Energy-saving and environment-friendly solder tip and production process thereof

An energy-saving, environmental-friendly, production-technical technology, applied in soldering irons, manufacturing tools, metal processing equipment, etc., can solve problems such as large thickness deviation of iron plating layer, long production cycle, wrong operation, etc. Electroplating wastewater, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

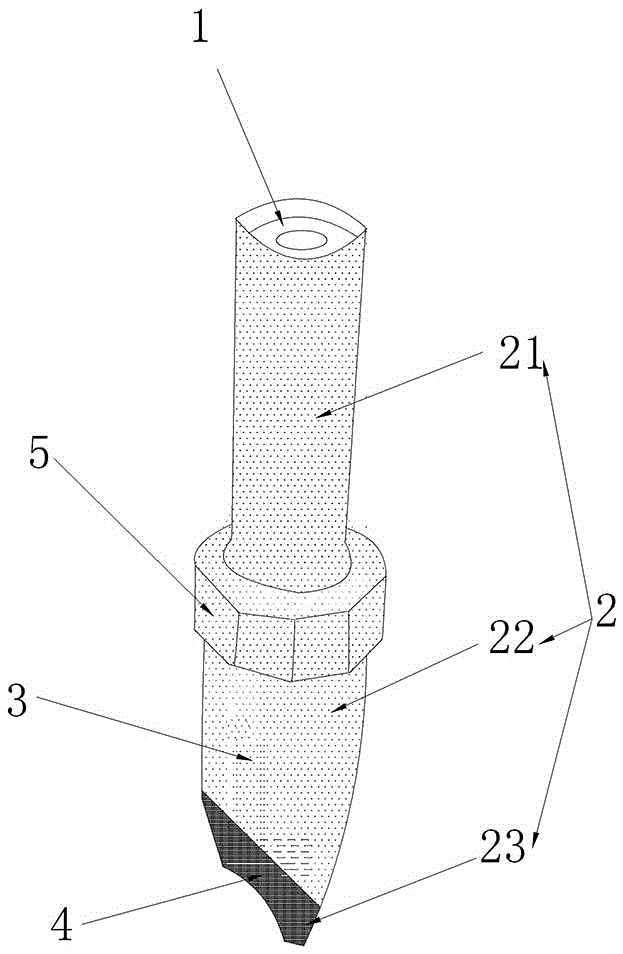

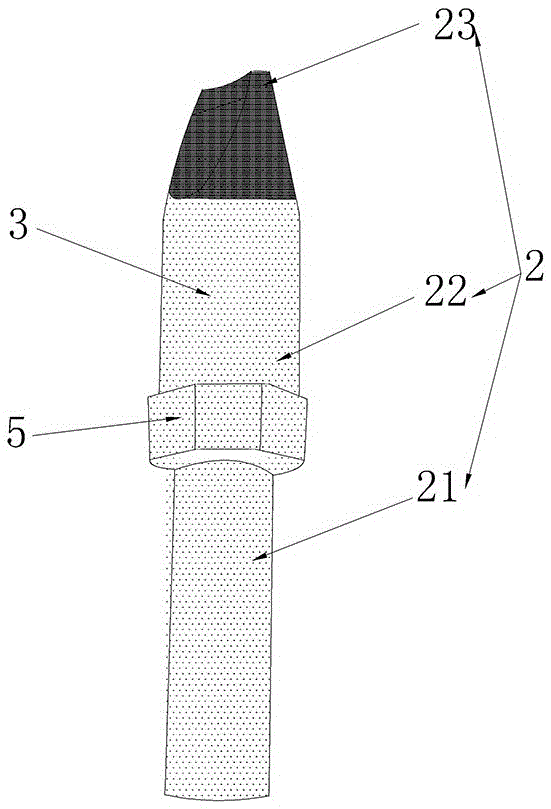

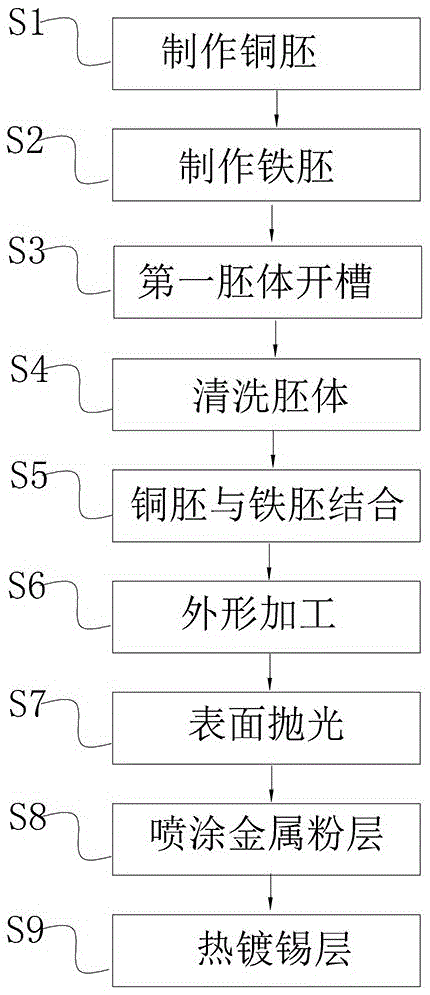

[0044] see Figure 1-2 , the energy-saving and environment-friendly soldering iron tip provided by the present invention and its production process include a copper embryo 1 for connecting with a soldering iron core, an iron embryo 2 for slowing down tin corrosion, a tin layer 4 and an anti-corrosion metal layer 3 that is not easily corroded by tin, The iron embryo 2 includes a first embryo body 21 and a second embryo body 22, the first embryo body 21 and the second embryo body 22 are integrally formed, and the first embryo body 21 is provided with a copper embryo groove for fixing and accommodating the copper embryo 1. The second blank body 22 is provided with a working end 23 for soldering operation; the anti-corrosion metal layer 3 is sprayed and covered on the outer surface of the first blank body 21 and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com