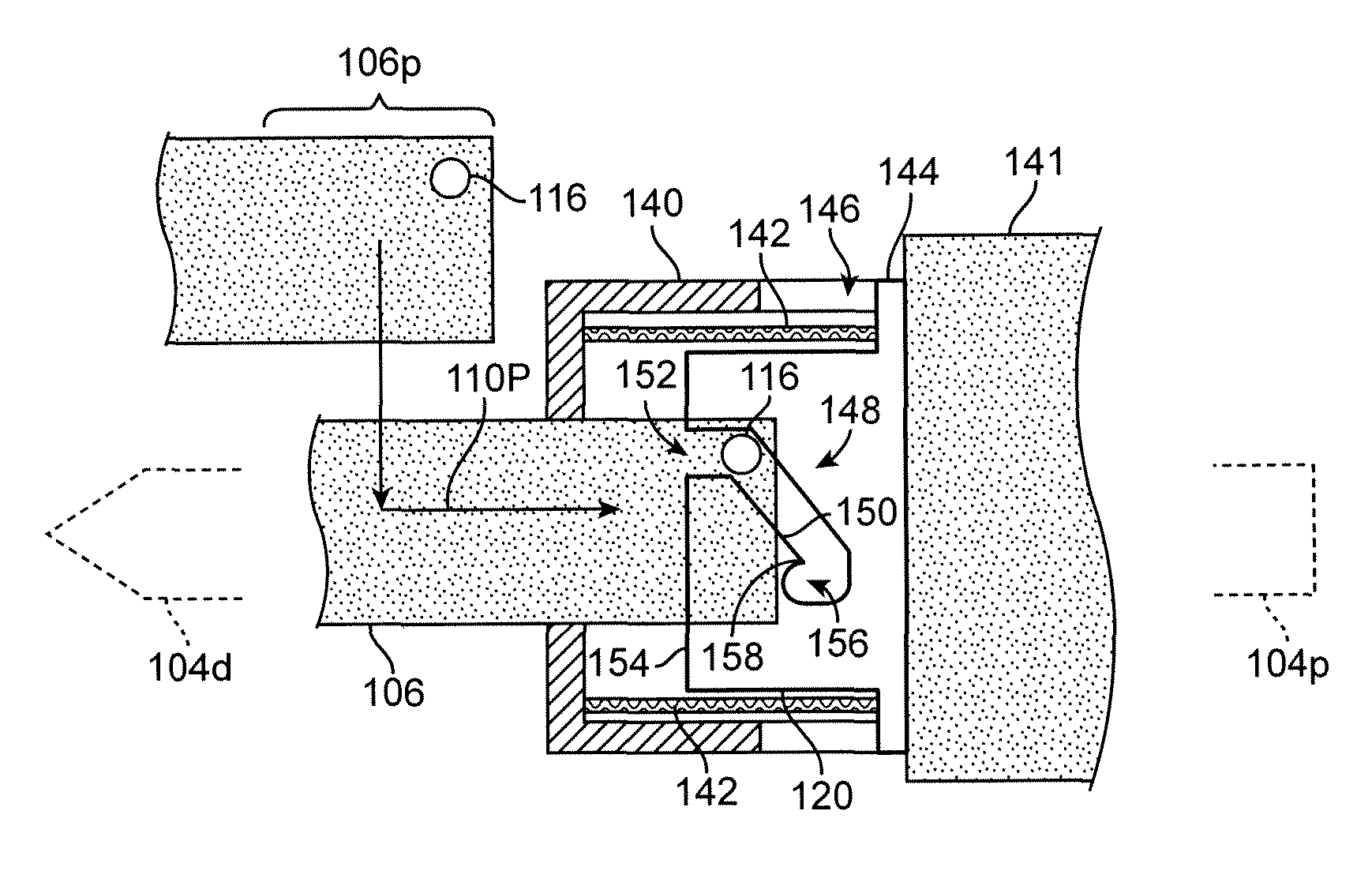

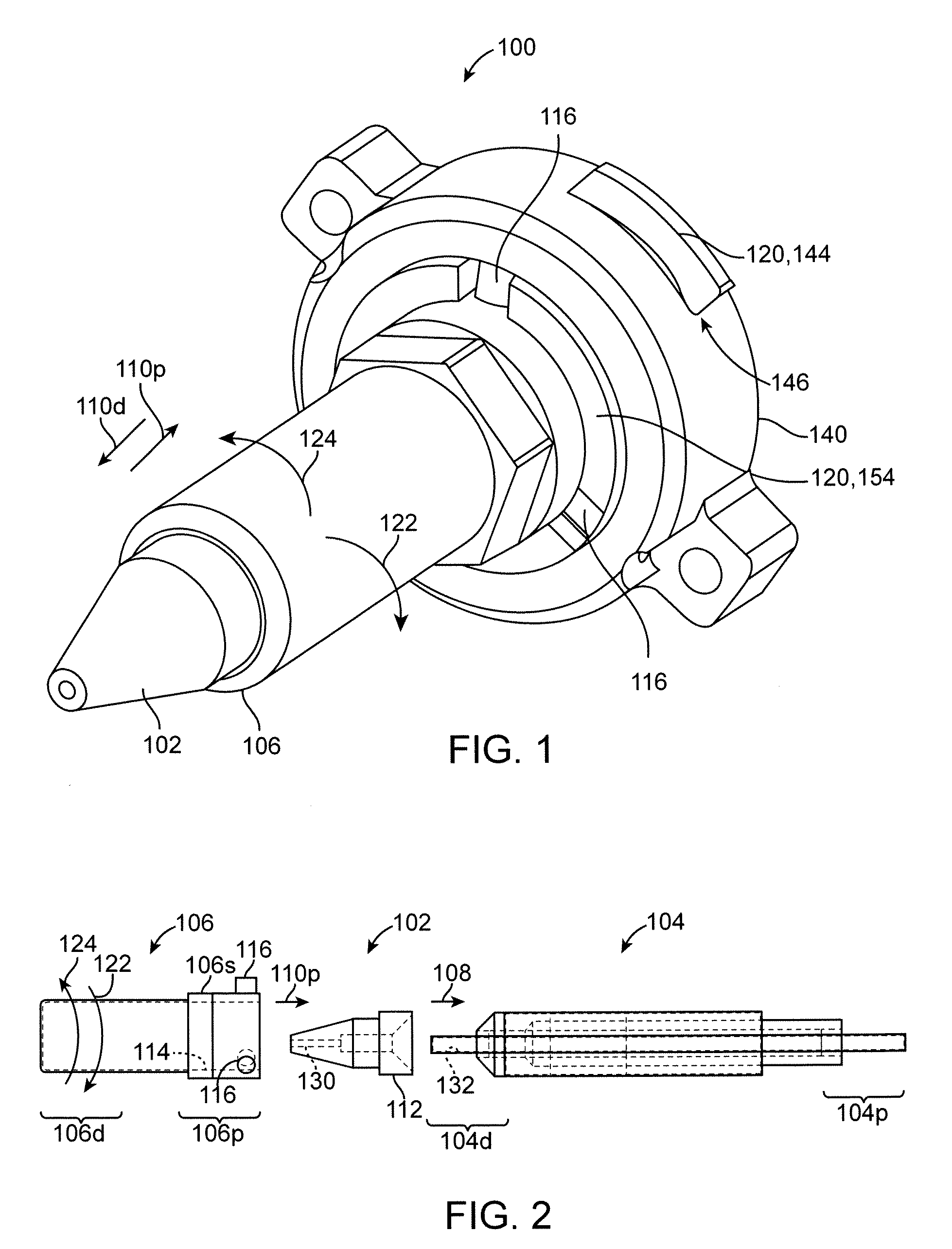

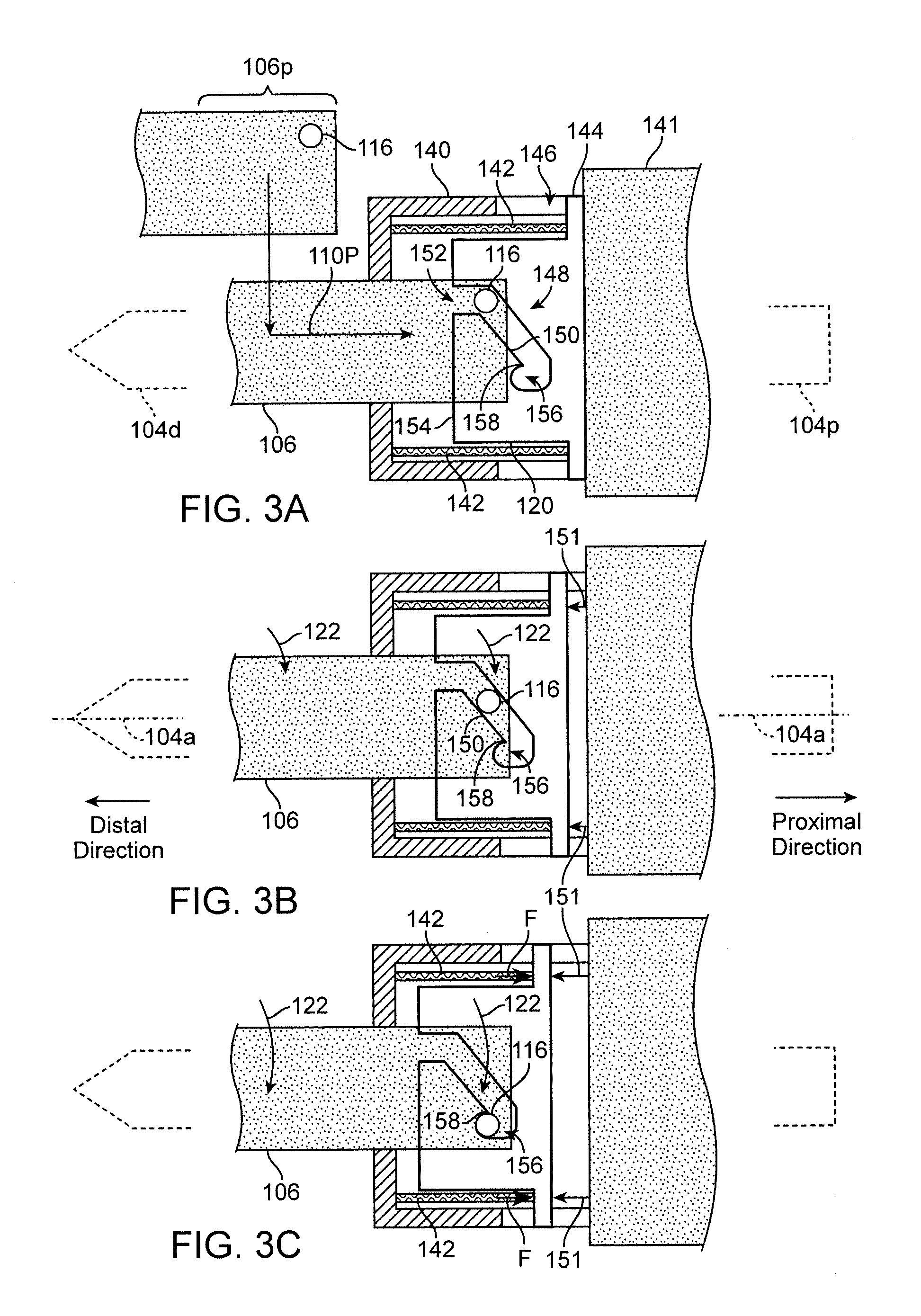

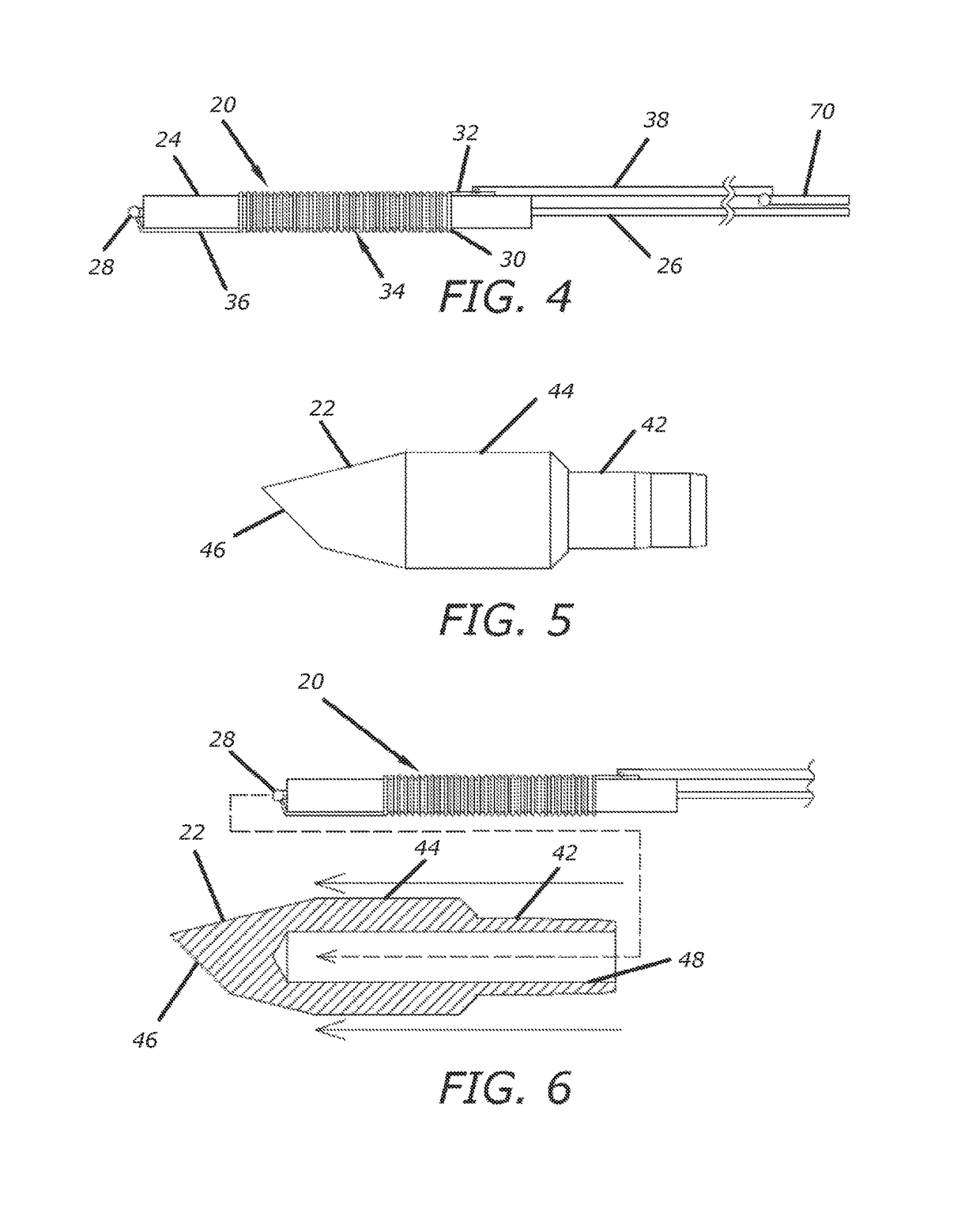

Soldering Assembly for Detachable Tip

A soldering assembly comprises a heater, a lock member, and a bias member. The lock member is moveable relative to the heater, includes a ramp feature, and is configured to receive a tip or a tip holder. The bias member is configured to urge movement of the lock member away from a distal segment of the heater.

Owner:HAKKO CO LTD

Wheel-type welding method

InactiveCN103692044AImprove welding efficiencySoldering bitsHeating appliancesEngineeringSoldering iron

The invention relates to a wheel-type welding method, which aims at solving the continuous welding problem of a linear welding material. The technical scheme is as follows: a solder tip adopts a roller, the roller is installed on the front end of a solder through a rotating shaft, the roller rolls on the linear welding material and a base plate so as to execute the welding in the rolling process. An electric heating part and a temperature sensor are installed inside the roller, and a power supply wire and a signal wire are respectively communicated through a slide ring which is installed on the rotating shaft; or the roller is heated by adopting a hot air gun or directly heated by flame. A roller set consists of a plurality of rollers corresponding multiple linear welding materials, so that the welding can be simultaneously carried out, and the welding efficiency can be further improved.

Owner:王锐

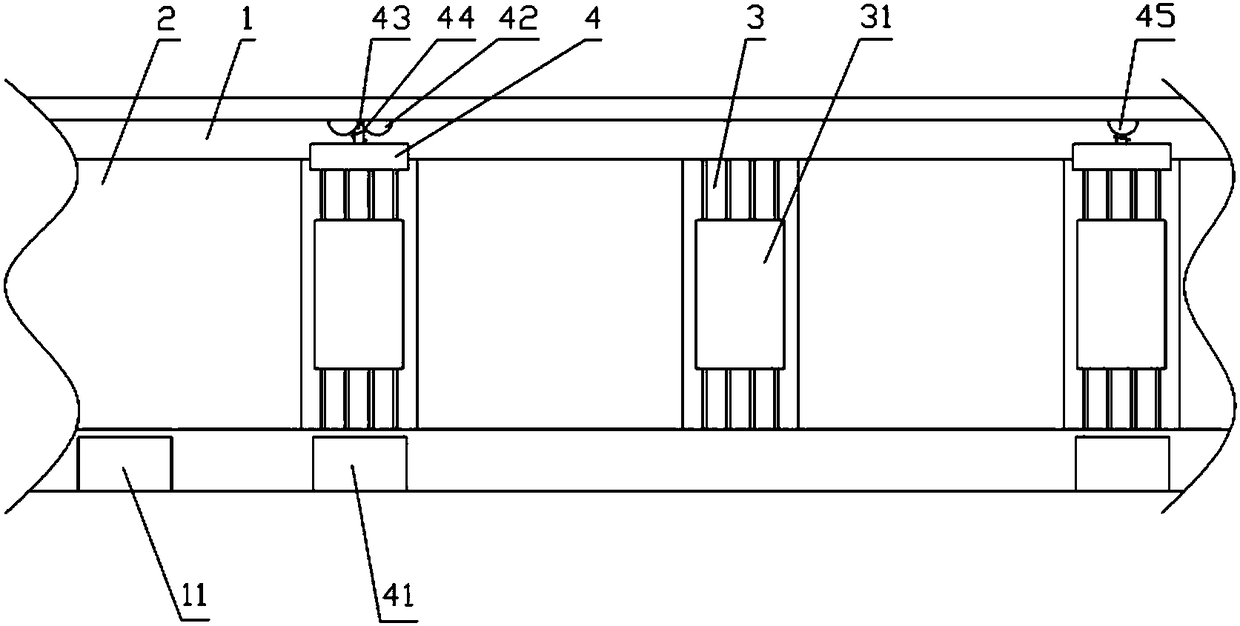

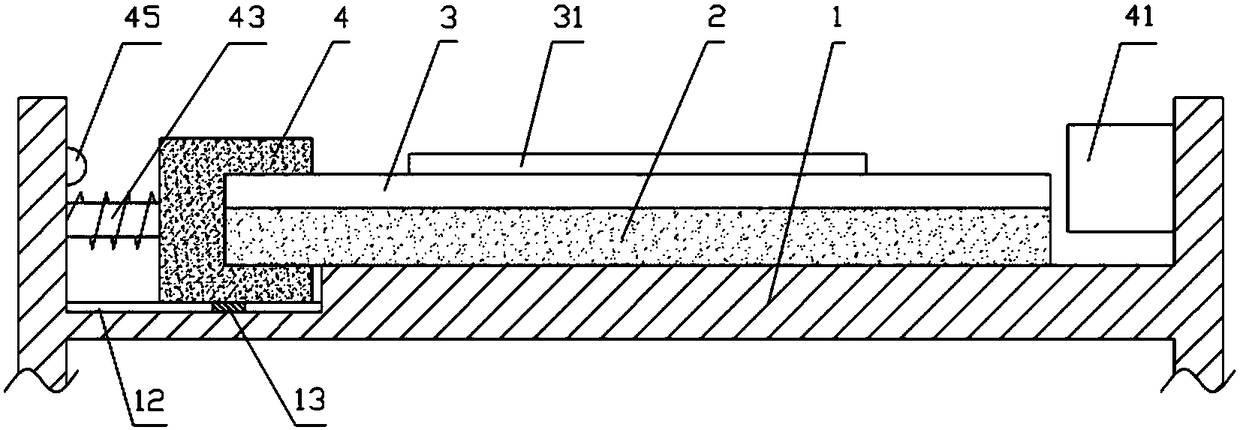

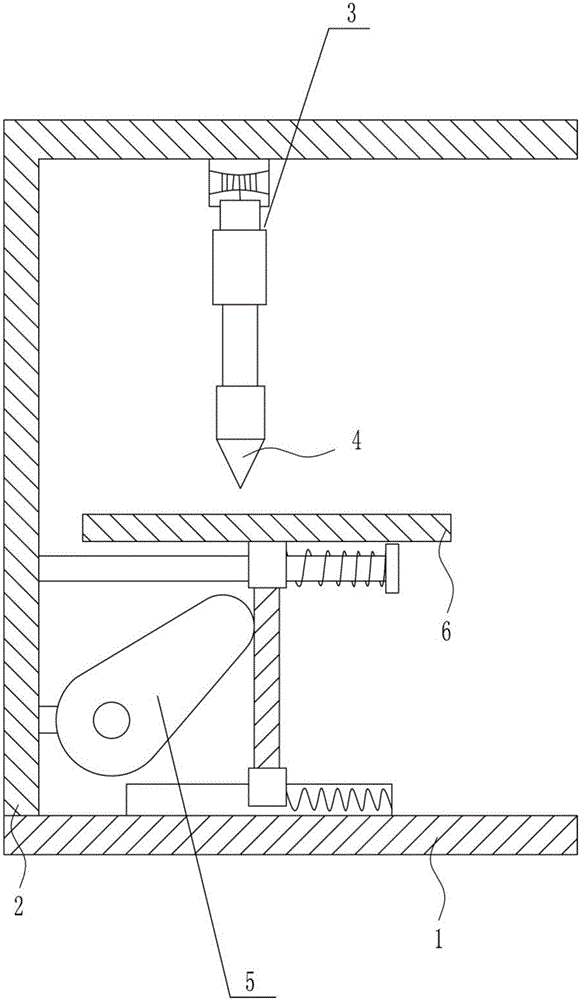

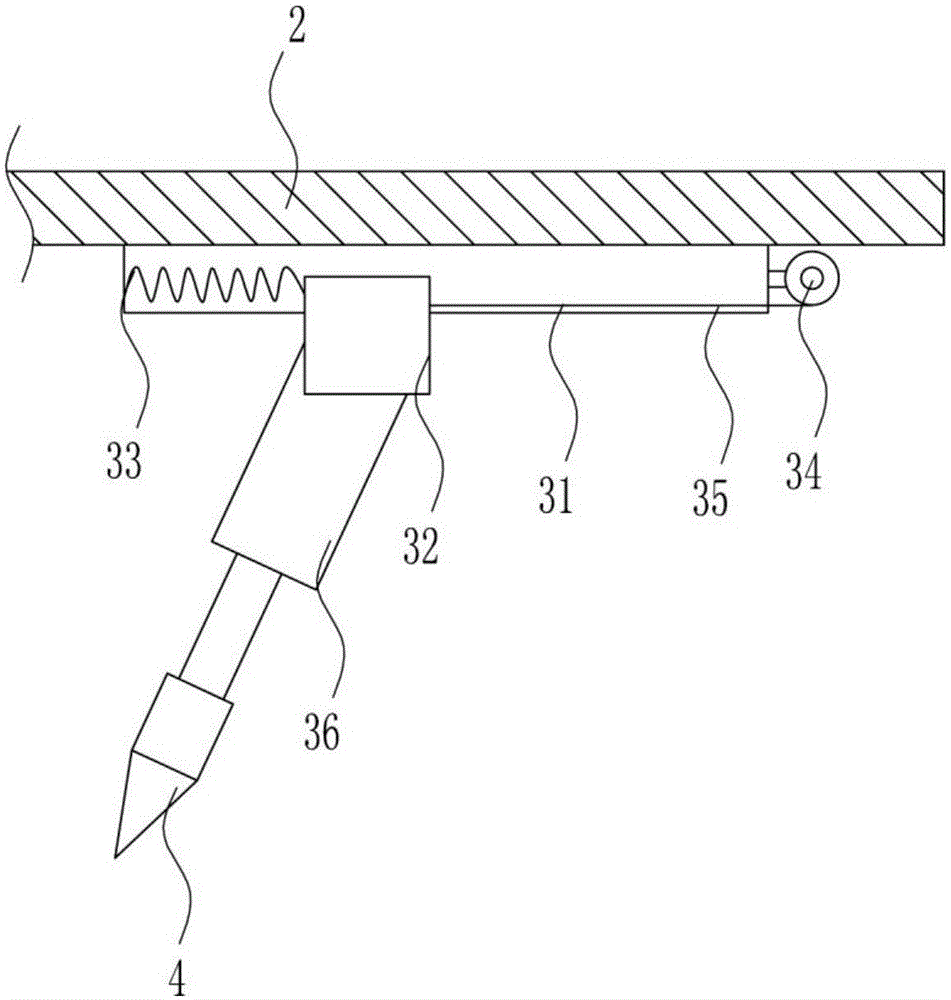

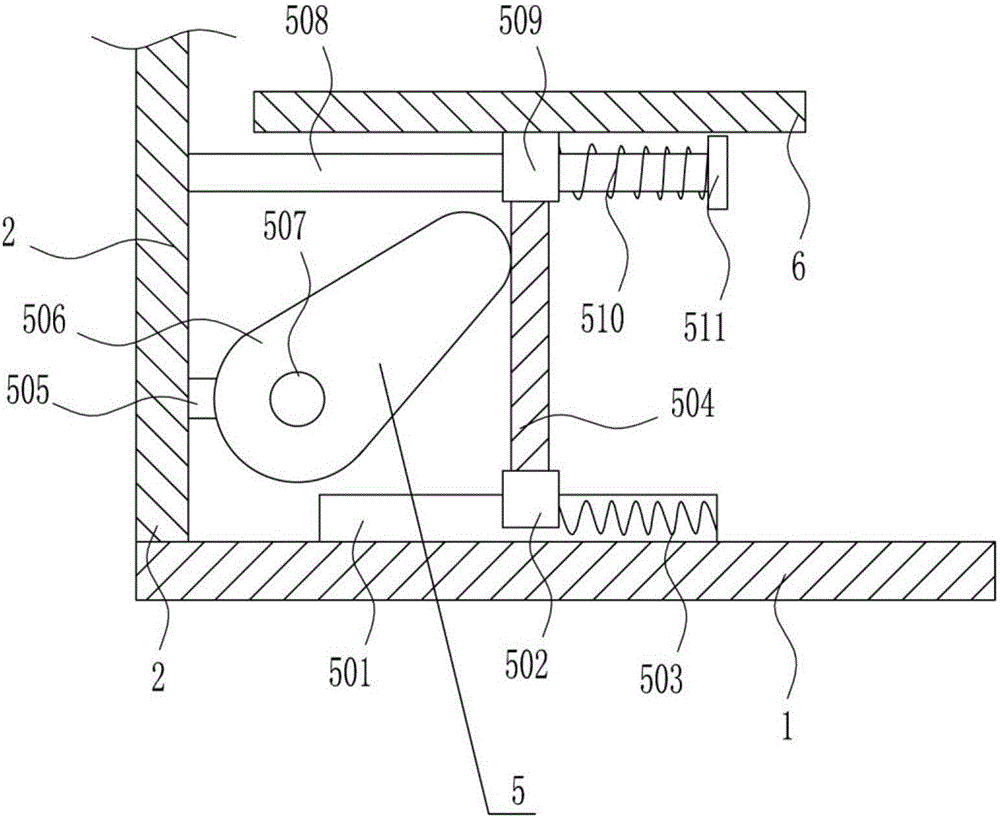

Auxiliary device for tin soldering for circuit board

InactiveCN107520518ARemove irritating odorTo achieve the role of auxiliary solderPrinted circuit assemblingSoldering bitsDip solderingEngineering

The invention relates to an auxiliary device for tin soldering, and particularly relates to an auxiliary device for tin soldering for a circuit board. The technical problem to be solved by the invention is to provide an auxiliary device for tin soldering for a circuit board, which is high in tin soldering speed, high in tin soldering efficiency, capable of carrying out front-rear tin soldering and left-right tin soldering on the circuit board, and further capable of removing a pungent odor. In order to solve the abovementioned technical problem, the invention provides an auxiliary device for tin soldering for a circuit board. The auxiliary device comprises a bottom plate and the like, wherein an L-shaped plate is arranged at the left side of the top of the bottom plate; an adjustment device is arranged at the top of the bottom plate; a placement table is arranged at the top of the adjustment device; a movement device is arranged at the inner top of the L-shaped plate; and a soldering bit is arranged at the bottom of the movement device. The auxiliary device disclosed by the invention achieves the effects of being high in tin soldering speed, high in tin soldering efficiency, and capable of removing the pungent odor. According to the device, the front-rear tin soldering is carried out on the circuit board through the movement device, the left-right tin soldering is carried out on the circuit board through the adjustment device, and therefore, tin soldering can be carried out on each orientation of the circuit board, and an odor removal device is capable of absorbing the pungent odor.

Owner:钟光文

Solder tip production process

ActiveCN104690513ARealize automatic processingFast processingSoldering bitsSoldering ironSewageCopper

Owner:陈爱华

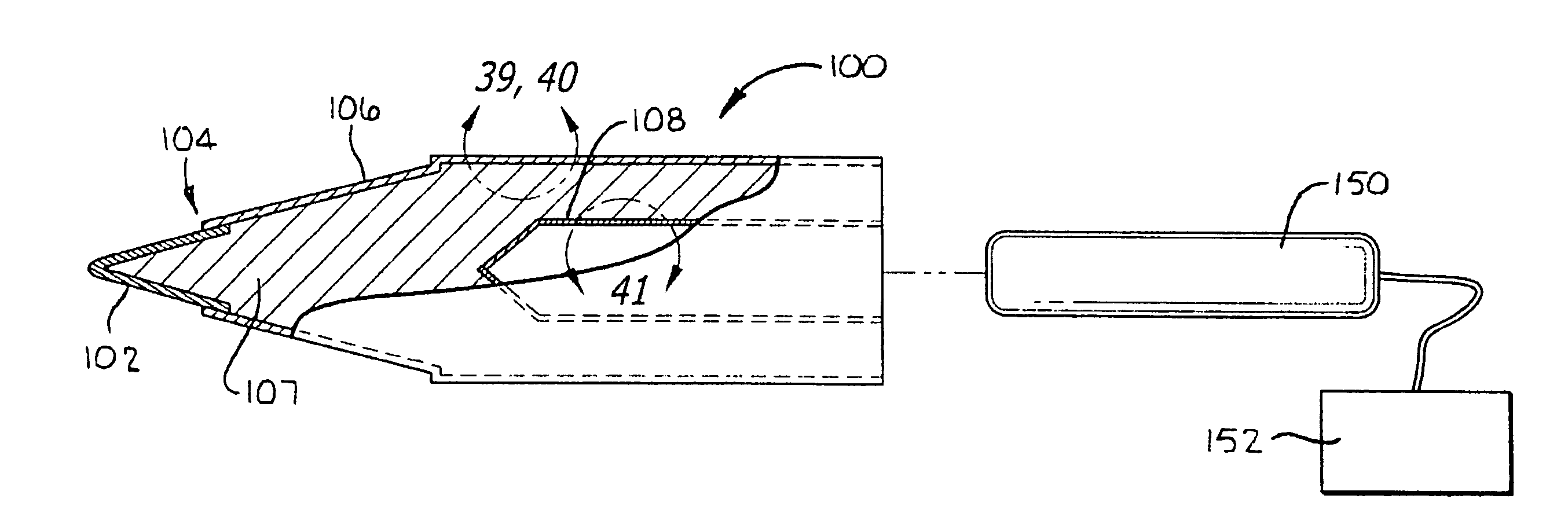

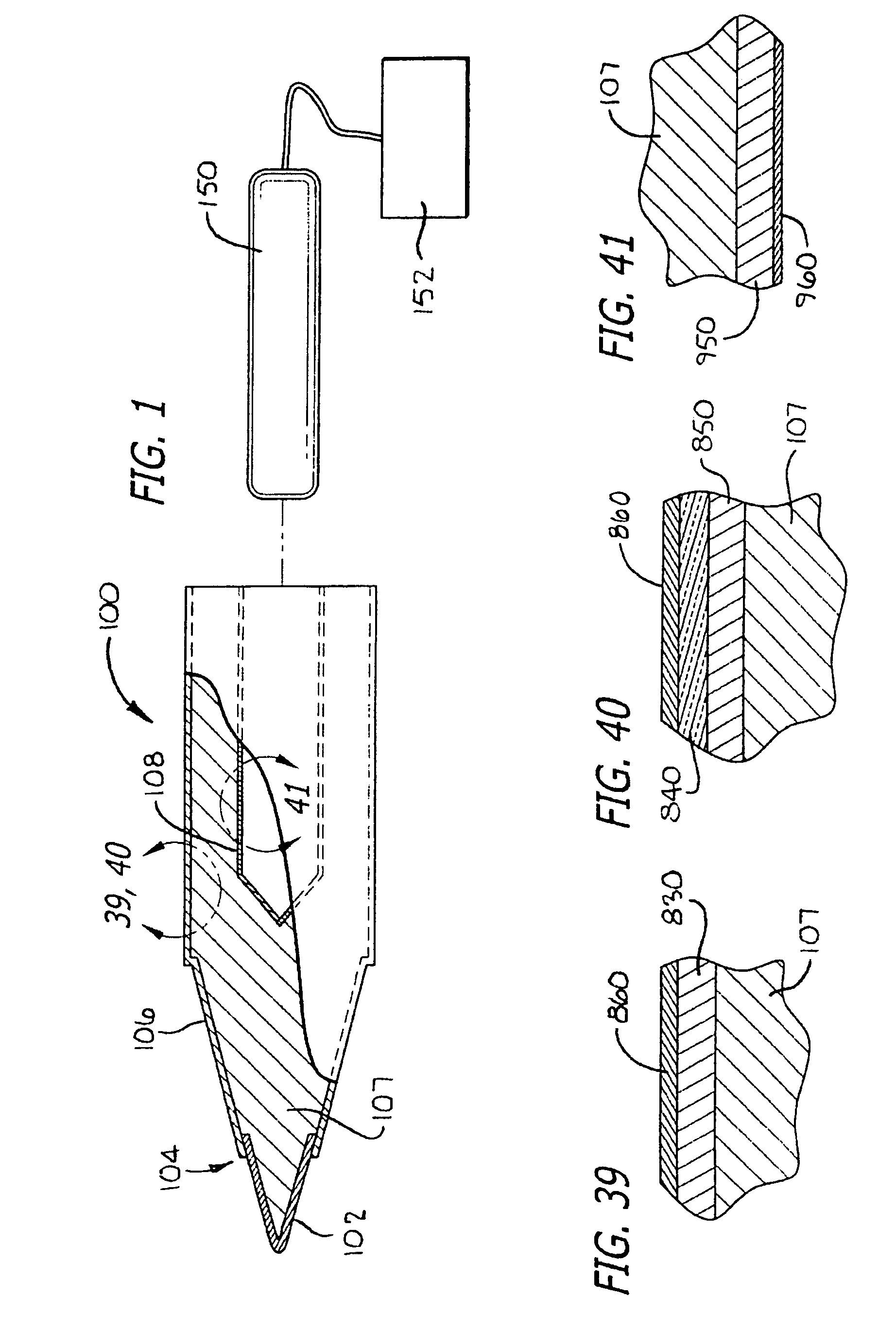

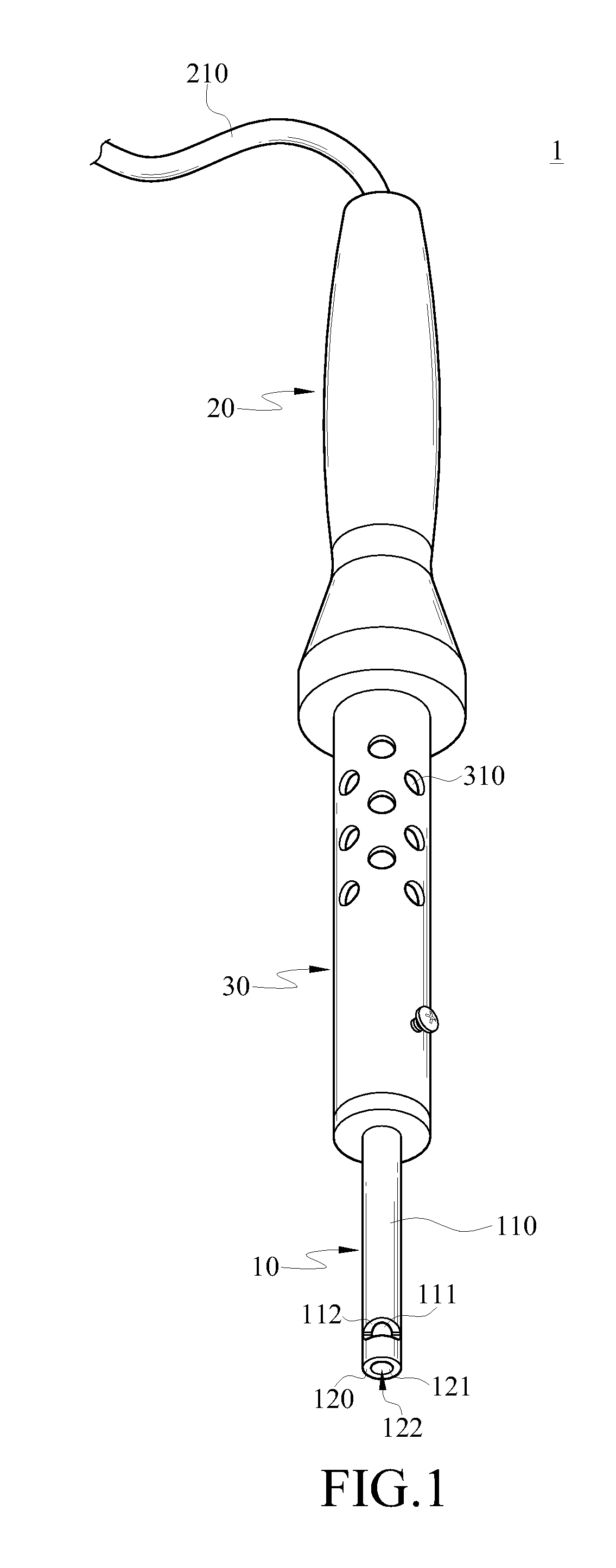

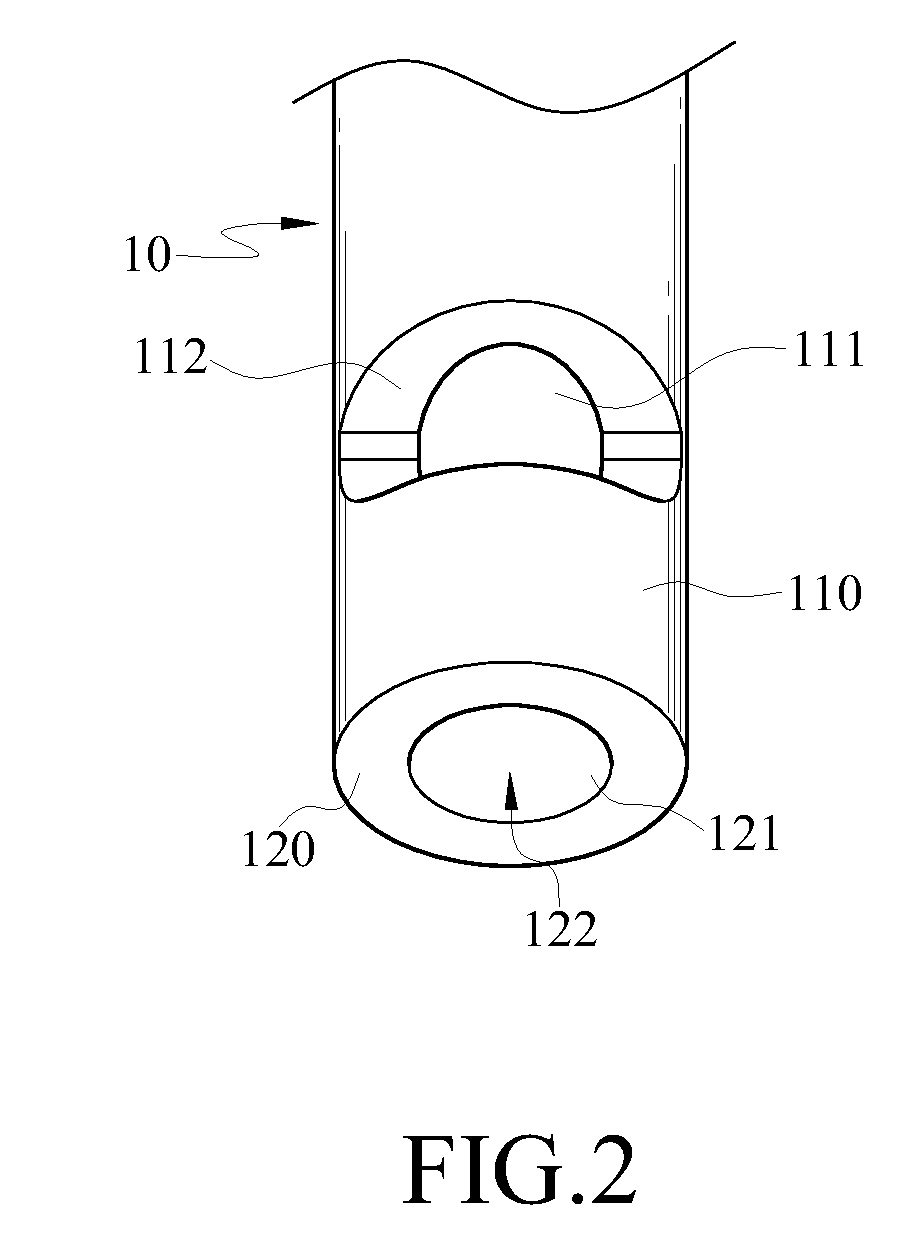

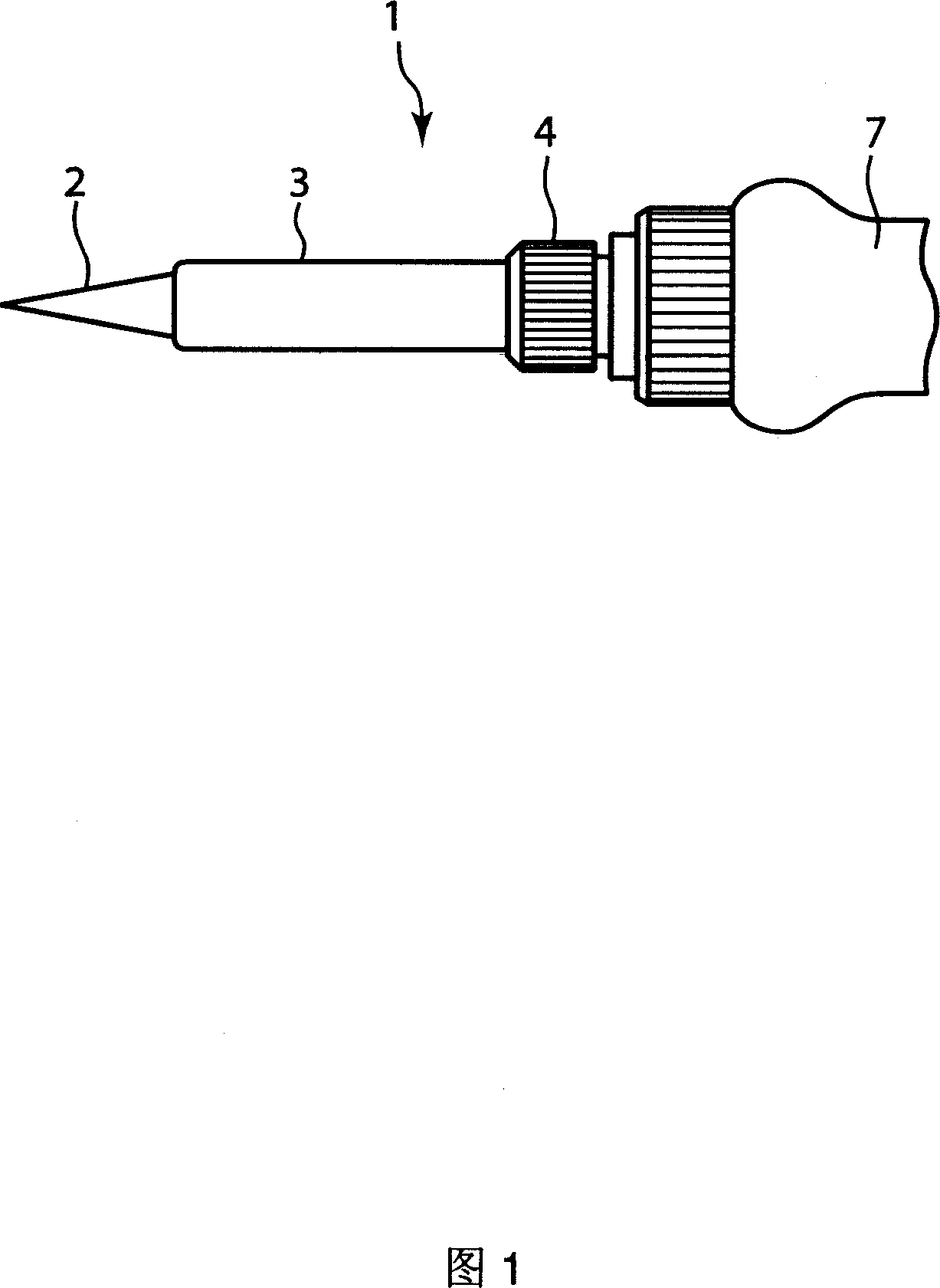

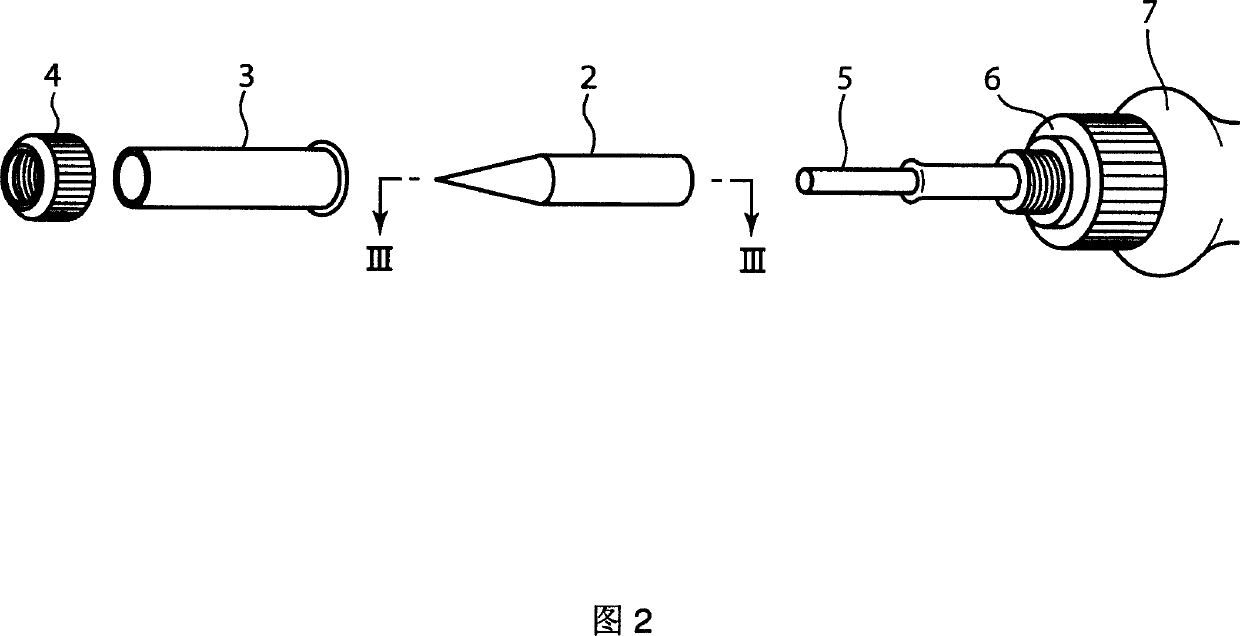

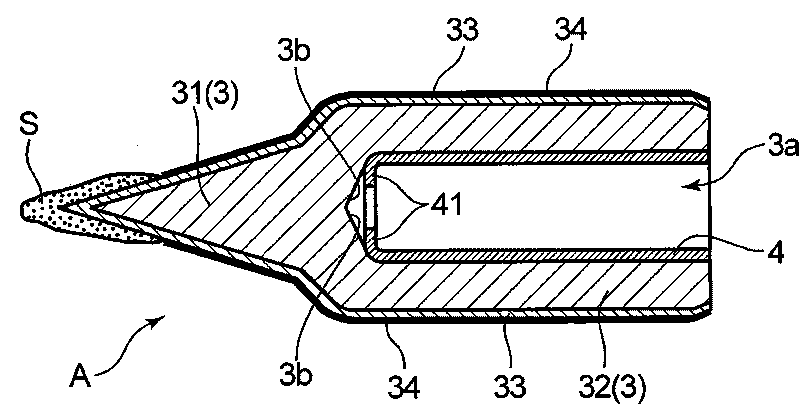

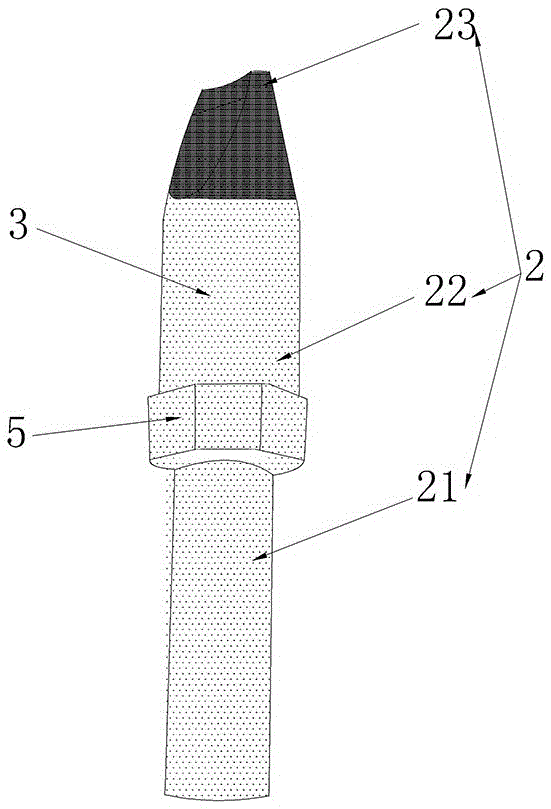

Soldering iron with replaceable tip

A soldering iron (and a desoldering iron) with a replaceable tip, which is releasably securable on the forward heat-conducting end of a soldering (or desoldering) iron heat assembly. The tip has a tapered heat conducting core in a tip cap. The face of the core can have a depression for mating engagement with a protrusion of the heatconducting end. Also, the face can lie in the rear plane of the tip cap. An assembly which allows for the easy removal and application of a replacement tip can include a sleeve with tightening bolt, a coil spring sleeve, or a slotted compressible sleeve. The tip can thus be replaced after it has worn out, and the heat assembly unit need not be replaced until it has burnt out. Methods of manufacturing and using the tip are also disclosed.

Owner:HAKKO CO LTD

Online coiling tin prewelding equipment for voice coil motor coil

The invention discloses online coiling tin prewelding equipment for a voice coil motor coil. A machine table is provided with an automatic tin prewelding mechanism, an automatic tin feeding mechanism, a tin blowing mechanism and a welding head cleaning mechanism which are matched with one another; the automatic tin prewelding mechanism comprises a tin prewelding moving mechanism which drives industrial welding heads to move in place to achieve precise tin feeding at the needed positions and needed length of a copper wire; the automatic tin feeding mechanism is matched with the industrial welding heads to achieve quantitative tin feeding on the welding heads; a tin blowing pipe of the tin blowing mechanism is matched with the industrial welding heads to remove residual tin which is located on the welding heads and welds the copper wire; the welding head cleaning mechanism comprises a brush moving mechanism which drives rotatable brushes to move to be matched with the industrial welding heads to clean oxides on the welding heads. According to the online coiling tin prewelding equipment for the voice coil motor coil, the production efficiency can be improved, the number of workers can be decreased, the labor intensity can be lowered, and the production reject ratio can be decreased.

Owner:AUDIX TECH XIAMEN CO LTD

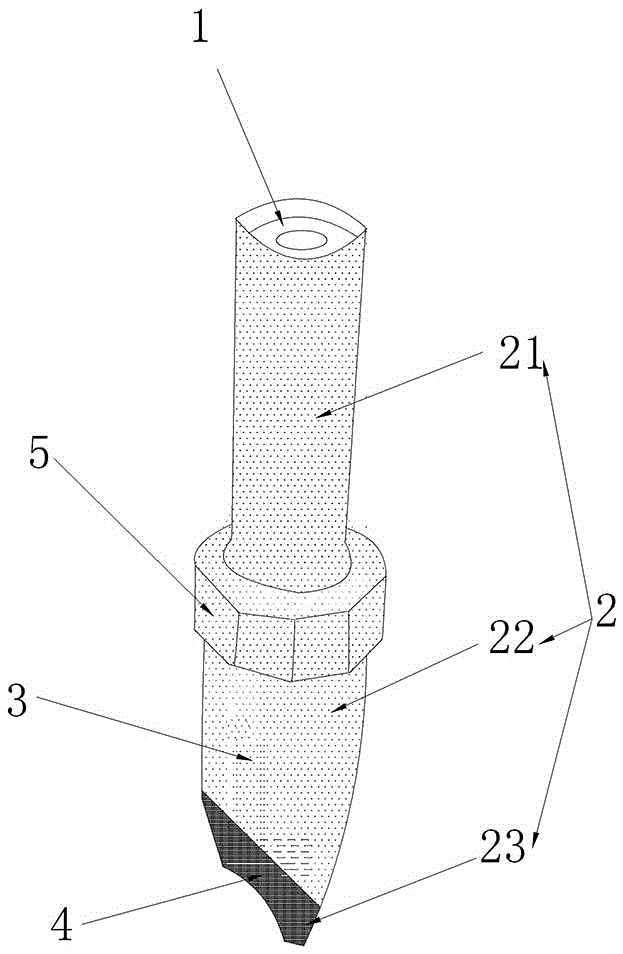

Soldering iron tip

A soldering iron tip is used for heating a solder bar during a soldering operation so as to solder a workpiece. An end surface of the soldering iron tip has a guide hole, and the guide hole forms a channel in the soldering iron tip. Meanwhile, a side surface of the soldering iron tip has a through hole in communication with the channel. When the soldering operation is performed, relative positions of the guide hole and the workpiece overlap each other. After the solder bar is made to pass through the through hole and heated inside the channel, the molten solder bar flows along the channel to reach the workpiece via the guide hole, thereby completing the soldering operation.

Owner:INVENTEC CORP

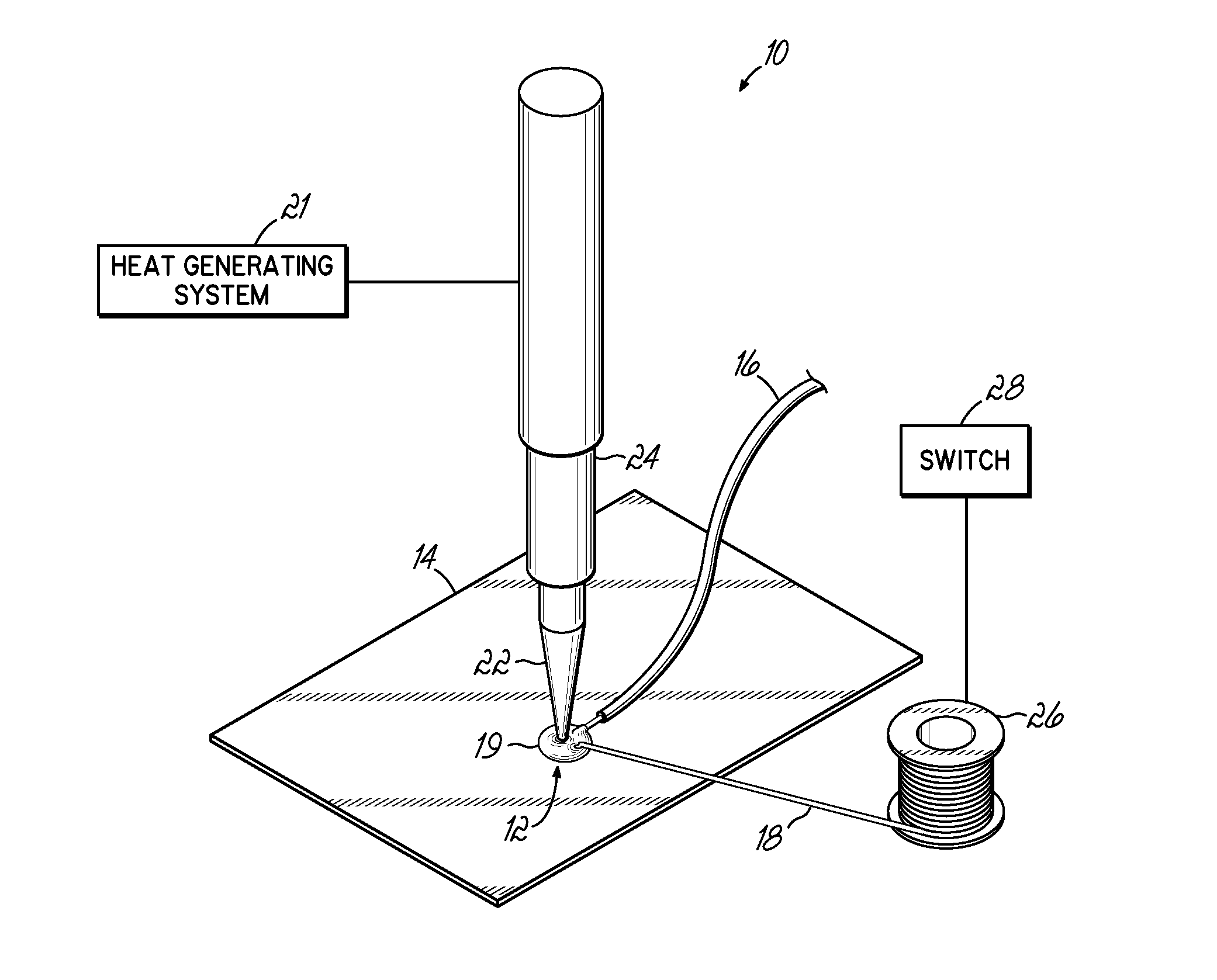

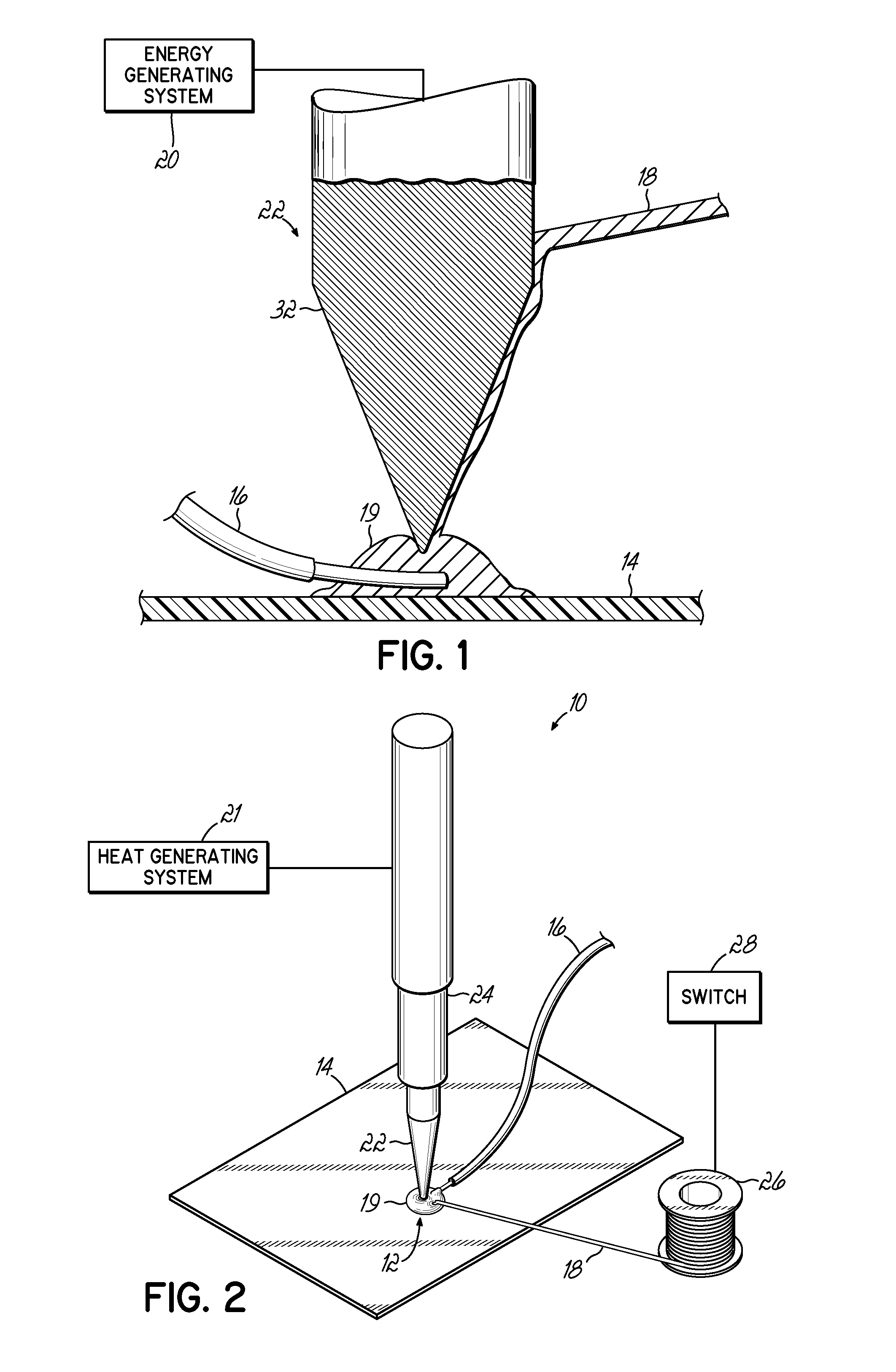

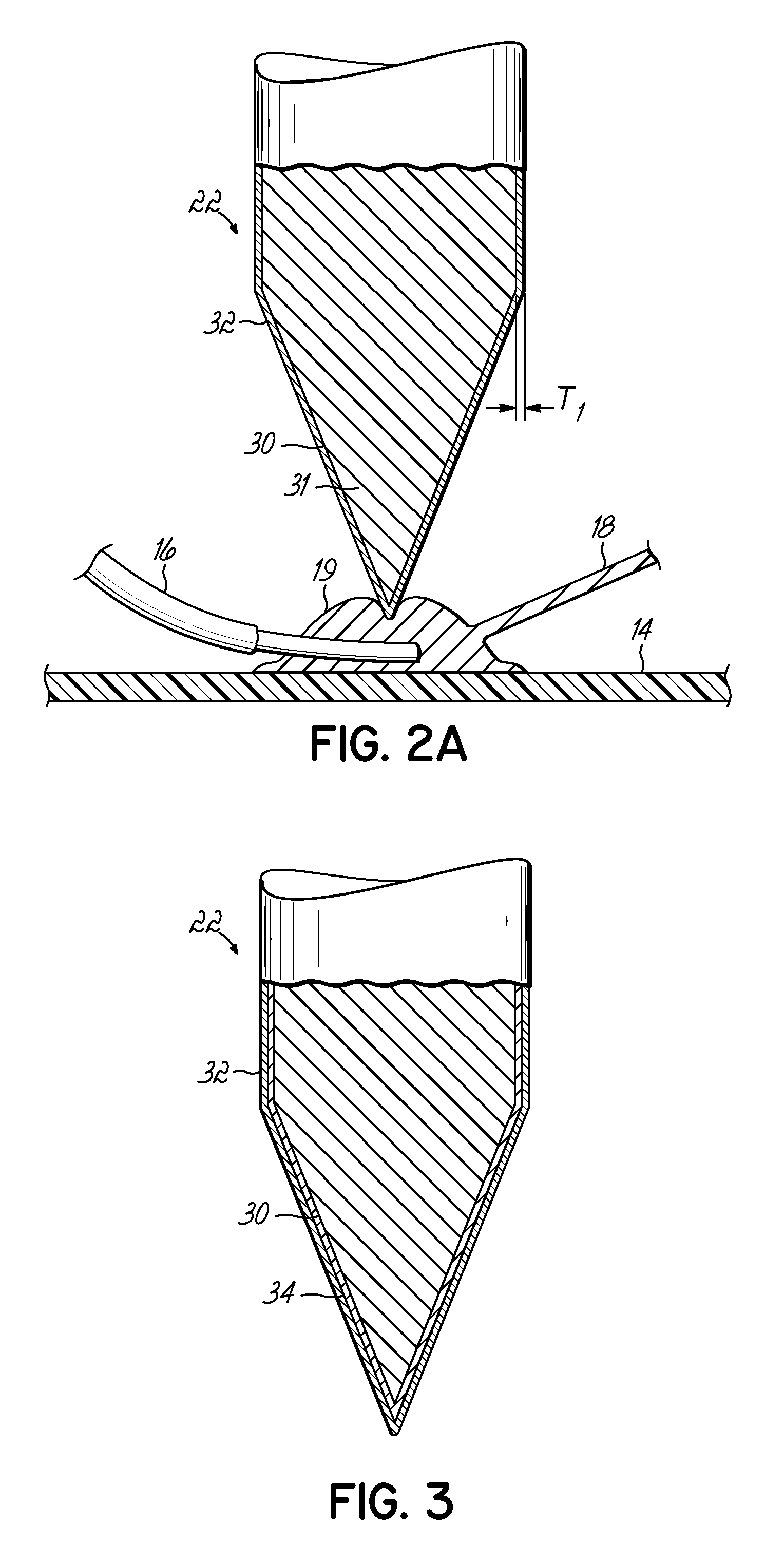

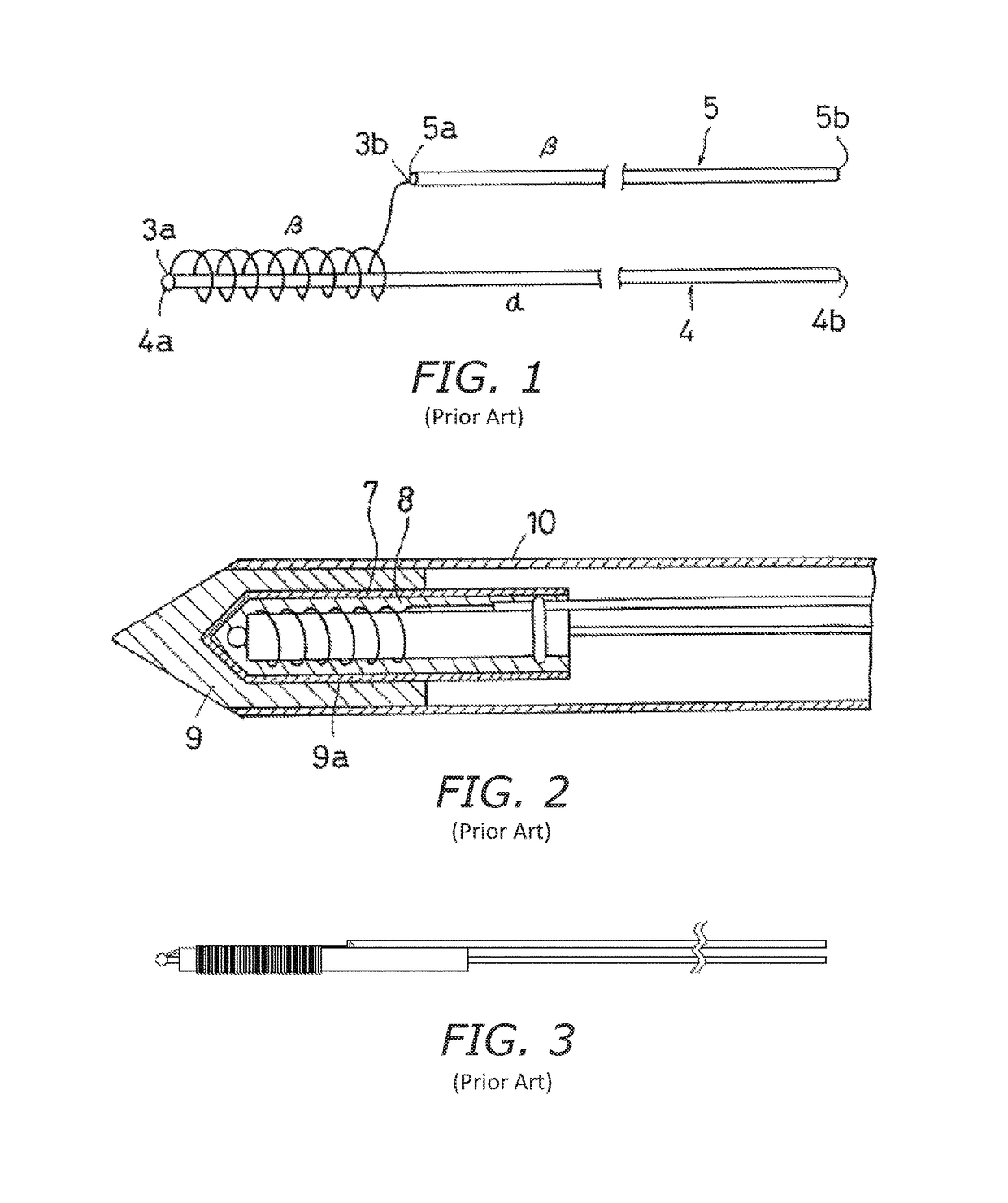

Soldering tip, soldering iron, and soldering system

A soldering system for melting a solder to form a joint between a first workpiece and a second workpiece is described. The system may comprise an energy generating system, a soldering tip, and a dispenser adapted to dispense controlled amounts of the solder. The soldering tip includes a non-wetting solder contact layer in operative communication with the energy generating system. The energy generating system may include induction, electrical, or heat generating systems in communication with the soldering tip. The non-wetting solder contact layer comprises a material that is not wettable by the molten solder. The system permits control of an amount of the solder in the joint.

Owner:NORDSON CORP

Method of soldering iron tip with metal particle sintered member connected to heat conducting core

ActiveUS7490751B2Increase plate thicknessWork has been limitedHeating element shapesSoldering bitsCeramic coatingHeat conducting

A soldering iron tip having a copper or copper alloy core and a metal particle sintered member connected to the core to transfer heat therefrom to form a working soldering tip. The sintered member can be manufactured by powder metallurgy from a base material (iron, nickel and / or cobalt particles) and an additive (silicon, copper, silver, tin, boron and / or carbon particles) where needed. The sintered member can be formed as a cap which is fitted onto the working tip with a silver paste sandwiched therebetween, a brazing filler metal ring is positioned between an abutment shoulder and the cap, flux applied to the joint and the cap brazed into place. A metal, cermet or ceramic coating sprayed on the outer surface of the core, except for the (masked) working tip end, is not wettable by solder. An Ag—Al—Cu alloy coating layer in the rearwardly-disposed cavity improves heat conduction from the heater therein.

Owner:HAKKO CO LTD

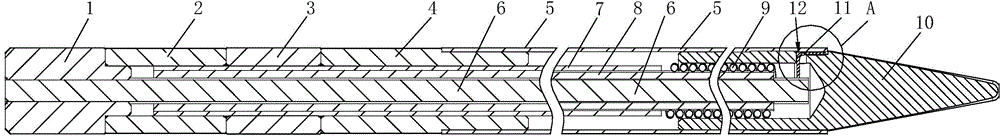

Soldering iron head

ActiveCN104646787AMiniaturizationHigh strengthSoldering bitsSoldering ironMiniaturizationEngineering

The invention relates to a soldering iron head, which comprises a welding head, an outer tube and a sensing wire, wherein the welding head is arranged at one end of the outer tube, the sensing wire is arranged inside the outer tube, the side face of the welding head is provided with a groove and a through-hole, one end of the sensing wire is led out from the groove and the through-hole and contacts with the outer surface of the welding head, and is welded with the outer tube to form a temperature measuring end of a thermocouple, the sensing wire and the outer tube respectively constitute two poles of the thermocouple. According to the soldering iron head disclosed by the invention, the sensing wire directly contacts with the surface of the welding head, the collected temperature is close to the real temperature, and the reaction rate to the temperature is rapid; the temperature sensing part and the heating wire heating part are fused together, the miniaturization of the whole soldering iron head is realized, the strength of the whole welding head is still high, and is not easy to break.

Owner:QUICK INTELLIGENT EQUIP CO LTD

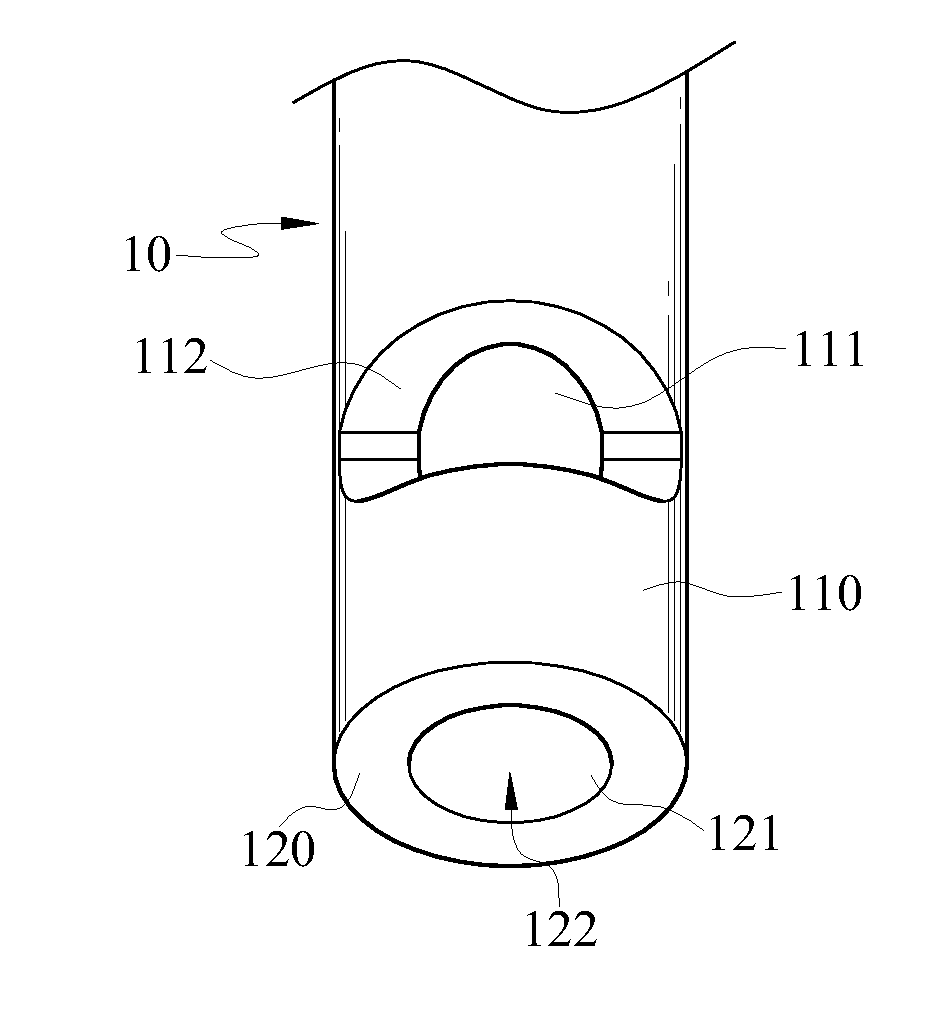

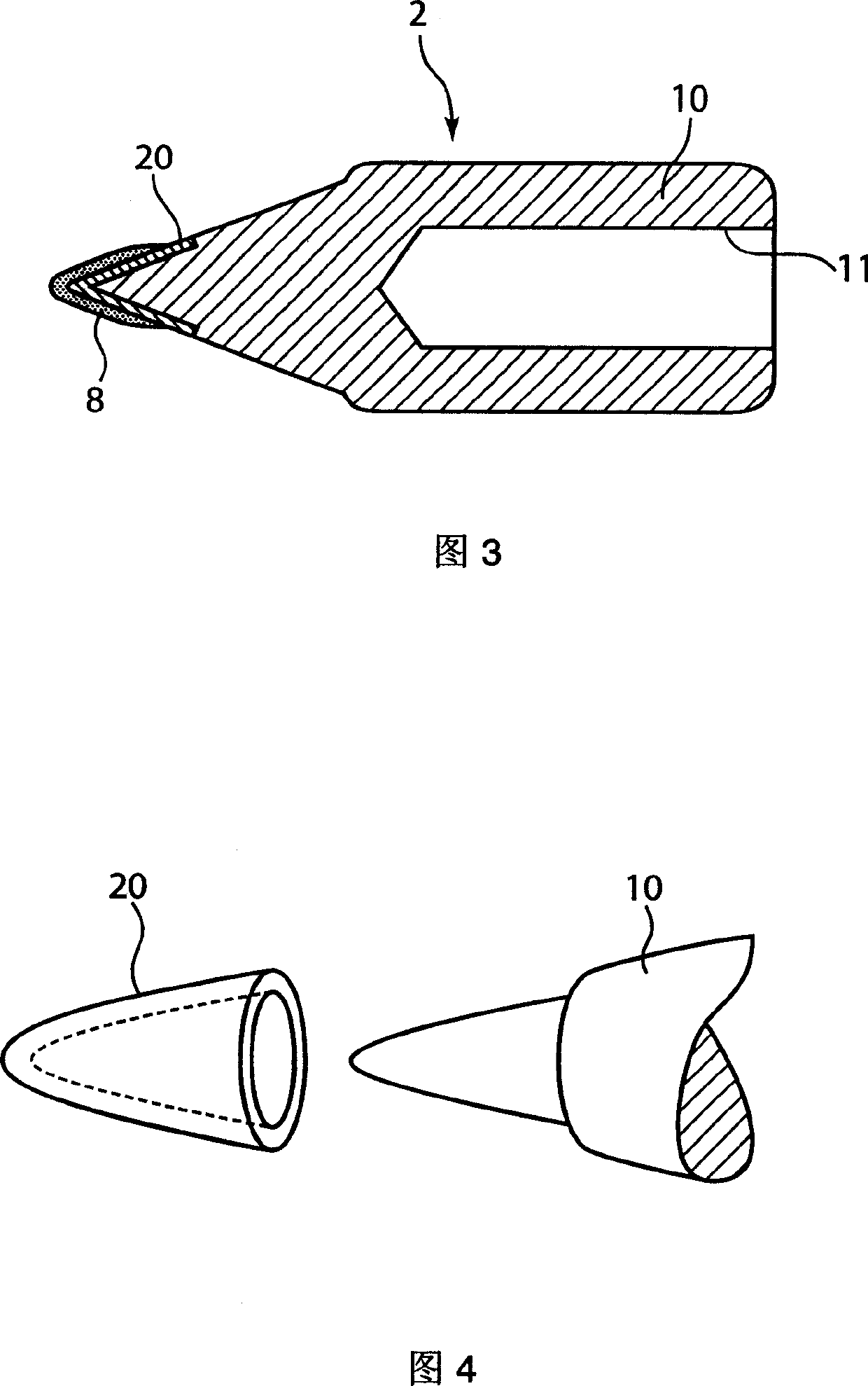

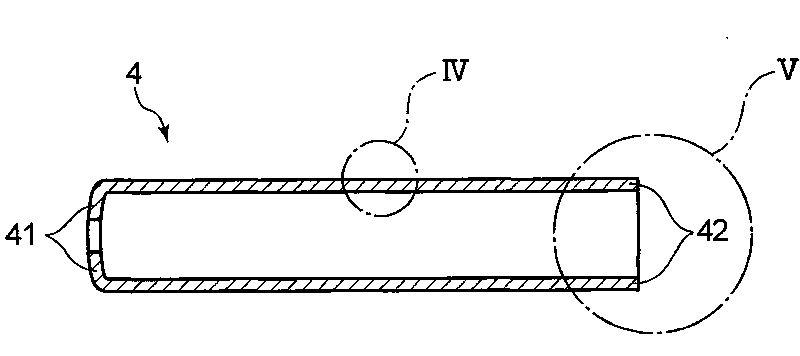

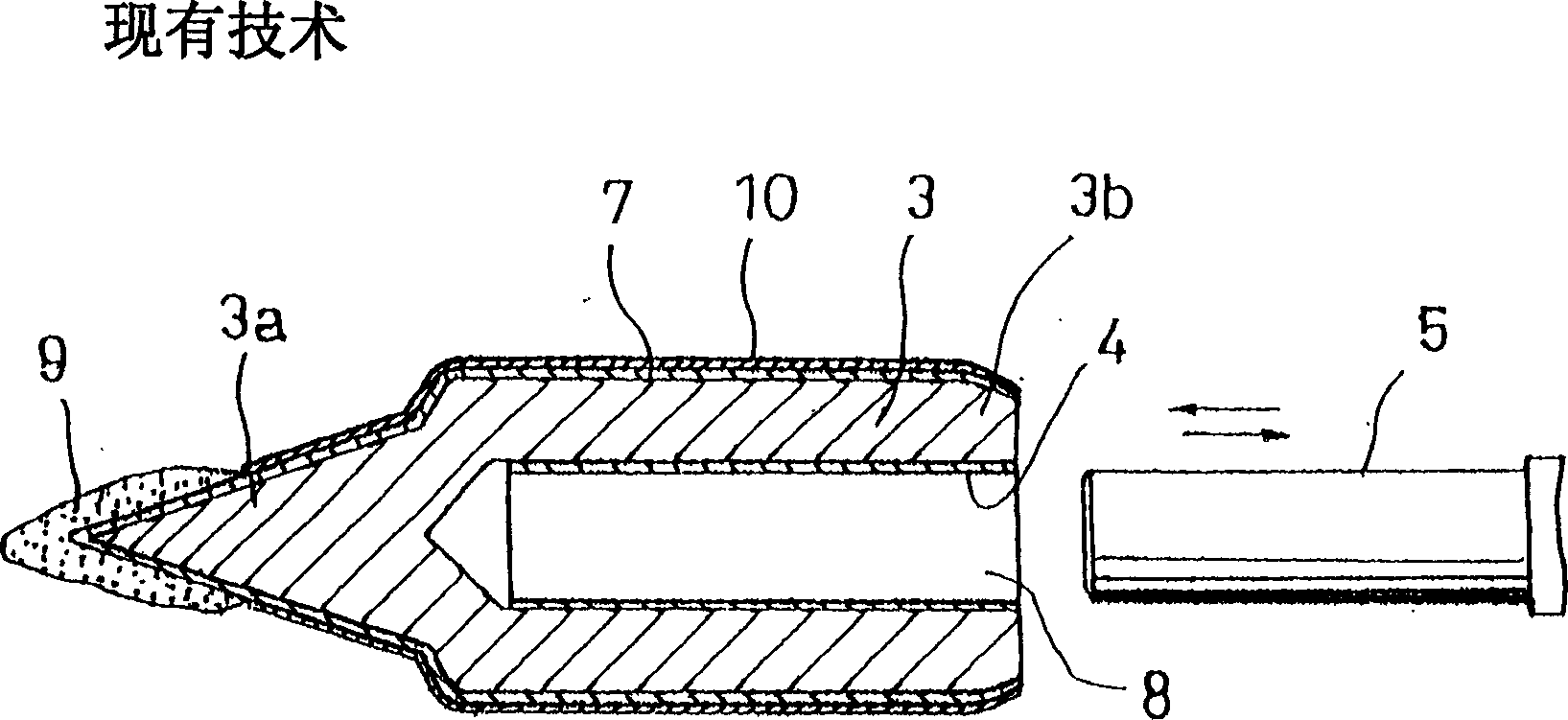

Tip of soldering iron, process for producing the same, and electrical soldering iron and electrical solder sucking iron including the iron tip

InactiveCN1717293AHigh densityImprove corrosion resistanceSoldering bitsWelding/cutting media/materialsNiobiumMetal particle

A tip 2 for handling solder used as a soldering bit of an electric soldering iron or an electric solder sucking iron, in which a soldering iron tip end member 20 formed of a metal particle sintered body manufactured using a powder metallurgy process is provided at the forward end of a soldering bit core 10 made of copper or a copper alloy. Used for the metal particle sintered body are: a sintering base material in which particles of iron, nickel, and cobalt are combined as needed; and when a need arises, a first sintering additive in which particles of copper, silver, tin, boron, and carbon are combined as need, or a second sintering additive in which particles of vanadium, niobium, tantalum, chromium, and molybdenum are combined as needed.

Owner:HAKKO CO LTD

Heat heat transferring member for a solder handling device, an electric iron and electric solder removing tool

A heat transferring member for a solder handling device, an electric iron with the heat transferring member and an electric solder removing tool with the heat transferring member are disclosed. The heat transferring member comprises a heat transfer body for melting solder, and a pipe inserted into a hole formed in the heat transfer body, wherein heat from a heating member is conducted to the heattransfer body. The pipe includes a tubular-shaped substrate made of copper or copper alloy, and an aluminum oxide film formed at least on a peripheral surface of the tubular-shaped substrate. Thus the heat transferring member can prevent the conducting member from being oxidized and keep high heat transfer efficiency.

Owner:HAKKO CO LTD +1

Electric soldering iron tip and electric soldering iron

InactiveCN1419610AImprove electrical performanceFast heat conductionSoldering bitsMetallic material coating processesAlloy coatingAtmosphere

In a tip for an electric soldering iron 3 made of copper or a copper alloy, the outer surface of the tip 3a except the part thereof coated with a solder 9 is coated with a mixture of Al particles and flux, and then the Al particles alone are molten in an inert gas atmosphere, to thereby modify said outer surface so as to have a Cu-Al alloy coating layer of a high Al concentration 10-1. As a result, without using Cr plating, it is possible to provide an electric soldering iron having an excellent resistance to oxidation under high temperature environment and a high heat conductivity.

Owner:HAKKO CO LTD

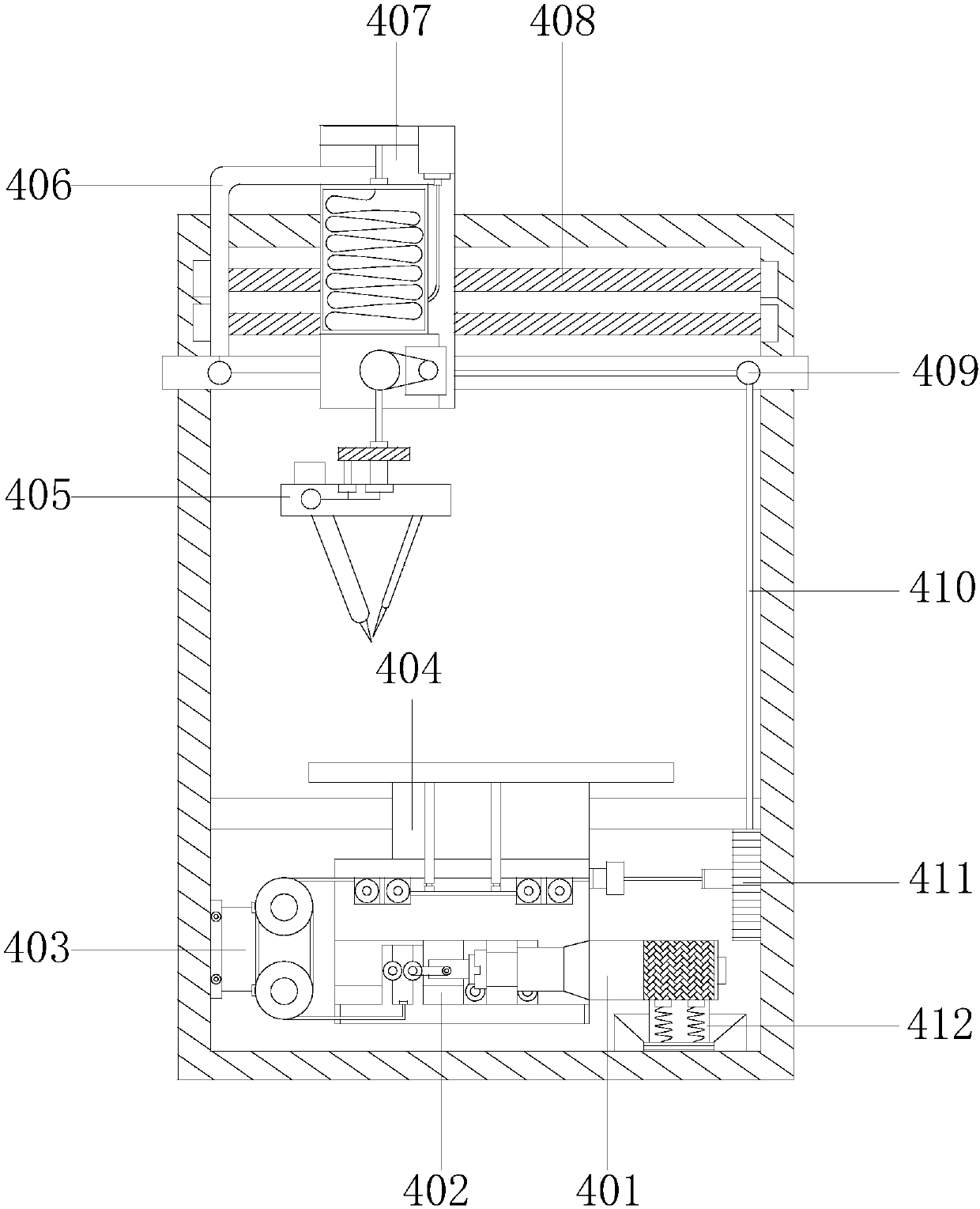

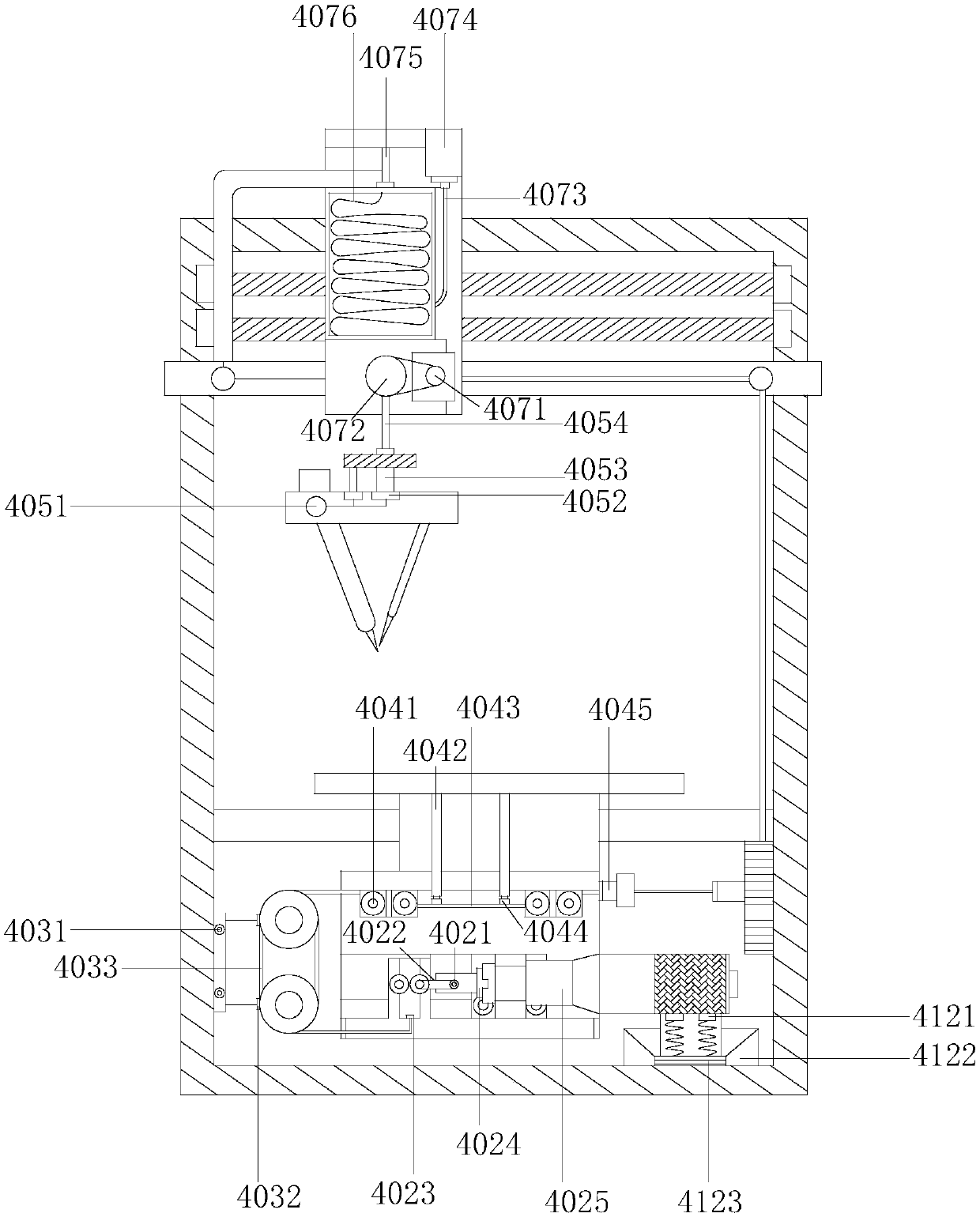

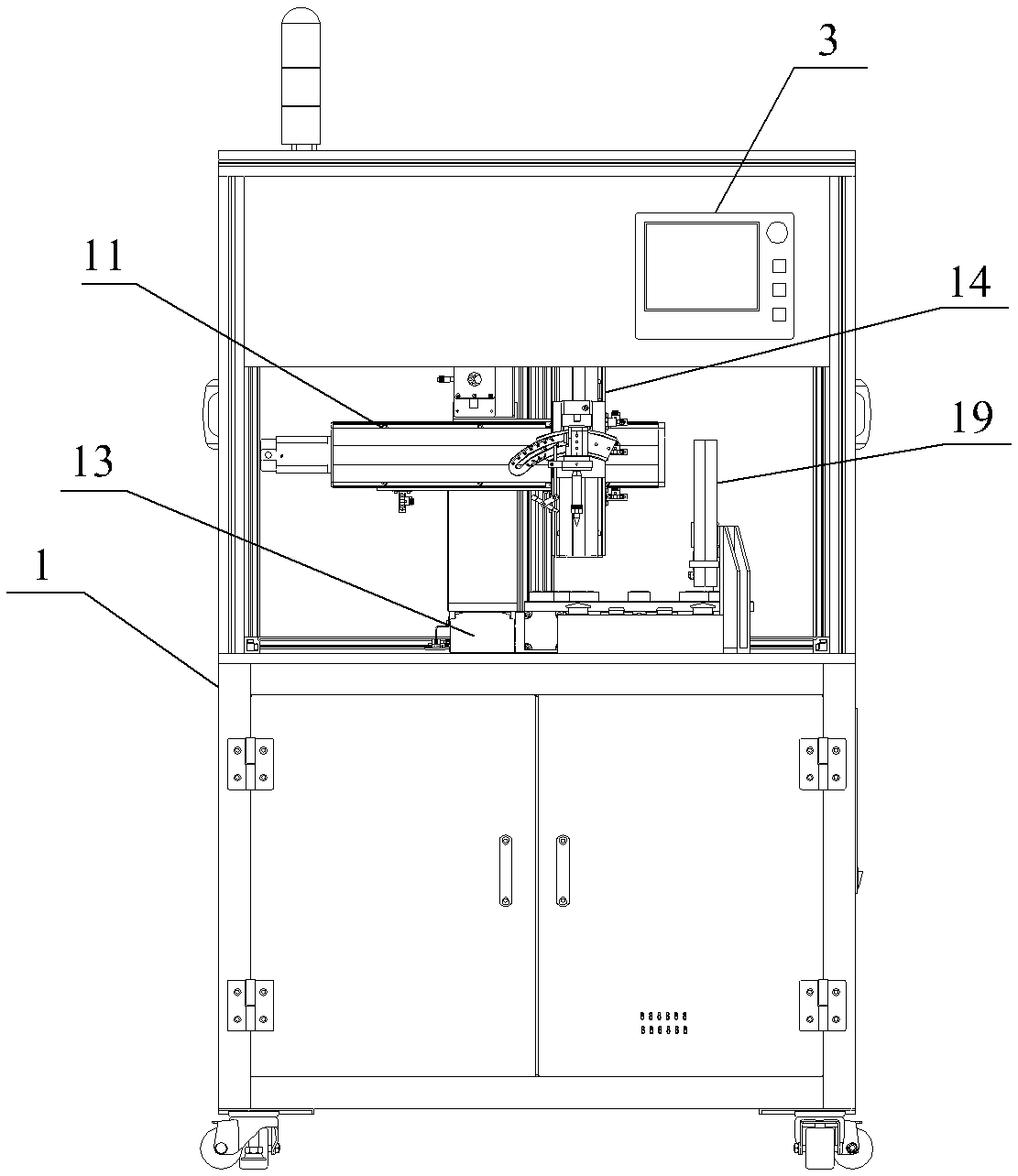

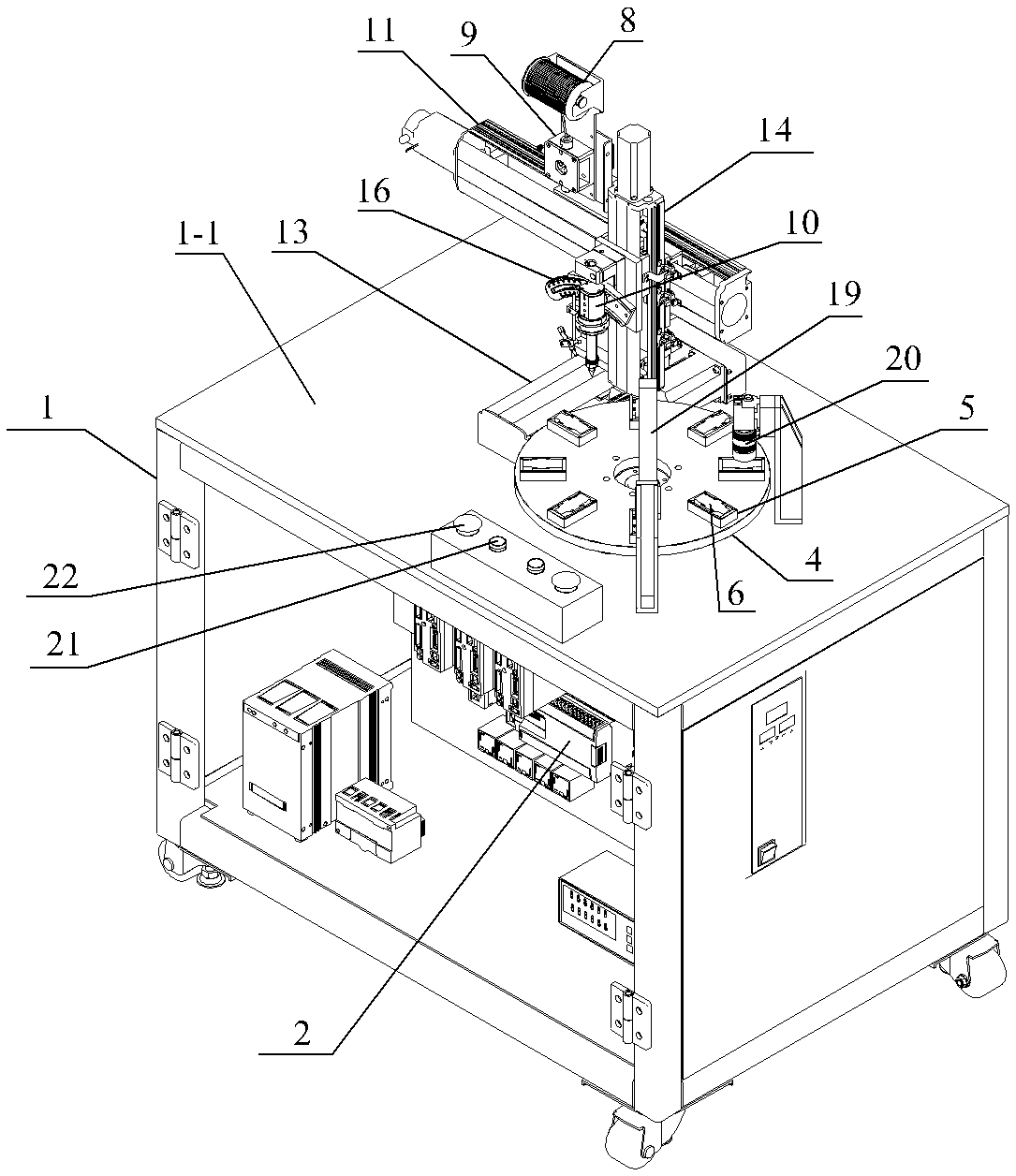

Tin welding machine

InactiveCN108044218ARealize automatic solderingStable solder qualitySoldering bitsSoldering ironEngineeringElectric control

The invention provides a tin welding machine. The problems that at present, an electronic device is manually welded to a circuit board, product defects need to be manually observed after welding, welding quality is instable, and production efficiency is low can be solved. The tin welding machine comprises a rack and a PLC. Multiple product carriers are evenly distributed and mounted on a rotary disc in the circumferential direction of the rotary disc. Workpiece grooves used for locating to-be-welded workpieces are formed in the product carriers. The rotary disc is driven by a hollow divider todo indexing rotating in the horizontal direction. A servo motor of the hollow divider is in electric control connection with the PLC. A tin wire coiling block, a wire feeder and a tin welding head are mounted on a tin welding head support. The tin welding head, a CCD camera and an ink jet marking machine are sequentially arranged in the rotating direction of the rotary disc and each correspond toone workpiece groove, and the CCD camera and the ink jet marking machine are arranged above the corresponding workpiece grooves correspondingly and are in electric control connection with the PLC.

Owner:WUXI CHANGZHISHENG MACHINERY MFG CO LTD

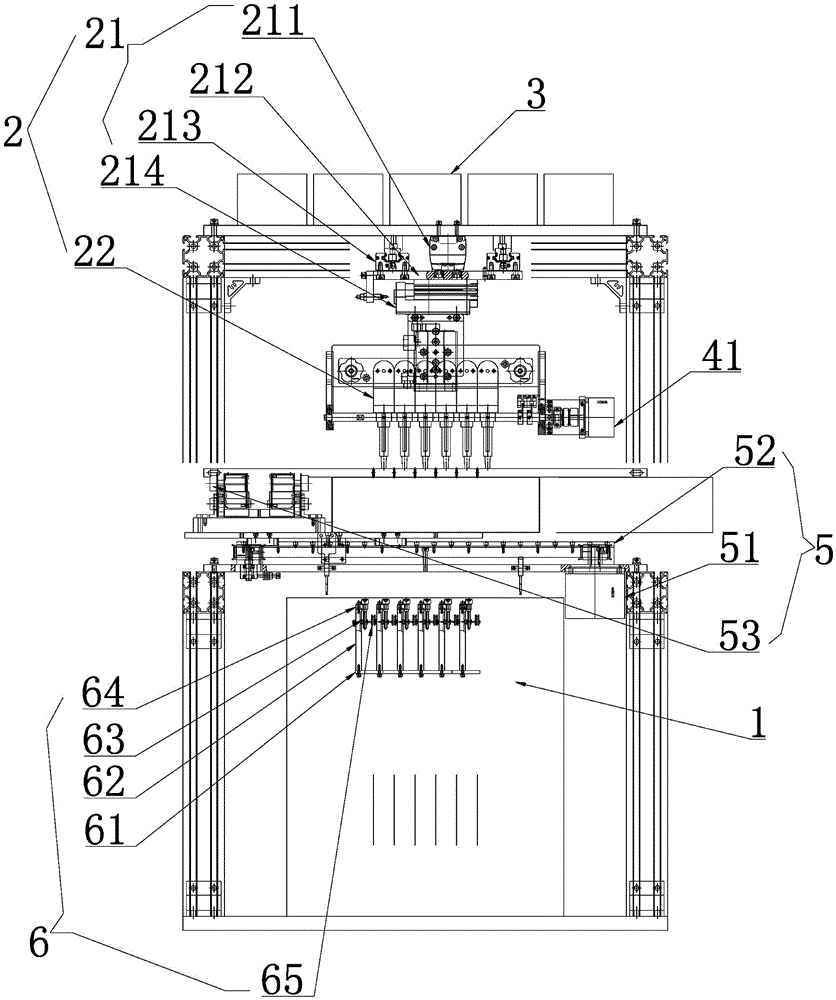

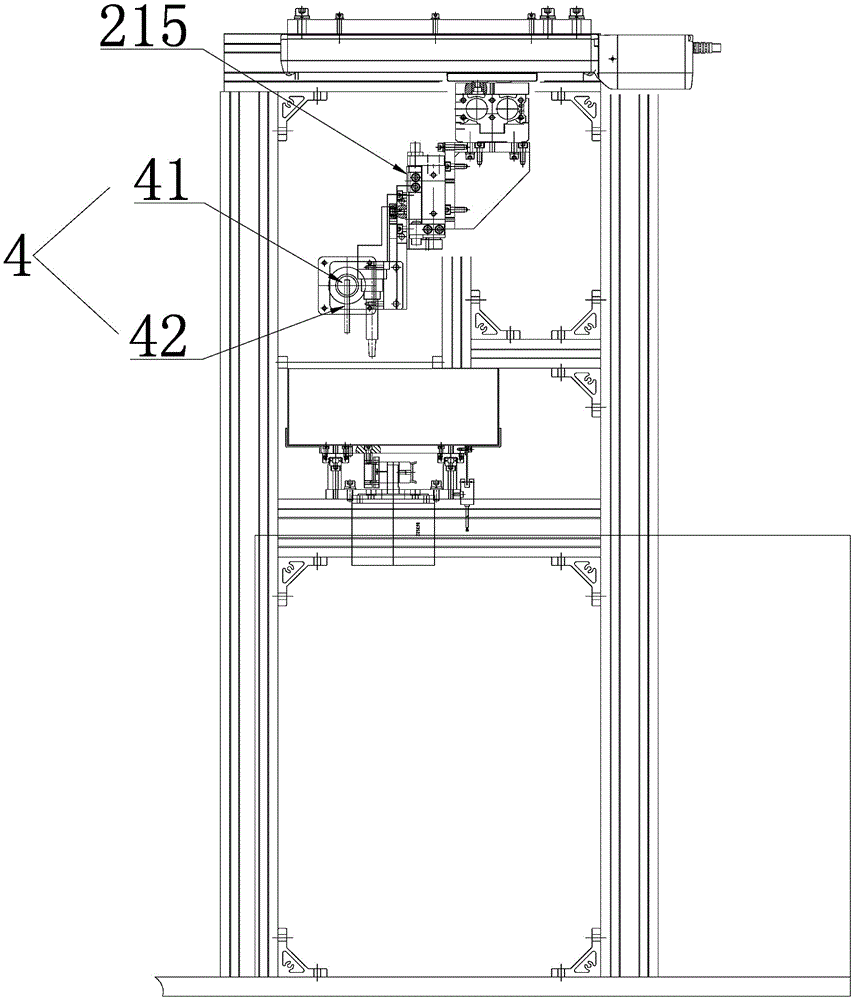

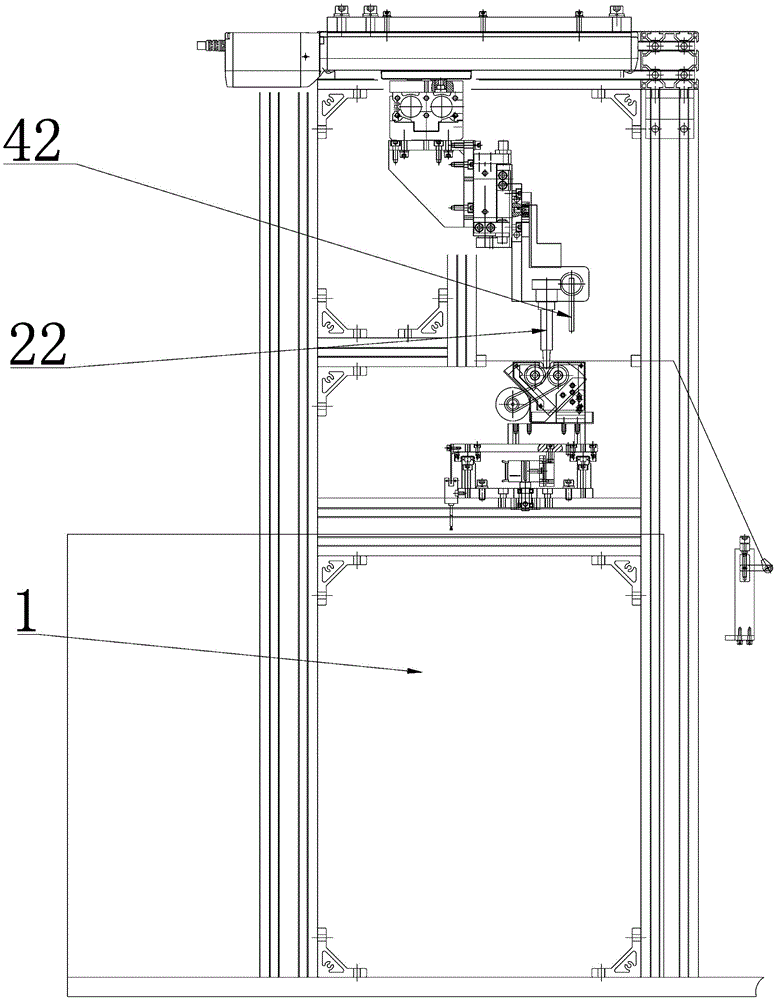

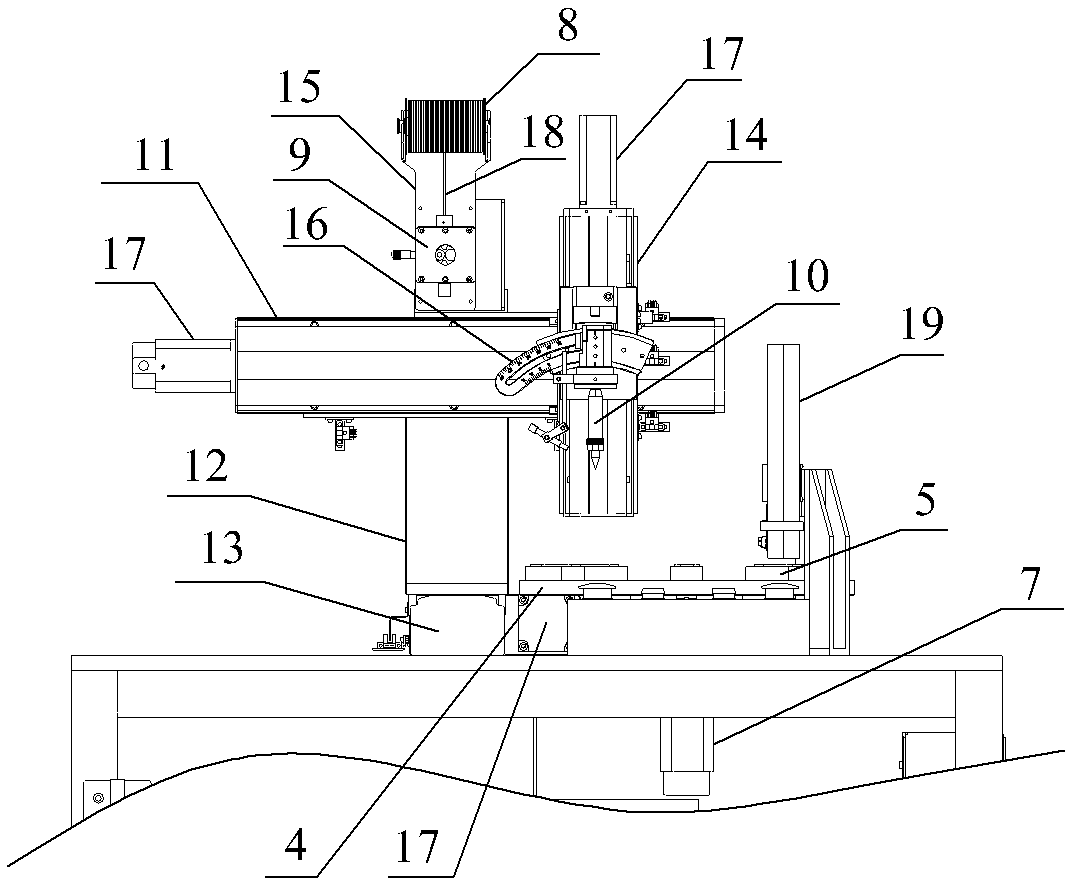

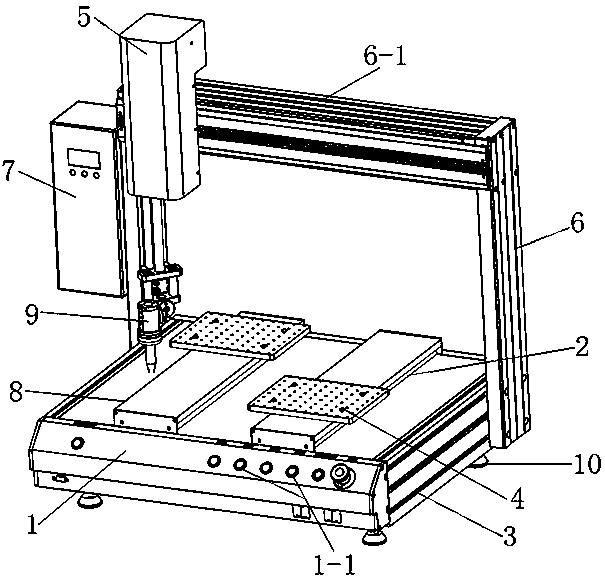

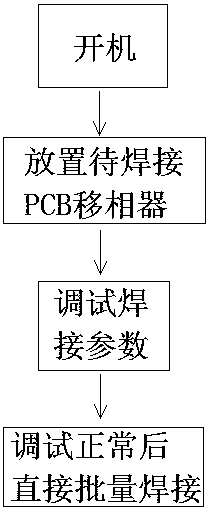

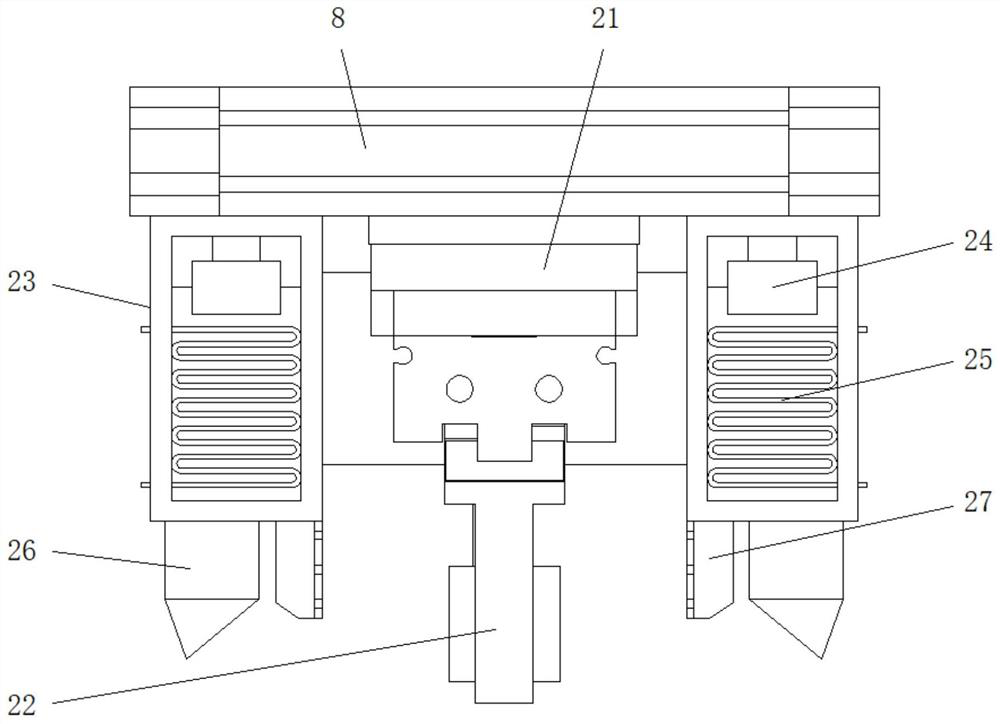

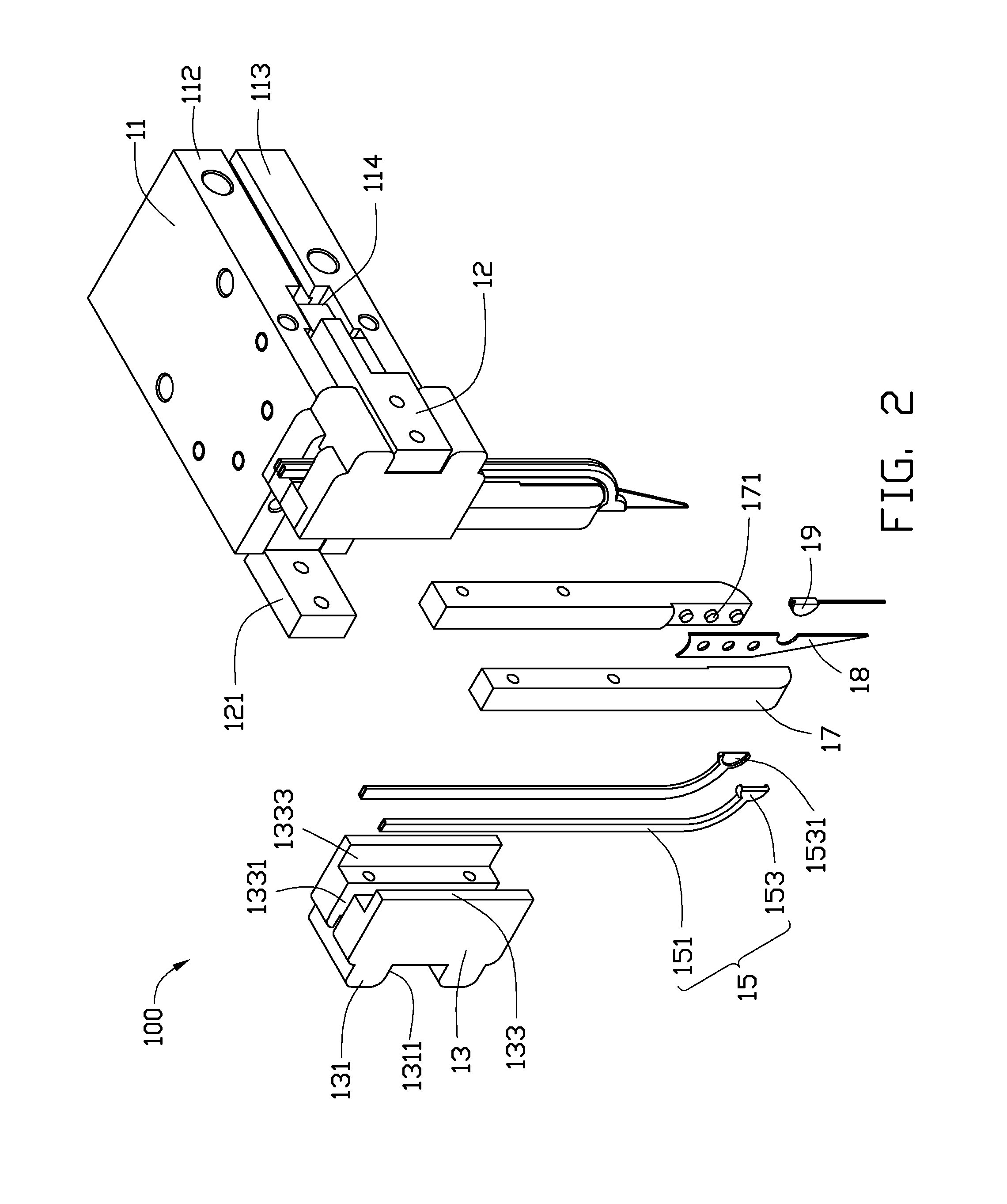

Automatic welding machine for welding of phase shifter

PendingCN108436213AIngenious ideaEasy to useSoldering bitsSoldering ironEngineeringMechanical engineering

The invention relates to welding equipment, in particular to an automatic welding machine for welding of a phase shifter. The automatic welding machine for welding of the phase shifter comprises a base, base upper tracks, base side tracks, welding tools, a welding arm, a welding arm support and a control box. The base is shaped like a cube. The upper surface of the base is provided with two equal-size tool locating bosses parallel to the side edges. The base upper tracks are arranged on the two sides of the tool locating bosses. One welding tool is arranged on each tool locating boss. The welding tools are fixed to the corresponding tool locating bosses through screws or buckled onto the base upper tracks through buckles to be movably mounted on the tool locating bosses. The automatic welding machine can be used for welding different sizes of products by replacing the welding tools.

Owner:ZHONGTIAN BROADBAND TECH +1

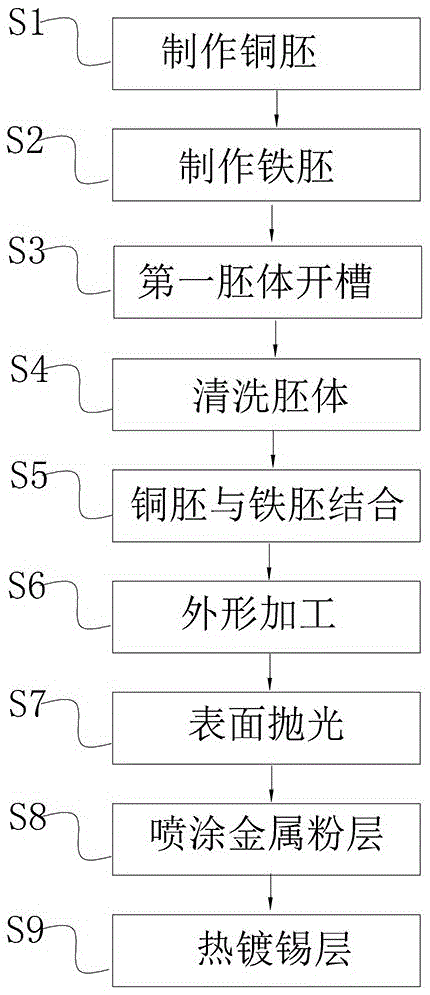

Energy-saving and environment-friendly solder tip and production process thereof

InactiveCN106670614AExtended service lifeSolve the problem of uneven life spanSoldering bitsSoldering ironCopperProtection layer

The invention discloses an energy-saving and environment-friendly solder tip and a production process thereof. During production of the solder tip, copper billet manufacturing, iron billet manufacturing, copper billet and iron billet combination, shape processing, surface polishing, spraying of an anti-corrosion metal layer, hot galvanizing of a molten tin protection layer and the like are sequentially conducted to finally form a copper billet, an iron billet, the anti-corrosion metal layer and a tin layer, wherein the iron billet comprises a first billet body and a second billet body which are integrally formed; a copper billet groove for fixing and accommodating the copper billet is formed in the first billet body; a working end for tin soldering operation is arranged at the second billet body; the anti-corrosion metal layer is sprayed to cover the outer surface of the second billet body; and the tin layer covers a solder tip on the outer surface of the working end. The process is simple, the cost is low, the environment is protected, a produced product is stable in performance, the production period is short, and automatic production can be realized.

Owner:深圳市吉美电子设备有限公司

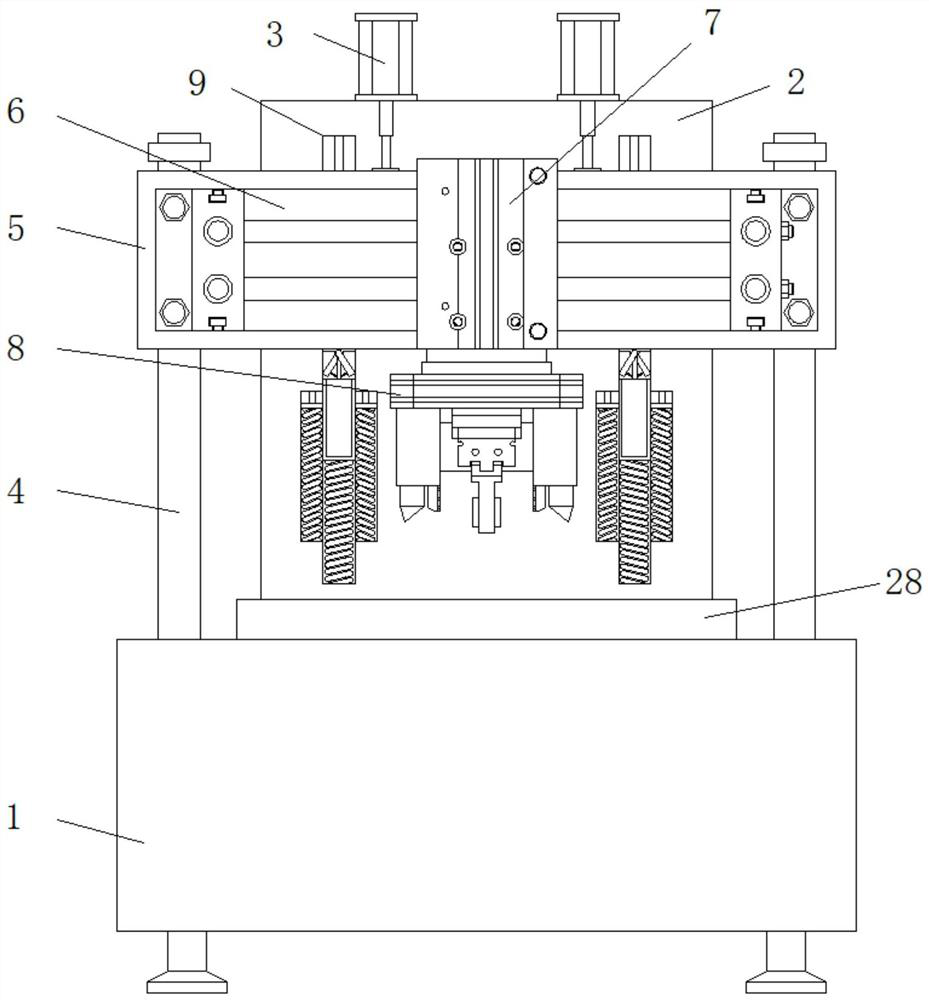

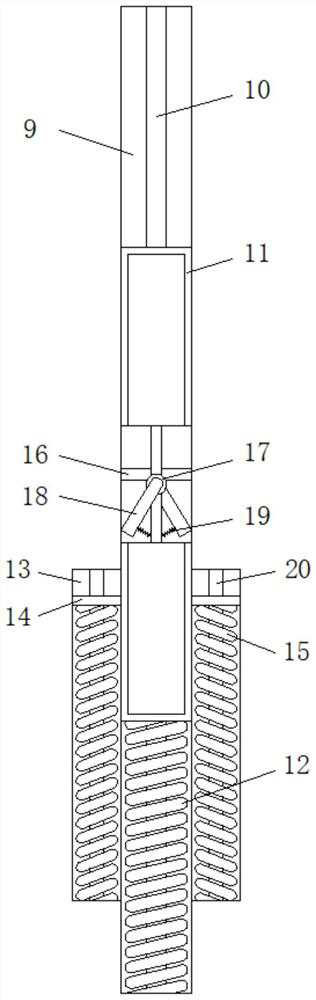

Thermal compression welding head pressure-buffering tin soldering device and tin soldering technology thereof

InactiveCN113664318ARelieve pressureImprove qualityPrinted circuit assemblingSoldering bitsHydraulic cylinderEngineering

The invention discloses a thermal compression welding head pressure-buffering tin soldering device and a tin soldering technology of the thermal compression welding head pressure-buffering tin soldering device. The device comprises a box body and a machine frame installed on the box body. Hydraulic cylinders are installed on the machine frame, the output ends of the hydraulic cylinders are connected with a sliding plate, an installation plate is installed on the sliding plate through an adjusting mechanism, and a welding head is installed on the installation plate through a welding head base. A pressure buffering mechanism is arranged on the machine frame, and a bearing platform mechanism is arranged at the position, located below the welding head, of the top of the box body. According to the device, the hydraulic cylinders push the sliding plate to move downwards, the adjusting mechanism adjusts the position of the welding head, the downward pressure is gradually buffered through the arrangement of the pressure buffering mechanism, the pressure on workpieces in the process of tin soldering operation of the welding head is gradually reduced, the quality and the reliability of welding spots of the workpieces are improved, the different machined workpieces can be conveniently positioned through the arrangement of the bearing platform mechanism, and the tin soldering operation is facilitated.

Owner:江苏诺森特电子科技有限公司

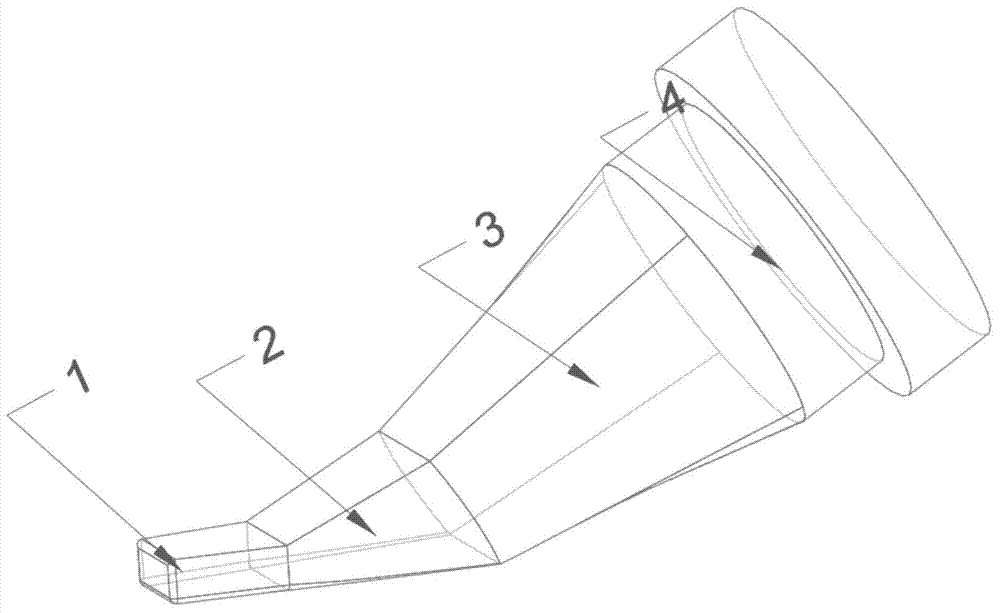

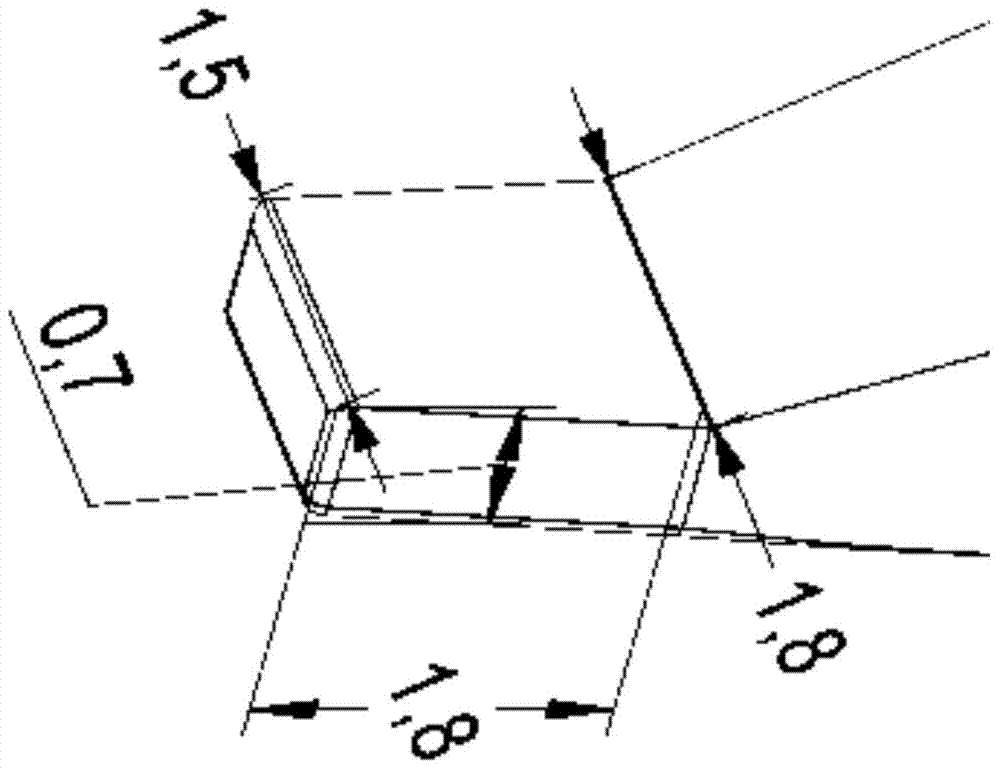

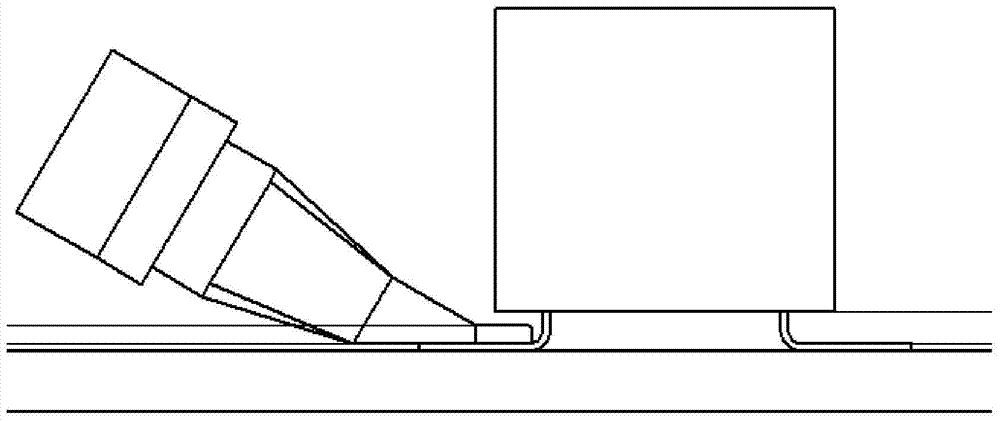

High-heat-transmission solder tip suitable for soldering in small spaces

ActiveCN104842036AMeet the requirements of relevant standardsAvoid Solder Sticking ProblemsSoldering bitsSoldering ironHeat resistanceEngineering

Disclosed is a high-heat-transmission solder tip suitable for soldering in small spaces. The solder tip comprises four parts, namely a soldering iron assembly part, two transition parts and a tip part, the assembly part is designed according to a used soldering station, assembling use is guaranteed, the transition parts are as large as possible and short so as to reduce heat resistance and can be in smooth transition with the tip part, and the tip part is in key size and enabled to go deep into the bottom of a device for narrow gap soldering. A base material of the solder tip is red copper, the solder tip is sequentially and integrally plated with iron and nickel, the portions except for bottom soldering positions are plated with chrome, and the bottom soldering positions are bonded with tin. The solder tip can be used for narrow-gap and high-heat-transmission soldering at the same time, and the non-soldering positions of the device are prevented from being bonded with tin. The solder tip is particularly applicable to SOP packaged 3D-PLUS devices.

Owner:BEIJING INST OF CONTROL ENG

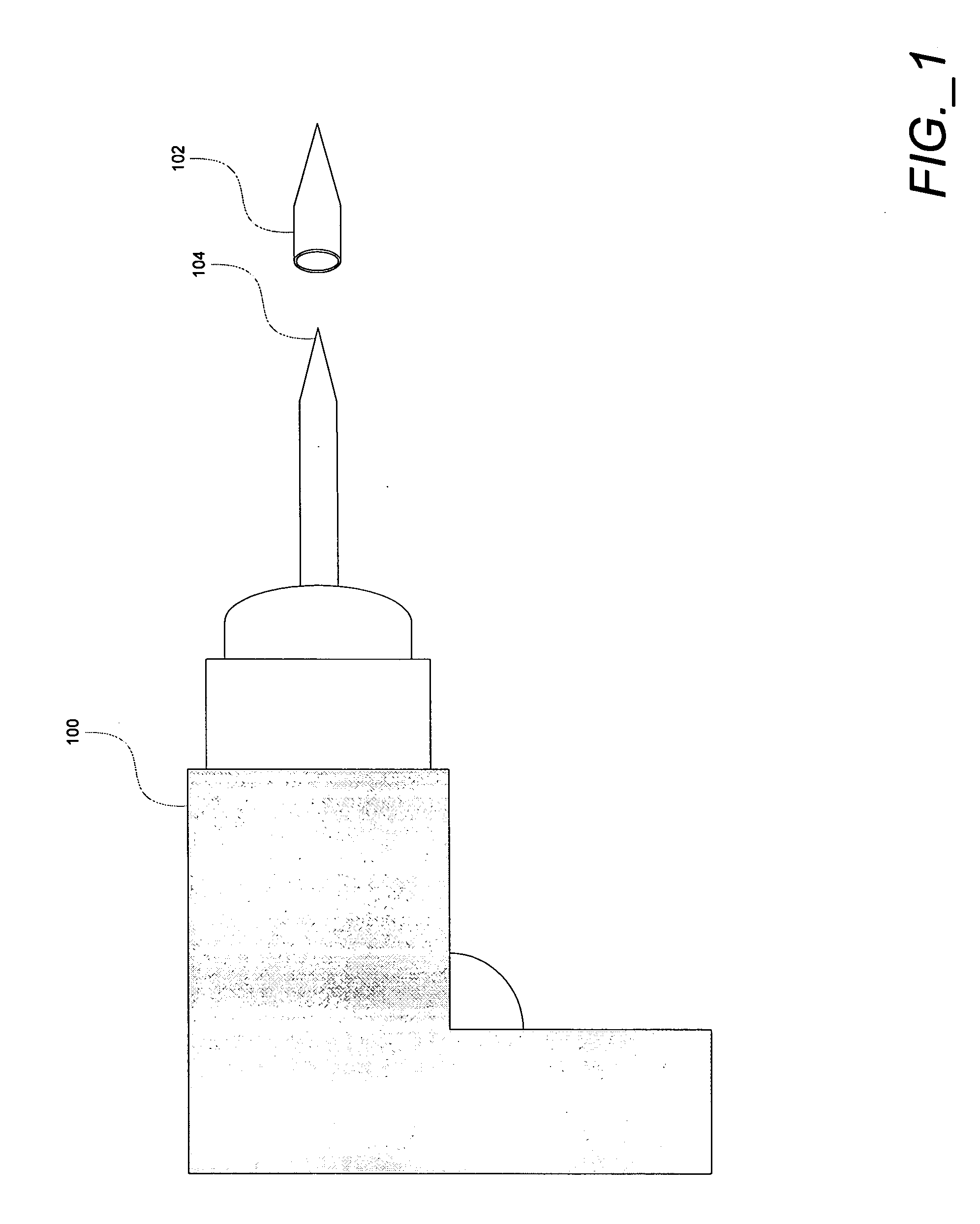

Soldering iron tip

ActiveUS20190299312A1Reduced risk of burnsEliminate riskSoldering bitsSoldering ironElectricityOperating temperature

The present invention provides a soldering iron with a tip having two separate halves that are electrically isolated from one another. When both halves of the tip are applied to an electrically conductive material, such as the material to be soldered, an electrical circuit between the tip halves and an electrical power source is completed. Therefore, the tip can reach operating temperatures quickly. When the tip is removed from the joint, the electrical circuit is broken and the tip material may quickly cool to a temperature safe for human contact. The tip material permits higher power outputs than other battery operated portable soldering irons and heat and cools faster the conventional soldering tips.

Owner:AXINTE DRAGOS

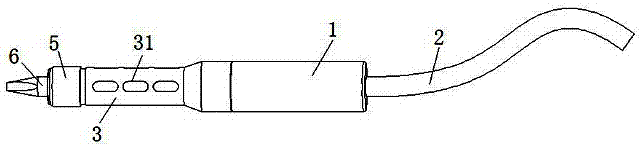

Electric soldering pen with soldering iron head conveniently replaced

InactiveCN106903392AEasy to replaceQuick changeSoldering bitsSoldering ironEngineeringFixed position

An electric soldering pen for convenient replacement of a soldering iron tip according to the present invention comprises a soldering iron tip handle, a power cord, a foolproof sheath, a heating core, a foolproof nut and a soldering iron tip. In the present invention, an upper plane and a lower plane are respectively arranged on the upper end of the middle part of the soldering iron tip and the lower end of the middle part of the soldering iron tip, so that the fool-proof sheath can firmly clamp the soldering iron tip through the upper plane and the lower plane, preventing the soldering iron tip from moving again. It can lock the fool-proof sheath, heating core and soldering iron tip together by setting the fool-proof nut to prevent the soldering iron tip from falling off, so as to achieve the purpose of fixing the position, so that the installation of the soldering iron tip does not need to be adjusted again, realizing In order to quickly replace the soldering iron tip, and do not need to reposition the soldering iron tip, it is convenient, fast and practical to use, fast in installation, simple in structure, low in cost, greatly improves welding efficiency, increases welding accuracy, and expands the range of electric soldering pens. range of use.

Owner:吴水鱼

Multifunctional dual-purpose electric soldering iron

InactiveCN104339062AFast solderingTo achieve the purpose of saving energy and reducing consumptionSoldering bitsSoldering ironDual purposeEngineering

The invention discloses a multifunctional dual-purpose electric soldering iron. The multifunctional dual-purpose electric soldering iron comprises an electric soldering iron handle, and a hollow welding head mounted at one end of the electric soldering iron handle, wherein a tin inlet is formed in the hollow welding head; a sliding high-temperature resistant piston is arranged inside the hollow cavity of the hollow welding head. The multifunctional dual-purpose electric soldering iron has the advantages that the electric soldering iron can be operated with one hand conveniently and fast; the welding fluid can be reused to achieve the purposes of saving energy and lowering consumption.

Owner:郑学东

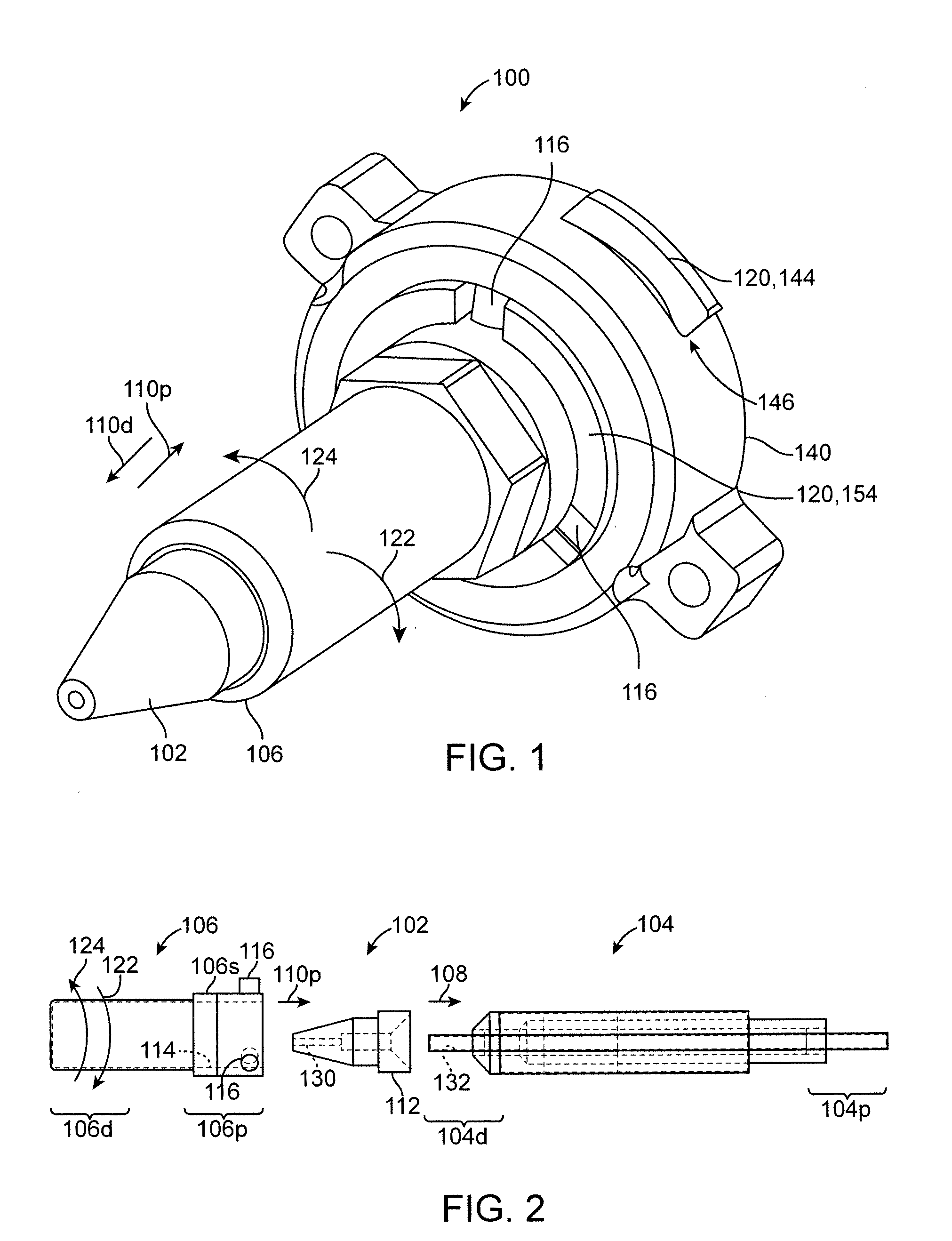

Soldering assembly for detachable tip

ActiveUS9168605B2Easy to understandSoldering bitsSoldering ironDistal segmentElectrical and Electronics engineering

A soldering assembly comprises a heater, a lock member, and a bias member. The lock member is moveable relative to the heater, includes a ramp feature, and is configured to receive a tip or a tip holder. The bias member is configured to urge movement of the lock member away from a distal segment of the heater.

Owner:HAKKO CO LTD

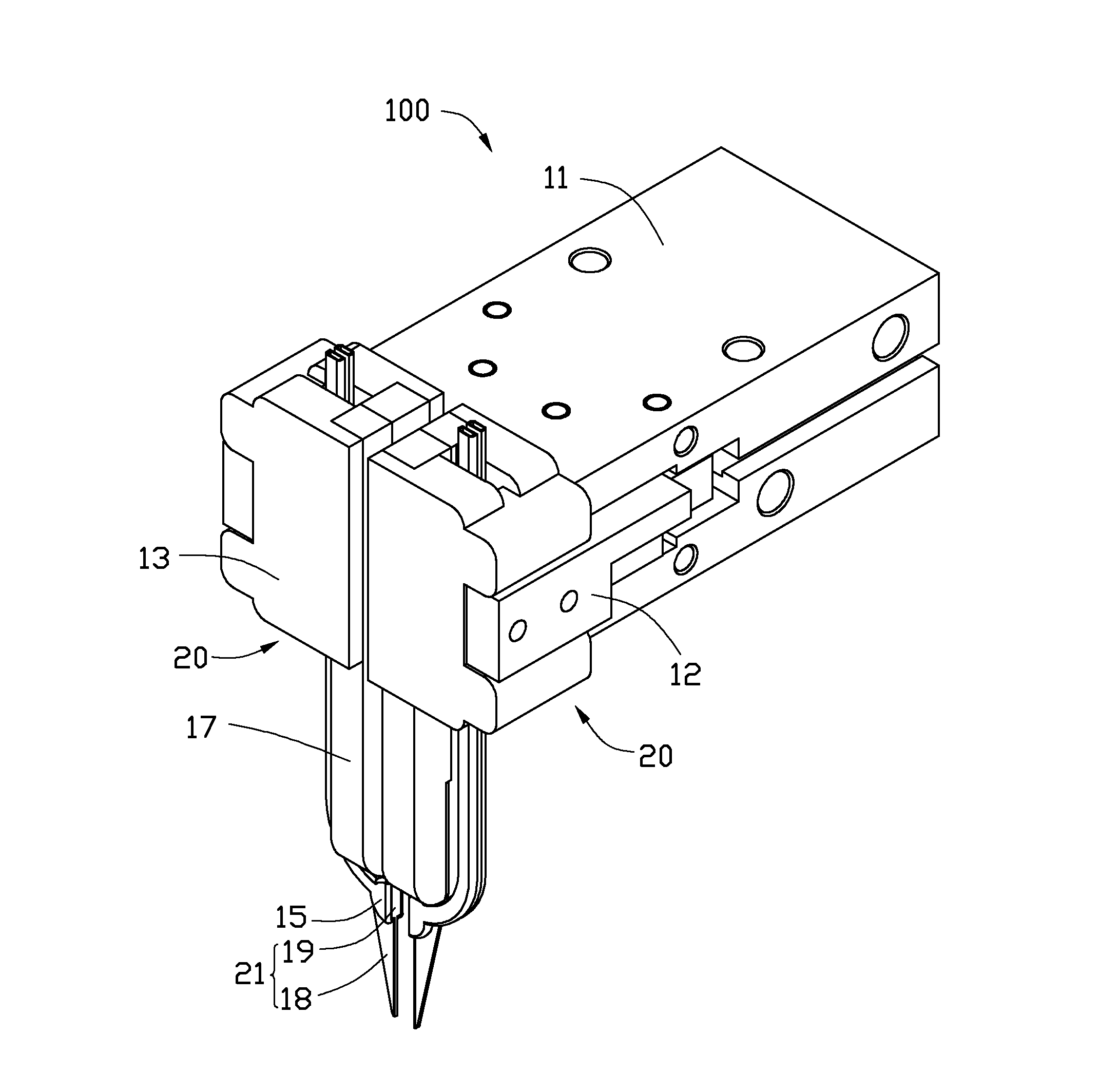

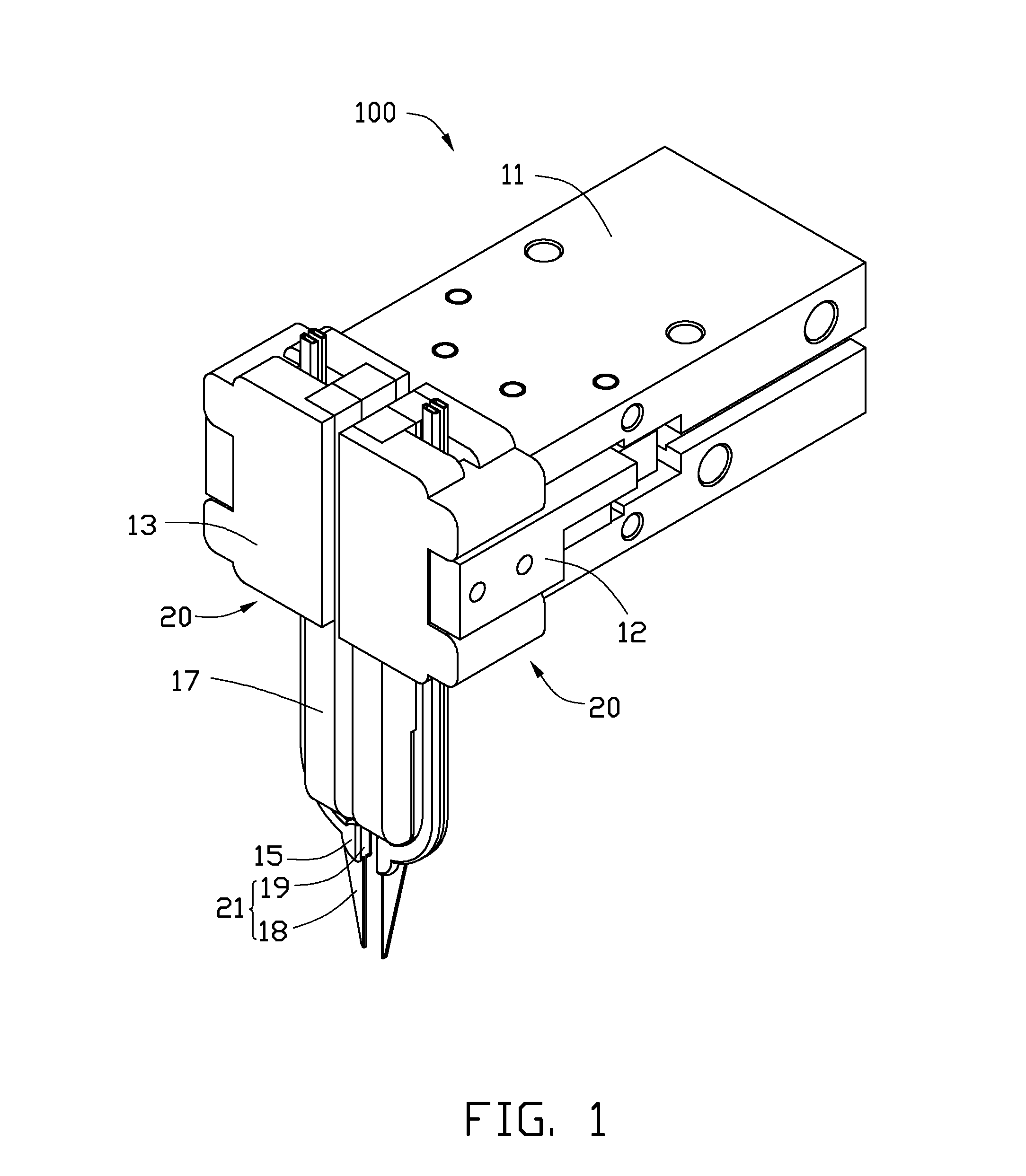

Soldering apparatus

A soldering apparatus includes a base body, an actuator connected to the base body, and a pair of soldering arms connected to the actuator, each of the pair of soldering arms including a heating member and a soldering tip thermally coupled to the heating member. The pair of soldering arms is moveable and the actuator is controllable to move one soldering arm relative to the other soldering arm.

Owner:HON HAI PRECISION IND CO LTD

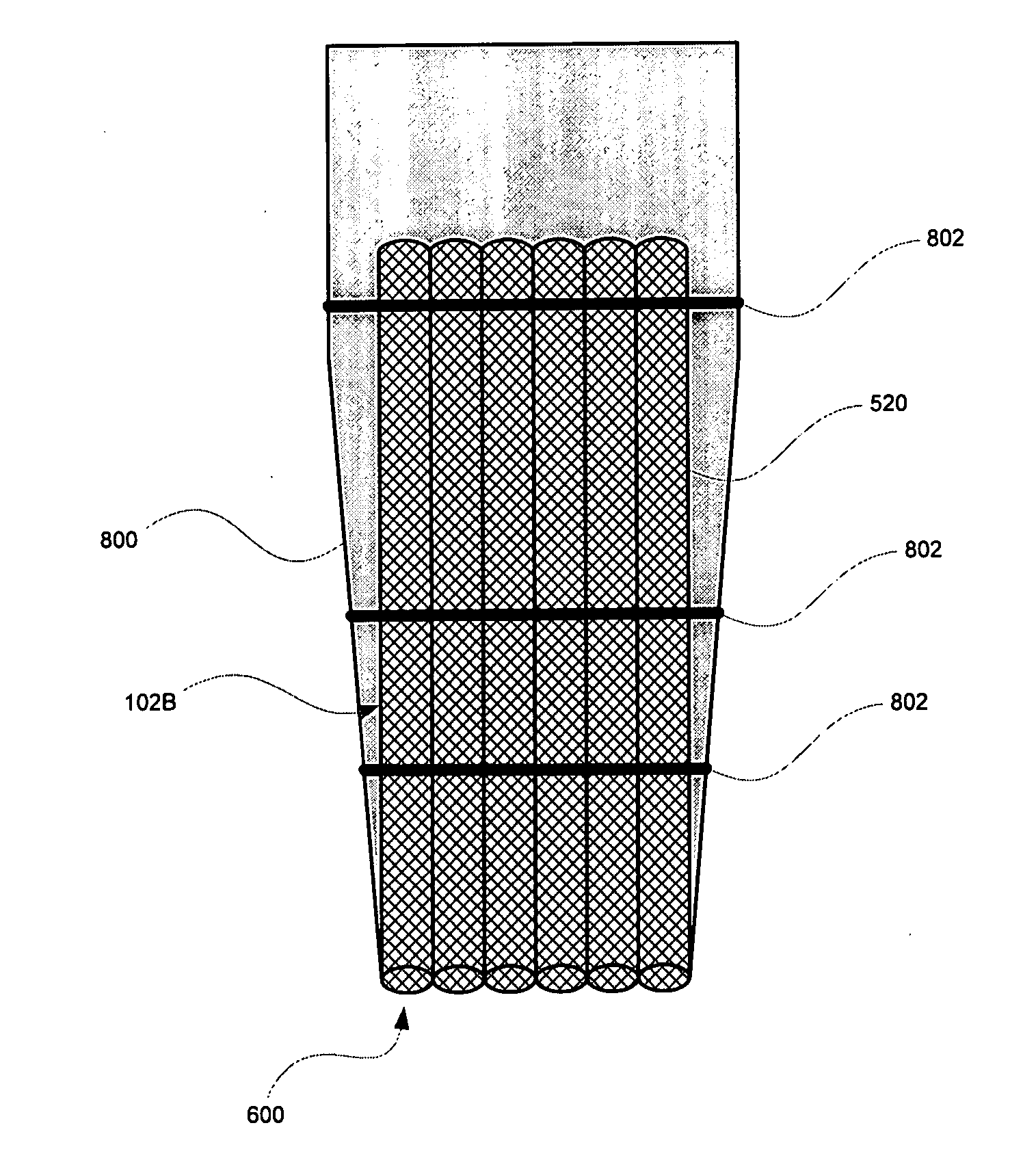

Heater sensor complex with high thermal capacity

ActiveUS9700951B2Reduce heat transferIncrease heating capacityThermometers using electric/magnetic elementsWelding/cutting auxillary devicesSolderingThermocouple

The invention is directed to designs for heater-sensor sub-assemblies for soldering cartridges and de-soldering cartridges for soldering systems. The designs provide a high thermal capacity and accurate tip temperature sensing and control features. The coil portion of the heater assembly is spaced proximally from the distal end of the subassembly to segregate the coil from the thermocouple temperature sensor. The solder cartridges include connector wires of dissimilar sizes and materials to couple the heater coil wire to the connections of a handle and the soldering station to reduce heat conduction to the handle.

Owner:HAKKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com