Two-stage fermentation method for reducing risk of stack burning in cigar tobacco leaf stacking process

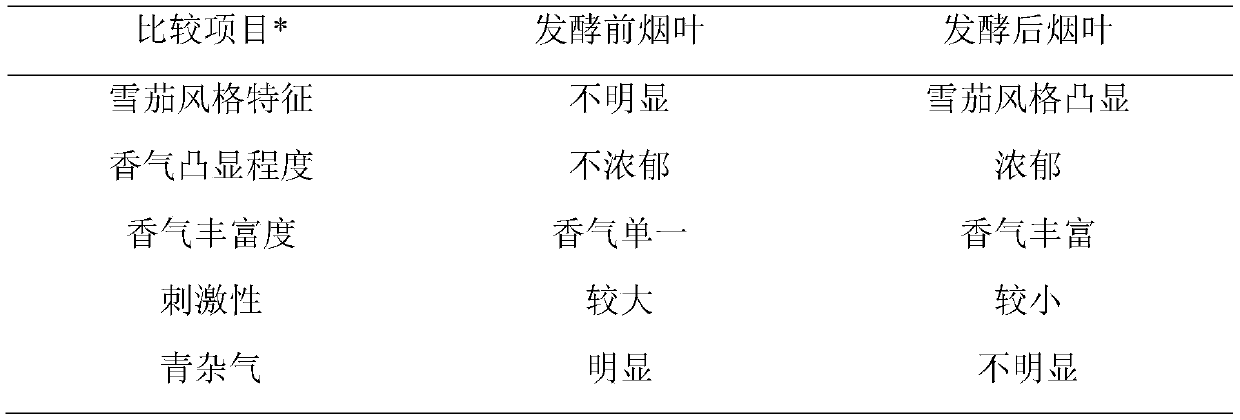

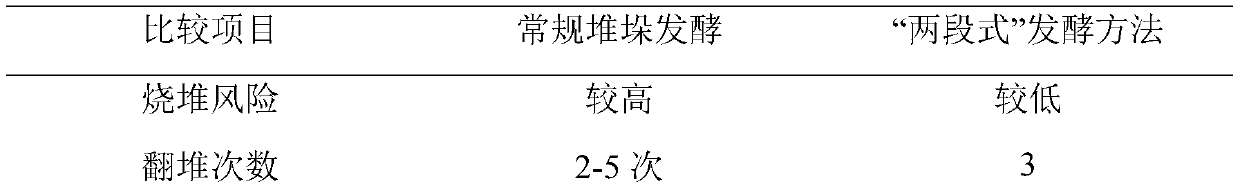

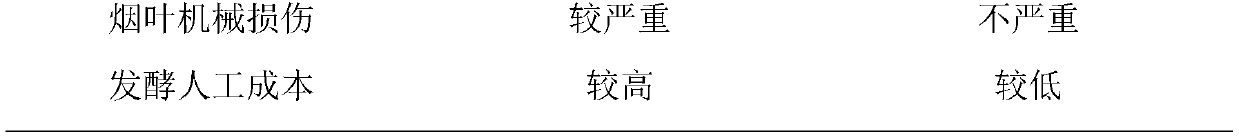

A fermentation method and cigar tobacco leaf technology are applied in the fields of tobacco, tobacco processing, application, etc., which can solve the problems of untimely stacking and burning of stacking cores, and achieve the effects of reducing labor costs, improving quality, and reducing irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: A "two-stage" fermentation method for reducing the risk of burning during stacking of cigar leaves.

[0023] Specific steps include:

[0024] Step (1), insecticide: remove insects and insect eggs in cigar leaves, evenly hang the cigar stems on the dampening car, and keep it for 120 minutes at a temperature of 55° C. and a relative humidity of 100%.

[0025] Step (2), moisture regain treatment of tobacco leaves: the cigar tobacco leaves after insecticide are kept at a temperature of 35° C. and a relative humidity of 100% for 180 minutes. After the end, the tobacco leaves are left standing at room temperature in the dampening car to balance the water and reduce the risk of tobacco leaf mold and rot during stacking. The balance is about 30 minutes until there are no obvious water droplets on the surface of the tobacco leaves, and the water content is about 20-30 %, indicating that the tobacco leaves are evenly rehydrated.

[0026] Step (3), stacking and fermen...

Embodiment 2

[0032] Example 2: A "two-stage" fermentation method for reducing the risk of burning during stacking of cigar leaves.

[0033] Specific steps include:

[0034] Step (1), insecticide: remove insects and insect eggs in cigar tobacco leaves, evenly hang cigar tobacco on the dampening car, and keep it for 110 minutes at a temperature of 60° C. and a relative humidity of 100%.

[0035] Step (2), moisture regain treatment of tobacco leaves: keep the cigar tobacco leaves after insecticide for 150 minutes at a temperature of 40° C. and a relative humidity of 100%. After the end, the tobacco leaves are left standing at room temperature in the dampening car to balance the water and reduce the risk of tobacco leaf mold and rot during stacking. The balance is about 45 minutes until there are no obvious water droplets on the surface of the tobacco leaves, and the water content is about 20-30 %, indicating that the tobacco leaves are evenly rehydrated.

[0036] Step (3), stacking and ferm...

Embodiment 3

[0038] Example 3: A "two-stage" fermentation method for reducing the risk of burning during stacking of cigar leaves.

[0039] Specific steps include:

[0040] Step (1), insecticide: remove insects and insect eggs in cigar tobacco leaves, evenly hang cigar tobacco on the dampening car, and keep it for 100 minutes at a temperature of 65° C. and a relative humidity of 100%.

[0041] Step (2), moisture regain treatment of tobacco leaves: the cigar tobacco leaves after insecticide are kept at a temperature of 45° C. and a relative humidity of 100% for 120 minutes. After the end, the tobacco leaves are left standing at room temperature in the dampening car to balance the water and reduce the risk of tobacco leaf mold and rot during stacking. The balance is about 60 minutes until there are no obvious water droplets on the surface of the tobacco leaves, and the water content is about 20-30 %, indicating that the tobacco leaves are evenly rehydrated.

[0042] Step (3), stacking and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com