Patents

Literature

270results about How to "Reduced risk of burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

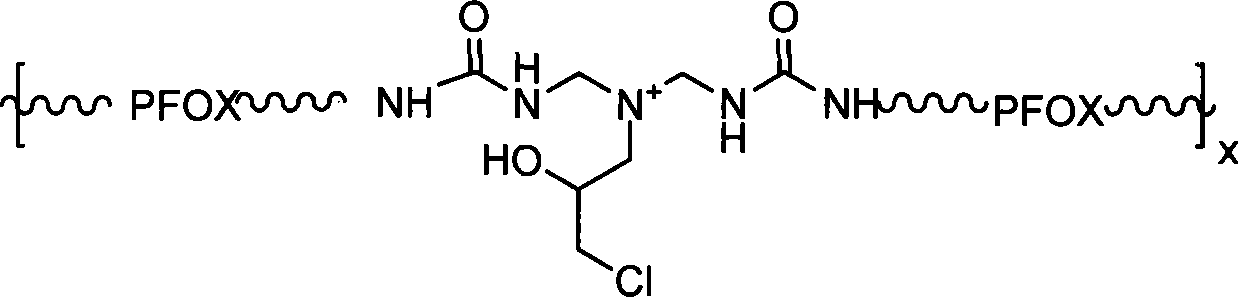

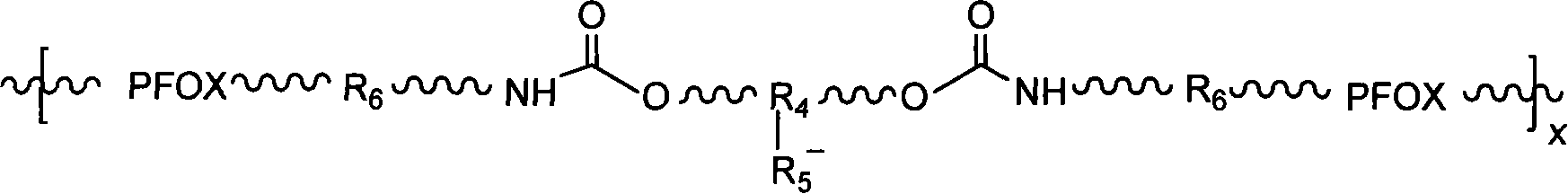

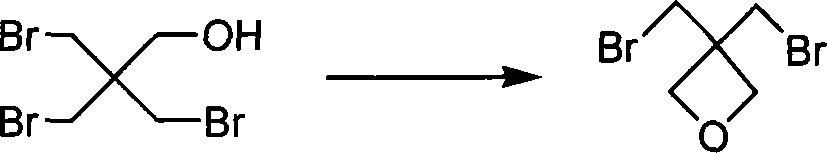

Fluorine-containing aqueous polyurethane and preparation method and application thereof

InactiveCN101041709AIncreased durabilityImprove waterproof performanceAntifouling/underwater paintsOther chemical processesGreen environmentFluorine containing

The invention discloses a making method and application of aqueous fluorine polyurethane, which contains cationic and anionic aqueous fluorine polyurethane with the making procedure comprises the following steps: (1) synthesizing bromoepoxybutane; (2) making fluoepoxybutane; (3) preparing fluorine polyether; (4) synthesizing aqueous polyurethane. The invention can be high-property green environment-protective water repellency, waterproof and stainproof paint, which possesses wide market prospect.

Owner:DONGHUA UNIV

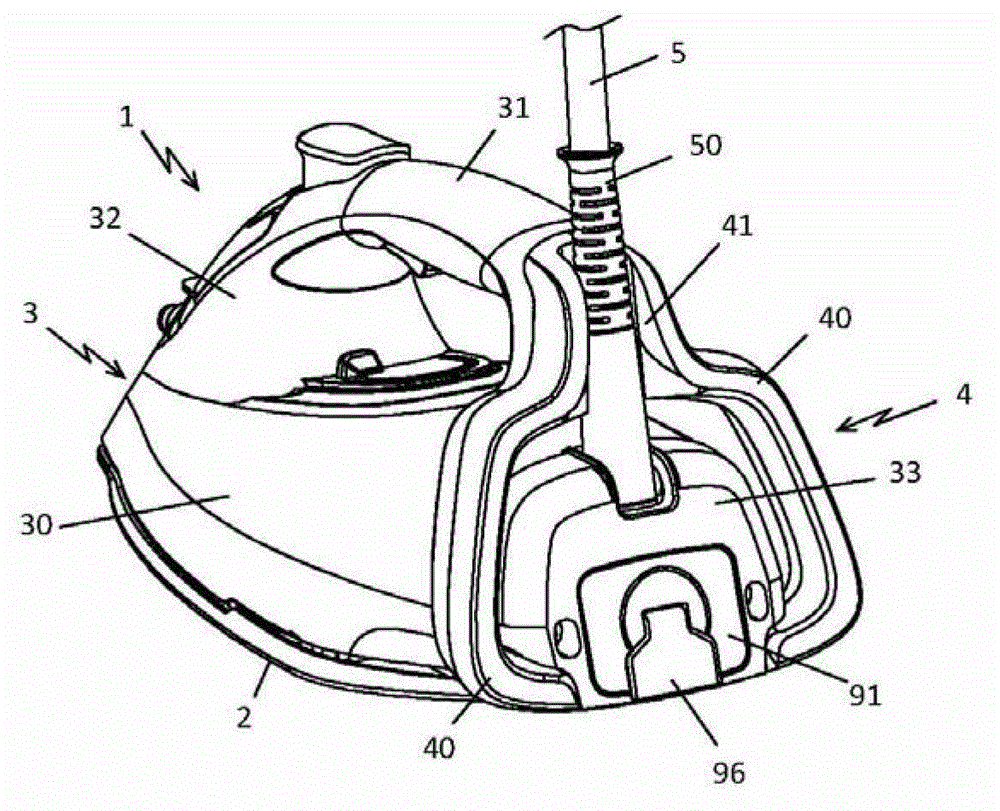

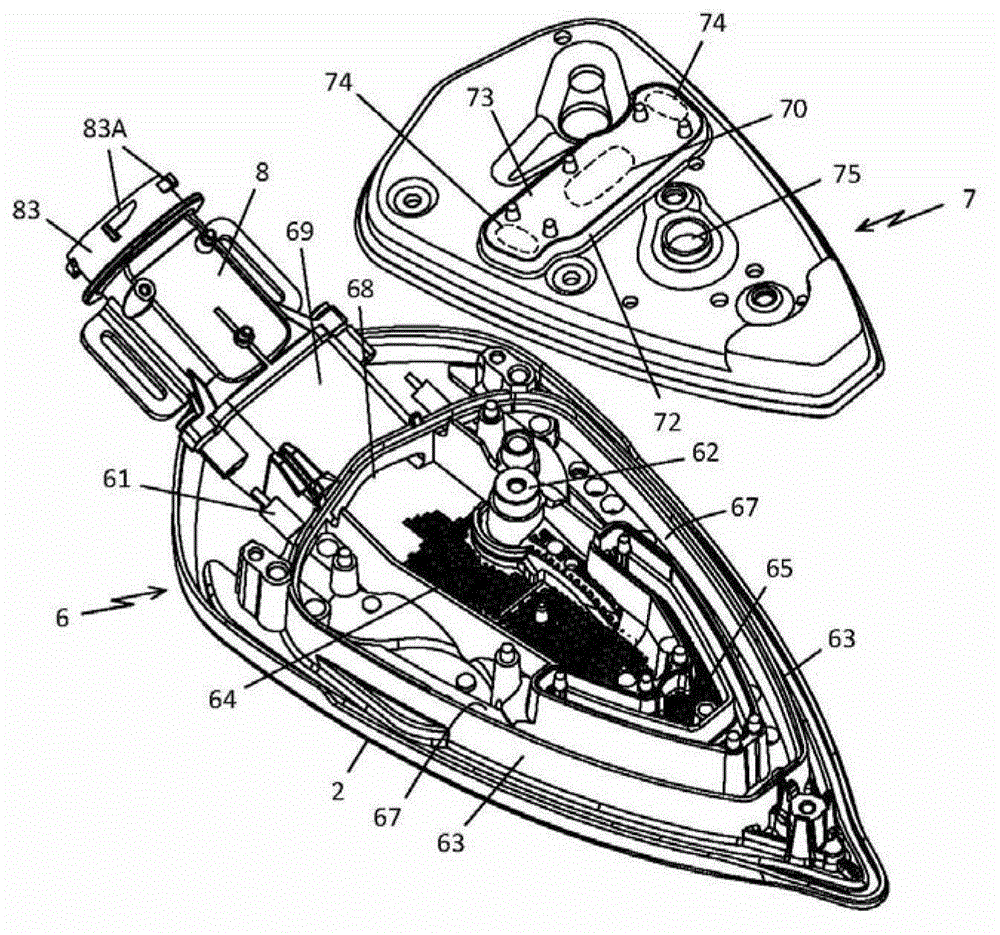

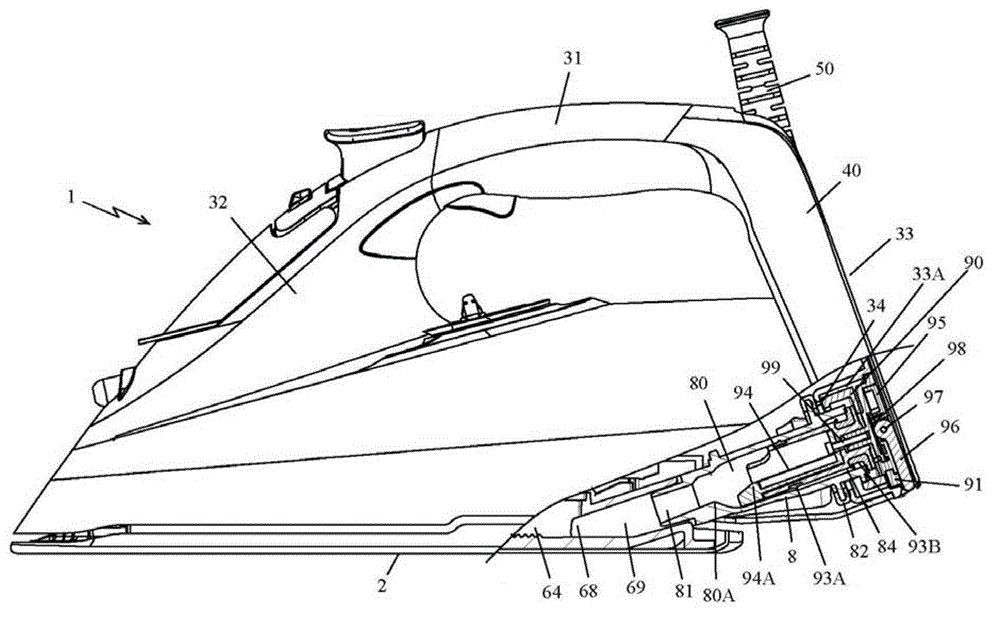

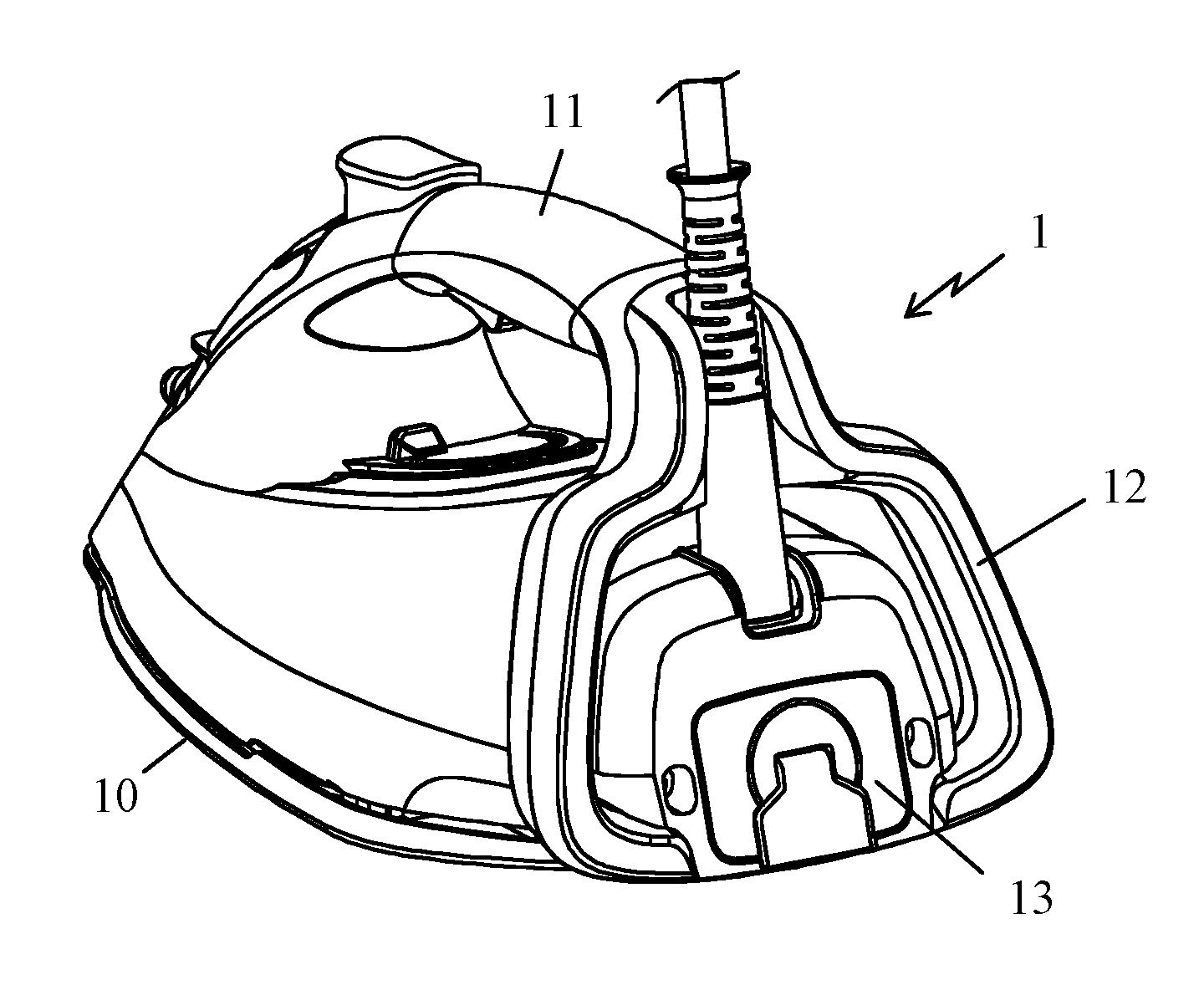

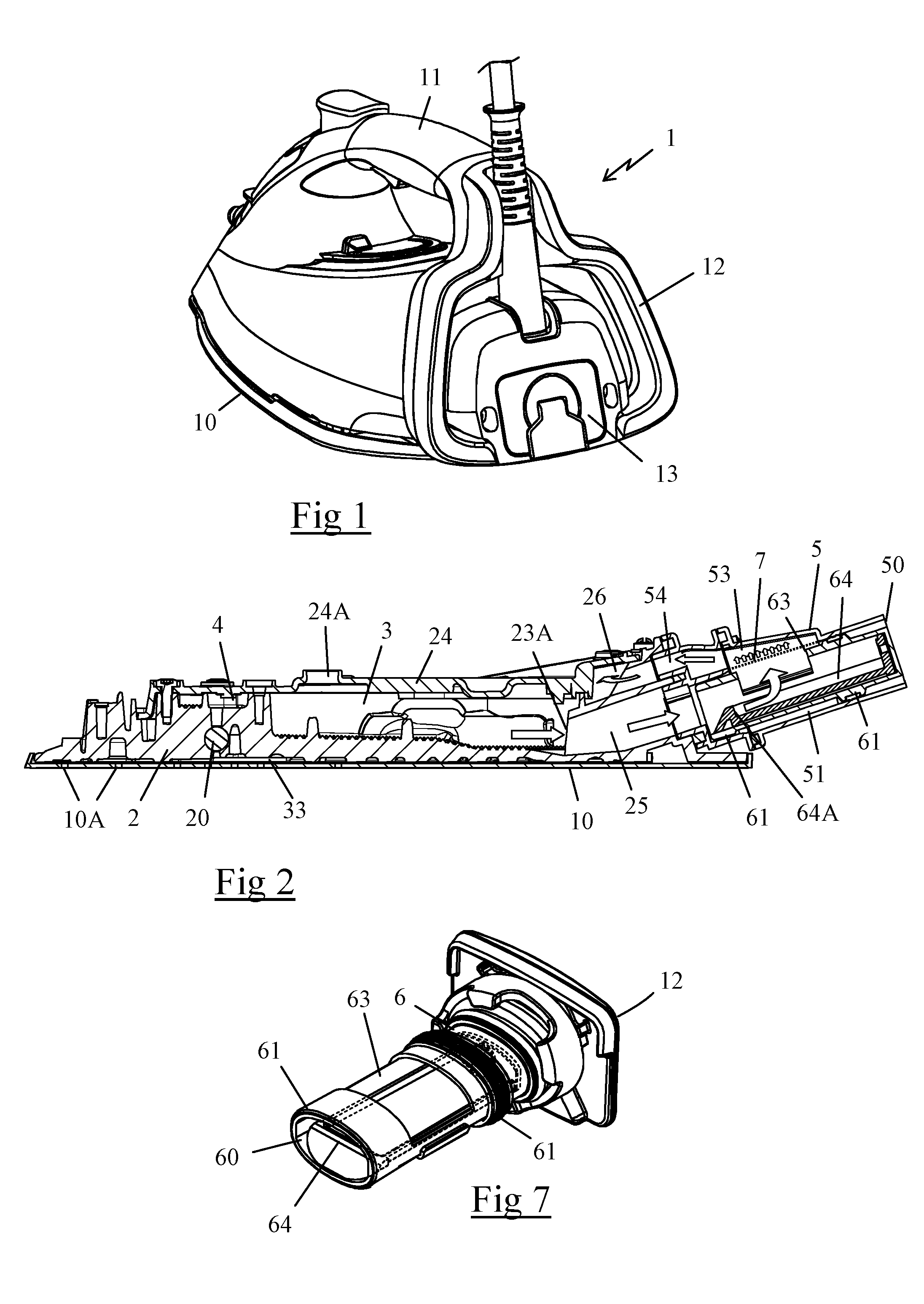

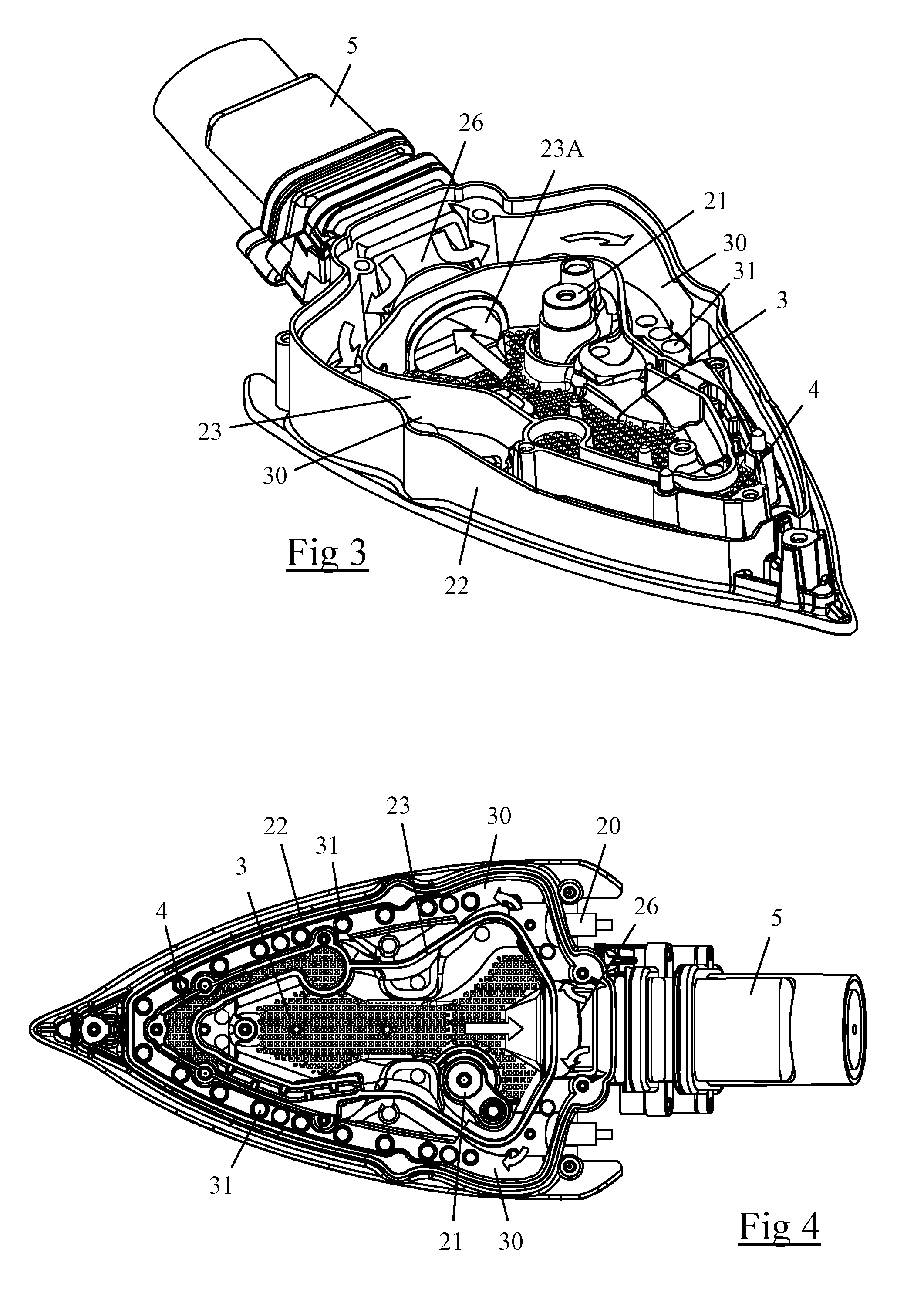

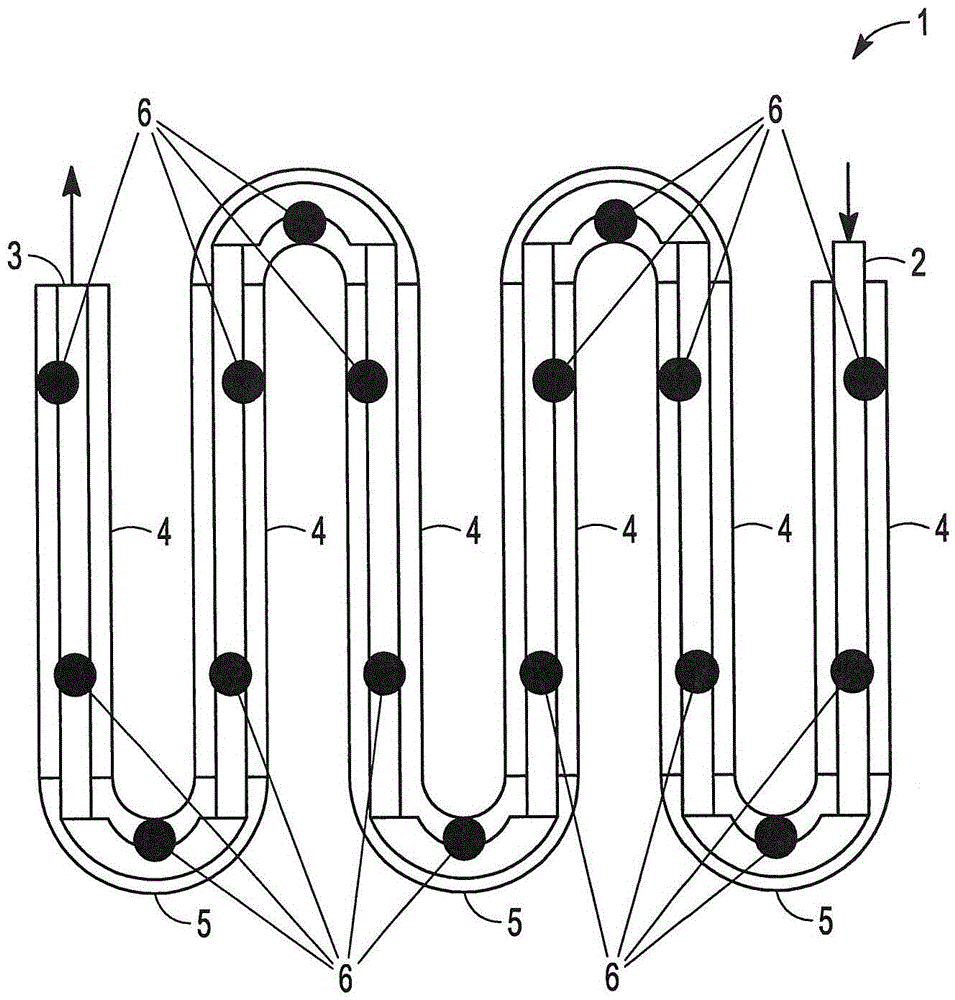

Flat iron including evaporation chamber connected with scale recycle chamber of scale-removing hole

ActiveCN103061097AEasy to transportNo danger of capsizingHand ironTextiles and paperEngineeringEvaporation chamber

The invention relates to a flat iron (1). The flat iron (1) comprises an ironing base plate (2); a heating main body (6) and a housing (3) are mounted on the ironing base plate (2); and the housing (3) comprises a base (4). When the ironing is not operated, the flat iron (1) can be placed using the base (4). The heating main body (6) comprises a steam distribution loop, the steam distribution loop comprises an evaporation chamber (64), the evaporation chamber (64) is connected with a scale recycle chamber (80), the scale recycle chamber (80) is positioned at a rear part of the flat iron (1) and comprises a scale-removing hole (84), the scale-removing hole (84) is closed by a detachable plug (9), the plug (9) can be contacted from the external of the flat iron. The scale-removing hole (84) is arranged in a recessed part (33A) on the housing (3). The detachable plug (9) is rotatably fixed on a fixing hoop (83), and the fixing hoop (83) surrounds the scale-removing hole (84). The detachable plug (9) supports a wrapping piece (91), and the wrapping piece (91) covers the recessed part (33A).

Owner:SEB SA

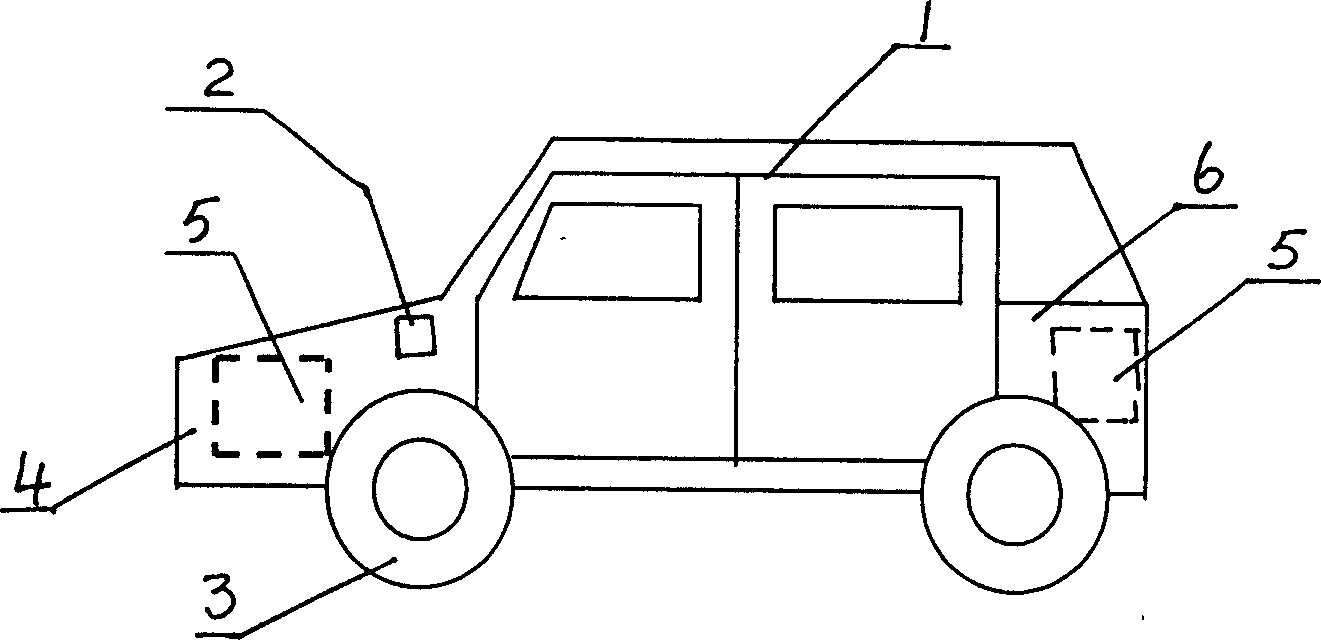

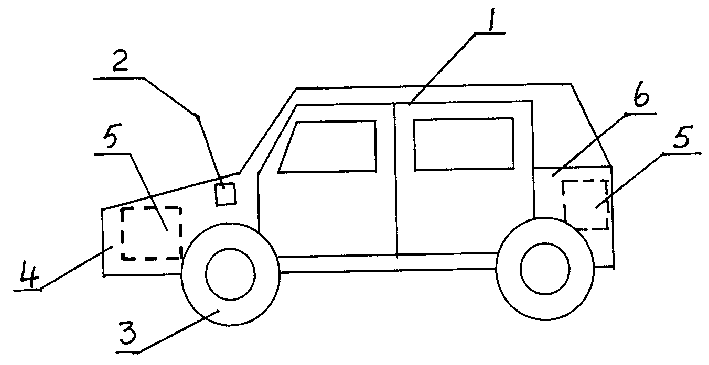

Electromobile capable of alternately changing battery and its operation system

InactiveCN1493475AReduce upfront investmentImprove performanceVehicular energy storageElectric propulsionElectricityElectric motor

An electric car with the changeable electric accumulator sets is composed of main body, fixed more than one set of exchangeable electric accumulators, motors, wheels and running unit. Said accumulators are electrically connected to motors. A running system for the electric cars in whole country is also disclosed, which is composed of the service stations for discharging the accumulators or providing the newly charged accumulators.

Owner:张乐平

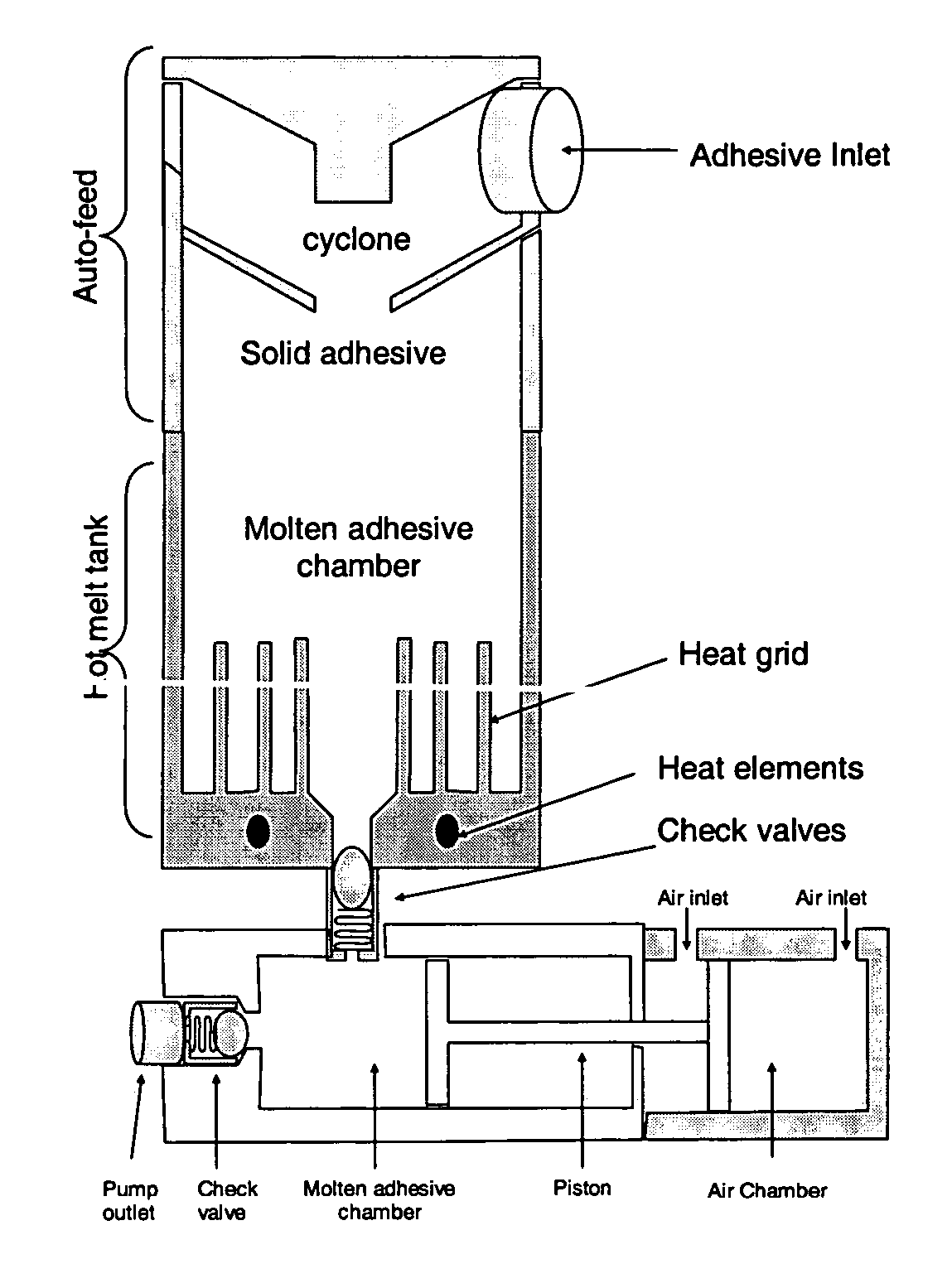

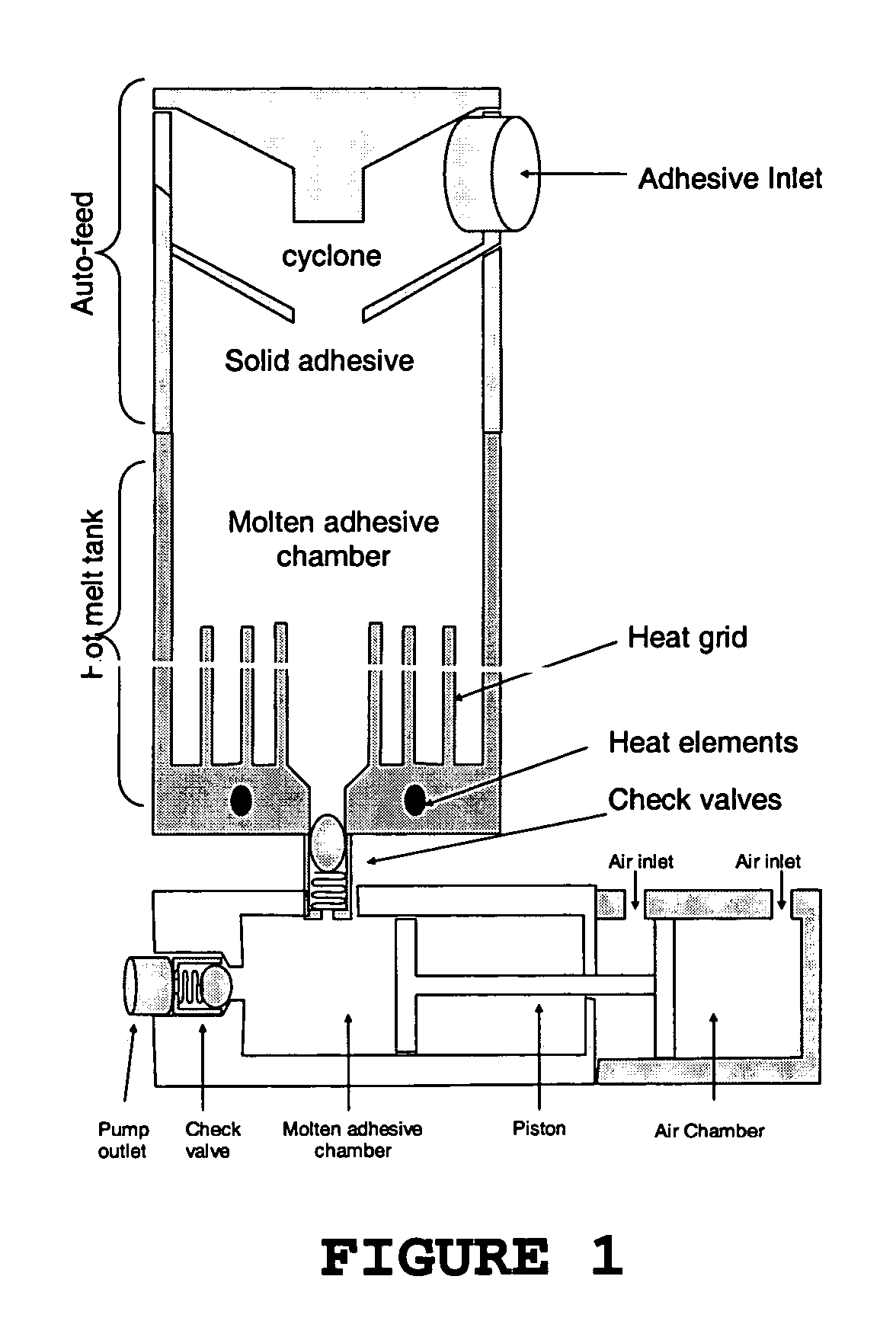

System for dispensing viscous liquids

InactiveUS20050274740A1Low costEasy to operateLiquid surface applicatorsLiquid transferring devicesViscous liquidMelting tank

Apparatus for dispensing viscous liquid, such as hot melt adhesive, including an automated adhesive conveyance (e.g., pneumatic transfer) feed unit, a heated melt tank, a pump, heated hose, dispensing valve, and control unit. The adhesive unit is specifically designed to run at maximum temperature of 275° F.

Owner:HENKEL KGAA

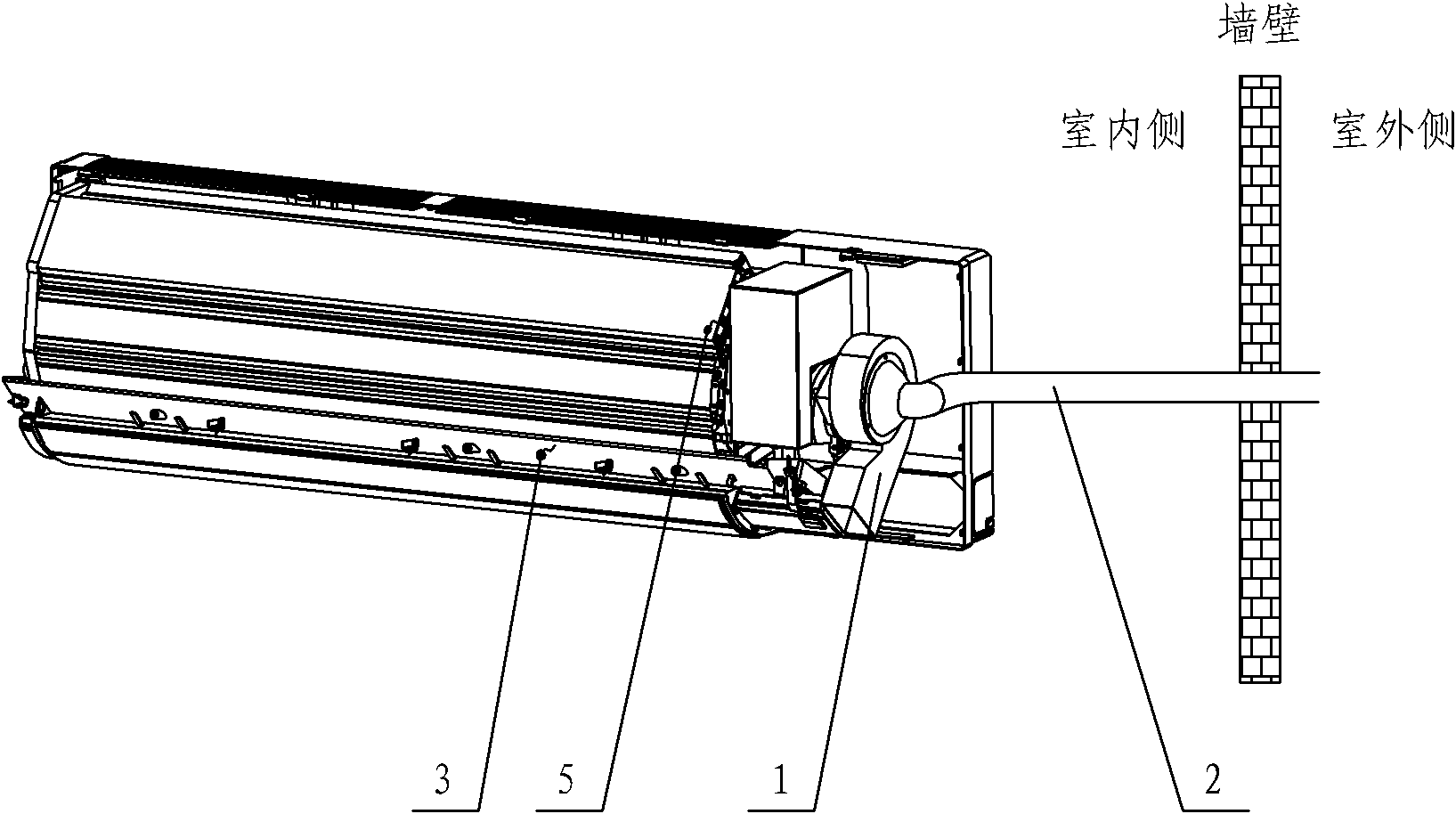

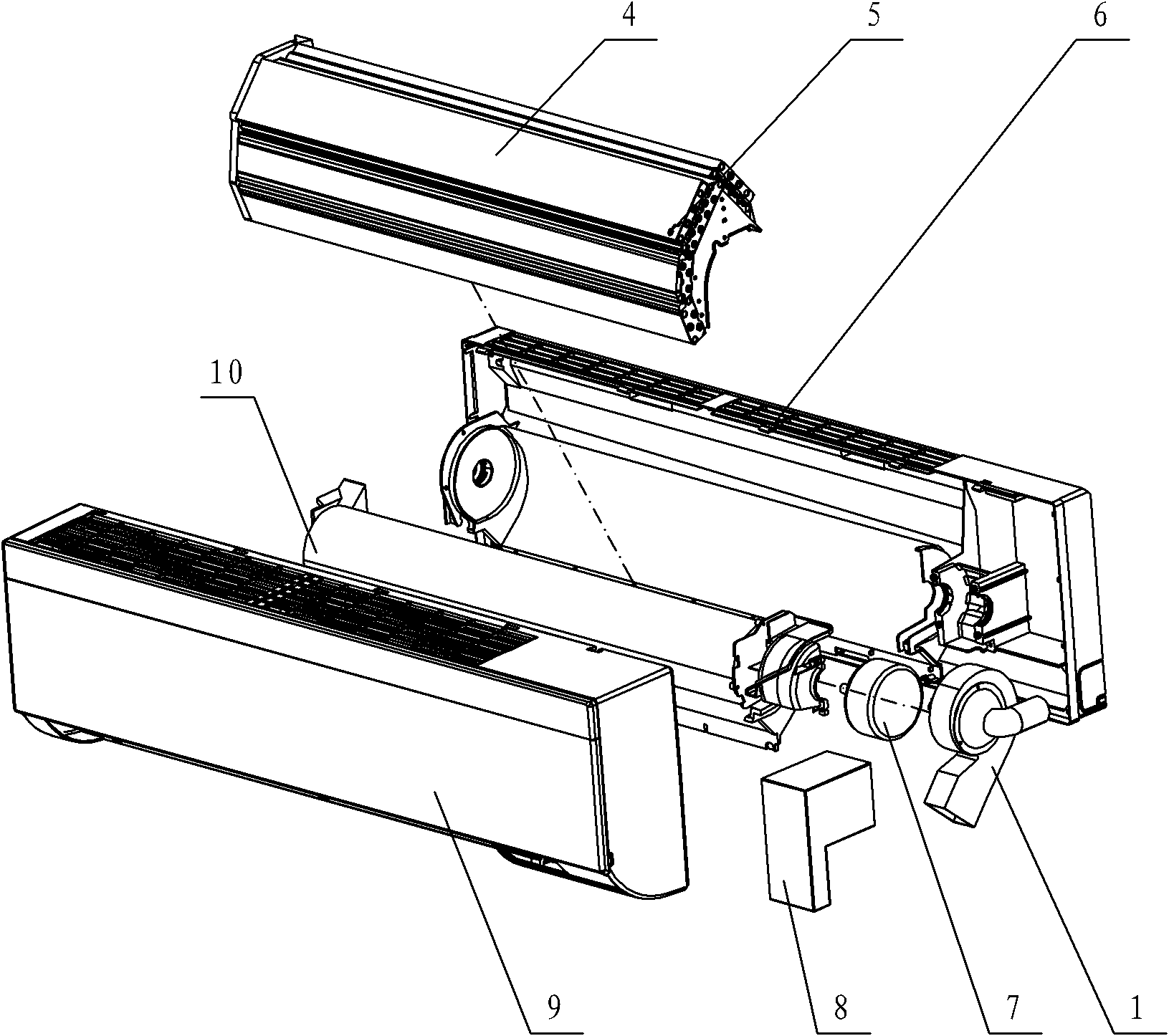

Air conditioner and control method thereof

InactiveCN102162658AGuaranteed safe operationReduced risk of burnsSpace heating and ventilation safety systemsLighting and heating apparatusElectricityCircular loop

The invention discloses an air conditioner and a control method thereof. The air conditioner comprises a control component, an indoor unit on an indoor side and an outdoor unit on an outdoor side, wherein the indoor unit and the outdoor unit are connected through a pipeline to form a circular loop; a leakage detector for detecting the concentration of a combustible refrigerant is arranged near an electric control box of the indoor unit or near an air outlet; the air conditioner also comprises an air exchange device; the air exchange device comprises an air exchange fan with an air exchange motor; an air inlet of the air exchange device is provided with a filter screen and an insect-proof net; and an air outlet of the air exchange device is provided with a baffle which is opened with the rotation of the air exchange motor and closed with the stop of the air exchange motor. According to the invention, as the leakage detector and the air exchange device are added, after the indoor unit of the air conditioner is power-on and the refrigerant leaks during the operation, the concentration of the combustible refrigerant of unit volume in the house can be reduced through air exchange; and the air conditioner has the characteristics of simple and reasonable structure, safety, reliability and wide application range, and is flexible to operate and low in manufacturing cost.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

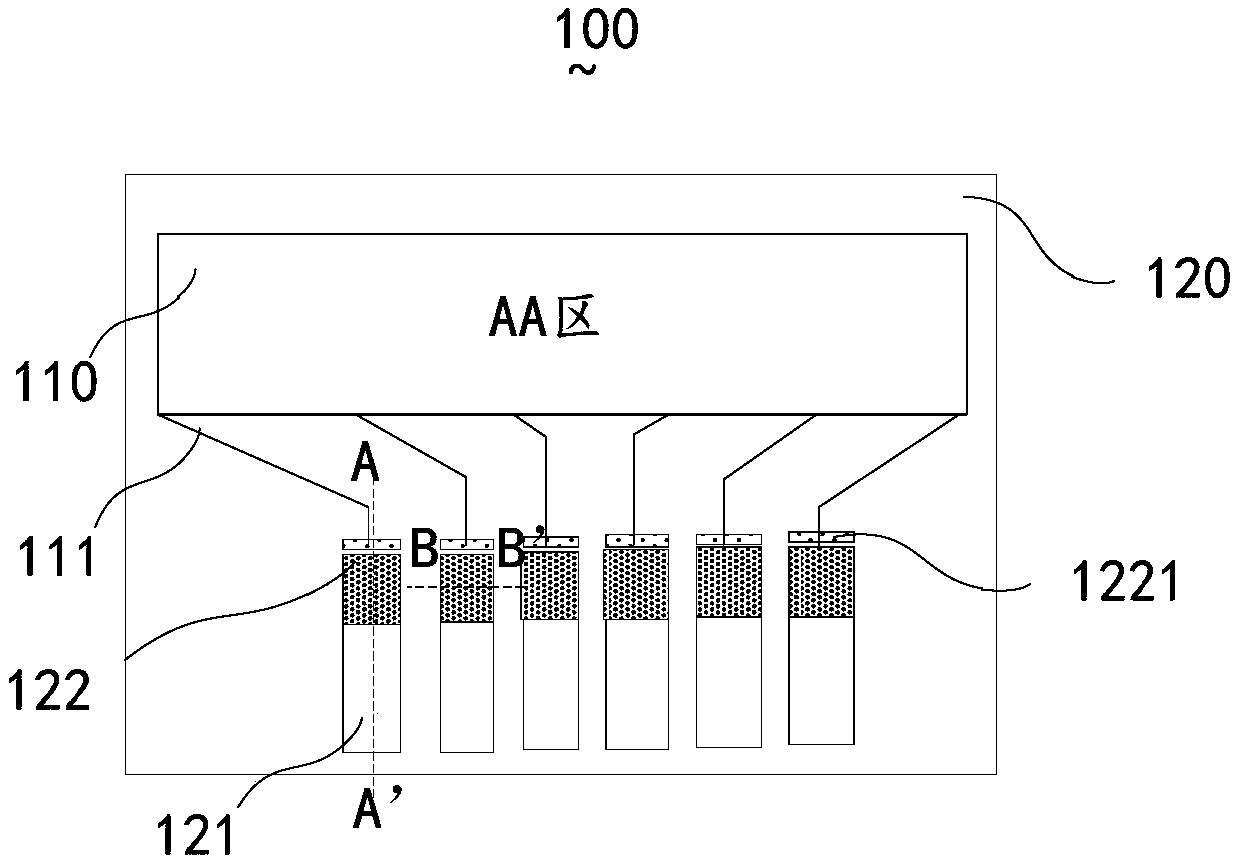

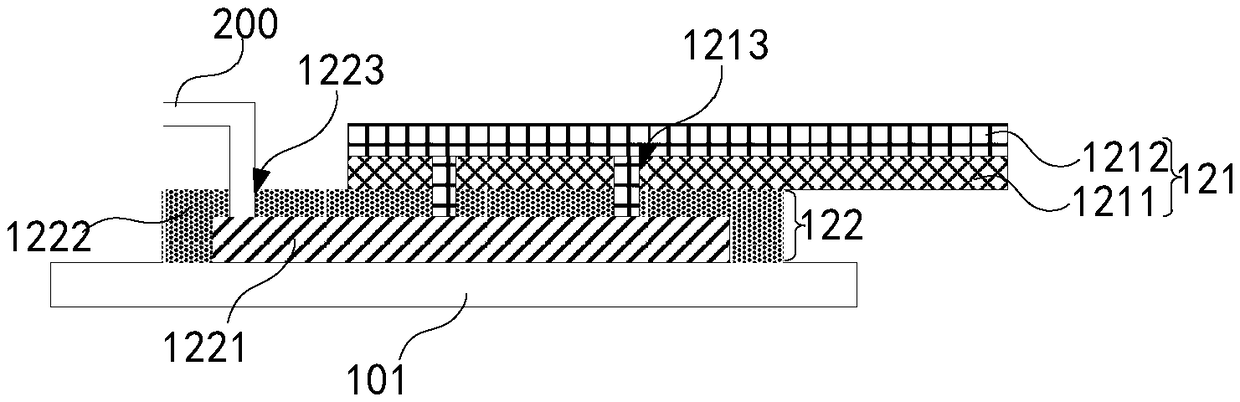

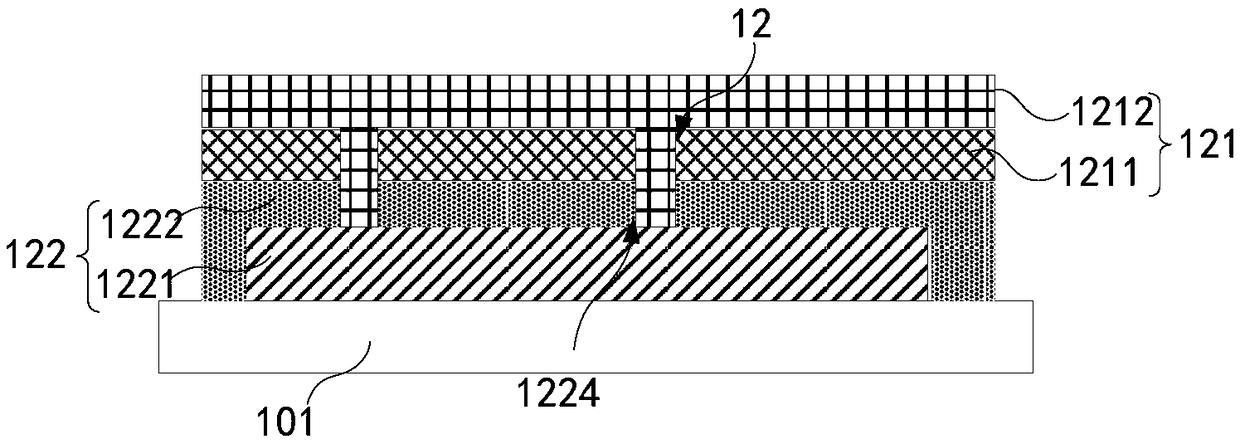

Display panel and display device

ActiveCN109166851AImprove electrostatic protection abilityImprove production yieldStatic indicating devicesDigital data processing detailsDisplay deviceSignal source

The invention discloses a display panel and a display device. The display panel defines a display area and a non-display area around the display area. The display area is provided with a plurality ofsignal leads, and the non-display area is provided with a plurality of conductive pads and a plurality of electrostatic discharges. Wherein one end of the plurality of electrostatic discharges is connected to the display region through a corresponding signal lead, and the plurality of electrostatic discharges and the corresponding conductive pads are at least partially overlapped and connected. Inthe above manner, the present invention can save the width of the lower frame of the display panel and increase the width of the signal source traces, thereby reducing the risk of burns of the signallines in the display panel and improving the production yield of the display panel.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

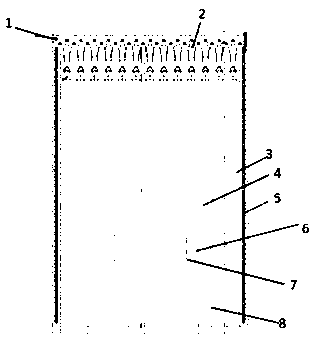

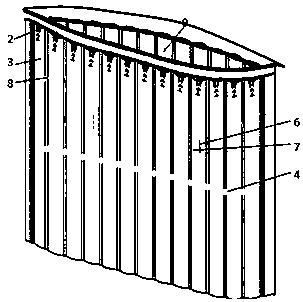

Household Electrical Ironing Appliance Comprising a Filter Designed to Retain Lime Scale Particles Transported by the Steam

ActiveUS20160258109A1Simple structureReduced risk of burnsDispersed particle filtrationHand ironFilter designParticle transport

An ironing appliance including a steam distribution circuit having at least one filter designed to retain lime scale particles transported by the steam flow, wherein it includes a lime scale disposal orifice that communicates with a portion of the steam distribution circuit located upstream of the filter and that said filter is fixedly mounted in the appliance or is removable via an orifice separate from the lime scale disposal orifice.

Owner:SEB SA

Binding method of rotary target material

InactiveCN110804726AReduce labor intensityLow proficiency requirementVacuum evaporation coatingSputtering coatingIndiumTitanium

The invention relates to a binding method of a rotary target material. The method includes the steps of performing roughening treatment on a target material and a titanium pipe, performing metallization treatment on the target material and the titanium pipe correspondingly, evenly coating the target material and the titanium pipe with a layer of scaling powder, assembling the target material and the titanium pipe, starting a heating device, removing an indium liquid oxidized film from an indium groove, switching on an indium pipeline valve so that indium liquid can slowly fulfill a whole weldjoint and an indium pool from the bottom, starting to perform segmented cooling on the target material, and finally cooling to the room temperature so as to complete the binding process of the whole target material. By means of the binding mode of the whole target material, the binding work of multiple segments of the target material can be simply and efficiently completed. The binding method hasthe advantages that no high-temperature assembling is needed, the assembling time is not strictly controlled, the automation level is high, the requirements for the labor intensity of workers and theproficiency of operation of personnel are not high, and the welding rate and welding quality are quite high.

Owner:GUANGXI CRYSTAL UNION PHOTOELECTRIC MATERIALS CO LTD

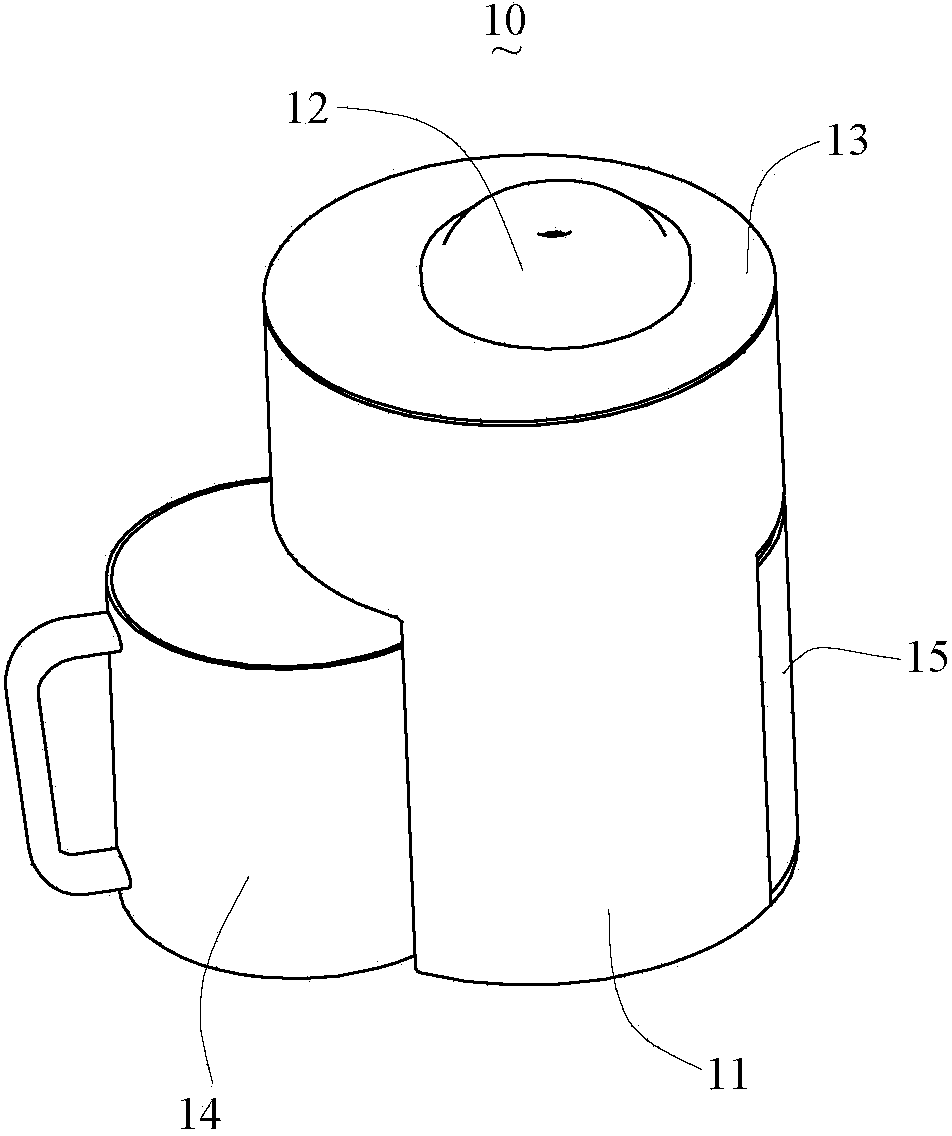

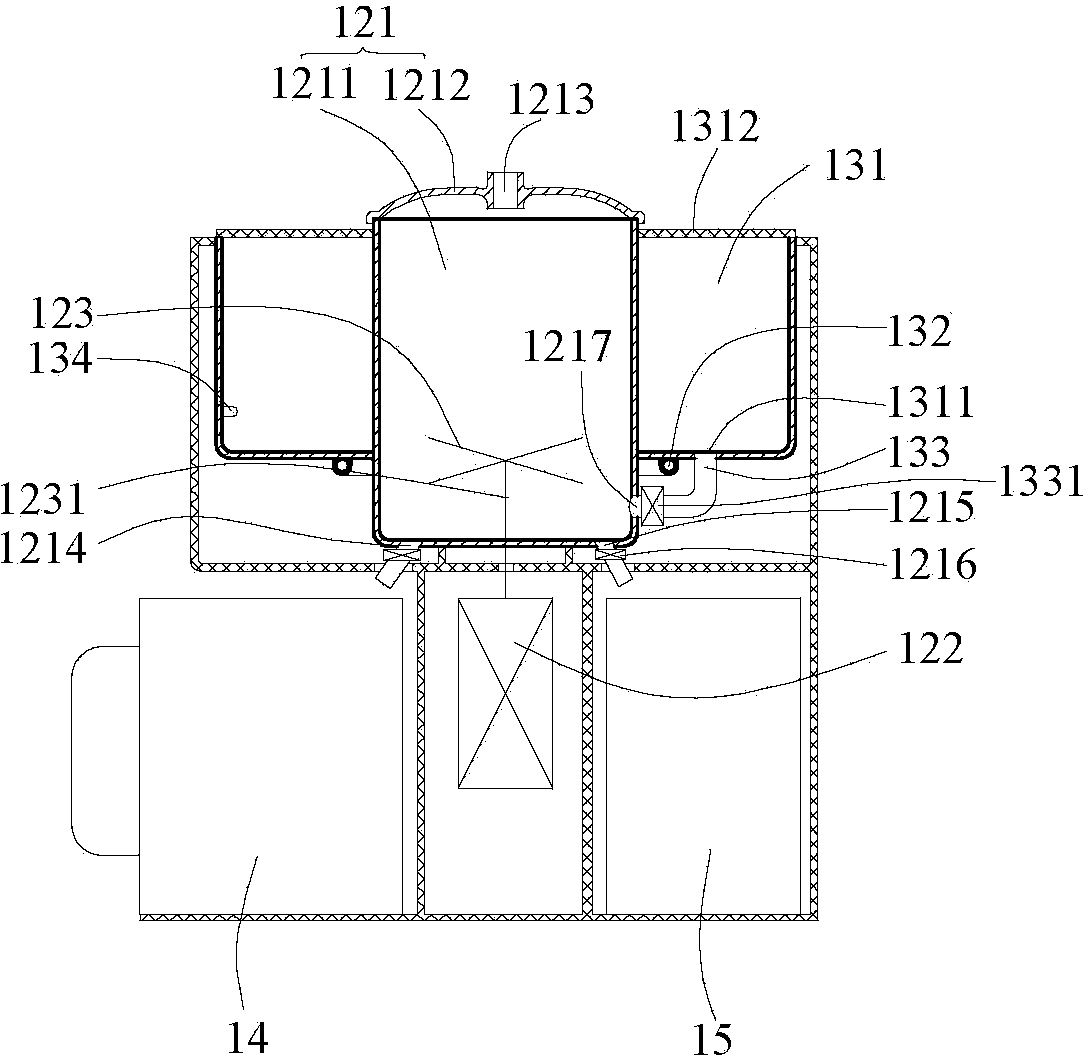

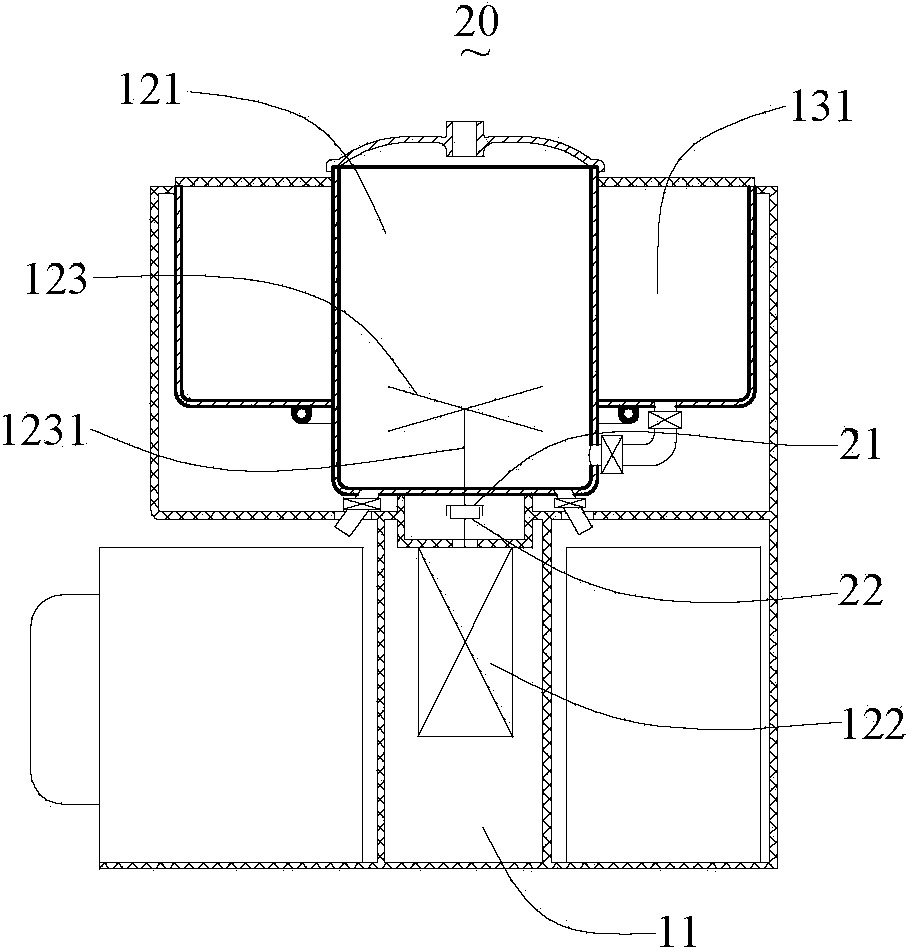

Soybean milk making method of energy-saving soybean milk machine

The invention relates to a soybean milk making method of an energy-saving soybean milk machine. The method comprises the following steps that a, water with the set amount is injected in a small-space pulverizator from a water tank; b, a motor is then started to drive a pulverization knife to rotate to pulverize materials in the small-space pulverizator, the water tank is heated through a heating element, and the heat of water is transferred to the interior of the small-space pulverizator to cook milk / a paste; c, the cooked milk / the cooked paste is discharged to a milk collection cup; d, water with the set amount is injected to the small-space pulverizator again from the water tank, and the milk / the paste in the small-space pulverizator is then discharged to the milk collection cup again. When the soybean milk making method of the energy-saving soybean milk machine is compared with the prior art, water in the water tank is heated through the heating element, the heat of the water is transferred to the small-space pulverizator, and accordingly the materials in the small-space pulverizator are preheated and cooked, the heat of the water in the water tank is reasonably and effectively utilized, energy is saved, the water tank can be continuously heated and kept warm and the soybean milk making period can also be effectively shortened.

Owner:JOYOUNG CO LTD

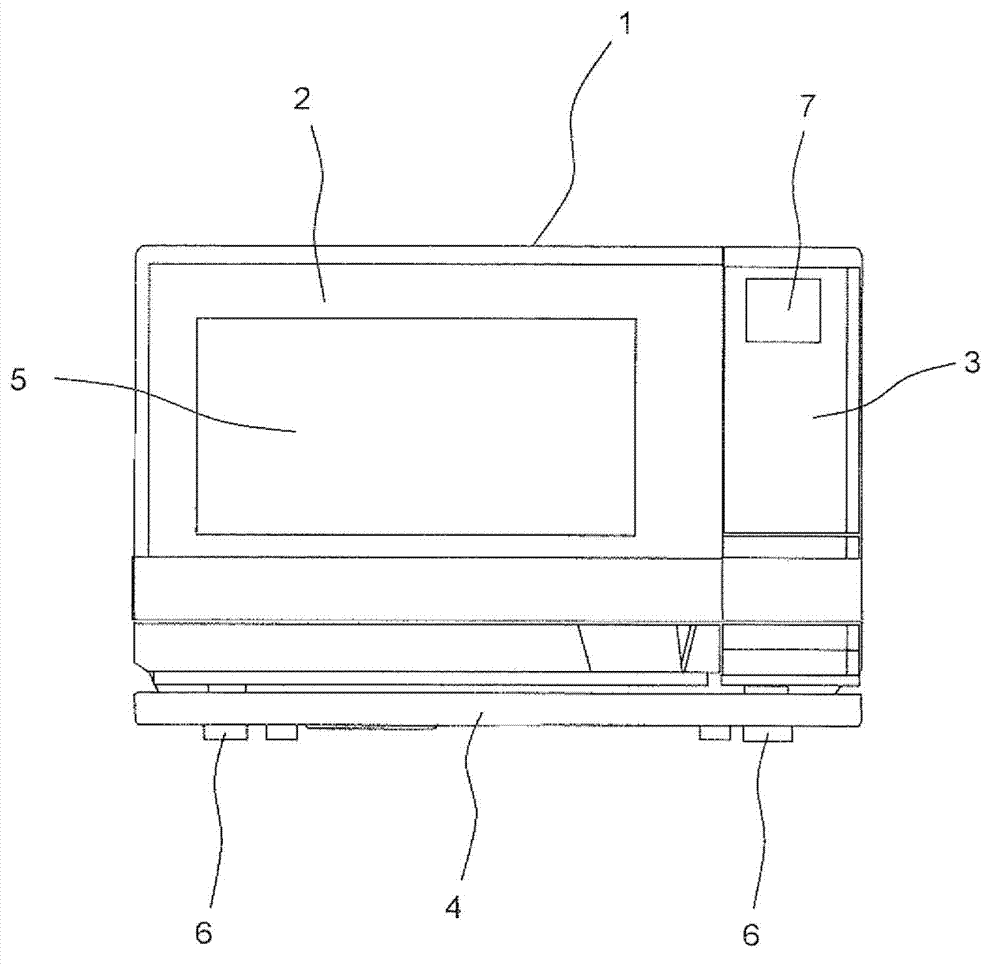

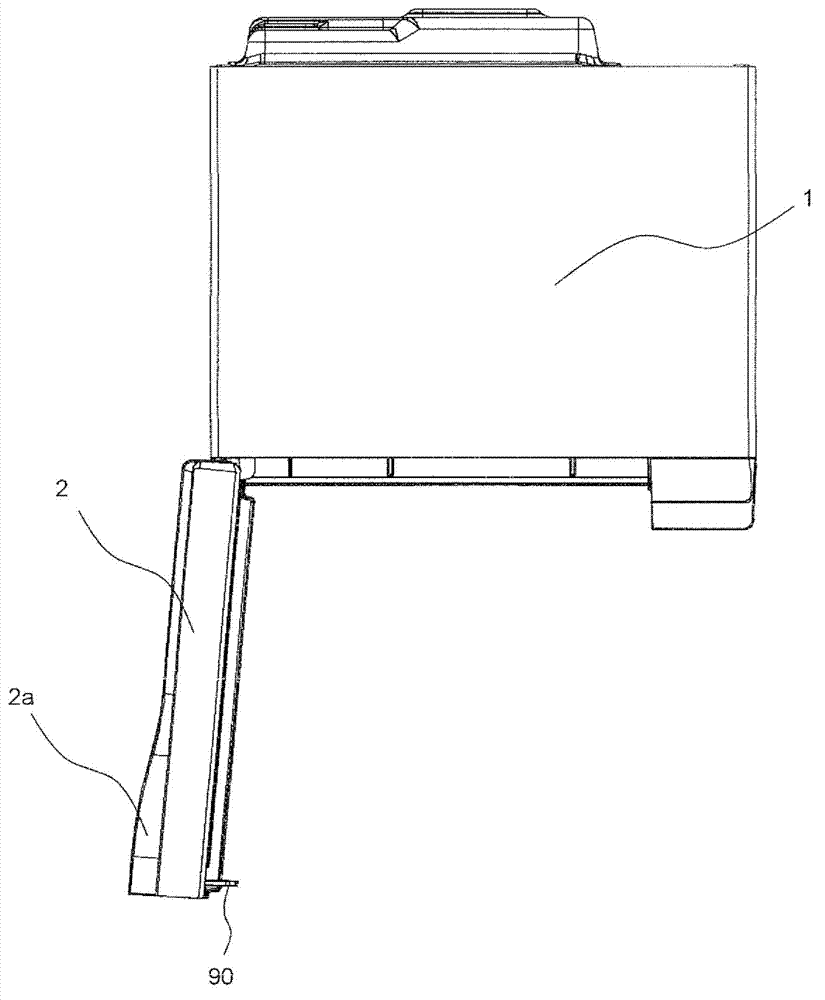

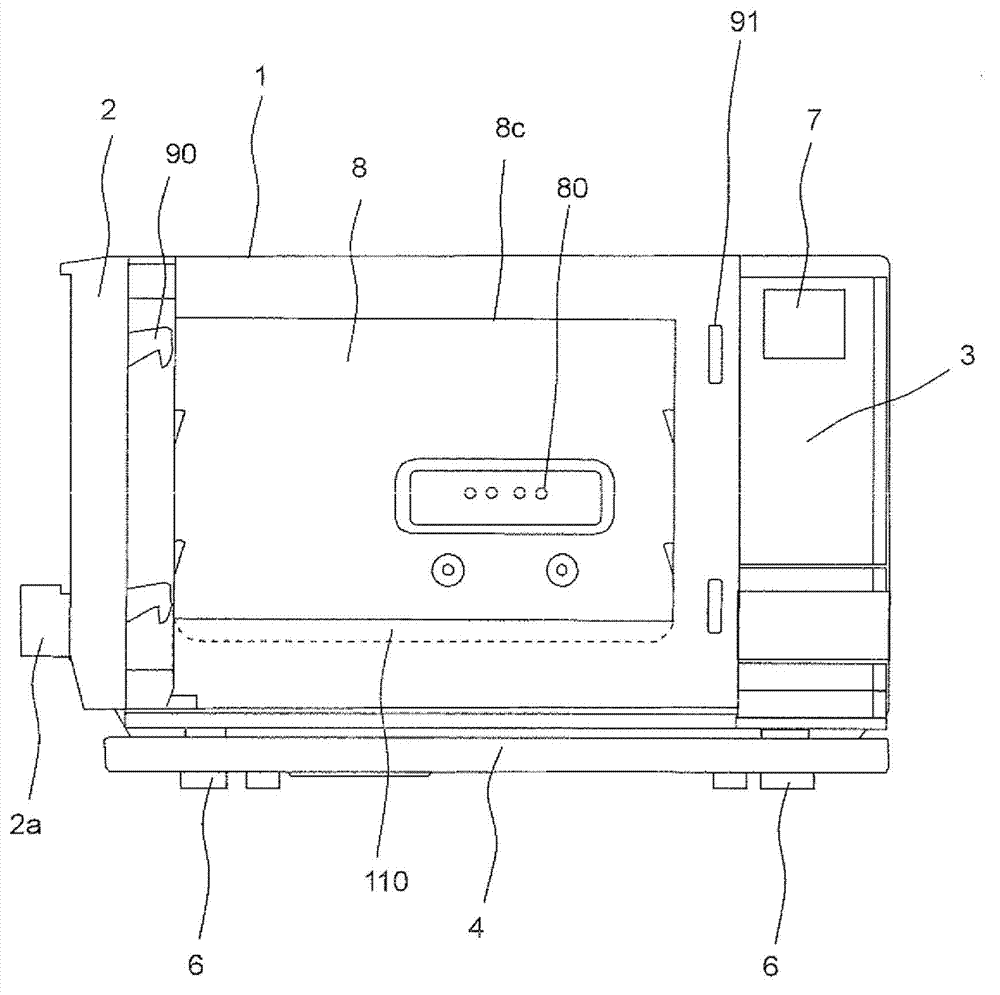

Cooking device

InactiveCN103097818APrevent outflowReduce pollutionDoors for stoves/rangesDomestic stoves or rangesEngineeringCondensed water

A cooking device is provided with a heating chamber (8) which is provided within a casing, has an opening (8c) on the front surface side thereof, and contains an object to be heated. A dam section (110) extending above the bottom surface inside the heating chamber (8) is provided at the lower edge of the opening (8c) of the heating chamber (8). The configuration prevents condensed water (W) from flowing out of the opening (8c) of the heating chamber (8) when the door (2) equipped with a hand grip is opened while the condensed water (W) pools on the bottom surface inside the heating chamber (8).

Owner:SHARP KK

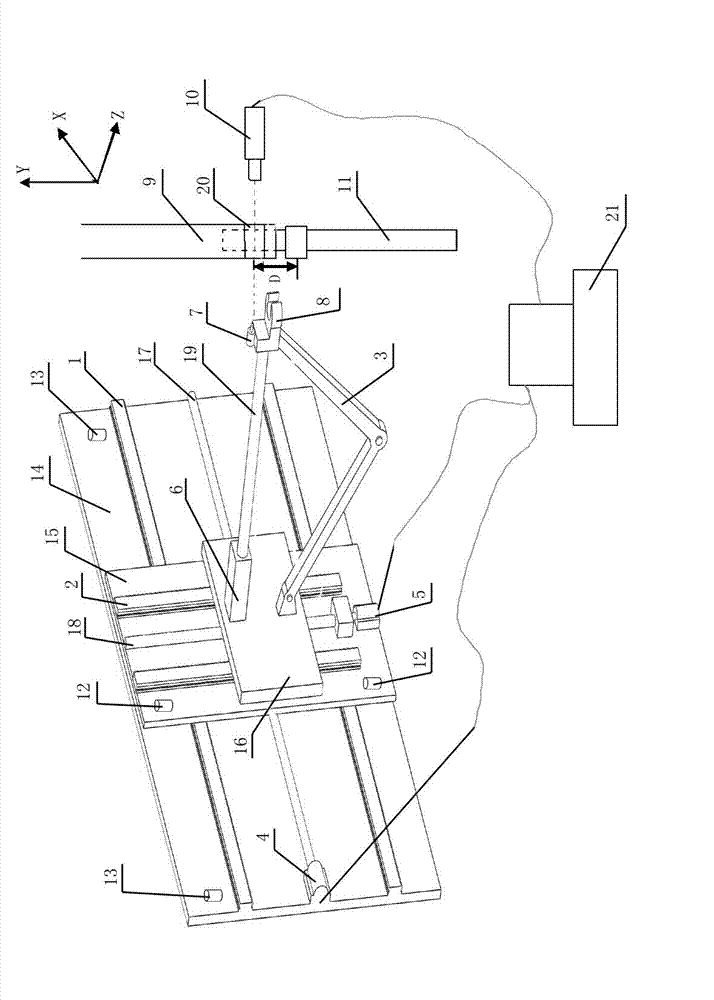

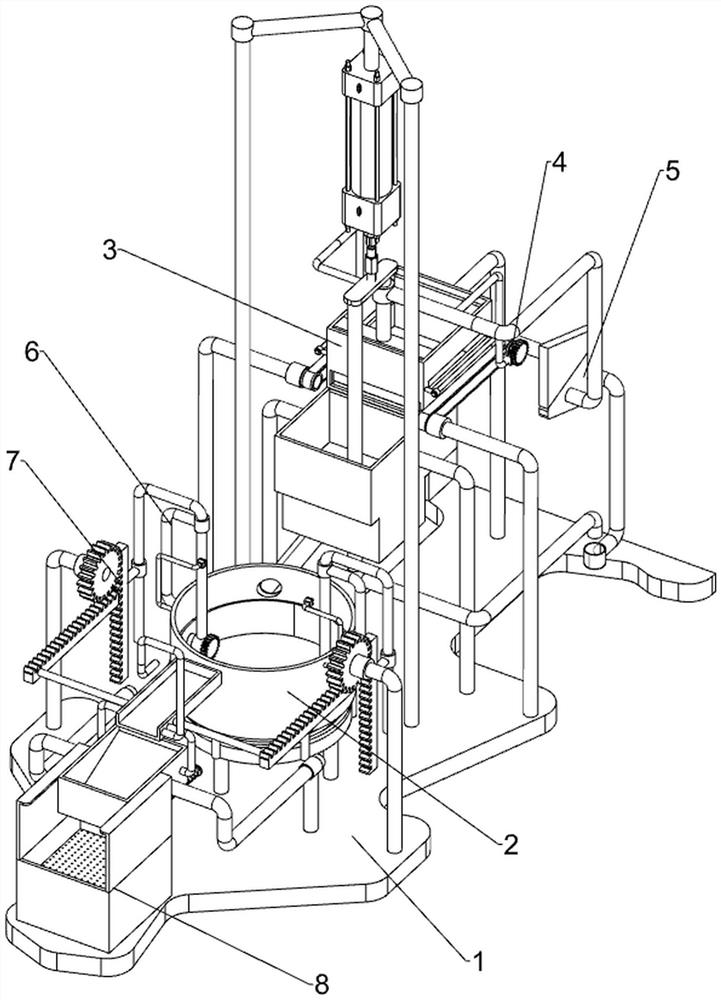

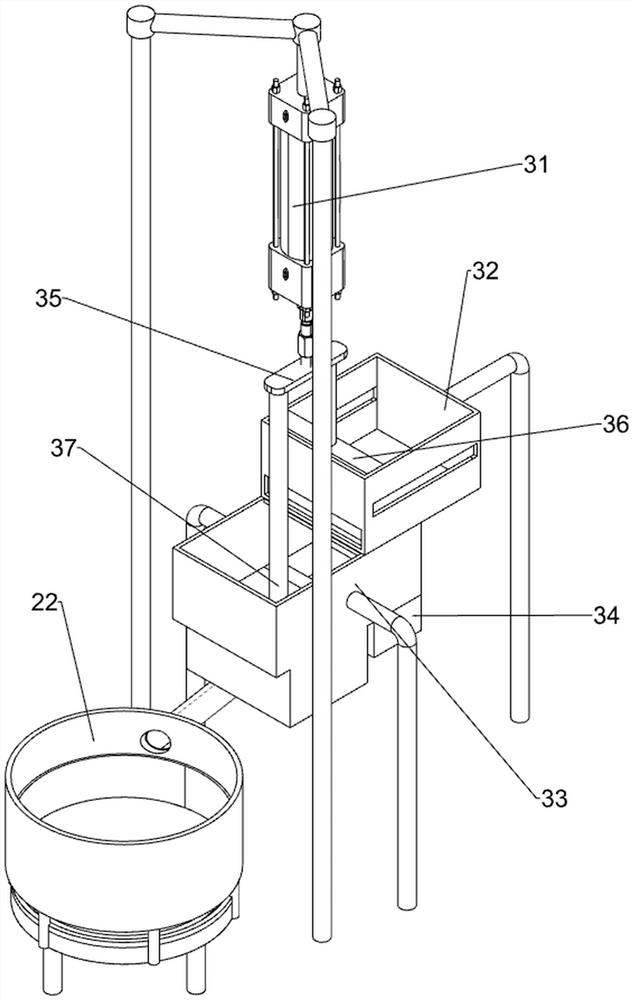

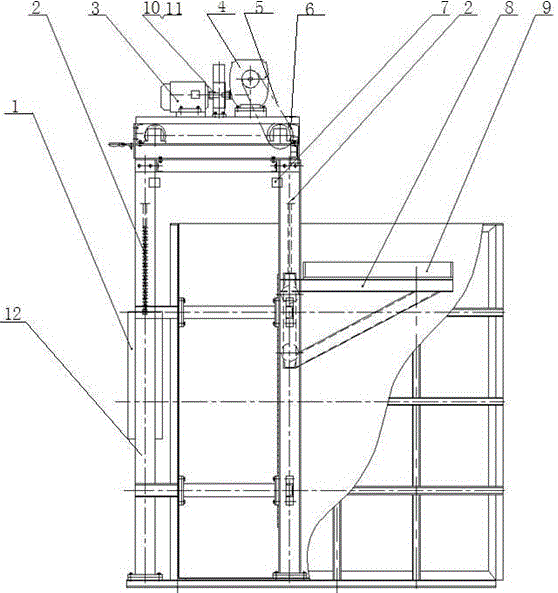

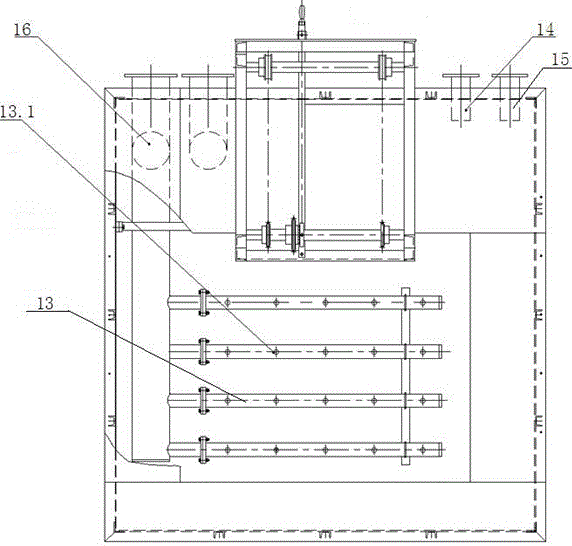

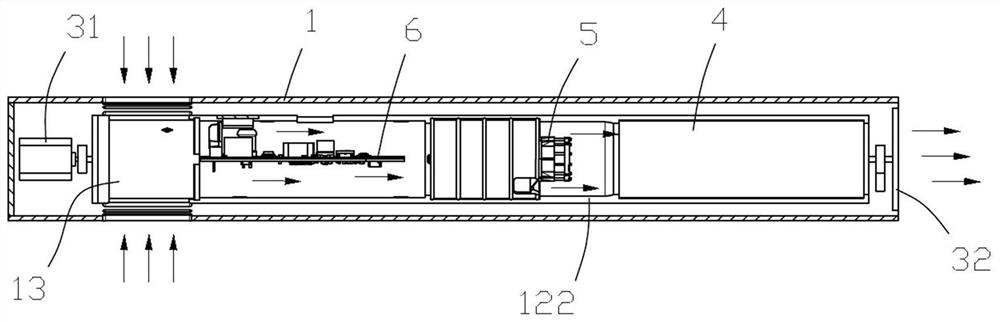

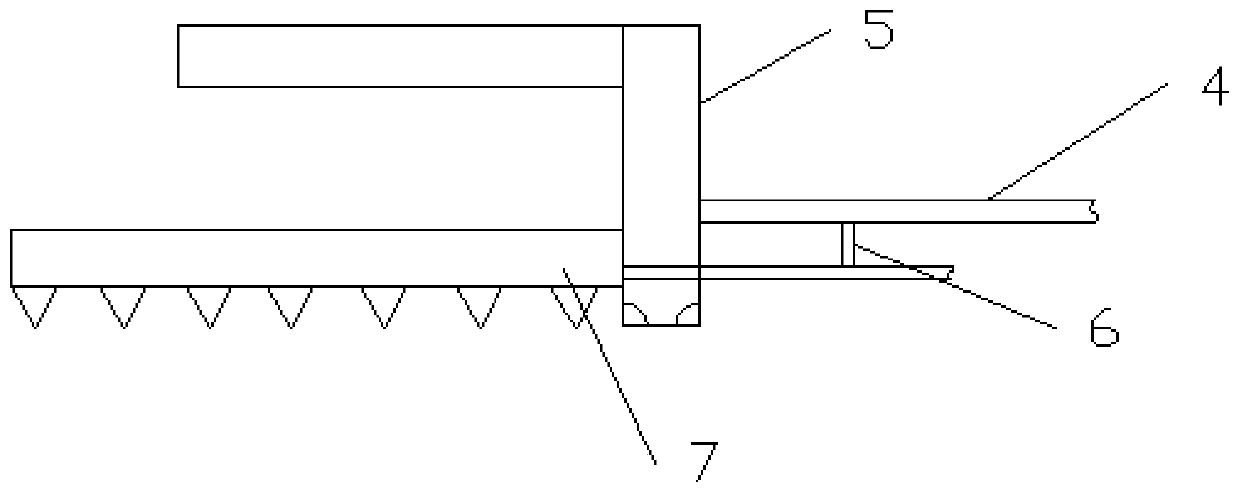

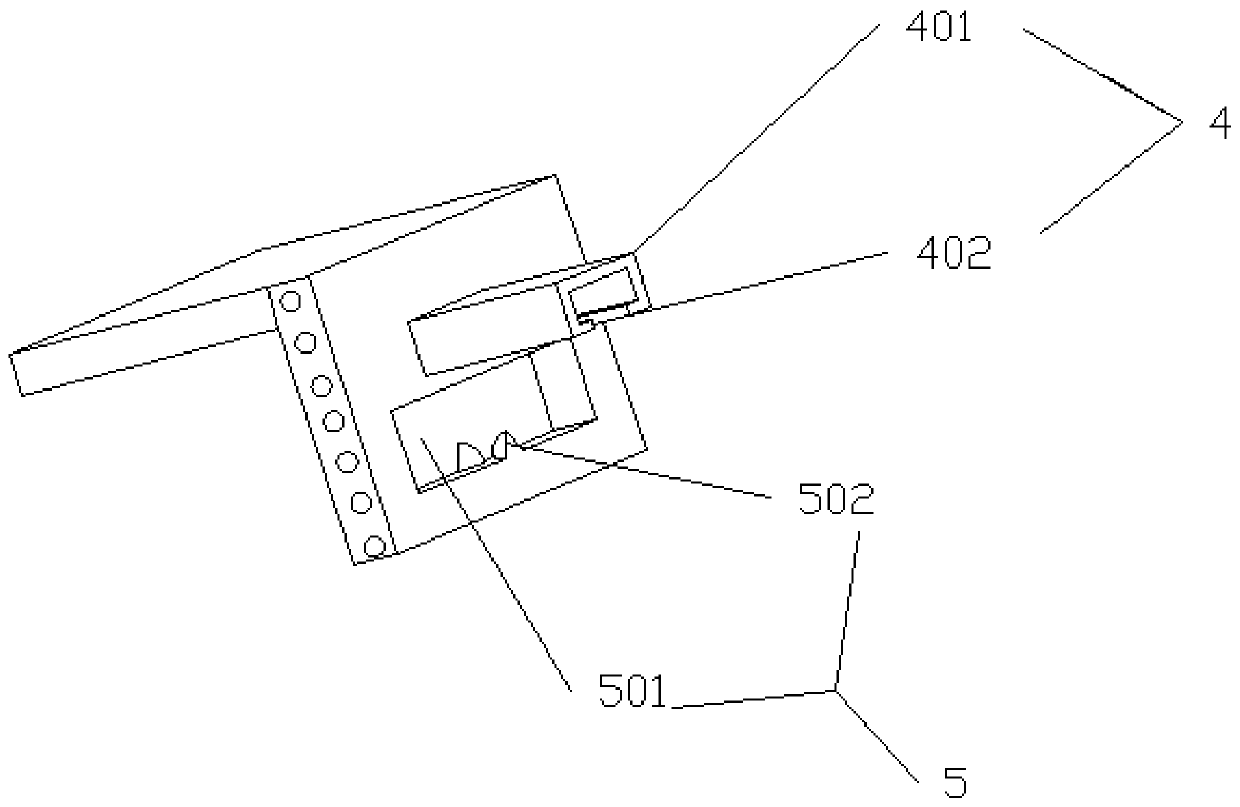

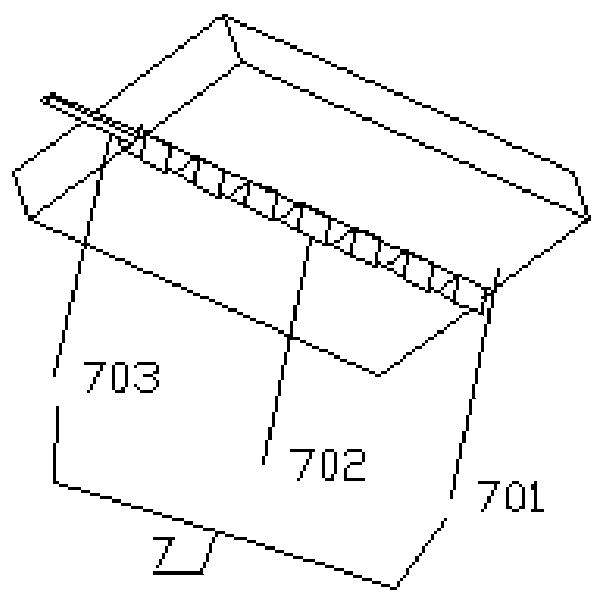

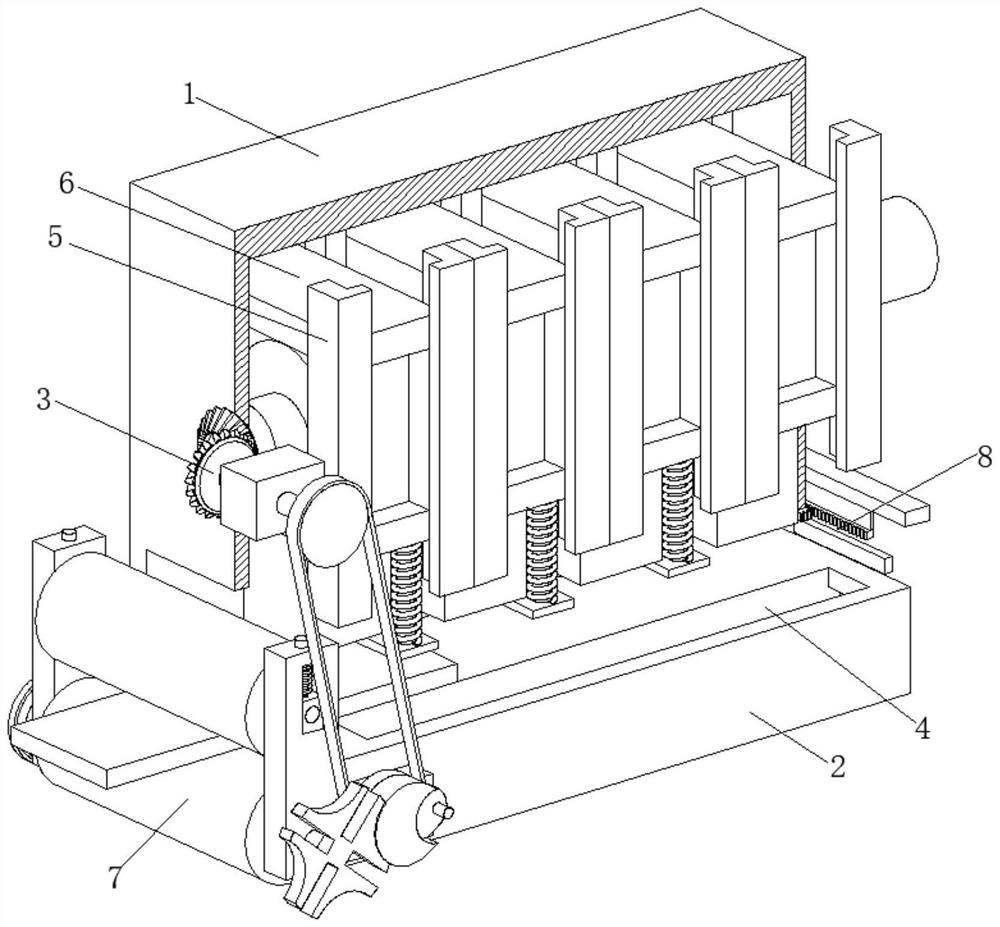

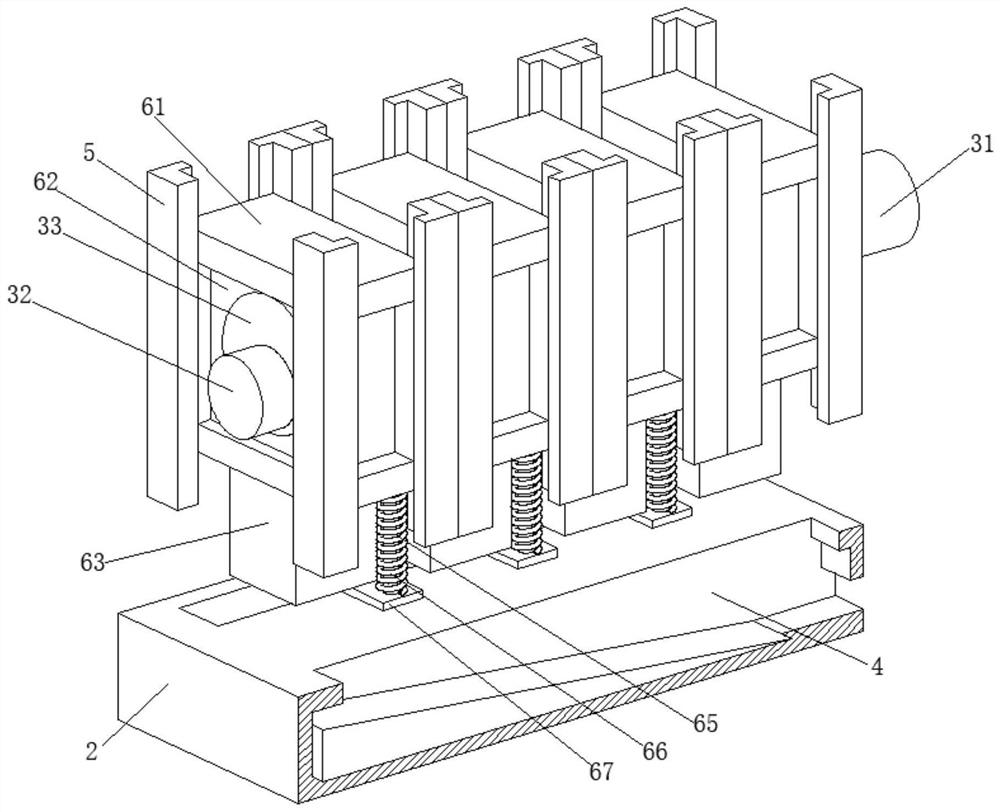

Precast rod handling system and control method thereof

InactiveCN102897531AReduced risk of burnsRealize safe and damage-free transportationConveyor partsClassical mechanicsStructural engineering

The invention belongs to the manufacturing field of an optical fiber precast rod, relating to an automatical handing system of the optical fiber precast rod, and achieving automation to the handing process of the high temperature precast rod after finishing producing. The precast rod handling system comprises a three-direction moving device, a control center and a precast rod lifting device; the three-direction moving device comprises an X axial shaft, an X axial moving guide rail, an X axial lead screw, an X axial moving servo motor, a Y axial plate, a Y axial moving guide rail, a Y axial lead screw, a Y axial moving servo motor, a Z axial plate, a Z axial driving cylinder, a Z axial arm, a supporting rod bracket, an emitter and a receiver. The control method of the precast rod handling system comprises: lifting the precast rod to a rod unloading position; moving the Y axial plate to move along X axis, controlling a server to record the position of the Y axial plate two times; calculating a difference value to obtain the diameter of the precast rod; moving the Z axial plate to move along Y axis; after the supporting rod bracket is close to a proper position along Z axis direction towards the precast rod, stopping; moving the supporting rod bracket along the Y axis, unloading the precast rod; and back moving the precast rod.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

Emergency or precaution disposal bag for lithium battery and electronic equipment comprising lithium battery

The invention relates to the field of lithium battery emergency and precaution protection, in particular to an emergency or precaution disposal bag for a lithium battery and electronic equipment comprising a lithium battery. The emergency or precaution disposal bag comprises a bag body. The bag body sequentially comprises a fire extinguishing gel layer and a heat-resistant anti-explosion layer from inside to outside. The fire extinguishing gel layer comprises a capsular bag made from a plastic film. The capsular bag is filled with fire extinguishing gel containing a propellant, or fire extinguishing gel release points are arranged on the inner side of the plastic film of the inner surface of the capsular bag. When the environment temperature exceeds the gel release point fracture temperature, the gel flows out of the gel bag from the release points and achieves the functions of lowering the lithium battery temperature and blocking thermal runaway after making contact with the lithium battery or the equipment comprising the lithium battery, and danger caused by smoking and fire of the lithium battery is reduced.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

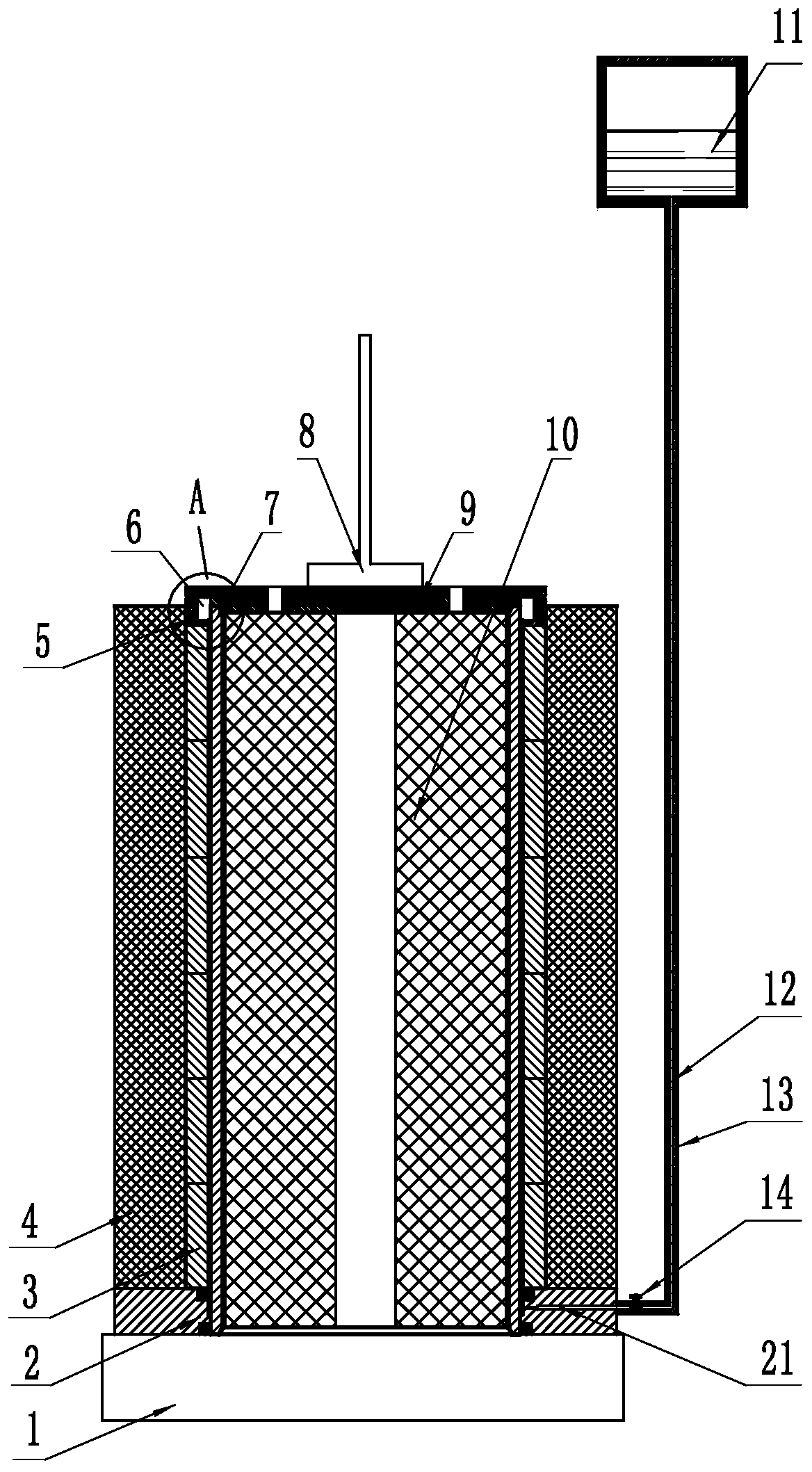

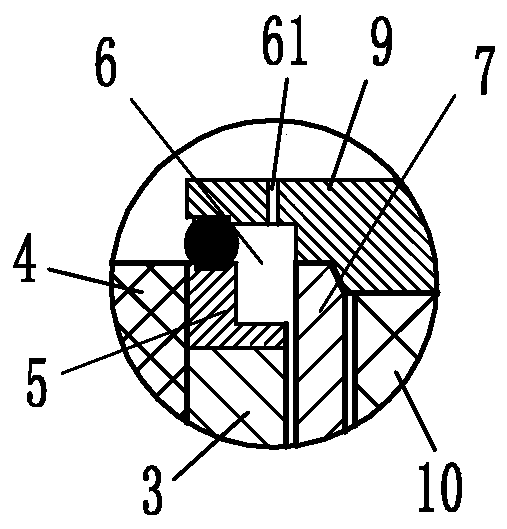

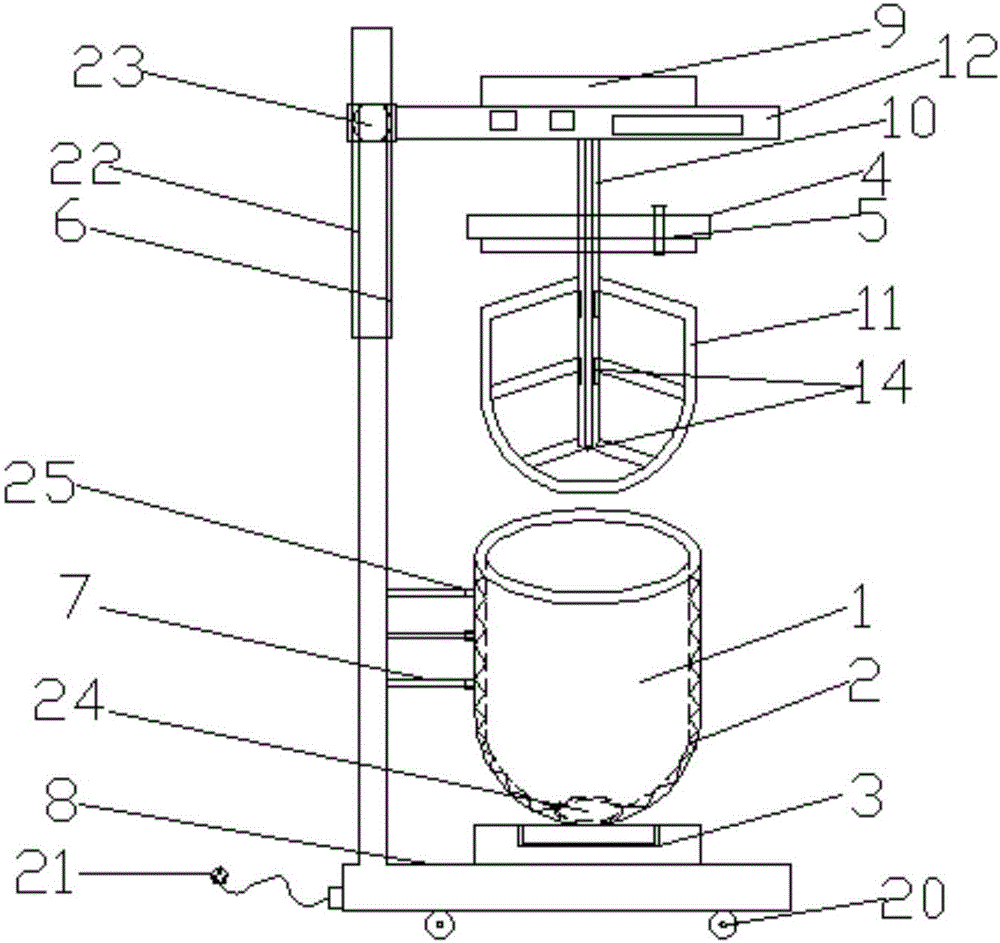

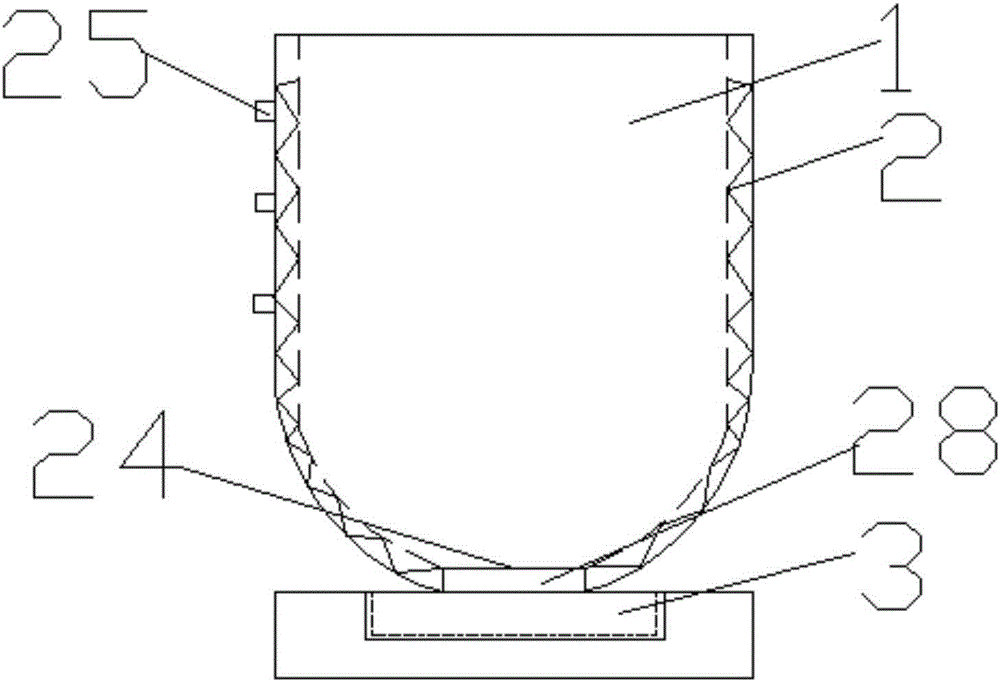

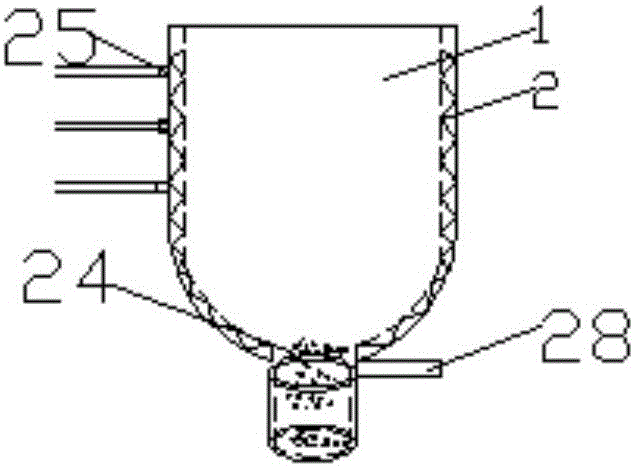

Portable weighing and charging-integrated asphalt mixture mixing device

ActiveCN106769373AMixing to achieveImprove mixing uniformityClimate change adaptationPreparing sample for investigationProcess engineeringHeat losses

The invention relates to a portable weighing and charging-integrated asphalt mixture mixing device, which comprises a mixing pot with a heating device, a horizontal base and a support skeleton arranged on the base, wherein a weighing and measuring system is arranged on the base; the mixing pot is located on the weighing and measuring system; the support skeleton is provided with a liftable and lowerable mixer; the mixer is located above the mixing pot; a mixing shaft of the mixer is sleeved with a sealing pot cover capable of sealing the mixing pot while mixing and the lower end of the mixing shaft is connected with a mixing blade; and the bottom of the mixing pot is connected with an automatic charging system. The raw materials can be directly weighed through the mixing pot, and the mass loss and the heat loss of raw materials in the transfer process are reduced, so that the dose of the raw materials is more accurate, the test temperature is more accurate, the test accuracy rate is improved, the quality of a prepared test specimen is improved, and asphalt mixture mixing, automatic weighing and charging integration is achieved.

Owner:CHANGAN UNIV

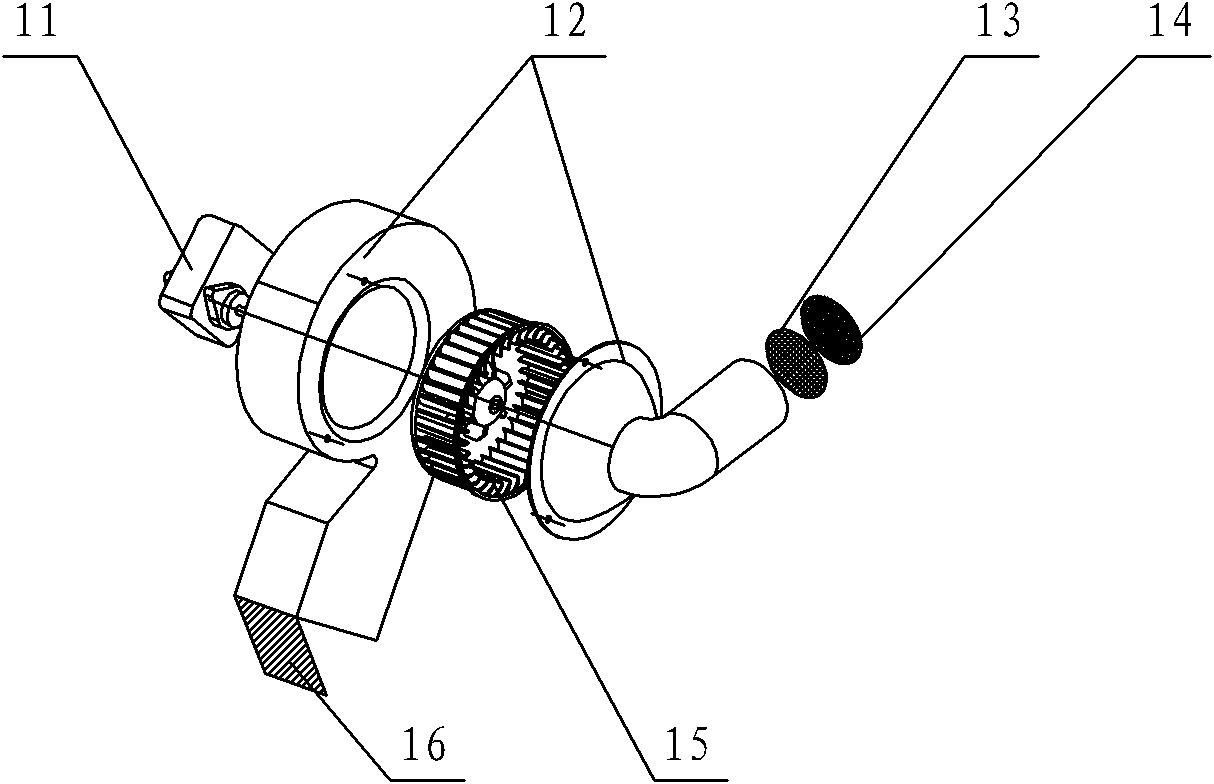

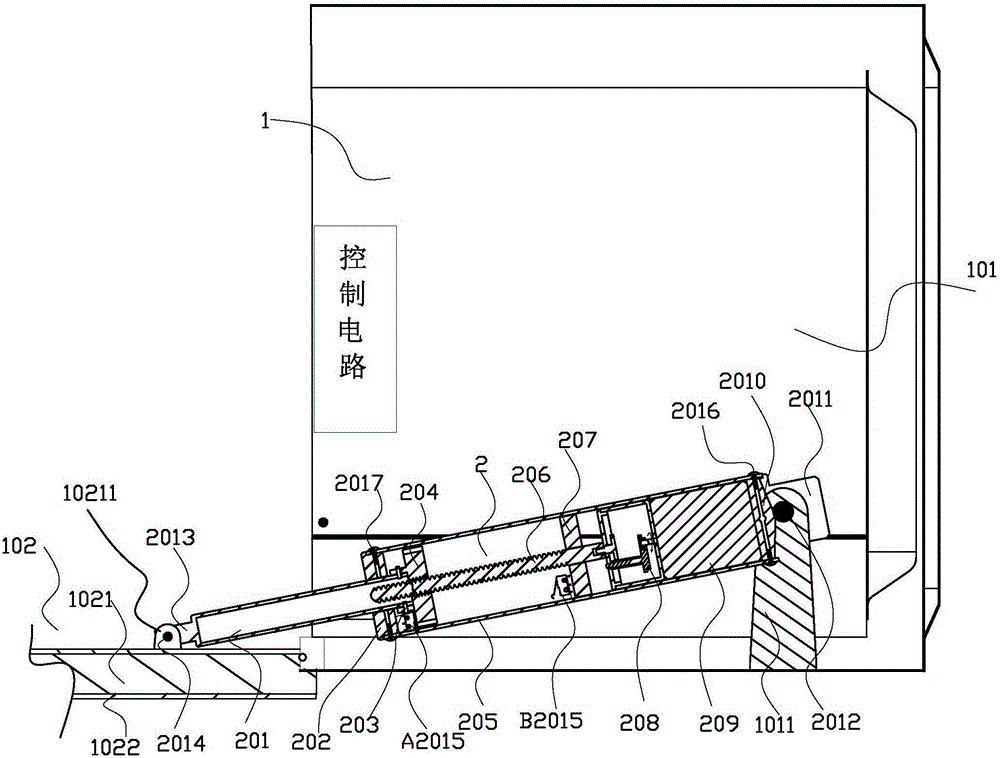

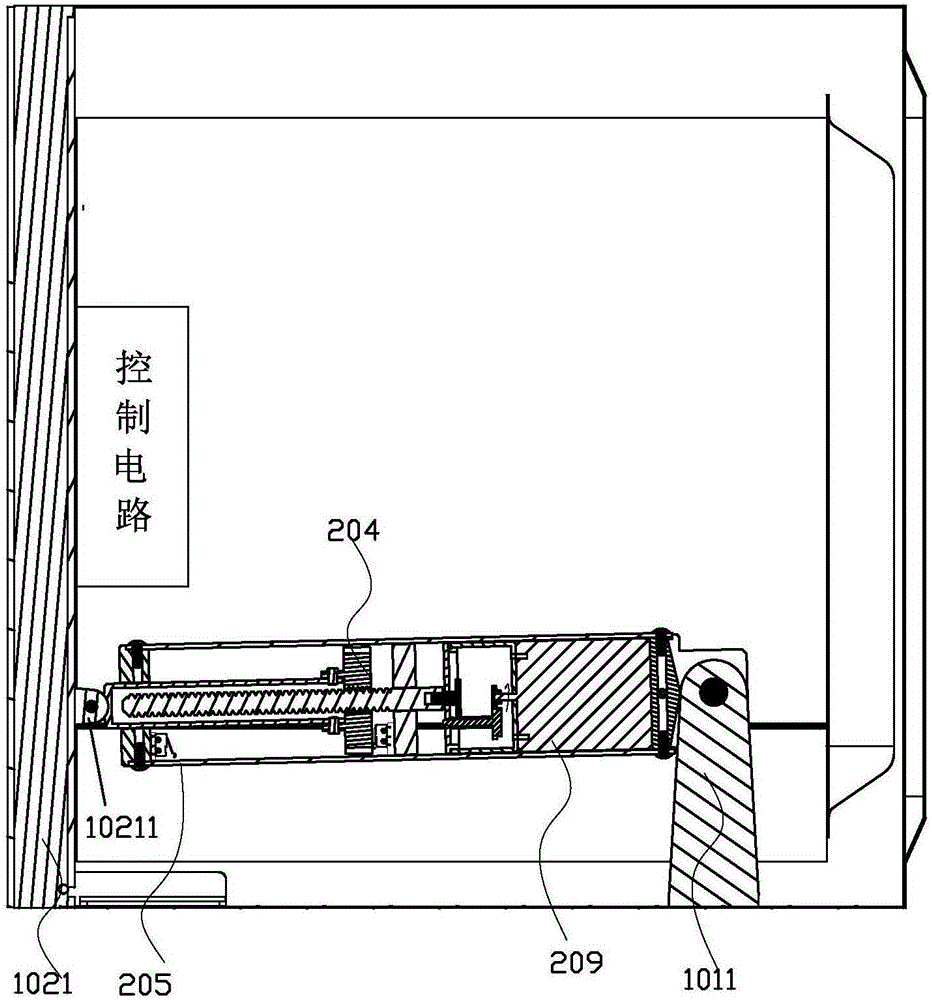

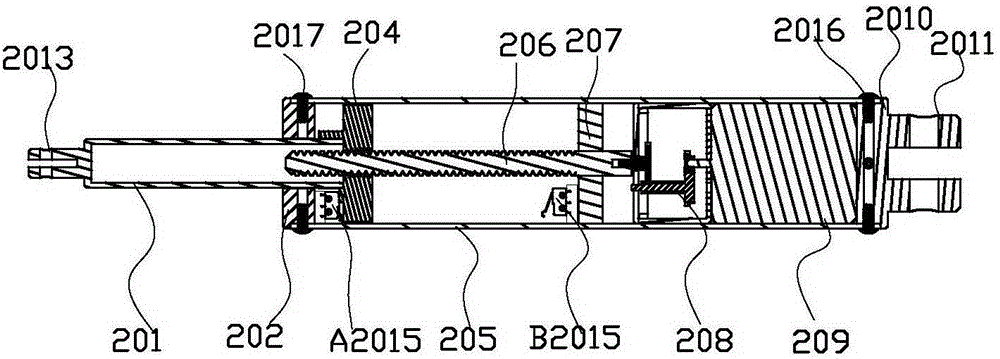

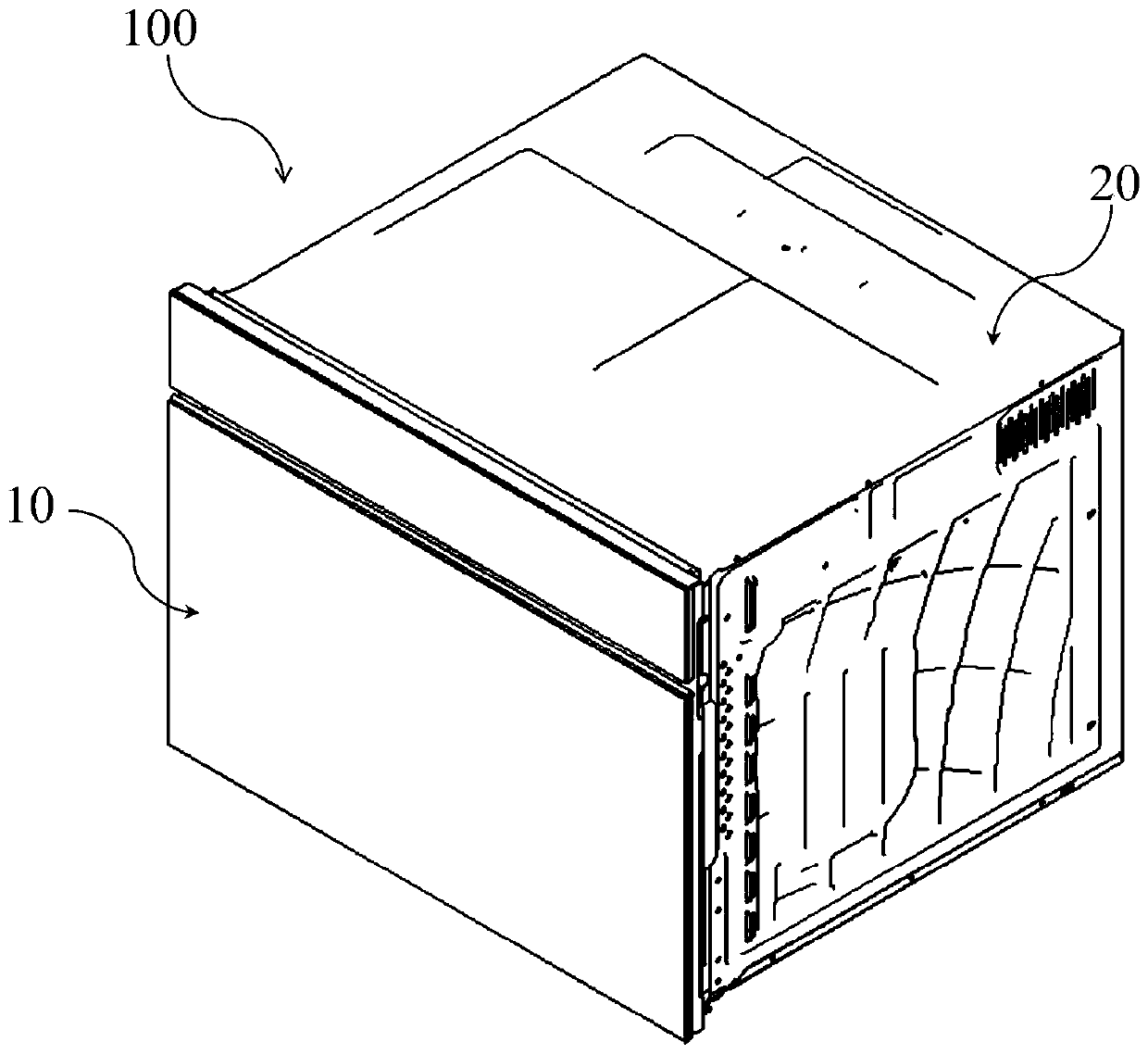

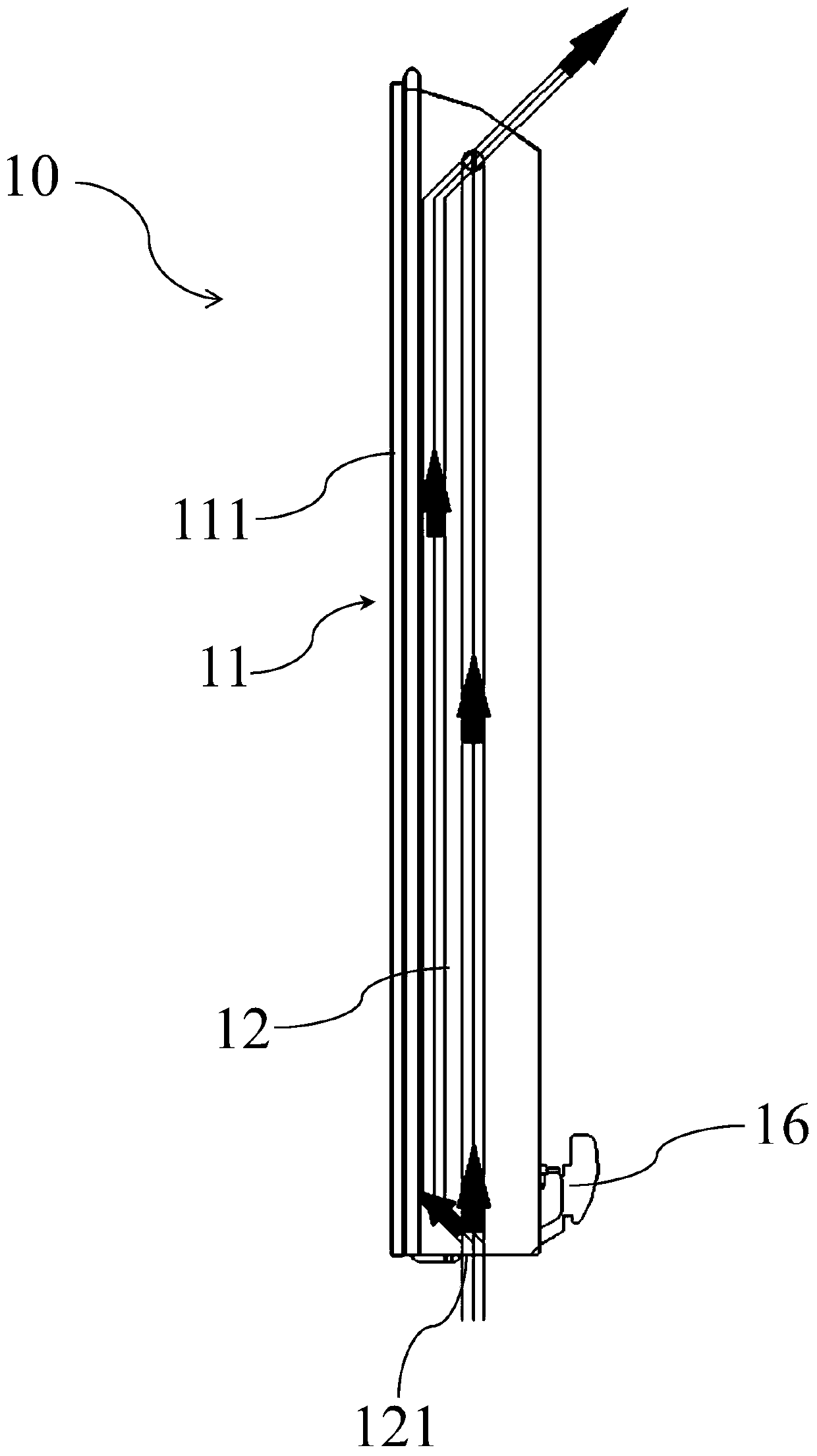

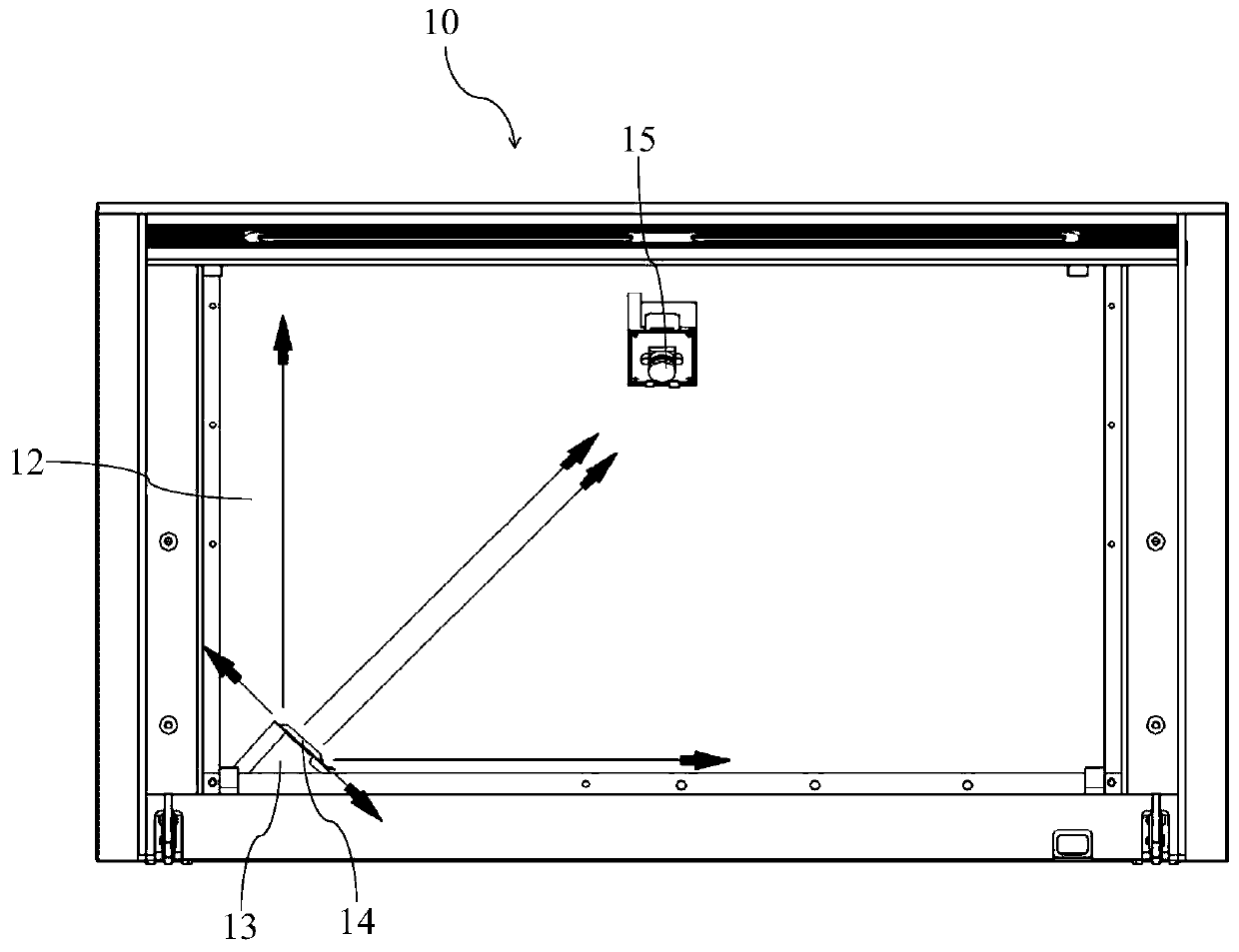

Door opening and closing structure of household electric oven and household electric oven with same

ActiveCN105220983AReduced risk of burnsSimple structurePower-operated mechanismElectric machineryDrive motor

The invention discloses a door opening and closing structure of a household electric oven and the household electric oven with same, and the door opening and closing structure is simple in structure, low in cost, safe and reliable, and automatically opens or closes an oven door by virtue of remote control or button control. The door opening and closing structure comprises an oven body, an oven door, a control room and a master control circuit, wherein a control system capable of opening or closing the oven door is arranged in the control room; the control system comprises a drive motor fixed in the control room, a transmission mechanism and a door connecting plate fixed on a door fixing part of the oven door; one end of the transmission mechanism is connected with the drive motor; the other end of the transmission mechanism is connected with the door connecting plate; and under the control of an instruction emitted by the master control circuit, the drive motor drives the transmission mechanism for driving the oven door to downwards open or upwards close. The door opening and closing structure is more convenient and safer for people in an oven using process; the oven door can be automatically opened or closed by only needing to pressing down a button on a control panel or using wireless remote control; and the risk that a consumer is burnt further can be effectively reduced.

Owner:SHENZHEN BUYDEEM TECH CO

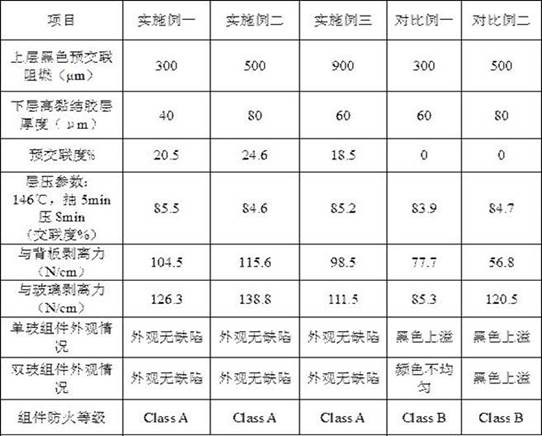

Pre-crosslinked black high-adhesion flame-retardant packaging adhesive film and preparation method thereof

PendingCN113150721AImprove flame retardant performanceImprove aestheticsNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceAntioxidant

The invention relates to a pre-crosslinked black high-adhesion flame-retardant packaging adhesive film and a preparation method thereof. The pre-crosslinked black high-adhesion flame-retardant packaging adhesive film comprises an upper-layer black flame-retardant packaging adhesive film and a lower-layer high-adhesion layer, and the upper-layer black flame-retardant packaging adhesive film is prepared from, by mass, 100 parts of ethylene-vinyl acetate copolymer resin, 20-100 parts of halogen-free flame-retardant efficient flame retardant, 2-10 parts of high-dispersion black filler, 0.02-1 part of an antioxidant, 0.005-0.5 part of a light stabilizer, 1-2 parts of a cross-linking agent and 0.5-3 parts of a silane coupling agent. The lower-layer high-adhesion layer is prepared from the following components in parts by mass: 100 parts of ethylene-acrylic acid-vinyl alcohol copolymer resin, 0.02-1 part of an antioxidant, 1-2 parts of a cross-linking agent and 0.2-1 part of a silane coupling agent. Through compounding of an inorganic flame-retardant system, the flame-retardant performance of the packaging adhesive film can be effectively improved, the operating temperature of outdoor power generation can be effectively reduced for a high-power assembly, and the combustion risk of the assembly is reduced.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

PCB board metal recycling device

InactiveCN112123636AAvoid cutsReduced risk of burnsPlastic recyclingProcess engineeringMetal recycling

The invention relates to a recycling device, in particular to a PCB metal recycling device. The invention provides a PCB metal recycling device, and through the PCB metal recycling device, a PCB can be cut into strips, and meanwhile, the PCB strips can be heated and melted, and moreover, a metal and resin fiber mixture in a PCB liquid can be filtered and separated, and moreover, the metal and resin fiber mixture can be poured to a designated position. The PCB metal recycling device comprises a bottom plate and a burning mechanism, and the burning mechanism is arranged in the middle of the topof the bottom plate. According to the PCB metal recycling device, by arranging the burning mechanism, the burning mechanism is matched with the cutting mechanism, so that the PCB can be cut up and melted; as an intermittent cutting, pushing and resetting mechanism is matched with the cutting mechanism, a worker does not need to push the PCB forwards manually, so that the situation that a single-sided cutting knife may cut the hands of the worker is avoided; and as an automatic scraping mechanism is matched with the cutting mechanism, the shredded PCBs can be pushed to the middle part of a conveying frame to work.

Owner:江西威尔高电子股份有限公司

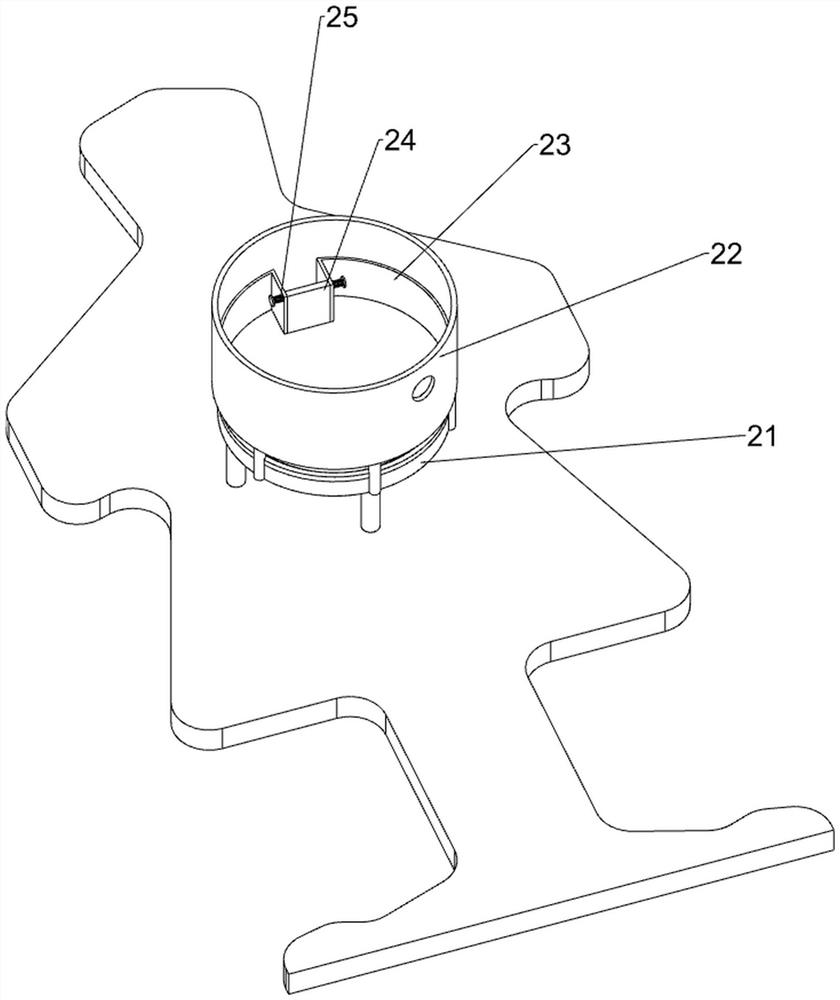

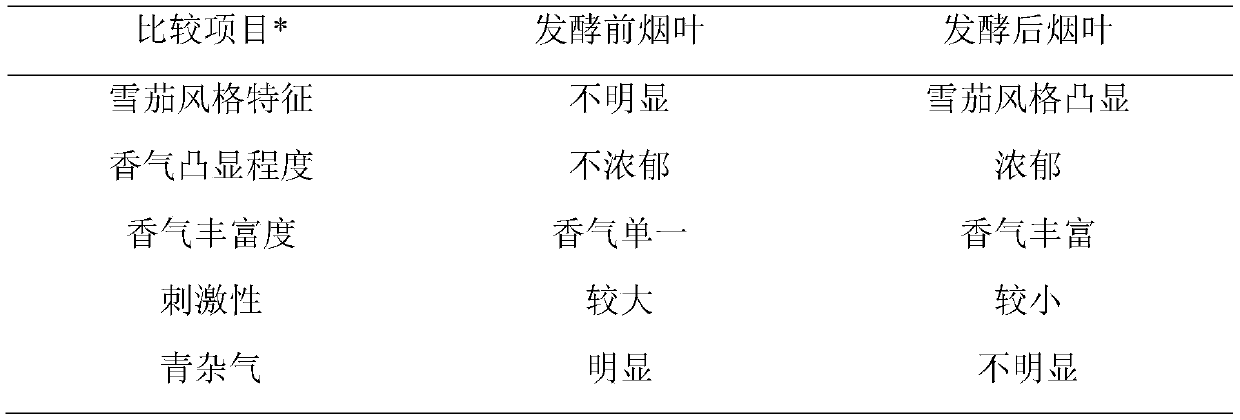

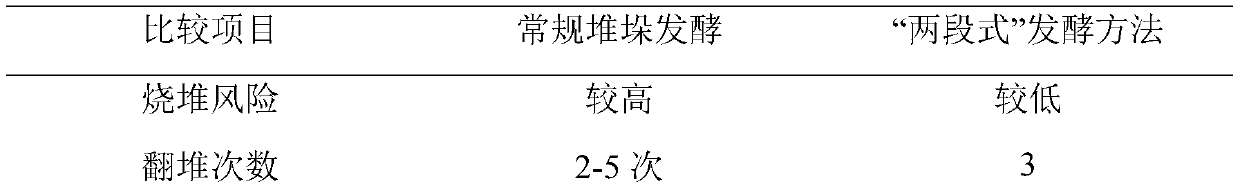

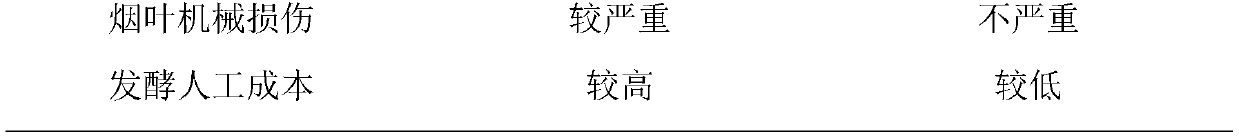

Two-stage fermentation method for reducing risk of stack burning in cigar tobacco leaf stacking process

ActiveCN110638087AReduce the risk of burningReduce mechanical damageTobacco treatmentBiotechnologyFermentation

The invention discloses a two-stage fermentation method for reducing the risk of stack burning in a cigar tobacco leaf stacking process and belongs to the technical field of tobacco leaf fermentation.Aimed at a stack burning problem caused by not turning over a stack core in time during cigar tobacco stacked fermentation, the invention provides a two-stage fermentation method for reducing the risk of stack burning in a cigar tobacco leaf stacking process, and the method comprises the following steps: (1) insecticide: removing insects and eggs in cigar tobacco leaves; (2) carrying out tobaccoleaf conditioning treatment; (3) carrying out stacking fermentation on small-stack cigarette stacks; and (4) carrying out stacking fermentation on large-stack cigarette stacks. According to the two-stage fermentation method in the present invention, the risk of stack burning of the tobacco stacks is reduced, and the quality of the cigar core tobacco leaves is improved.

Owner:中国烟草总公司海南省公司

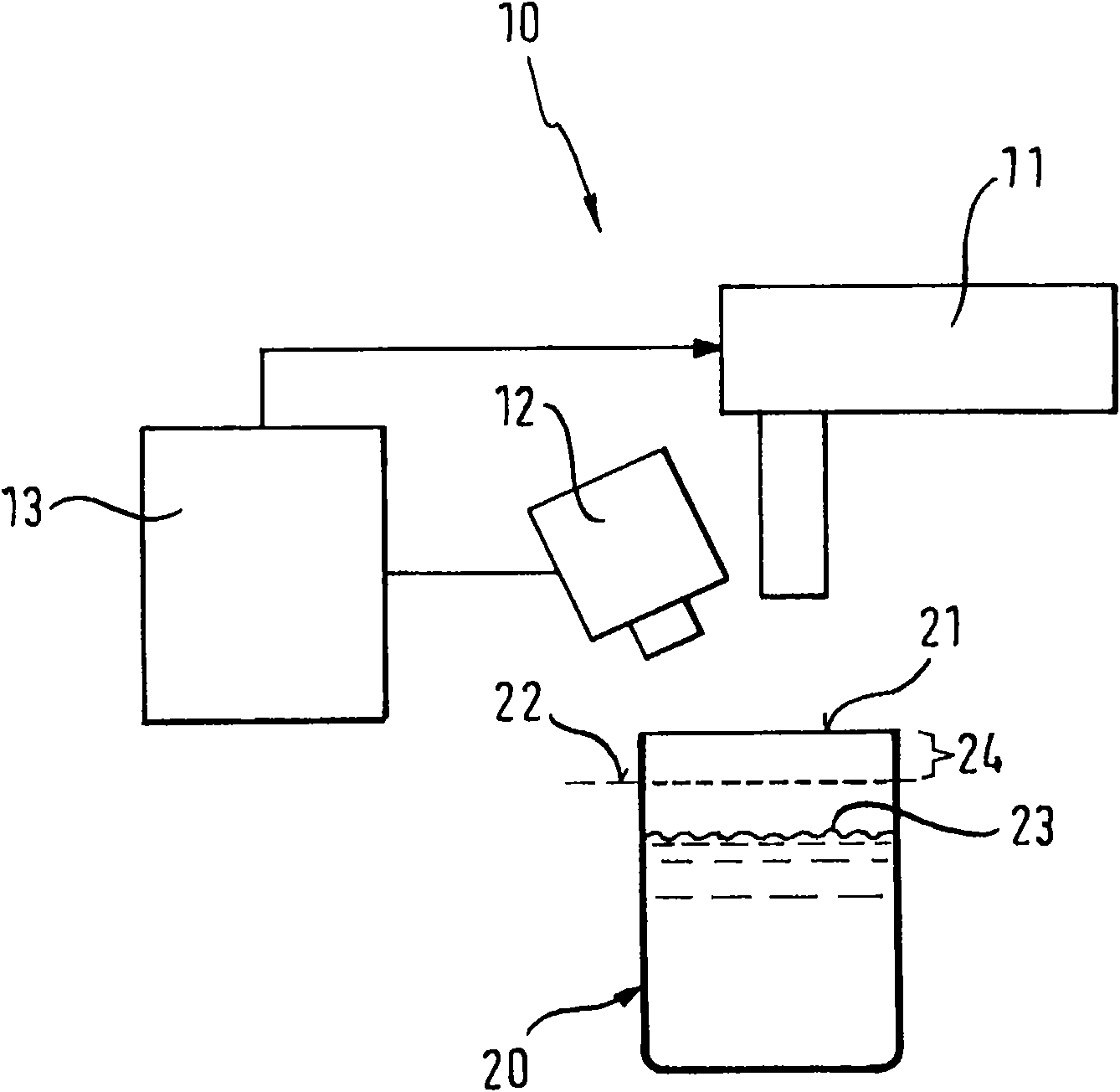

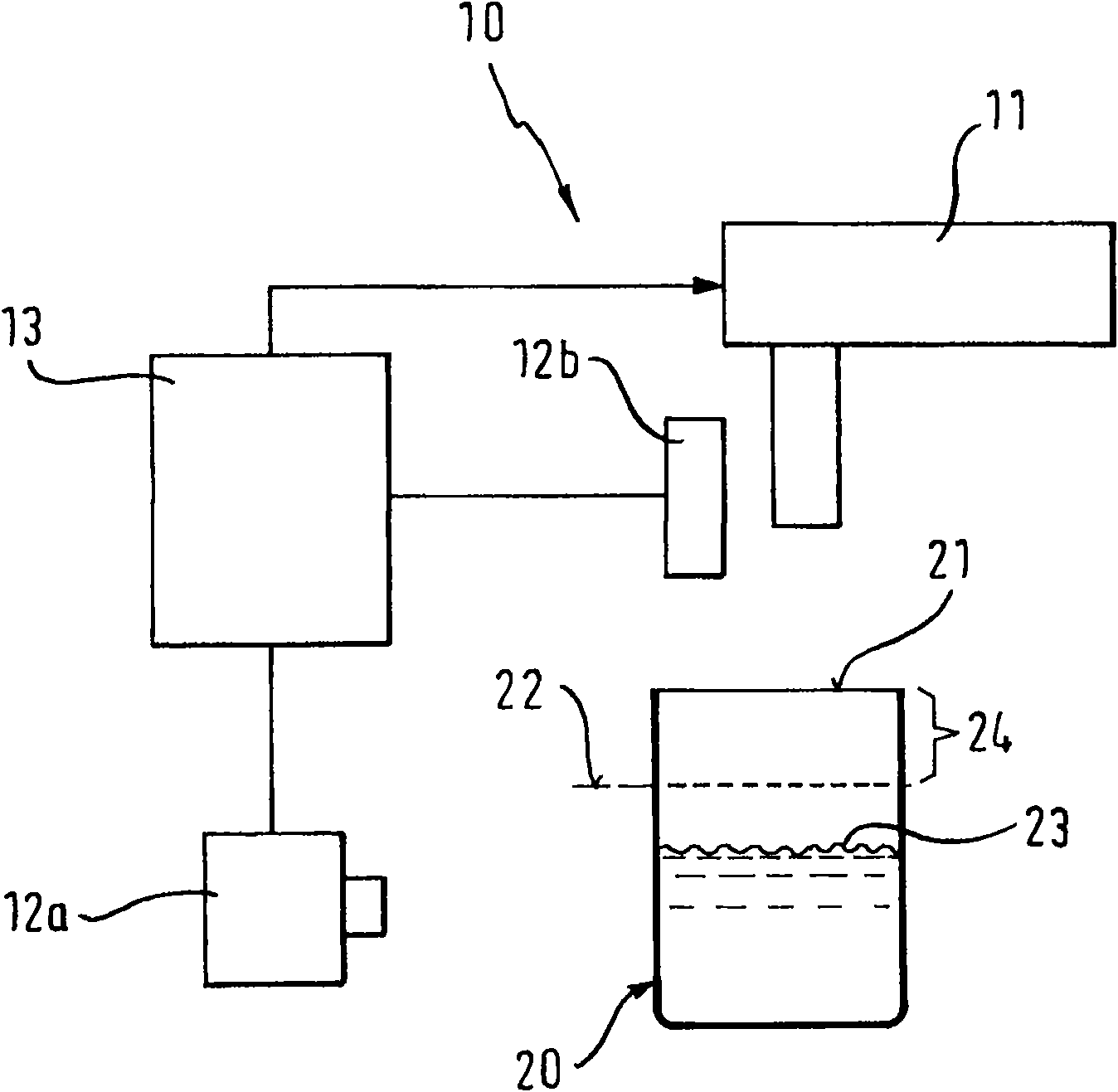

System for filling a vessel

InactiveCN101652731AImplement autofillIncrease demandLevel controlLiquid transferring devicesEngineering

The invention relates to a system (10) for filling a drinking vessel (20) with a beverage, wherein a first measuring device (12a; 12) determines the maximum fill level (21) of the drinking vessel (20)to be filled, the fill level being defined by the upper edge (21) of the drinking vessel (20), wherein the first (12a; 12) or a second measuring device (12b) determines the current actual fill level(23) at least cyclically, and wherein a control means (13) automatically aborts the filling process as soon as the current actual fill level (23) substantially agrees with a predefined target fill level (22), wherein the target fill level (22) is determined from a predefined or individually definable distance (24) to the maximum fill level (21). The system (10) according to the invention guarantees optimal filling of vessels of any arbitrary height in a cost-effective and reliable manner.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

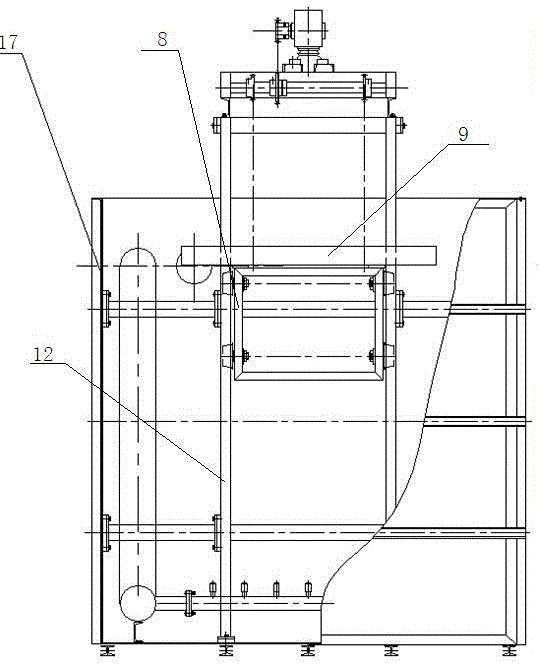

Automatic quenching oil groove and quenching method by utilizing automatic quenching oil groove

InactiveCN105002334AGuaranteed quenching effectImprove quenching uniformityQuenching devicesBiochemical engineeringQuenching

The invention provides an automatic quenching oil groove and a quenching method by utilizing the automatic quenching oil groove. According to the technical scheme, the automatic quenching oil groove comprises a groove body, a liquid spraying mechanism and an oil liquid circulating mechanism are arranged inside the groove body, a stand is arranged inside the groove body, a material containing mechanism is arranged on the stand, and a hoisting mechanism drives the material containing mechanism to move up and down along the stand. Automatic quenching on a workpiece is achieved, the manpower operation is lowered, the dangerousness is lowered, the efficiency is improved, and the production cost is lowered.

Owner:SHANTUI CONSTR MASCH CO LTD

Automatic hairdressing device

The invention discloses an automatic hairdressing device. The automatic hairdressing device comprises a handle internally provided with an air duct; a fan used for guiding air in the air duct; a heating body arranged in the air duct and used for heating air guided in the air duct; a motor rotating mechanism arranged in the handle and comprising a connecting disc which is rotationally arranged at the front part of the air duct; a hair curling column arranged on the connecting disc, wherein an air outlet part communicated with the air duct is arranged on the hair curling column; wherein the haircurling column comprises two semi-column shells provided with a gap, an air outlet part comprises an air outlet groove, the air outlet groove is obliquely formed in the side, facing the gap, of the semi-column shell. Based on the structure, the hair curling column can automatically wind hair, and the hair wound on the hair curling column can be quickly shaped under the action of hot air. When thehair styling is finished, the fan is controlled to operate independently, and the air outlet part can blow out cold air to the hair, so that the hair is quickly styled.

Owner:DREAME TECH (SHANGHAI) CO LTD

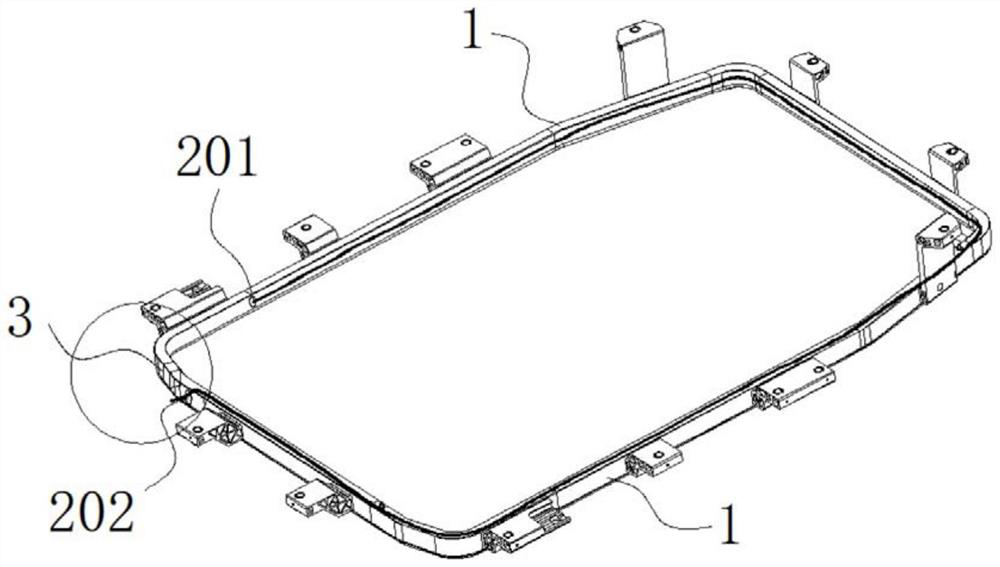

Method for disassembling flexible screen and TP and clamp

ActiveCN110328637AReduced risk of burnsSimple structureWork holdersMetal-working hand toolsTectorial membraneEngineering

The invention relates to a method for disassembling a foldable flexible screen and a TP. The method comprises the following steps that S1, the TP is placed downwards to be adsorbed on a heating platform, a hard protective film is attached on the flexible screen, and it needs to be ensured that the attachment is smooth and free of bubbles; S2, then heating is carried out by using heating equipmentto reach 50-70 DEG C; S3, a diamond wire with the diameter of 0.05-0.07 mm is used for separating the flexible screen and the TP through scraping, a disassembling clamp for the flexible screen and theTP is used for supporting the flexible screen, the flexible screen is taken down and reversely rotated, so that the hard protective film faces downwards to be adsorbed on the heating platform, and then the protective film is attached to the TP for protection; and S4, the hard protective film is heated by utilizing the heating equipment again. The invention further discloses the disassembling clamp for the flexible screen and the TP. When the disassembling clamp for the flexible screen and the TP is used for disassembling, the relative position of a connecting piece and a sliding assembly is adjusted so that the distance between an arm of an operator and the heating platform can be relatively far away during disassembly, and then the risk of scalding is reduced.

Owner:淮北摩兰科技有限公司

Halogen-free and flame-retardant polypropylene material with high flame retardance and high oxygen index and preparation method of halogen-free and flame-retardant polypropylene material

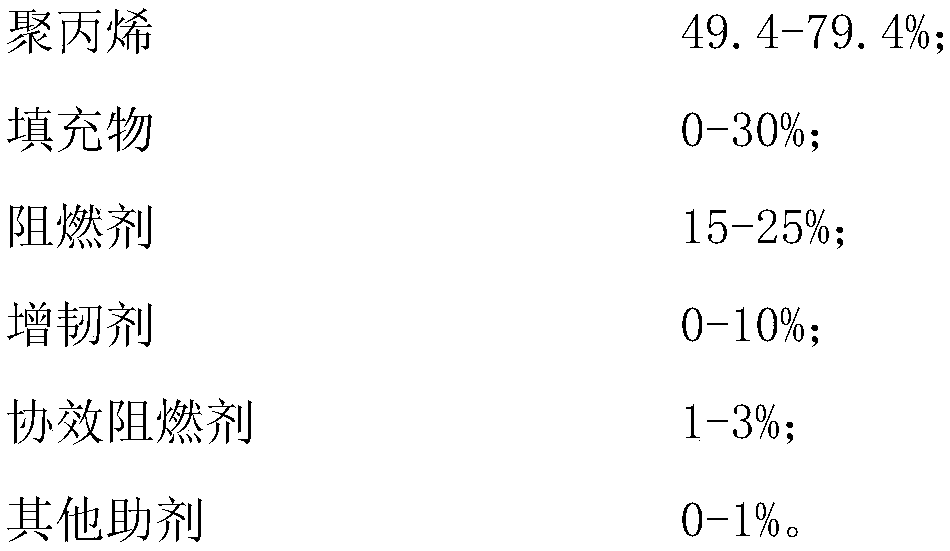

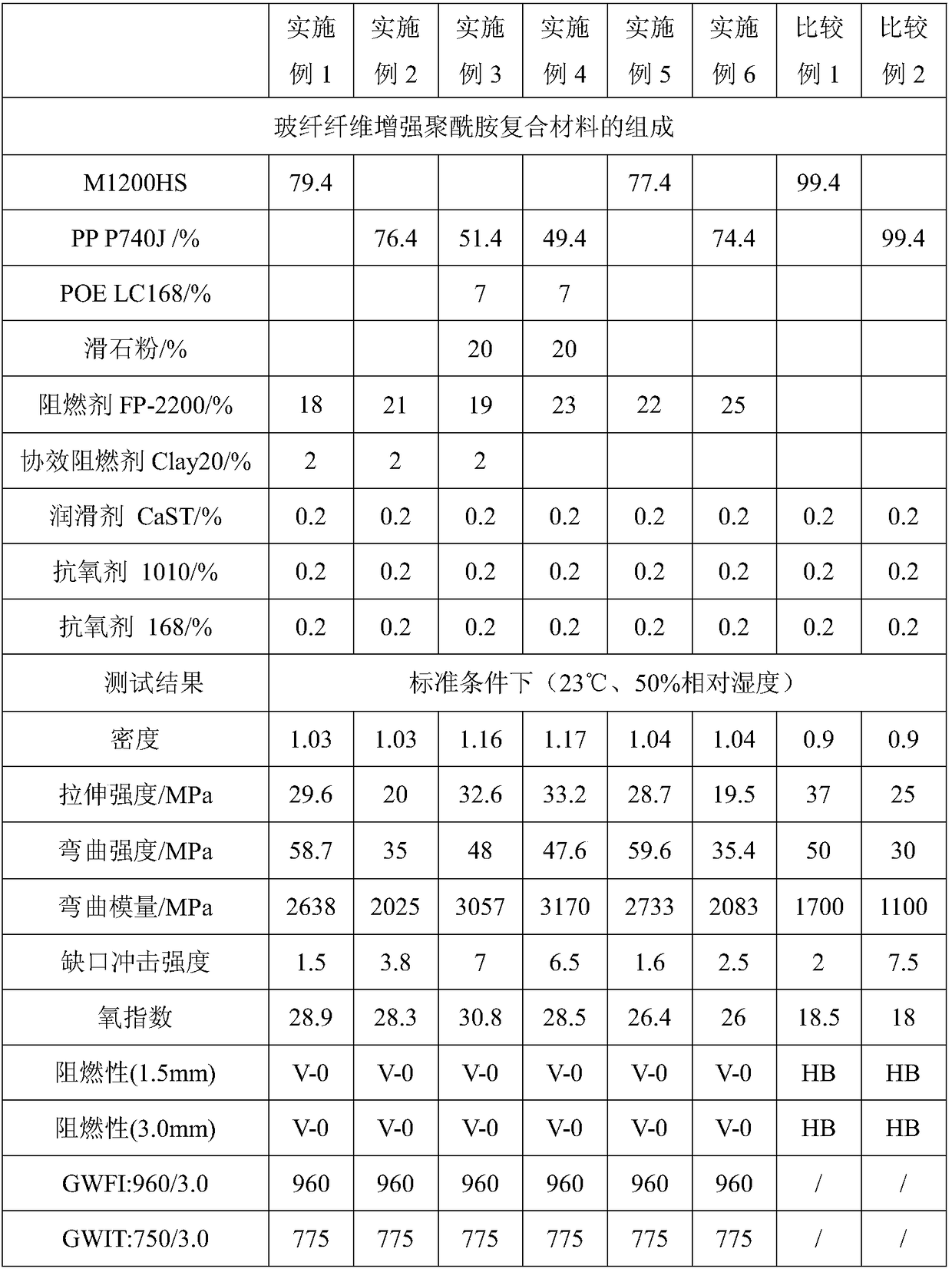

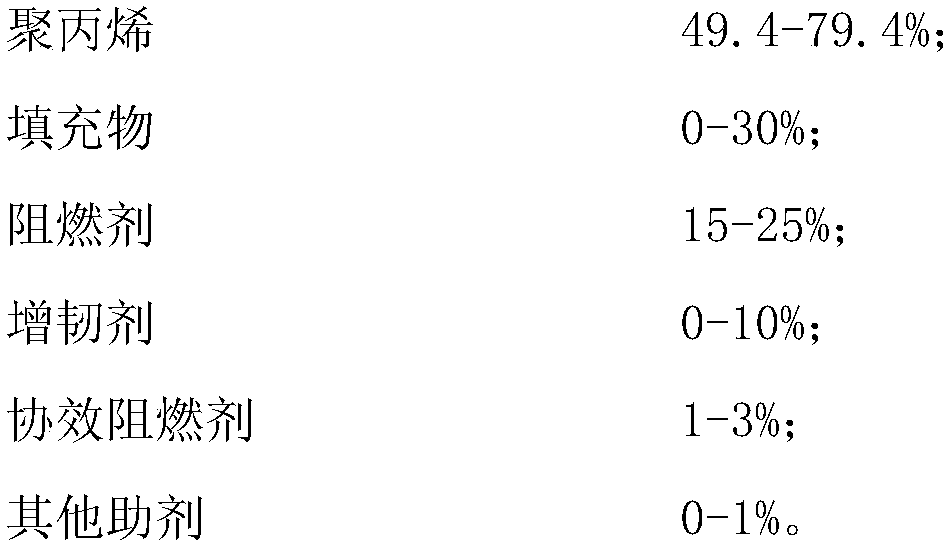

The invention discloses a halogen-free and flame-retardant polypropylene material with high flame retardance and high oxygen index and a preparation method of the halogen-free and flame-retardant polypropylene material. The halogen-free and flame-retardant polypropylene material comprises raw materials in percentage by weight as follows: 49.4%-79.4% of polypropylene, 0-30% of filler, 15%-25% of aflame retardant, 0-10% of a flexibilizer, 1%-3% of a flame retardant synergist and 0-1% of another auxiliary. Compared with the prior art, the halogen-free and flame-retardant polypropylene material has the following advantages: with adoption of a halogen-free and flame-retardant system, polypropylene reaches UL 94 V-0, a burning process is environmentally friendly, and toxic gas is not produced;by optimizing the formula design, glow wire testing meets GWFI:960 / 3.0 and GWIT:775 / 3.0, the flame retardant synergist is added, accordingly, the oxygen index of the flame-retardant polypropylene material is increased remarkably, and burning risks of the polypropylene material prepared with the method are reduced.

Owner:CHONGQNG PRET NEW MATERIAL +4

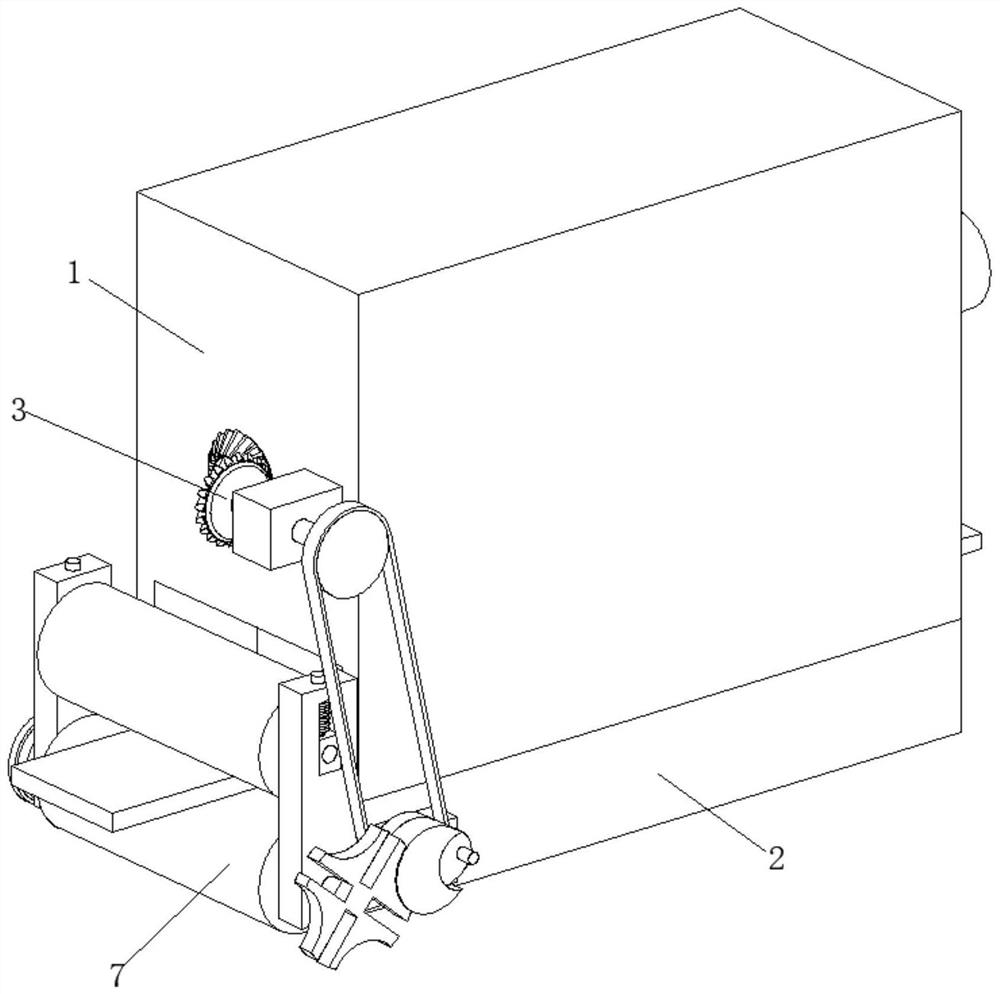

Continuous forging device with automatic cleaning function

ActiveCN112719183AShorten forging timeImprove work efficiencyDrop hammersHammer drivesEngineeringWorkbench

The invention relates to the technical field of forging equipment, and discloses a continuous forging device with an automatic cleaning function. The device comprises a box body, a workbench is welded at the bottom of the box body, a transmission mechanism is arranged at the front part of the box body, two discharge grooves are formed in the top of the workbench, and a plurality of limiting columns are welded on the inner wall of the box body. A forging mechanism is arranged on the surfaces of the limiting columns, a feeding mechanism is arranged at the front part of the workbench, and a cleaning mechanism is arranged at the rear part of the box body. According to the continuous forging device, through cooperative work of the transmission mechanism and the forging mechanism, a steel plate can be continuously forged, so that the situation that forging equipment is replaced after forging is conducted once is avoided, the stroke of the forging equipment is adjusted, forging time can be greatly shortened, the working efficiency is improved, the practicability is greatly improved, the cleaning mechanism can clean the finally forged steel plate, manual cleaning by workers is not needed, and the labor intensity of the workers is reduced.

Owner:山东圣利锻造有限公司

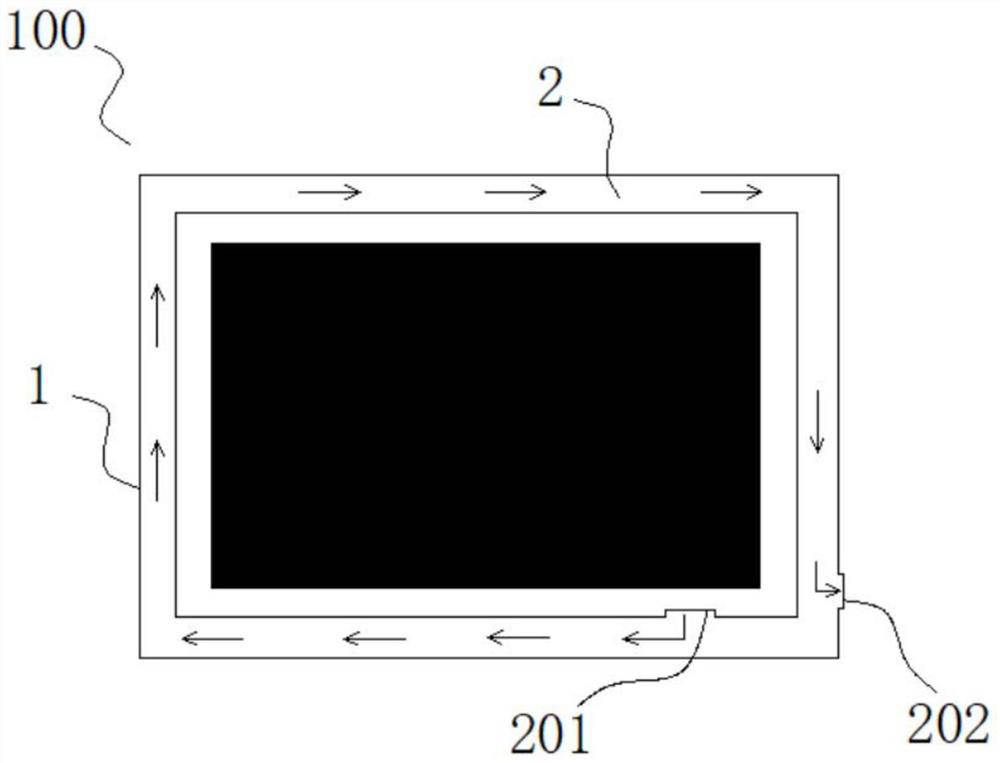

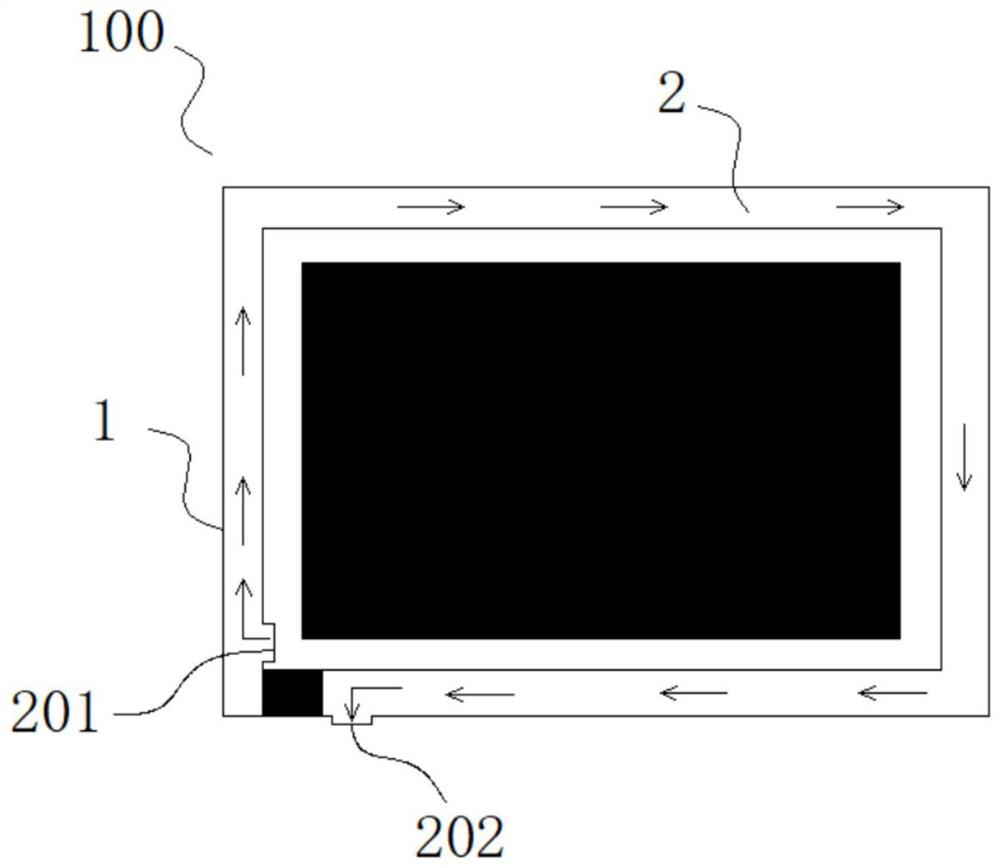

Oven door assembly for embedded oven and embedded oven with oven door assembly

The invention belongs to the field of kitchen appliances, and particularly relates to an oven door assembly for an embedded oven and the embedded oven with the oven door assembly, the oven door assembly comprises a door body, a cooling air duct, a fan and a flow guide part; the door body comprises a first door plate and a second door plate arranged on the rear side of the first door plate; the cooling air duct is arranged between the first door plate and the second door plate, an air duct inlet is formed in the bottom of the door body, and an air duct outlet is formed in the top of the door body; the fan is arranged in the cooling air duct and is close to the air duct inlet; and the flow guide part is arranged at the air outlet of the fan and used for distributing outlet air of the fan, sothat one part of the outlet air moves towards the direction where the first door plate is located. According to the oven door assembly for the embedded oven, under the action of active air supply ofthe fan, the cooling speed of the first door plate is increased, the first door plate is rapidly cooled, and therefore the risk that a user is scalded by the first door plate is reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

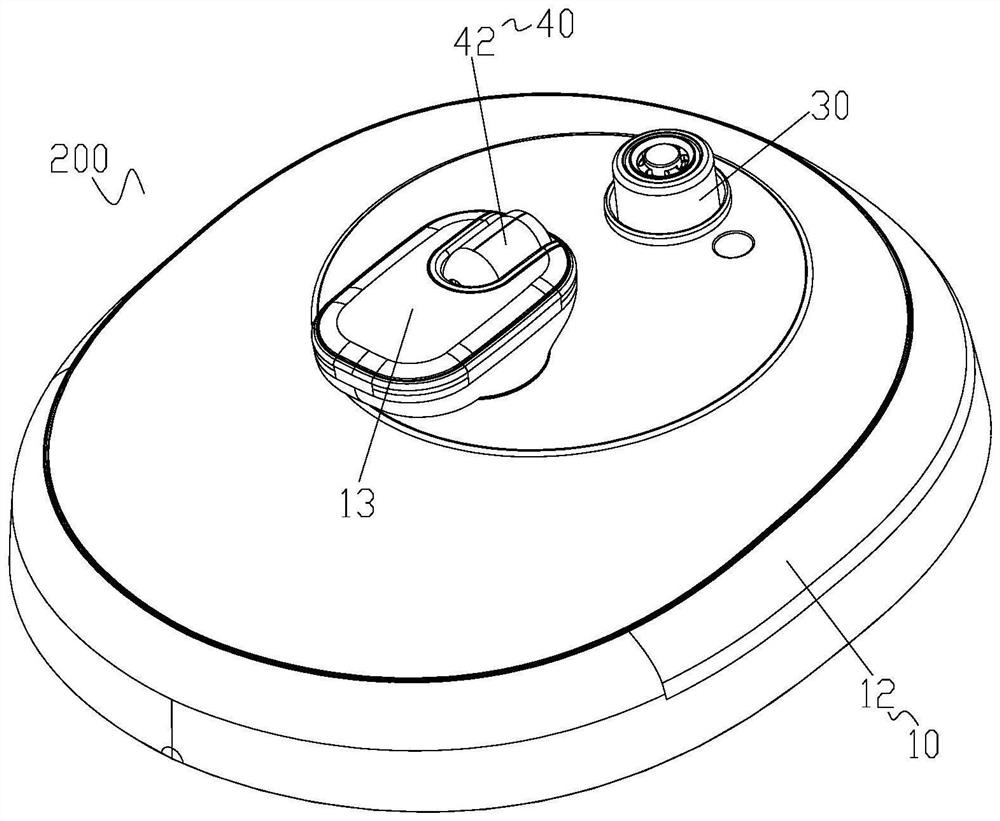

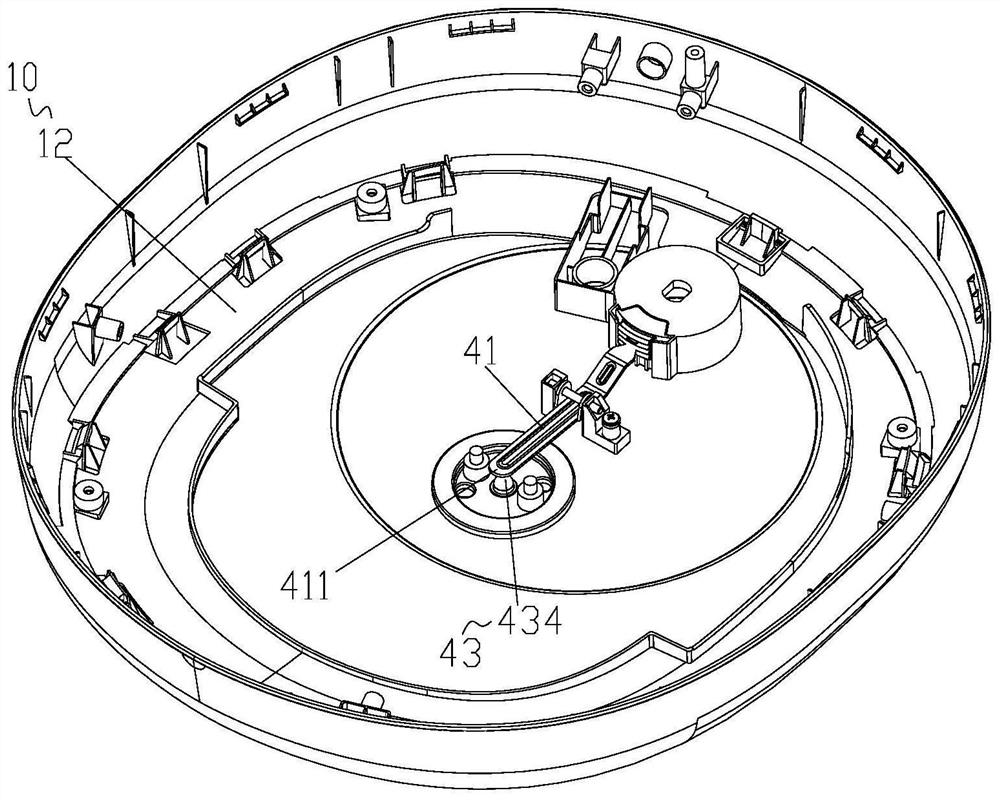

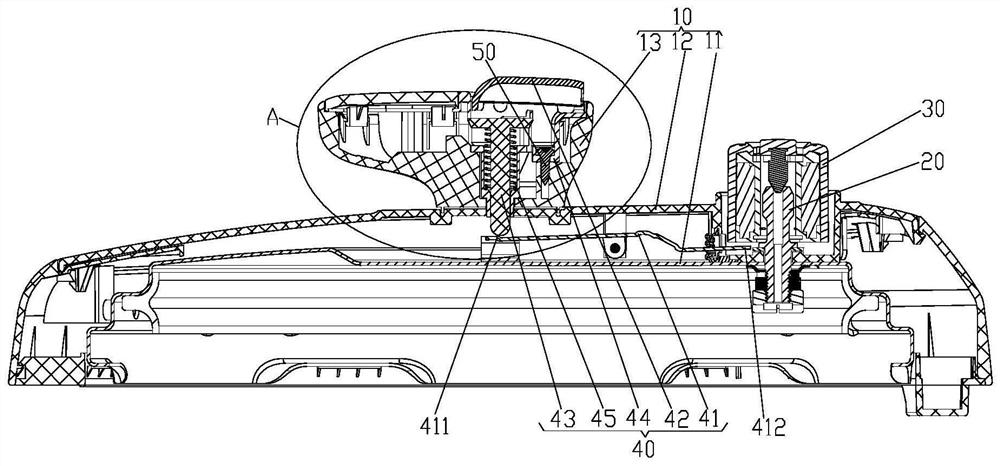

Cooking utensil

PendingCN112869549AImprove contact stabilityReduced risk of burnsPressure-cookersEngineeringExhaust pipe

The invention provides a cooking utensil, which comprises a pot body and a pot cover arranged on the pot body in a covering mode; an exhaust pipe arranged on the pot cover body; a pressure limiting valve pressed on the exhaust pipe; a jacking exhaust mechanism comprising an exhaust lever and a spinning button, wherein the exhaust lever is rotatably arranged on the pot cover body; and a spinning button pivotally connected with the cooker cover body, wherein the spinning button is provided with an initial position and an exhaust locking position in the rotating direction of the spinning button, and the spinning button abuts against the exhaust lever so that the exhaust lever can jack up the pressure limiting valve; and after the spinning button rotates to the exhaust locking position, the position is locked, so that the pressure limiting valve is limited in a jacked state. The cooking utensil solves the problems that in the prior art, in the process of releasing high-temperature steam in a cooker body of the electric pressure cooker, a user needs to continuously operate a rapid exhaust mechanism, the good use experience of the user on the electric pressure cooker is seriously affected, the user is likely to touch the continuously-exhausted high-temperature steam, and the potential safety hazard that the user is scalded exists.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

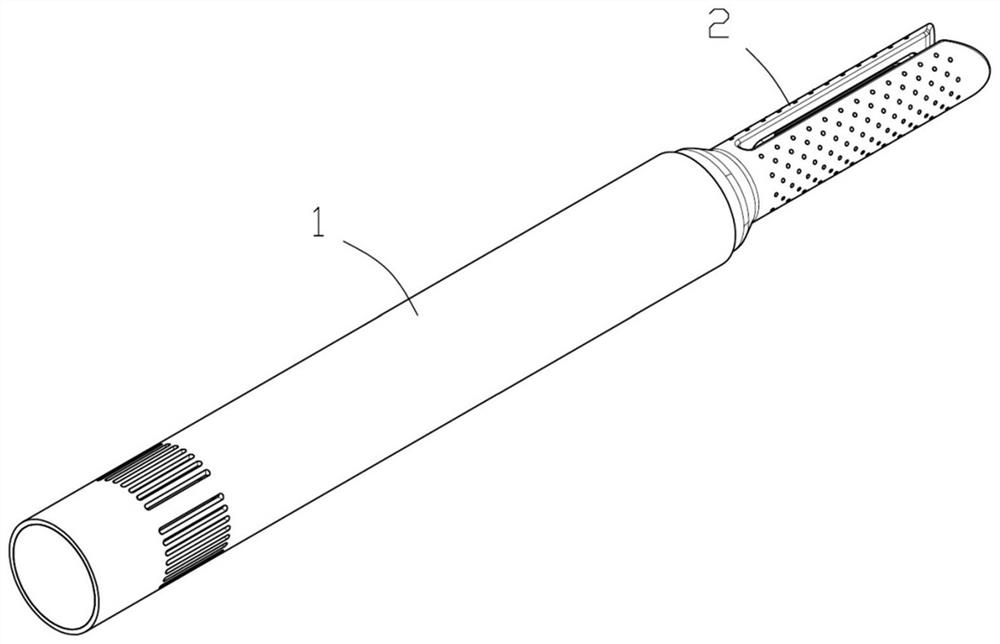

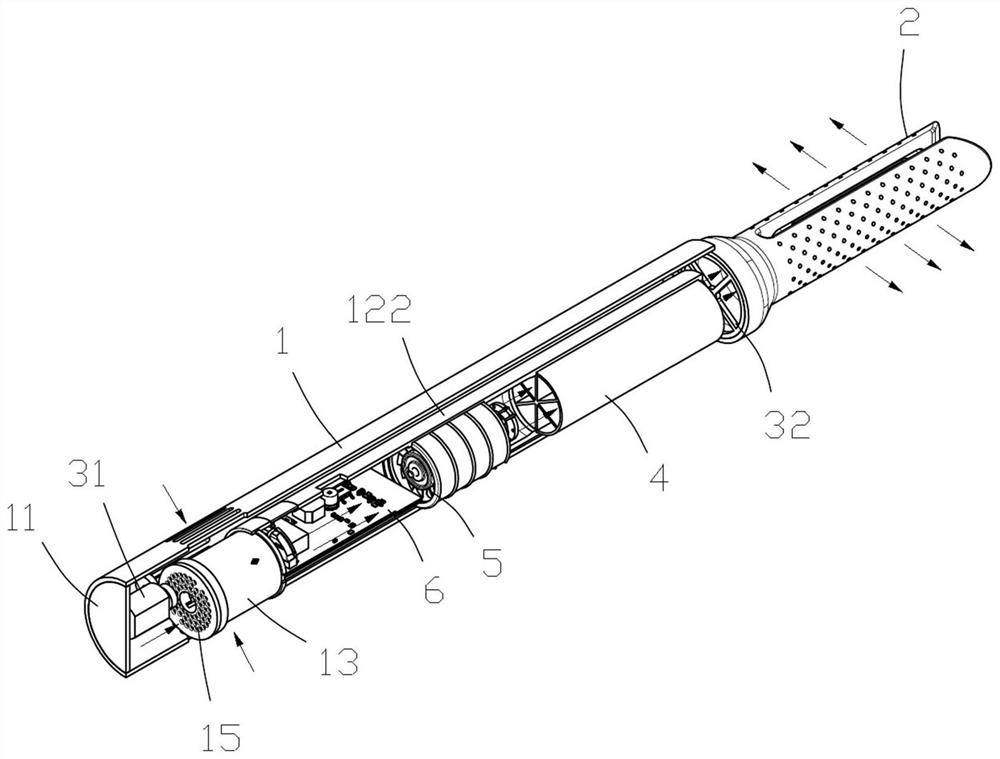

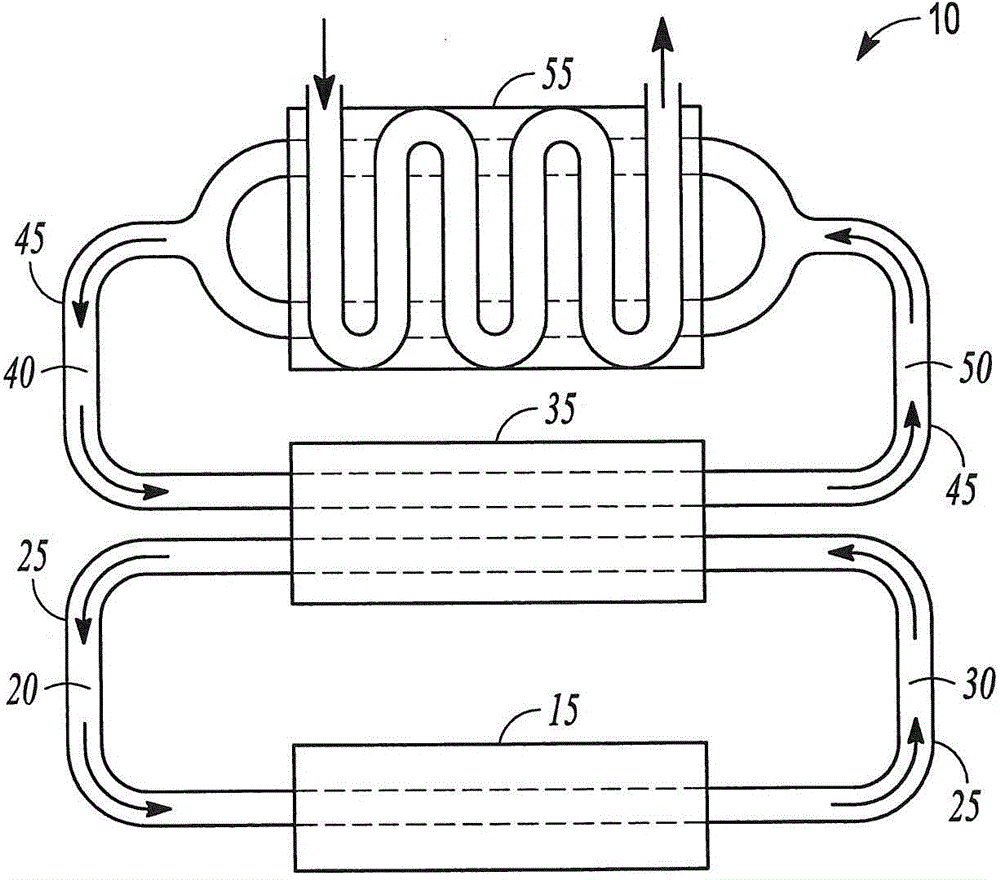

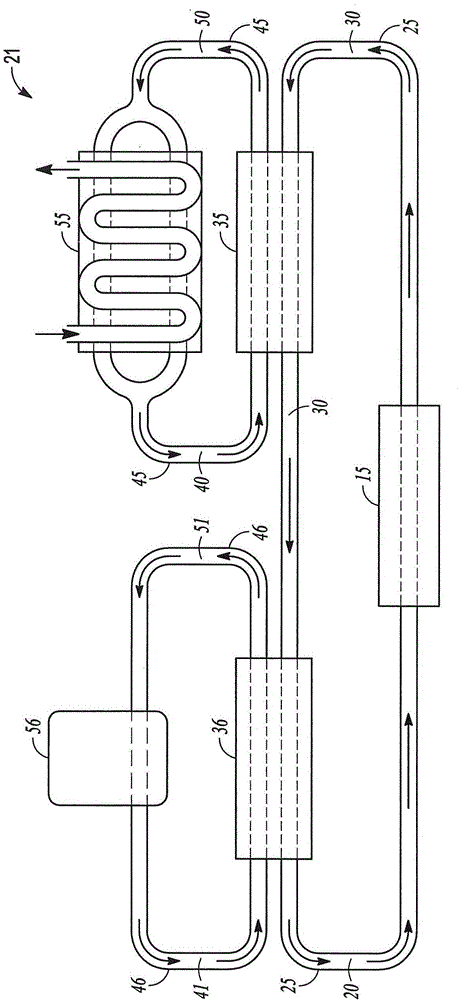

Tubular reactor with improved design and method of using the same

ActiveCN104128139AReduced risk of burnsTemperature controlPressurized chemical processIndirect heat exchangersPolyamideProcess engineering

The present invention relates to methods, systems, and apparatus for making polyamides having at least two heat-transfer media for transferring heat to a tubular reactor. The method includes heating a first flowable heat-transfer medium, to provide a heated first flowable heat-transfer medium. The method includes transferring heat from the heated first flowable heat-transfer medium to a second flowable heat-transfer medium, to provide a heated second flowable heat- transfer medium. The method also includes transferring heat from the heated second flowable heat-transfer medium to a tubular reactor of a polyamide synthesis system.

Owner:INVISTA TEXTILES (U K) LTD

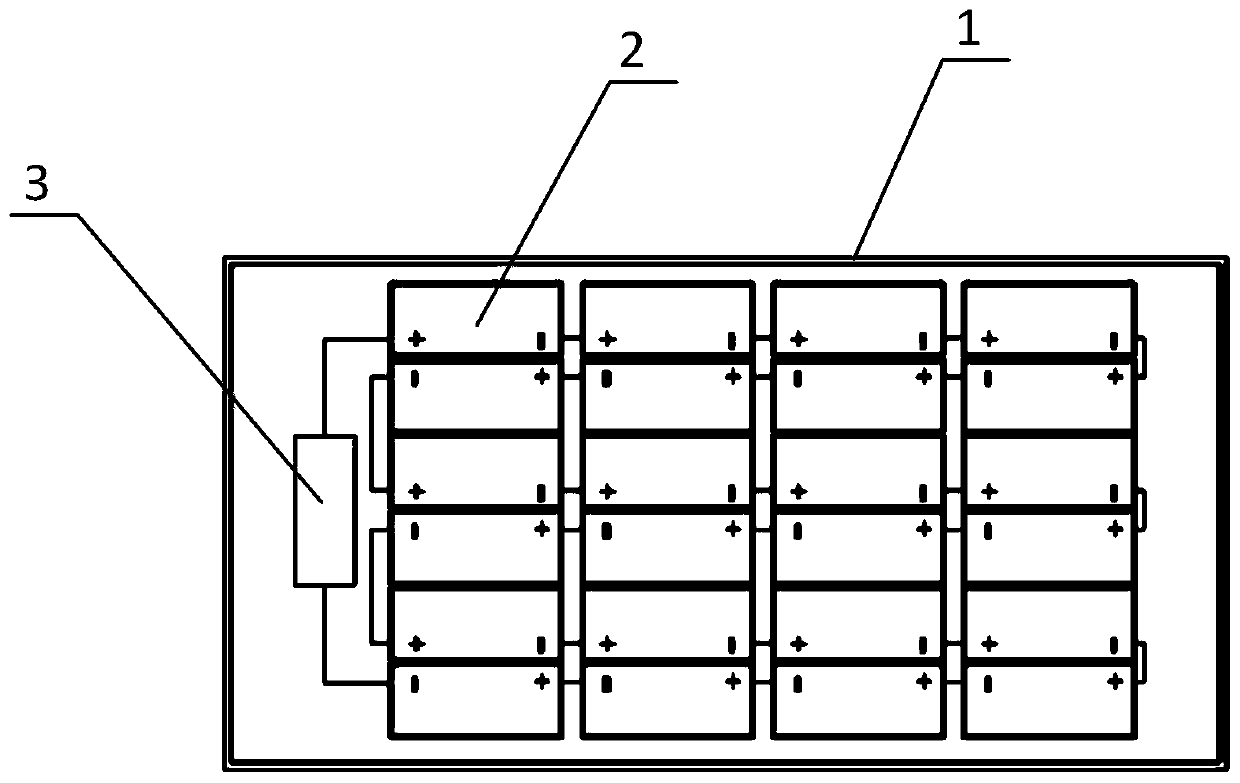

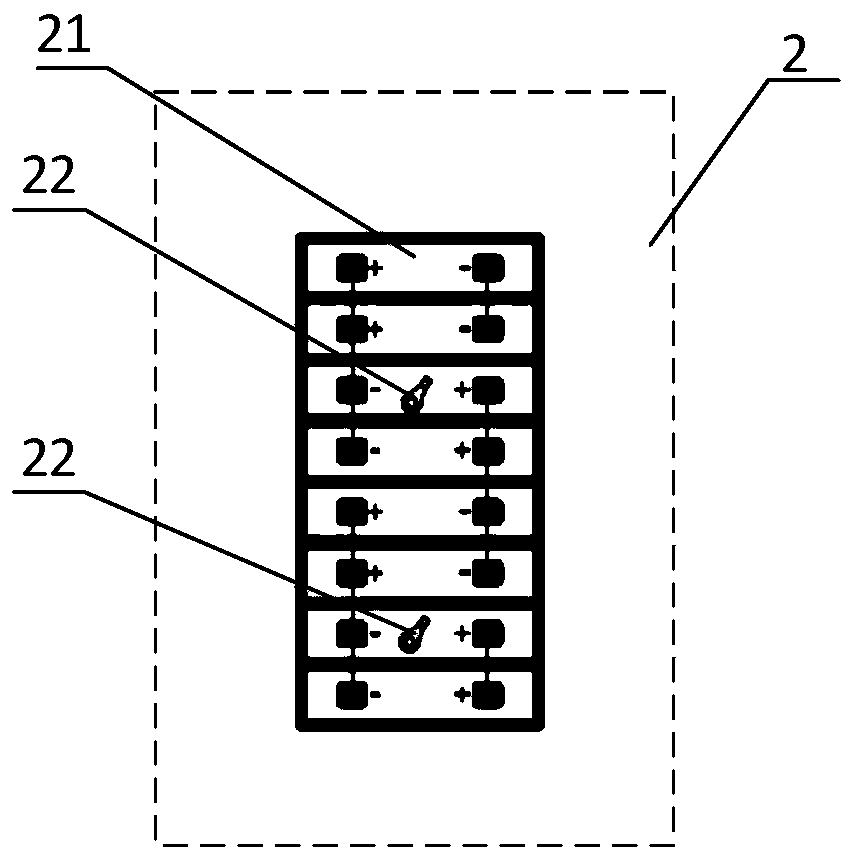

Battery pack temperature detection system and method

ActiveCN111403836ADelay thermal runawayReduced risk of burnsSecondary cells testingCell component detailsComputer scienceInfrared thermal imaging

The embodiment of the invention provides a battery pack temperature detection system and method. Temperature of a plurality of temperature points in a battery pack, which is detected by a battery management system, is combined with an infrared thermal imaging total graph of all battery cells in the battery pack; the temperature of each single battery in the battery pack is calculated on the infrared thermal imaging total graph by taking the temperature of the temperature point as the reference temperature, so that the temperature of each single battery in the battery pack can be comprehensively acquired, the temperature abnormity in the battery pack can be early warned and controlled in advance, and the risk of thermal runaway of the battery pack and even vehicle combustion is reduced.

Owner:重庆金康赛力斯新能源汽车设计院有限公司

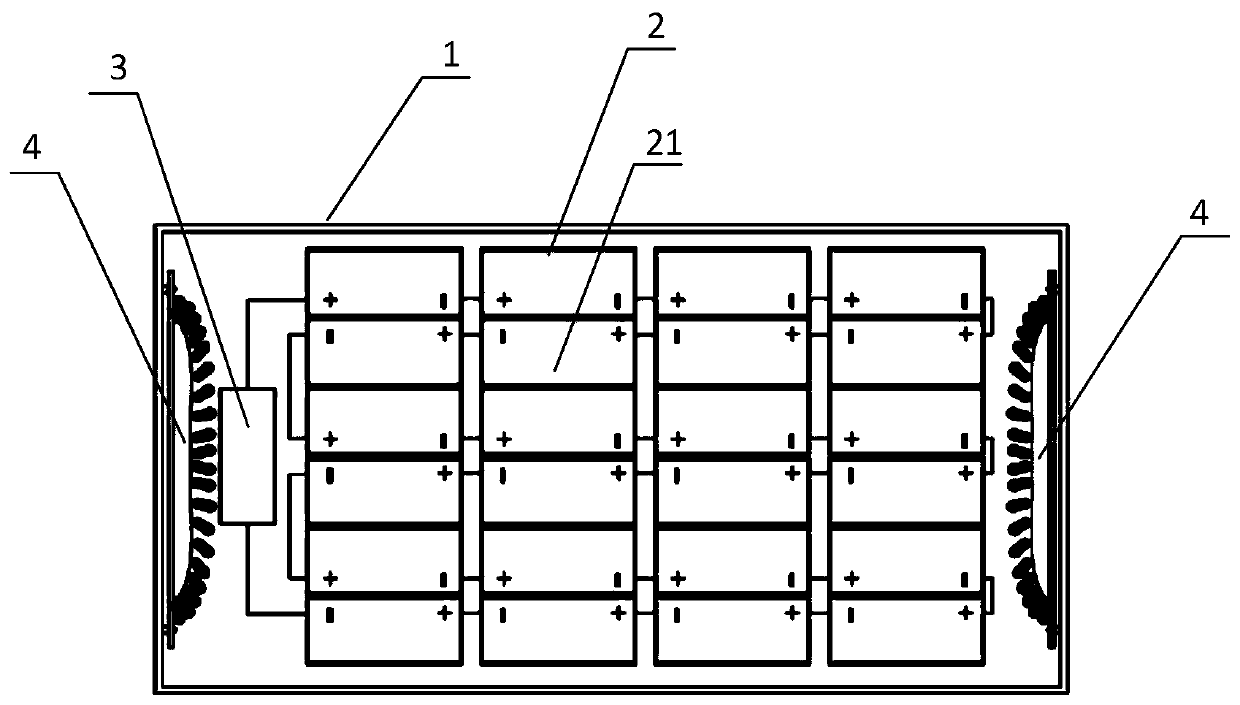

Sealed battery pack

PendingCN111969158AReduce the temperatureReduced risk of burnsSecondary cellsFire rescueThermodynamicsFresh air

The invention discloses a sealed battery pack. The sealed battery pack comprises a sealed box body and at least one heat dissipation pipeline system; a battery cell mounting cavity is formed in the closed box body; a battery cell is mounted in the battery cell mounting cavity; an inlet communicated to the battery cell mounting cavity is formed in the heat dissipation pipeline system; the heat dissipation pipeline system is provided with an outlet communicated to the external environment of the sealed box body; and the heat dissipation pipeline system is used for cooling gas released in the thermal runaway process of the battery cell. According to the sealed battery pack, in the process that gas released by thermal runaway of the battery cell enters from the inlet and moves towards the outlet, the heat of the gas is transferred to the surface of the sealed box body through the heat dissipation pipeline system, so that the temperature of the gas is gradually reduced and finally discharged out of the sealed battery pack, and the risk that the gas burns after encountering fresh air is reduced.

Owner:欣旺达惠州动力新能源有限公司

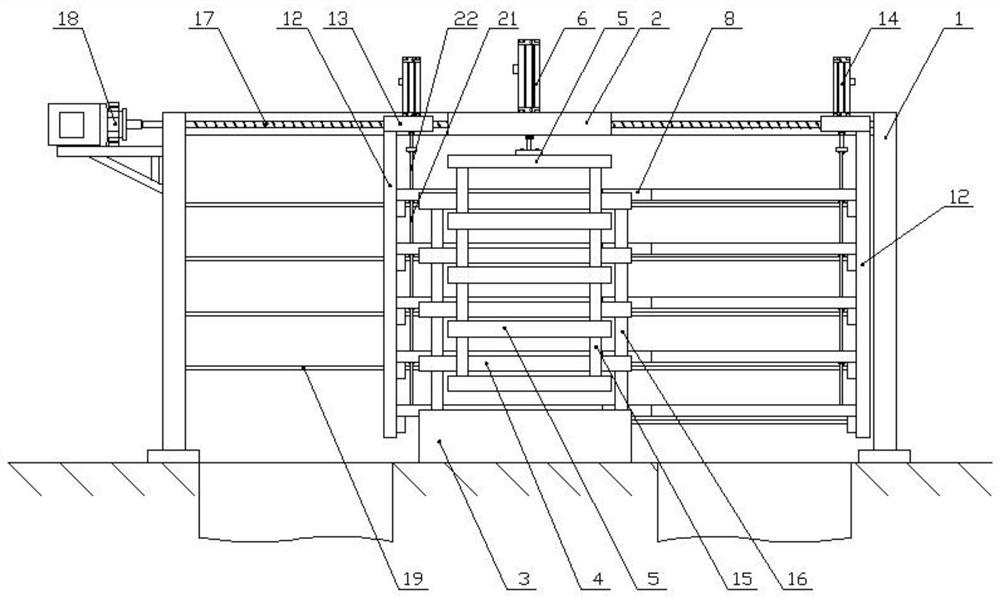

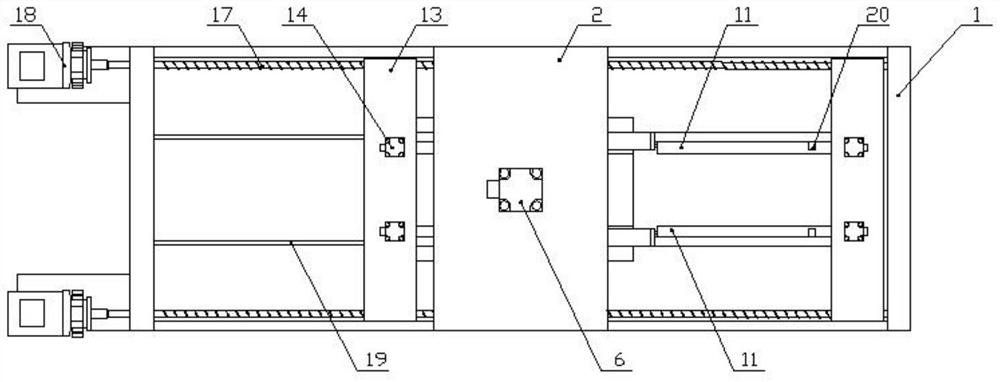

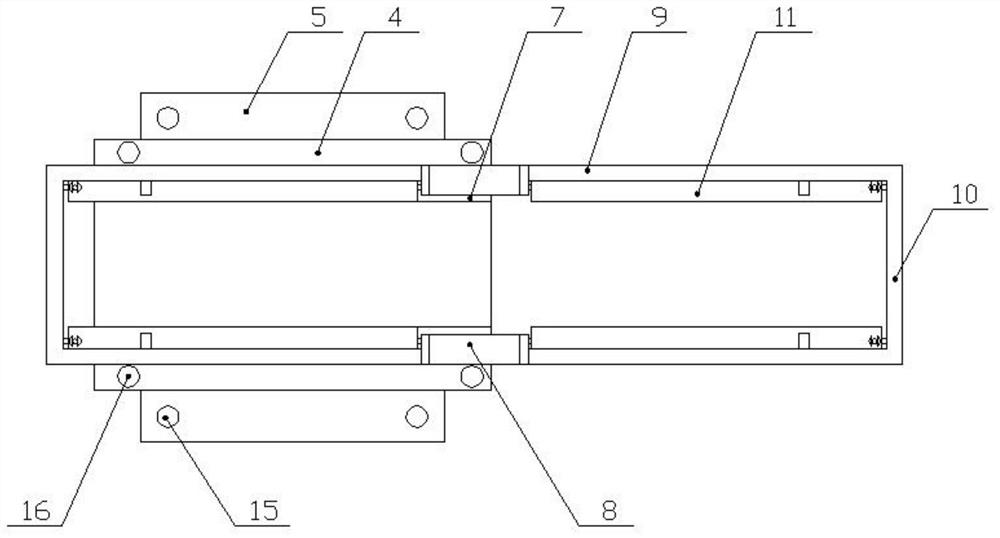

Reciprocating plywood production device

ActiveCN112077955AAvoid burnsReduced risk of burnsPlywood pressesVeneer pressesStructural engineeringMechanical engineering

The invention discloses a reciprocating plywood production device, and belongs to the field of plywood processing. The reciprocating plywood production device comprises a machine frame, a top wall isarranged in the middle of the upper end of the machine frame, a base is arranged at the lower end of the machine frame and below the top wall, a lower hot pressing plate is arranged at the upper end of the base, and an upper hot pressing plate is arranged on the upper part of the lower hot pressing plate. The upper hot pressing plate ascends and descends in a reciprocating mode under the action ofa hot pressing driving device, sliding grooves with the two communicating ends are formed in the upper end face of the lower hot pressing plate at intervals, connecting parts are movably arranged inthe sliding grooves, plate blank containing frames are oppositely arranged at the two ends of the connecting parts, the plate blank containing frames include movably arranged object carrying plates, and the object carrying plates on the two sides are arranged oppositely. The plate blank containing frames are connected with sliding parts through connecting plates, the sliding parts are arranged atthe upper end of the machine frame and slide in a reciprocating mode in the length direction of the sliding grooves, and the sliding parts is provided with discharging driving devices for pushing theobject carrying plates to turn over downwards. According to the reciprocating plywood production device, and rough boards can be conveniently taken out of hot pressing equipment.

Owner:湖南闽新新材料股份有限公司

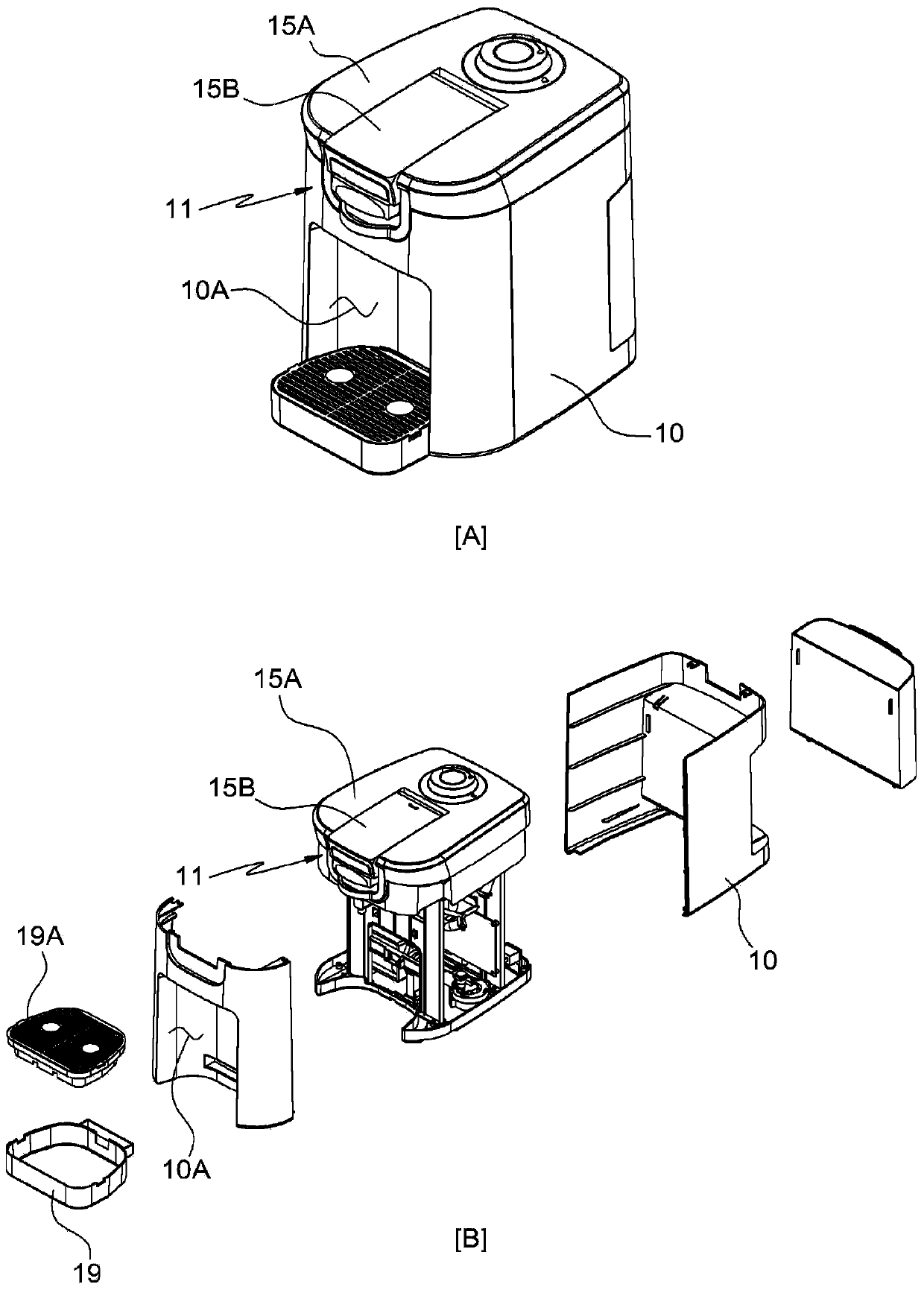

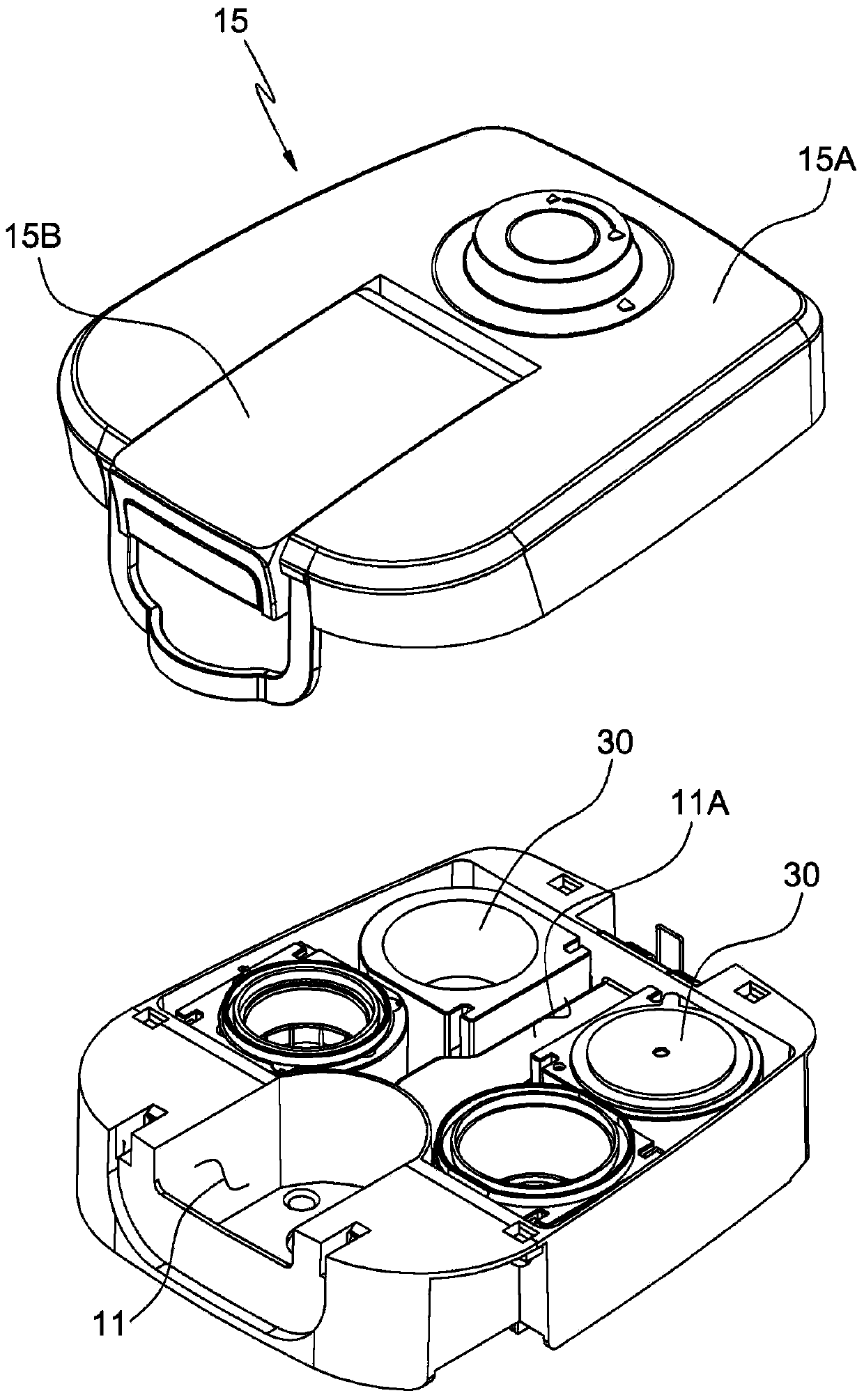

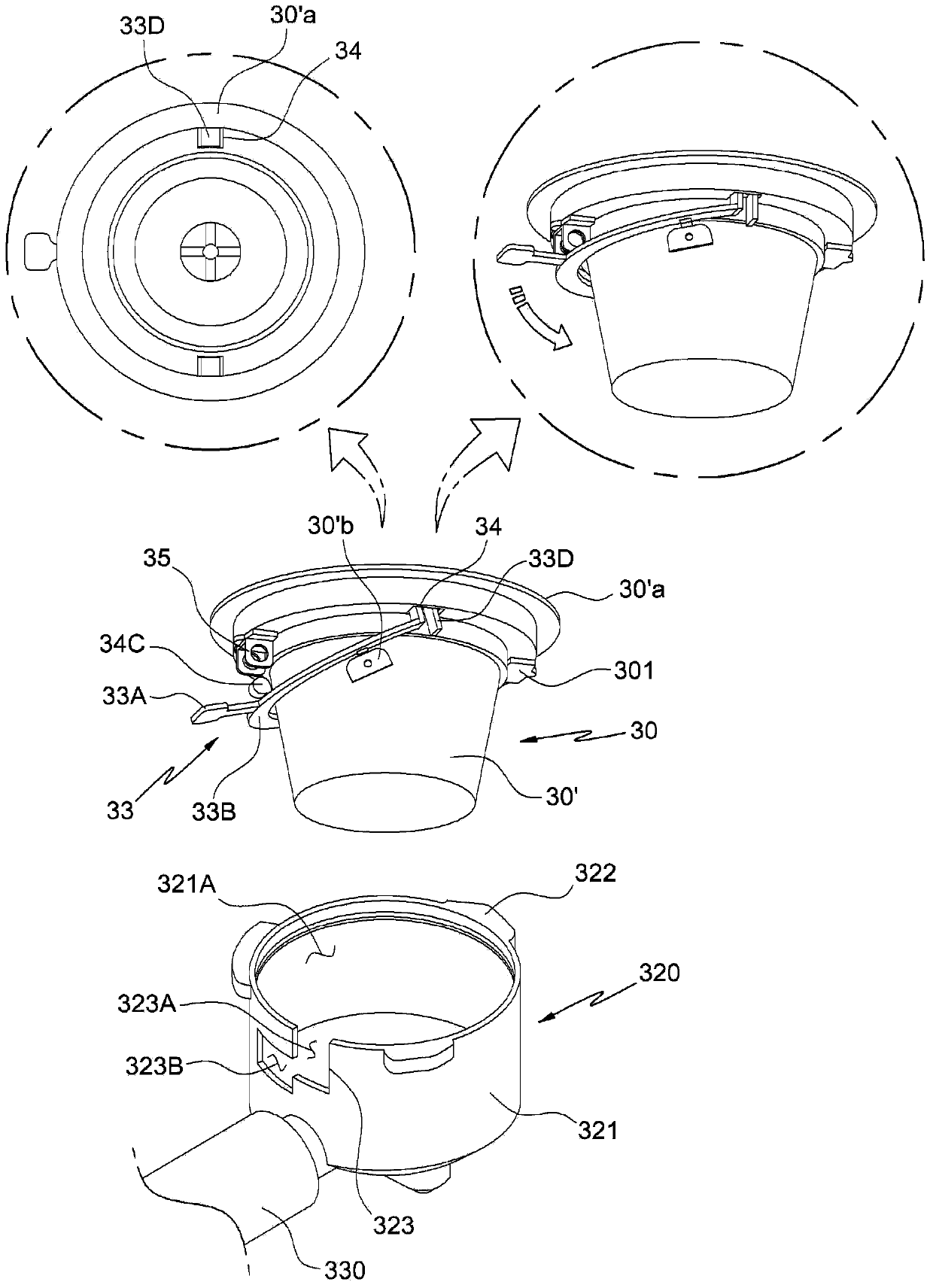

Beverage maker equipped with cartridge separator

The invention relates to a beverage maker equipped with a cartridge separator. Especially a brewing container equipped with a cartridge is arranged in a beverage extraction section for extracting beverage of a beverage maker. After beverage extraction, the cartridge is easy to be separated from the brewing container, and therefore the cartridge is easy to change. Bright beverage is easy to be extracted. The beverage maker comprises a pressing section which is used for holding and pressing for users to prevent scalds caused by residual water in the cartridge, and a separation section for separating the cartridge from the brewing container through going up and down of the above pressing section.

Owner:CONVEX KOREA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com